Silicon film coated aluminum pigment as well as preparation method and application thereof

An aluminum pigment and coating technology, applied in inorganic pigment treatment, chemical instruments and methods, powder coatings, etc., can solve the problems of inability to produce high-flash effect coatings, easy agglomeration and scrapping of aluminum pigments, and destruction of aluminum pigments, etc. Achieve the effect of avoiding caking and scrapping, improving the flickering effect, and improving the powdering rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

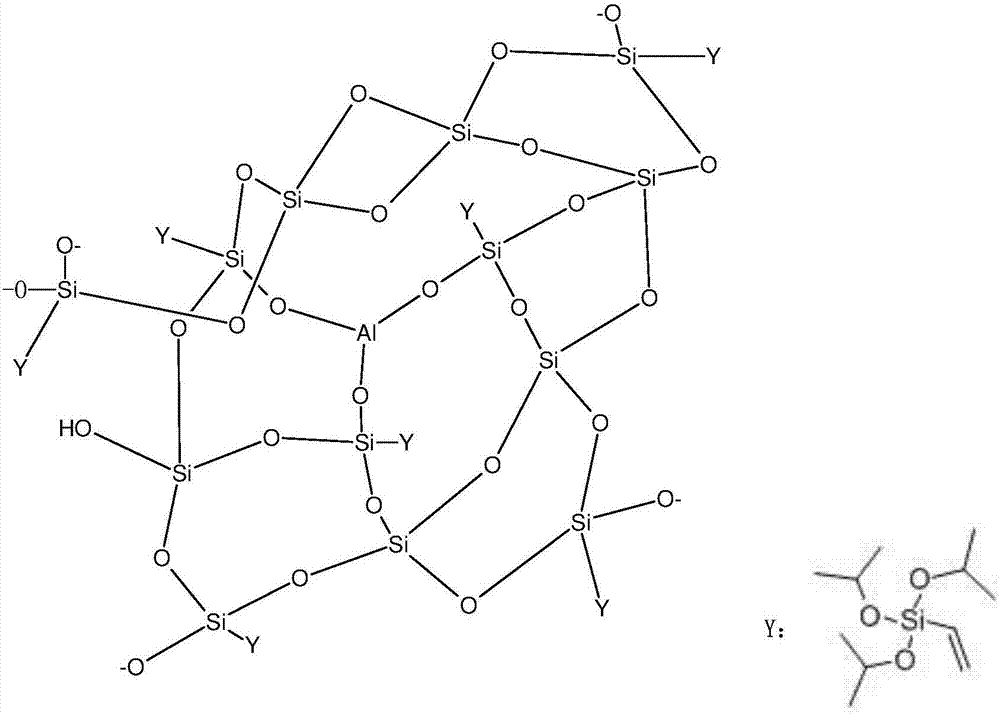

[0038] The present invention also provides a method for preparing the above-mentioned silicon film-coated aluminum pigment, comprising the following steps:

[0039](1) Disperse the aluminum pigment that removes impurity oil in an alcohol solvent, add water and stir, and then add a coupling agent to obtain the first mixed solution; mix water, tetraethyl orthosilicate, and alcohol solvent, and add The pH regulator adjusts the pH to 7.5-11 to obtain the second mixed solution;

[0040] (2) Adding the second mixed solution dropwise to the first mixed solution, and reacting for 4 to 6 hours to obtain the first product solution;

[0041] (3) Mix the coupling agent, tetraethyl orthosilicate and the alcohol solvent, add dropwise to the first product liquid obtained in step (2), and obtain the second product liquid after reacting for 6 to 12 hours; and so on , repeating the reaction of this step, each time adding the amount of coupling agent and the reaction time are all gradually incr...

