Intrinsic luminescent scintillation crystal magnesium tantalum oxide, and preparation method and use thereof

A technology of scintillation crystals and magnesium tantalate, which is applied in the chemical industry, can solve problems such as cracks and low-quality crystal rods, and achieve the effects of simple operation, stable crystallization quality, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) High-purity powder MgO (99.9995%) and Ta 2 o 5 (99.99%) batching according to the molar ratio of 4.04:1, ball milling for 1 hour, filling and pounding the mixed powder into a long plastic tube, sealing and clamping the plastic tube between two metal semicircular thin tubes Fix it, put it into an isostatic press and hold it for 1 hour under a pressure of 350MPa, remove the plastic tube to make a raw material rod with a length of about 10cm and a diameter of 5mm;

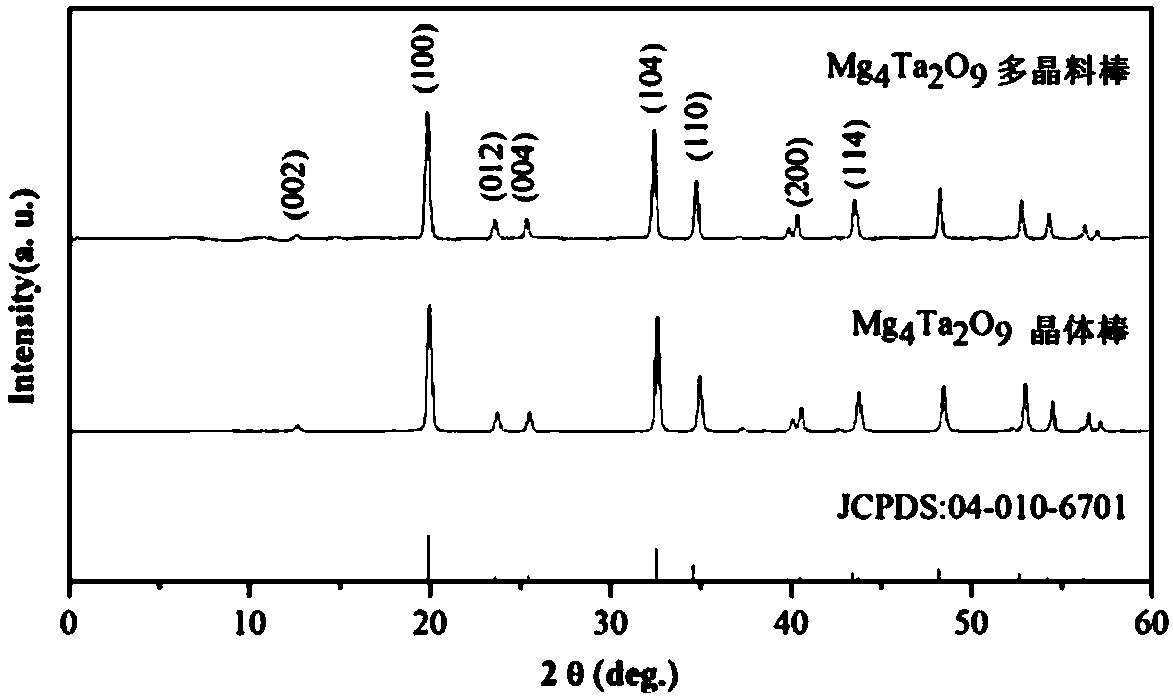

[0028] 2) Put the raw material rod prepared in step 1) into a long crucible, sinter in a muffle furnace, raise the temperature to 1400 °C at a rate of 1400 °C / h, keep it warm for 2 hours, and drop it at a rate of 1400 °C / h to room temperature, that is, a dense and uniform polycrystalline rod with equal diameter is produced, and a part is intercepted for powder XRD characterization, as shown in figure 2 shown;

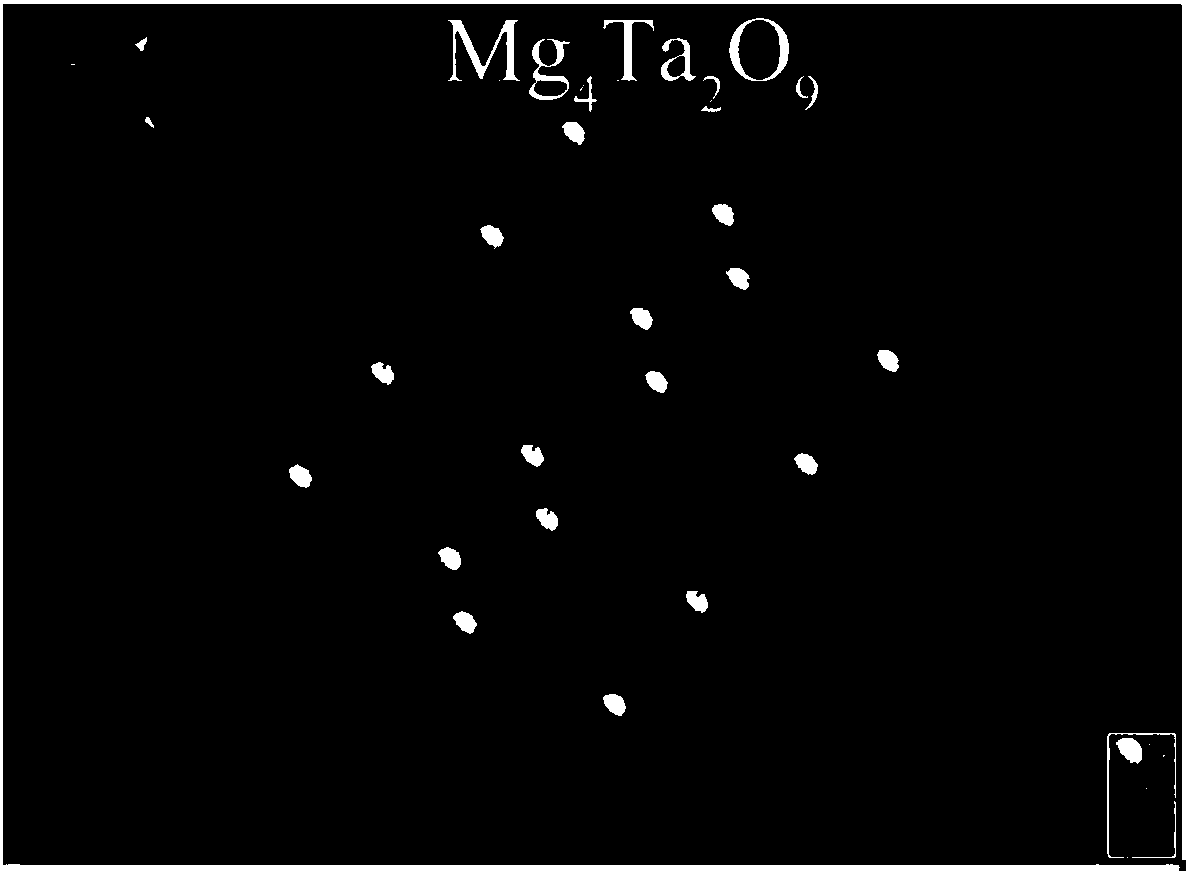

[0029] 3) with the pure phase Mg that step 2) makes 4 Ta 2 o 9 Part of the polycrystalline ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com