Pressureless sintering preparation method of Ce:Lu2SiO5 polycrystal flicker optical ceramics

An optical ceramics and preparation process technology, applied in the field of preparation of polycrystalline scintillation optical ceramics, can solve the problems of sample contamination, cracking, increase equipment requirements, etc., and achieve the effects of reducing intermediate steps, simplifying the preparation process, and fast decay characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

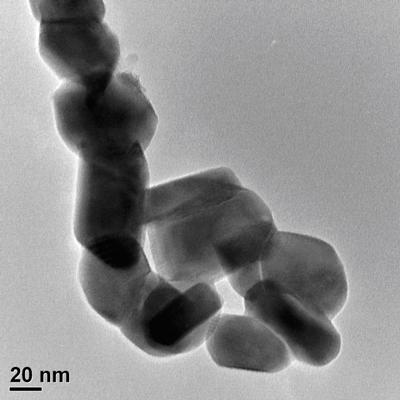

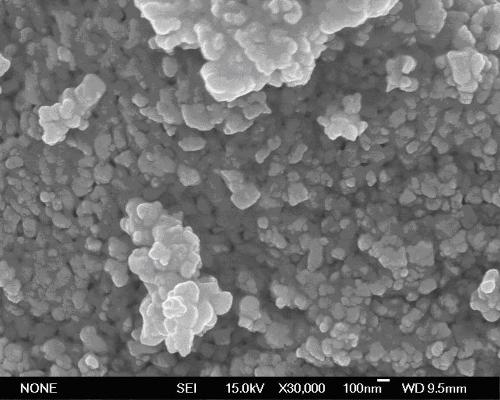

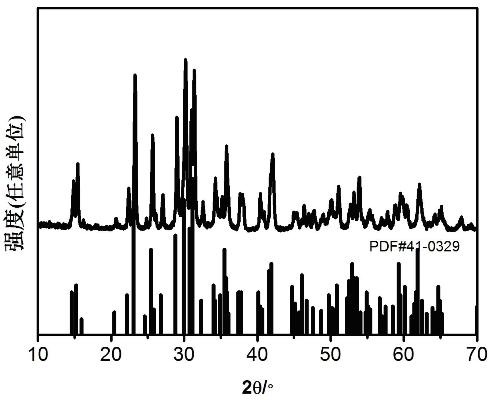

[0028] 20 g of lutetium chloride (LuCl 3 ) and 8.05ml of tetraethyl orthosilicate (Si(C 2 h 5 O) 4 ) dissolved in 142.5 ml of isopropanol ((CH 3 O) 2 CHOH), add another 0.68 ml concentration of 0.522 mol / L cerium nitrate (Ce(NO 3 ) 3 ), followed by adding 99.61 mol propylene oxide (C 3 h 6O), a white gel-like precipitate was obtained after stirring for 30 hours. The precipitate was dried under air atmosphere at 60°C for 24 hours, then calcined and synthesized in a muffle furnace at 1100°C, and kept for 2 hours to obtain submicron 0.5mol%Ce:Lu 2 SiO 5 Luminous powder.

[0029] The obtained powder was first placed in a stainless steel mold with an inner diameter of Φ10 mm, and double-pressed under a pressure of 1 MPa, and then the sample was sealed and pressed under a cold isostatic pressure of 200 MPa to form a powder with a relative density of 51%. Plain embryo. Finally, place the shaped green body in a hydrogen furnace for H 2 Pressureless sintering process unde...

Embodiment 2

[0031] 40 g of lutetium chloride (LuCl 3 ) and 16.1 ml of tetraethyl orthosilicate (Si(C 2 h 5 O) 4 ) dissolved in 142.5 ml of isopropanol ((CH 3 O) 2 CHOH), add another 0.68 ml concentration of 0.522 mol / L cerium nitrate (Ce(NO 3 ) 3 ), followed by adding 199.22 mol propylene oxide (C 3 h 6 O), a white gel-like precipitate was obtained after stirring for 30 hours. The precipitate was dried under air atmosphere at 60°C for 24 hours, then calcined and synthesized in a muffle furnace at 1100°C, and kept for 2 hours to obtain submicron 0.25mol% Ce:Lu 2 SiO 5 Luminous powder.

[0032] The obtained powder was first placed in a stainless steel mold with an inner diameter of Φ20 mm, and double-pressed under a pressure of 4 MPa, and then the sample was pressed under a cold isostatic pressure of 200 MPa to form a green body with a relative density of 50%. . Finally, put the formed blank in a hydrogen furnace through a reducing atmosphere pressureless sintering process, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com