Embodiment 1

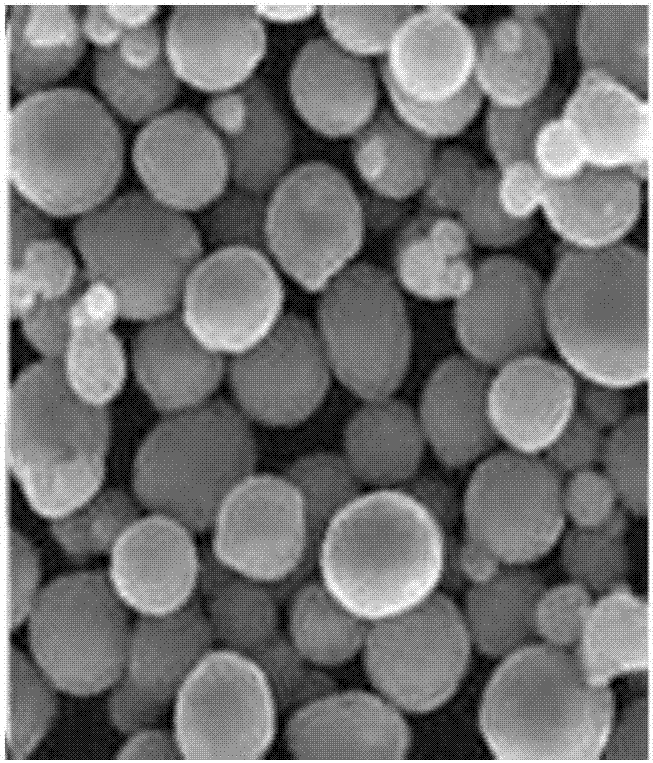

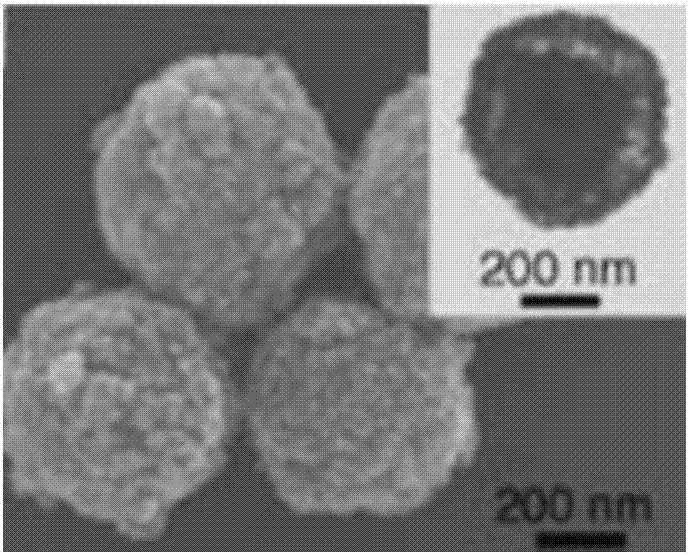

[0061] The silicon film-coated aluminum pigment in this embodiment is a Si—O—Si film with three layers of network structure coated on the outside of the aluminum pigment, and each layer of network structure is connected by a coupling agent. Wherein, the coupling agent is a vinyl silane coupling agent. The particle size of the aluminum pigment is 15 μm.

[0062] The preparation method of above-mentioned silicon film coated aluminum pigment is as follows:

[0063] (1) Remove impurity oil from aluminum pigment: mix 15 parts of aluminum pigment with 50 parts of ether solvent or alcohol solvent in parts by weight, stir at 30°C for 120 minutes, remove impurity oil from aluminum pigment, and filter with suction Keep the solid content at 85%±2 to obtain a clean aluminum pigment, which is stored at 30°C until use.

[0064] (2) Add 10 parts of aluminum pigment and 50 parts of ethanol to the reaction vessel, stir at 30°C until uniformly dispersed, then add 3 parts of water, continue st...

Embodiment 2

[0071] The silicon film-coated aluminum pigment in this embodiment is a Si—O—Si film with four layers of network structure coated on the outside of the aluminum pigment, and each layer of network structure is connected by a coupling agent. Wherein, the coupling agent is a vinyl silane coupling agent. The particle size of the aluminum pigment is 50 μm.

[0072] The preparation method of above-mentioned silicon film coated aluminum pigment is as follows:

[0073](1) Remove impurity oil from aluminum pigment: mix 15 parts of aluminum pigment with 50 parts of ether solvent or alcohol solvent in parts by weight, stir at 30°C for 120 minutes, remove impurity oil from aluminum pigment, and filter with suction Keep the solid content at 85%±2 to obtain a clean aluminum pigment, which is stored at 30°C until use.

[0074] (2) Add 10 parts of aluminum pigment and 45 parts of ethanol to the reaction vessel, stir at 30°C until uniformly dispersed, then add 2 parts of water, continue stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com