Method for producing cerium fluoride hollow nanostructured material

A technology of hollow nano and structural materials, applied in the direction of nanostructure manufacturing, chemical instruments and methods, nanotechnology, etc., to achieve the effect of low synthesis cost, controllable shape and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

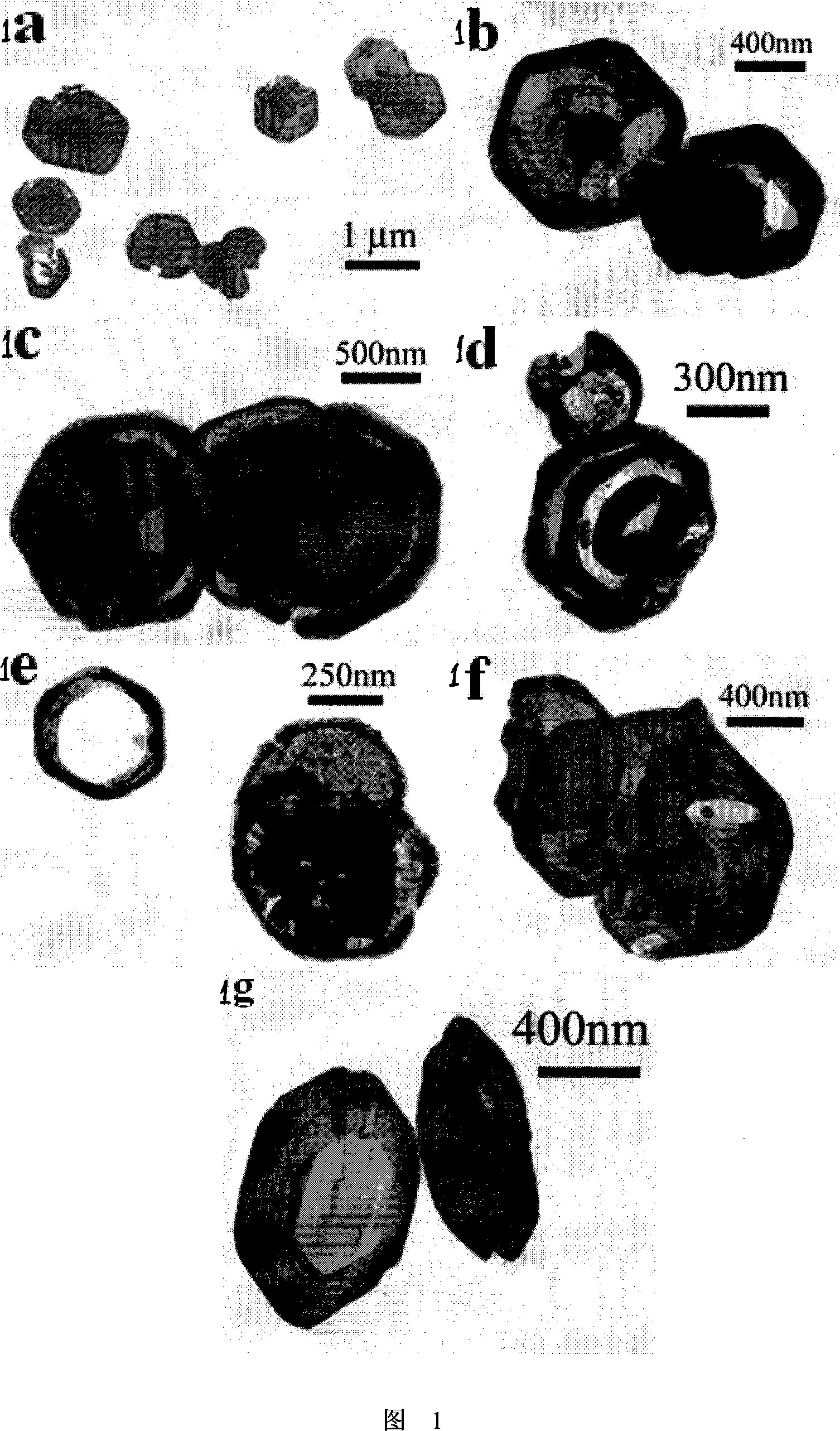

[0044] Example 1 Preparation of CeF with hexagonal cross-section using cerium ammonium sulfate as raw material 3 Hollow nanostructured materials.

[0045] Add 29mL distilled water, 1mL concentrated sulfuric acid, 0.3g KBrO 3 , 0.4g citric acid, 0.2g NaF, 0.4g ceric ammonium sulfate, sealed in the autoclave after stirring, and placed in an oven at 160°C for 24 hours, the CeF with hexagonal cross section can be obtained 3 Hollow nanostructure materials, hollow nanostructures include hollow nanocages, nanorings or nano "cocoons", helical nanocages, etc. (Fig. 1, Fig. 4, Fig. 11). Wherein the temperature range may be 140-170° C., the reaction time may be 12-100 hours, and the amount of ammonium cerium sulfate may be 0.1-0.8 g. 0.4g oxalic acid or glucose instead of citric acid is also the same.

