Metal sliver-coated glass-based effect pigment and preparation method thereof

An effect pigment and glass-based technology, which is applied in the direction of inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., can solve the problems of large differences in structure, large differences in color effects, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

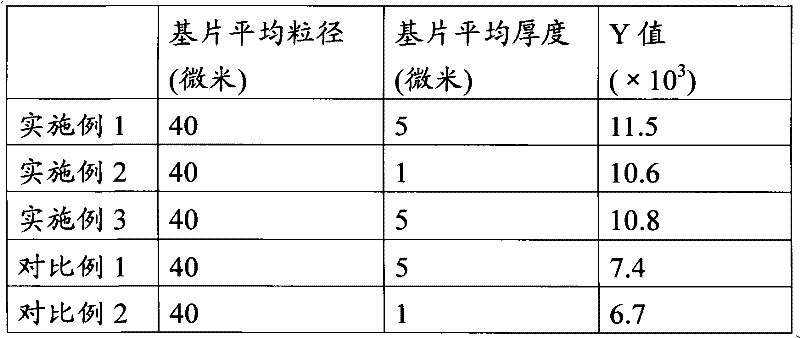

Examples

preparation example Construction

[0033] The preparation method of effect pigment of the present invention comprises the following steps:

[0034] (A) A certain amount of glass flakes with an average thickness in the range of 0.1 micron to 5 microns and an average particle size in the range of 1-1000 microns as the substrate are added to deionized water, stirred to form a suspension, and heated to 70-80 After ℃, add dropwise SnCl 4 aqueous solution. A certain amount of SnCl 4The solution is added within ten minutes, which is beneficial to the coating of metallic silver, and at the same time improves the compactness and strength of the coated film.

[0035] (B) Put the glass sheet through the above-mentioned treatment into aqueous glucose solution (general concentration is 1g / L-30g / L, preferably 3g / L-25g / L, more preferably 5g / L-20g / L, more preferably 6g / L -15g / L; for example, 20g / L corresponds to 2% concentration) and keep the temperature at 70-80°C.

[0036] (C) Add Tollens' reagent solution prepared from ...

Embodiment 1

[0050] Put 832 grams of glass flakes with an average particle size of 40 microns and an average thickness of 5 microns into a 5-liter vessel with stirring, add 2.07 liters of deionized water and stir at a high speed at 75°C. Formulated to contain 4.16 g of SnCl 4 , a solution of 3.5 ml of 1:1 HCl and 20 g of deionized water. The prepared solution was added to the above liquid with the glass flakes and kept stirring for 1 hour.

[0051] The above liquid was filtered and washed with 2 L of deionized water. The filtered glass flakes were transferred to a 12 liter container with stirring, followed by adding an aqueous solution formed by 186.8 grams of glucose in 6.5 liters of water, keeping the temperature of the system at 75° C. and the stirring speed at 250 rpm.

[0052] With 166.5 g of AgNO 3 , 540 grams of deionized water and 270 grams of commercially available AMP of 95% purity (containing about 5% water) prepared a solution. Add the prepared solution to the above-mention...

Embodiment 2

[0057] Repeat embodiment 1, just be 40 microns with the mean particle diameter of 516 grams, the glass flake of 1 micron average thickness replaces the glass flake in embodiment 1, other reaction conditions are constant, finally obtain the finished product pigment of 576 grams.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com