Fixed bed desulfurization reaction device and use method thereof

A technology of reaction device and fixed bed, which is applied in the field of fixed bed desulfurization reaction device, can solve the problems of low fluency of added materials, low utilization efficiency of desulfurization agent, and large resistance consumption of the device, so as to improve the utilization rate of desulfurization agent and improve The smoothness of blanking and the effect of eliminating the dead angle of refueling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

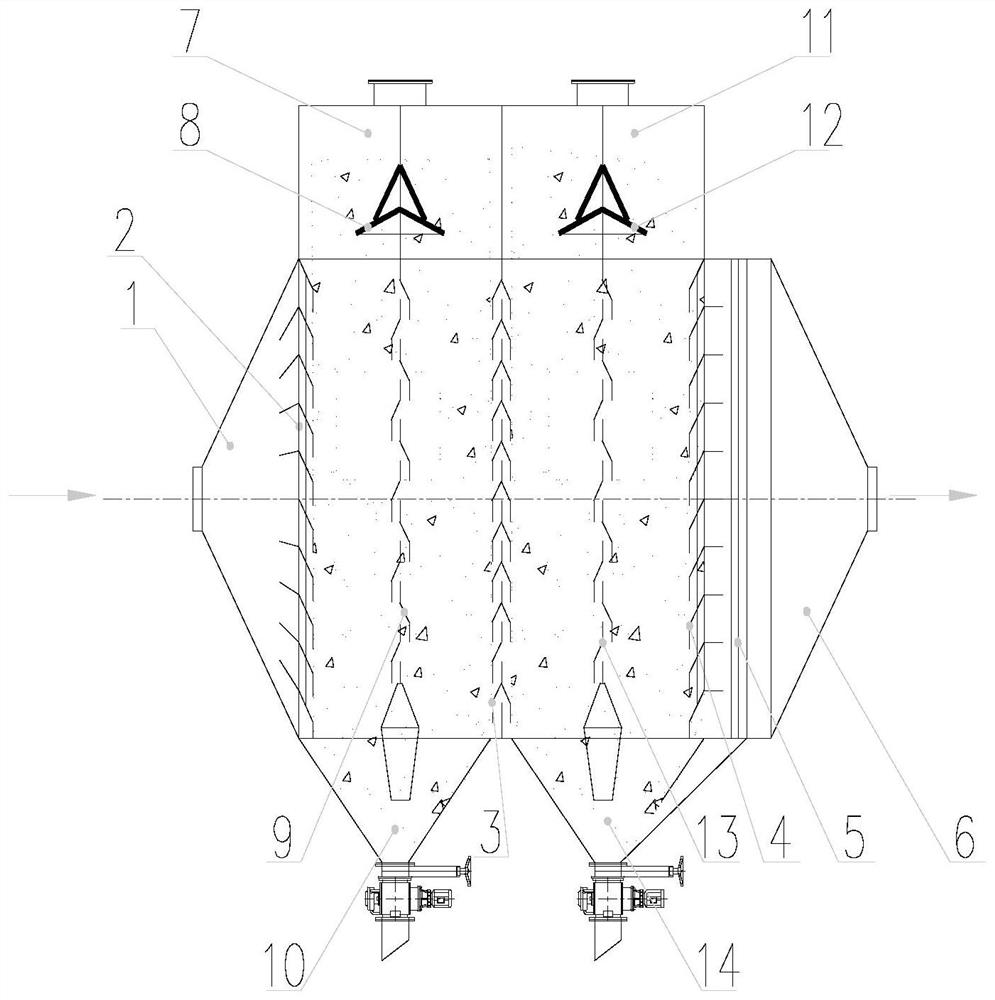

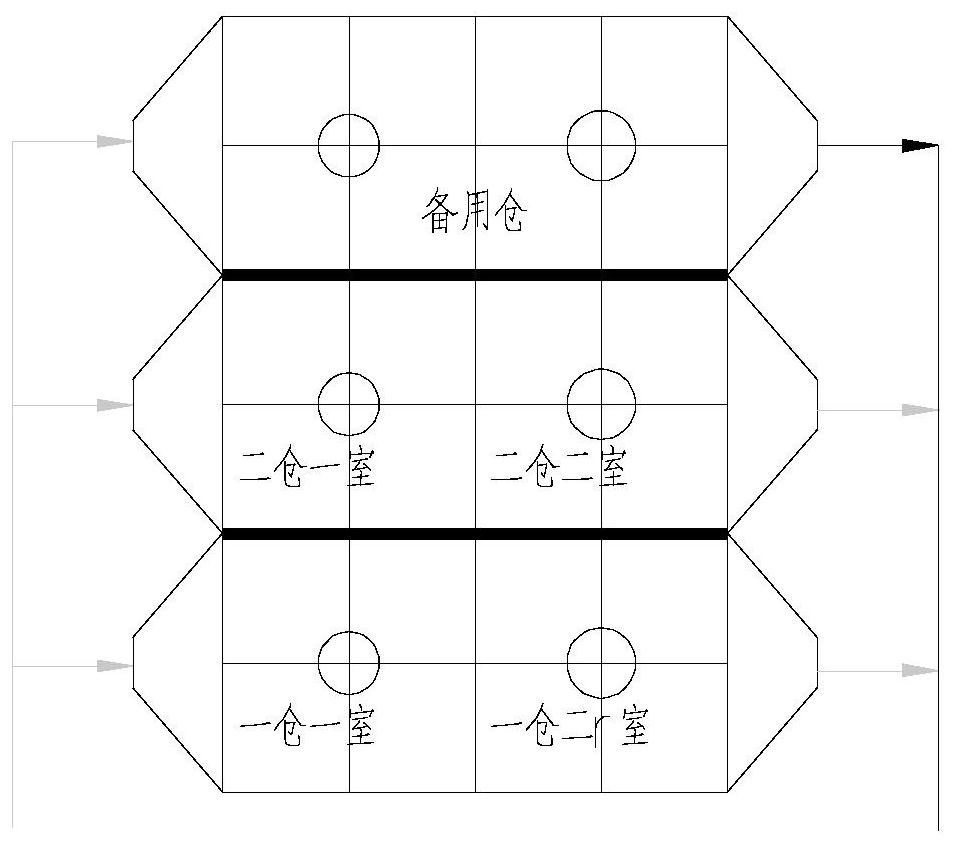

[0067] Such as figure 1 As shown, this embodiment provides a fixed bed desulfurization reaction process. The overall process route is to enter the flue gas inlet 1 of each warehouse first, enter the reaction chamber through the inlet grid diversion wall 2 for desulfurization reaction, and then enter the next reaction chamber through the inter-chamber grid diversion wall 3 , and then the