Cerium-doped gadolinium disilicate luminescent material and preparation method thereof

A luminescent material, gadolinium silicate technology, applied in the direction of luminescent materials, polycrystalline material growth, chemical instruments and methods, etc., can solve problems such as shortening scintillation crystal decay time, achieve improved scintillation performance, easy to realize, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

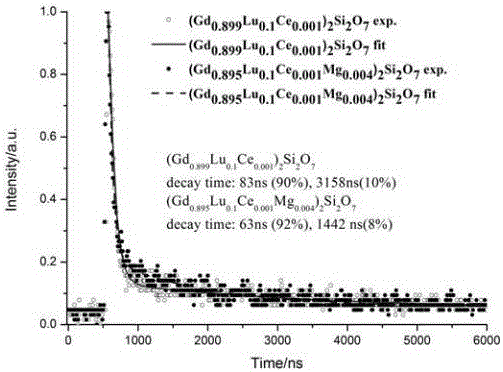

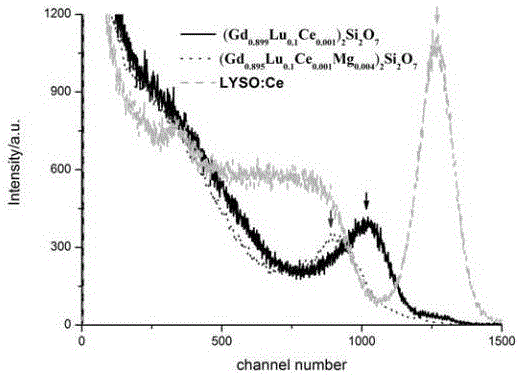

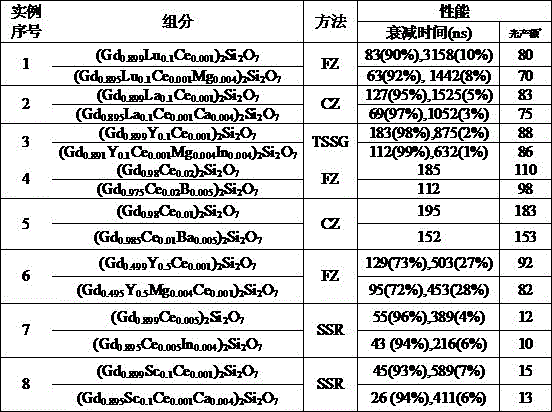

Embodiment 1

[0037] In this embodiment, a method for preparing a cerium-doped gadolinium disilicate luminescent material is to prepare a scintillation single crystal of cerium-doped gadolinium disilicate by using the optical floating zone method, including the following steps:

[0038] ① Ingredients: According to the chemical formula (Gd 0.899 Lu 0.1 Ce 0.001 ) 2 Si 2 o 7 and (Gd 0.895 Lu 0.1 Ce 0.001 Mg 0.004 ) 2 Si 2 o 7 The stoichiometric ratio of Gd 2 o 3 、Lu 2 o 3 , SiO 2 , CeO 2 and each raw material in MgO are evenly mixed to prepare two groups of raw material mixtures;

[0039] ② Sintering: The raw material mixture uniformly mixed in step ① is fully and evenly mixed, put into a Ф10mm rubber tube and sealed, and isostatically pressed at a pressure of 200Mpa to form a dense billet blank, and then use Pt wire to seal it. Hanging in a muffle furnace for sintering, the sintering temperature is 1600°C, the sintering time is 20 hours, and two sets of polycrystalline rods...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, especially in that:

[0045] In this embodiment, a method for preparing a cerium-doped gadolinium disilicate luminescent material is to prepare a scintillation single crystal of cerium-doped gadolinium disilicate by a pulling method, including the following steps:

[0046] ⅰ. Ingredients: According to the chemical formula (Gd 0.899 La 0.1 Ce 0.001 ) 2 Si 2 o 7 and (Gd 0.895 La 0.1 Ce 0.001 Ca 0.004 ) 2 Si 2 o 7 The stoichiometric ratio of Gd 2 o 3 , La 2 o 3 , SiO 2 , CeO 2 and CaCO 3 The raw materials in the mixture are uniformly mixed to prepare two groups of raw material mixtures;

[0047] ⅱ. Sintering: The raw material mixture uniformly mixed in step i is fully and evenly mixed and then put into a rubber tube of Ф10mm for sealing, pressed into a dense ingot green body by isostatic pressing at a pressure of 20Mpa, and then put into a muffle Sintering in the furnace, the sintering temperature i...

Embodiment 3

[0052] This embodiment is basically the same as the previous embodiment, and the special features are:

[0053] In this embodiment, a method for preparing a cerium-doped gadolinium disilicate luminescent material, using the top seed method to prepare a scintillation single crystal of cerium-doped gadolinium disilicate, includes the following steps:

[0054] Ⅰ. Ingredients: According to the chemical formula (Gd 0.899 Y 0.1 Ce 0.001 ) 2 Si 2 o 7 and (Gd 0.895 Y 0.1 Ce 0.001 Mg 0.004 In 0.004 ) 2 Si 2 o 7 The stoichiometric ratio of Gd 2 o 3 , Y 2 o 3 , SiO 2 , Ce(NO 3 ) 3 , MgO and In 2 o 3 The raw materials in the mixture are uniformly mixed, and two sets of raw material mixtures are prepared. When batching, SiO 2 As a flux, the excess molar ratio of the ingredients is 10%;

[0055] Ⅱ. Sintering: The raw material mixture uniformly mixed in step Ⅰ is fully and evenly mixed and then put into a Ф50mm rubber tube for sealing, and isostatically pressed at a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com