Oil soluble nanometer scintillation crystal and preparation method thereof

A scintillation crystal, oil-soluble technology, applied in nanotechnology, crystal growth, nano-optics and other directions, can solve the problems of lack of high-quality nano-scintillation crystals, poor uniformity of crystal composition distribution, reduced crystal scintillation performance, etc., to achieve good scintillation performance. , the preparation method is simple and easy to implement, and the effect of reducing the detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

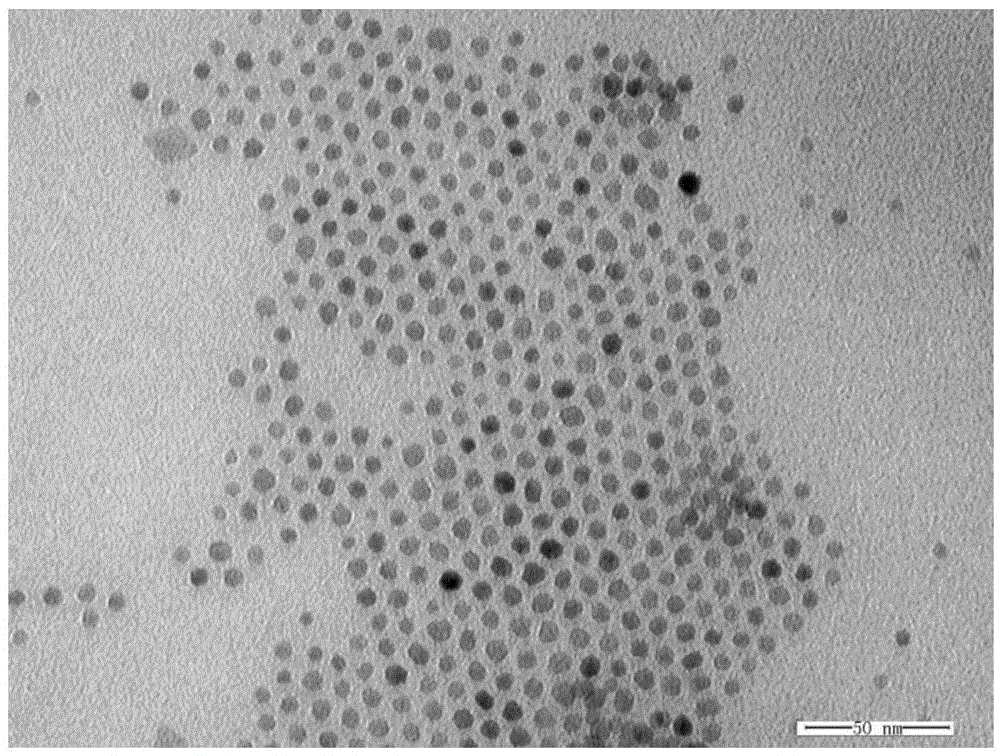

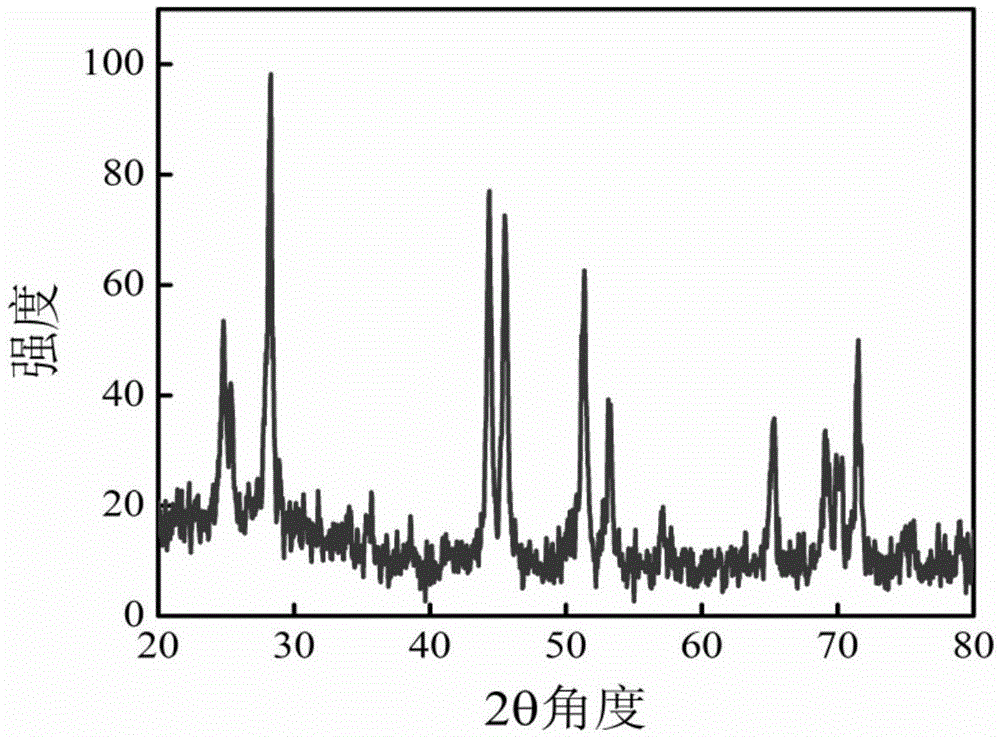

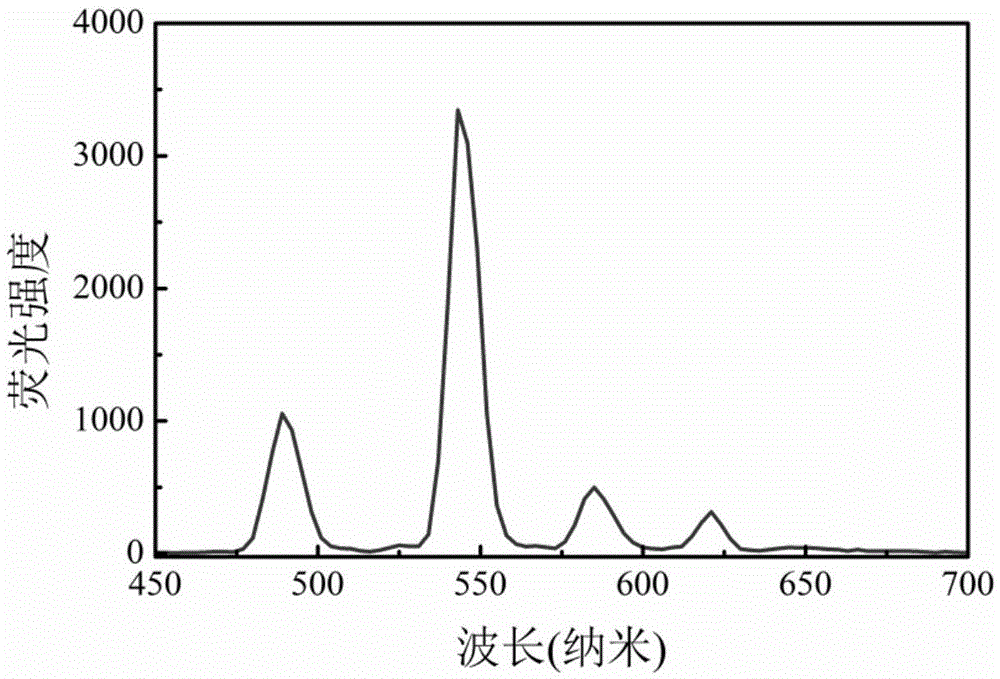

[0032] Example 1La 0.9 f 3 :Tb 0.1 Oil-soluble nano-scintillation crystals

[0033] 1) Weigh 0.9mmol LaCl 3 ·7H 2 O and 0.1 mmol TbCl 3 ·6H 2 O, add 10ml of oleic acid and 8ml of octadecene to it, first raise the temperature to 100°C, then raise the temperature to 160°C under an argon atmosphere, and stir for 1h to obtain solution A;

[0034] 2) Solution A is cooled to room temperature, and 3 mmol NH 4 10ml of methanol solution of F, control the rotating speed of the peristaltic pump, and adjust the dropping rate to be 0.3ml / min to obtain solution B;

[0035] 3) Solution B was stirred and reacted at room temperature for 1 hour, then heated to 70°C, vacuumed to remove methanol, heated to 280°C at 10°C / min in an argon atmosphere, and reacted for 60 minutes to obtain a mixed liquid of oil-soluble nano-scintillation crystals;

[0036] 4) The oil-soluble nano-scintillation crystal mixture was cooled to room temperature, and then 3 times the volume of ethanol was added to th...

Embodiment 2

[0038] Example 2La 0.3 f 3 : Ce 0.6 Tb 0.1 Oil-soluble nano-scintillation crystals