Embodiment 2

[0046] Example 2 Preparation of CeF with hexagonal cross-section using cerium ammonium nitrate as raw material 3 Hollow nanostructured materials.

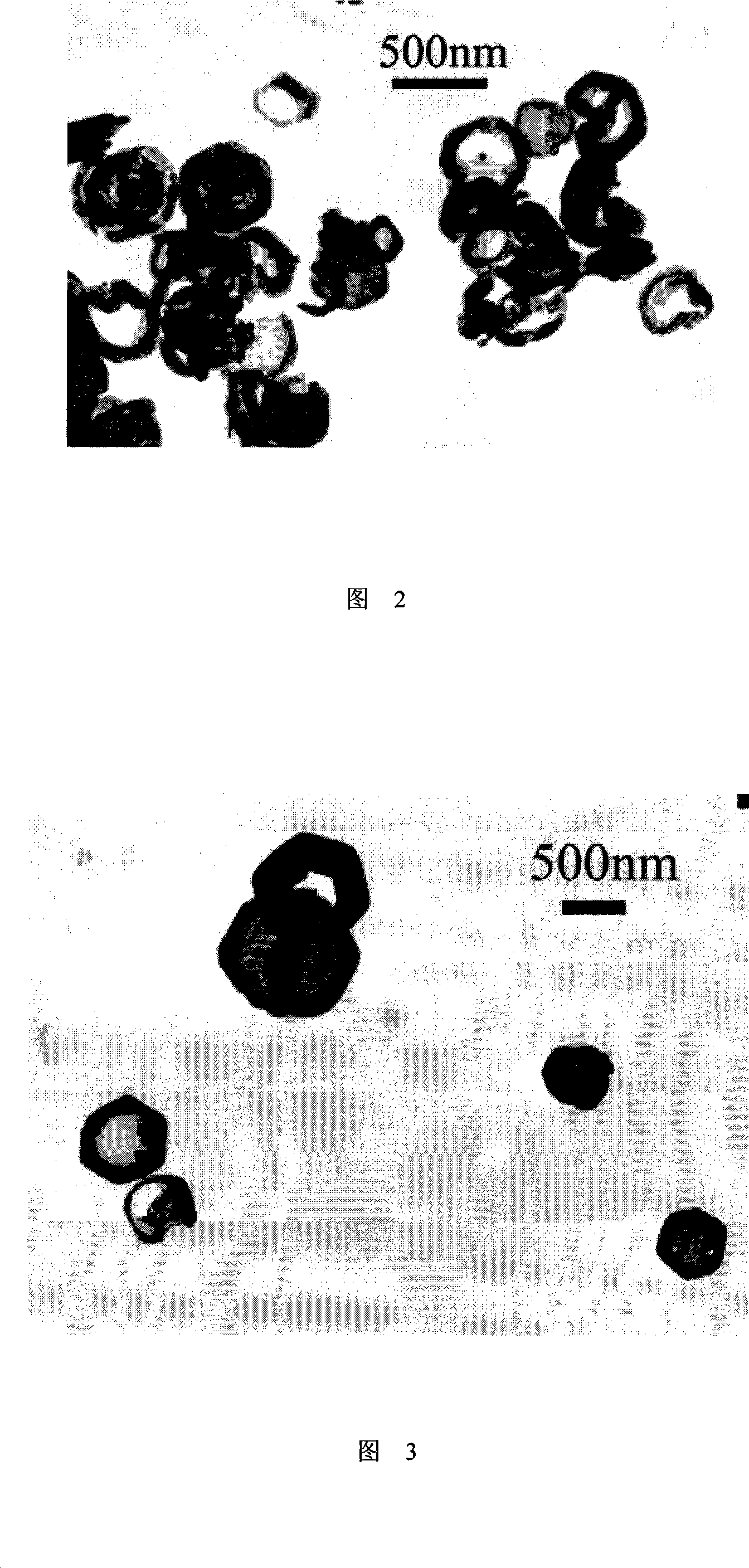

[0047] Add 29mL distilled water, 1mL concentrated sulfuric acid, 0.3g KBrO 3 , 0.4g citric acid, 0.2g NaF, 0.4g cerium ammonium nitrate, sealed in the autoclave after stirring, and placed in an oven at 160°C for 24 hours, the CeF with hexagonal cross section can be obtained 3 Hollow nanostructured materials (see Figure 2). Wherein the temperature range may be 140-170° C., the reaction time may be 12-100 hours, and the amount of ceric ammonium nitrate may be 0.1-0.8 g. 0.3g NaBrO 3 Replace KBrO 3 The same is true.

Embodiment 3

[0048] Example 3 with K 7 Ce 6 f 31 Preparation of CeF with hexagonal cross-section as raw material 3 Hollow nanostructured materials.