[0039] 1) Weigh 0.3mmol LaCl 3 ·7H 2 O, 0.6mmol CeCl3 ·7H 2 O and 0.1 mmol TbCl 3 ·6H 2 O, add 12ml of oleic acid and 8ml of octadecene to it, first raise the temperature to at least 100°C, then raise the temperature to at least 160°C under an argon atmosphere, and stir for at least 1h to obtain solution A;

[0040] 2) Solution A is cooled to room temperature, and 3 mmol NH 4 F methanol solution 10ml, control the rotating speed of the peristaltic pump, adjust the dropping rate to be 0.8ml / min, obtain solution B;

[0041] 3) Solution B was stirred and reacted at room temperature for at least 1 hour, then heated to at least 70°C, vacuumed to remove methanol, heated to 260°C at 15°C / min in an argon atmosphere, and reacted for 120 minutes to obtain a mixed liquid of oil-soluble nano-scintillation crystals ;

[0042] 4) The oil-soluble nano-scintillation crystal mixture was cooled to roo...

Embodiment 3

[0043] Example 3La 0.8 f 3 :Tb 0.2 Oil-soluble nano-scintillation crystals

[0044] 1) Weigh 0.8mmol LaCl 3 ·7H 2 O and 0.2 mmol TbCl 3 ·6H 2 O, add 7ml of oleic acid and 8ml of octadecene to it, first raise the temperature to 100°C, then raise the temperature to 160°C under a nitrogen atmosphere, and stir for 1h to obtain solution A;

[0045] 2) Solution A is cooled to room temperature, and 3 mmol NH 4 10ml of methanol solution of F, control the rotating speed of the peristaltic pump, and adjust the dropping rate to be 0.5ml / min to obtain solution B;

[0046] 3) Solution B was stirred and reacted at room temperature for 1 hour, then heated to 70°C, vacuumed to remove methanol, heated to 280°C at 8°C / min under nitrogen atmosphere, and reacted for 80 minutes to obtain a mixed liquid of oil-soluble nano-scintillation crystals;

[0047] 4) The oil-soluble nano-scintillation crystal mixture was cooled to room temperature, and then 3 times the volume of ethanol was added to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com