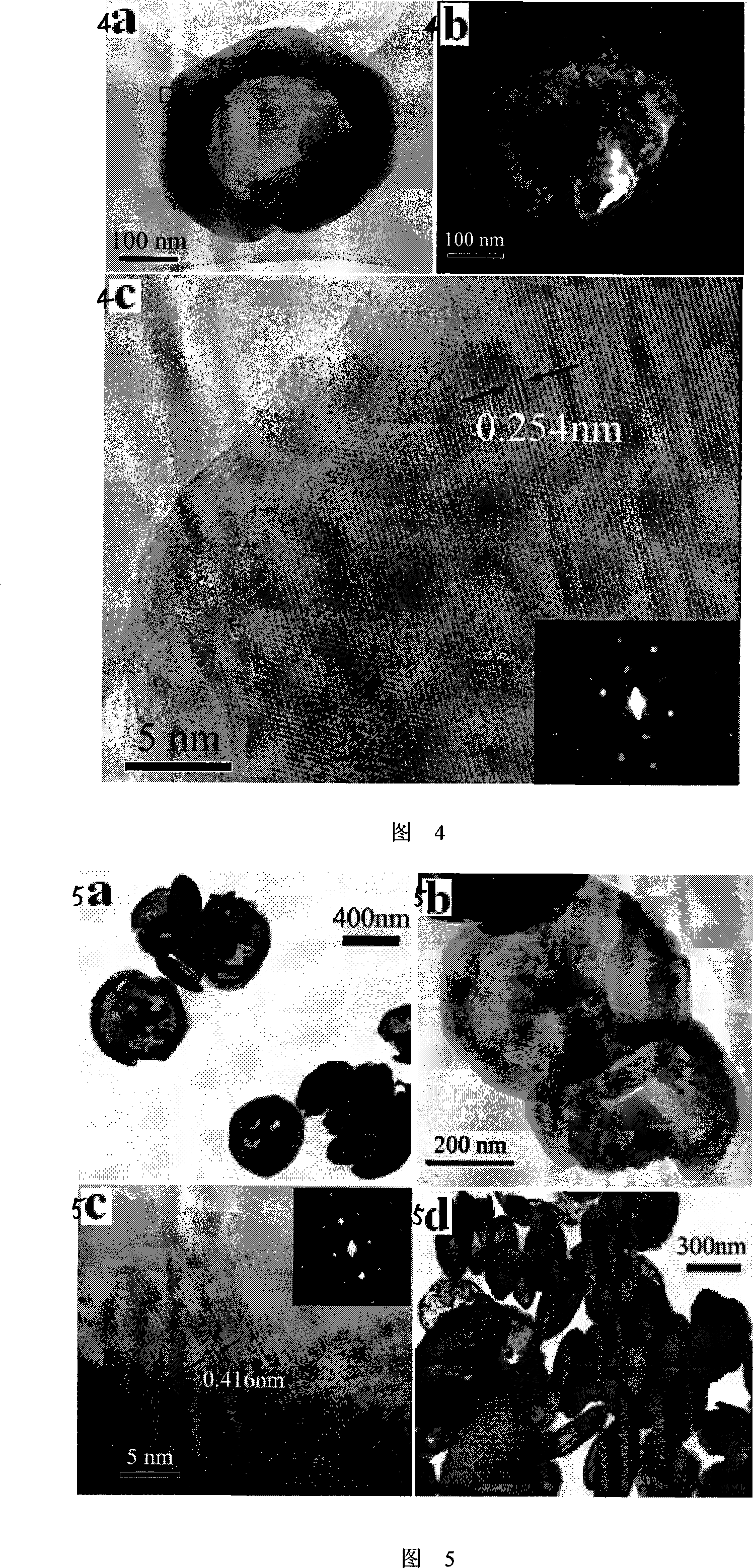

[0049] K 7 Ce 6 f 31 The raw materials can be prepared at room temperature (see Figure 10), take a small beaker, add 40mL of distilled water, and then add 0.6g of potassium salt (such as KBrO 3 , KCl, KNO 3 etc.), 0.4g fluoride (such as NaF, NH 4 F, NH 4 F·HF, etc.), 0.8g cerium salt (such as cerium ammonium sulfate, cerium ammonium nitrate, etc.), stirred for 5min, aged for 10 hours, filtered, washed, and dried to obtain K 7 Ce 6 f 31 powder. Add 29mL distilled water, 1mL concentrated sulfuric acid, 0.3gKBrO 3 , 0.4g citric acid, 0.1gNaF, 0.2g K 7 Ce 6 f 31 powder, sealed in an autoclave after stirring, and placed in an oven at 160°C for 24 hours to obtain CeF with a hexagonal cross-section 3 Hollow nanostructured materials (see Figure 3). Wherein the amount of NaF can be 0-2g, K 7 Ce 6 f 31 The amount of powder can be 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com