gas that reaches the standard is discharged through the outlet grid guide partition wall 4, the outlet groove plate 5, and the flue gas outlet 6 in sequence.

[0068] The specific process route includes the following steps:

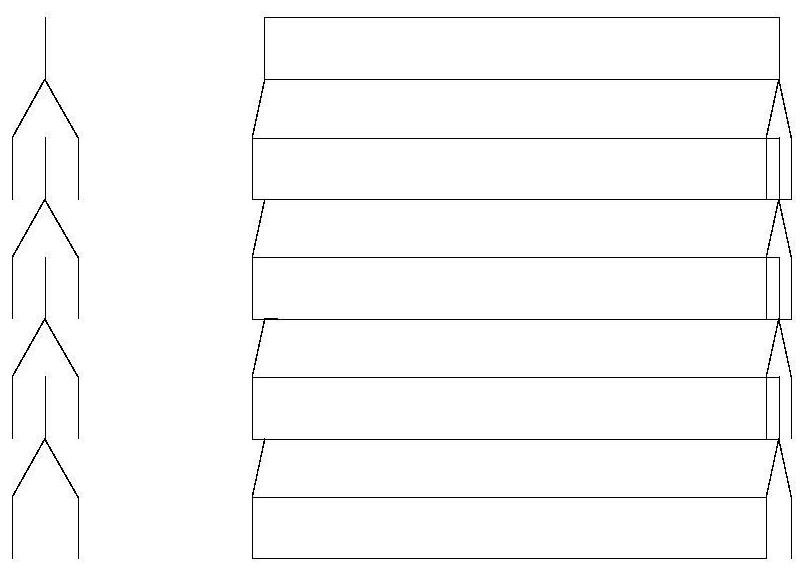

[0069] 1) The raw flue gas to be treated enters through the flue gas inlet 1, and then passes through the inlet grid to divert the partition wall 2. The angle of the deflector at the front end of the module of the inlet grid diversion partition wall 2 fits the flue gas flow field, so that the flue gas can pass through smoothly and completely isolate the closed materials ...

Embodiment 2

[0075] This embodiment provides a blanking process, which includes the following steps: the desulfurizer filling process is arranged vertically, and the layout of the first room and the second room is the same. Taking the first room as an example, it enters from the material dosing section 7 at the top of the device, and passes through Butterfly buffer material guide 8 evenly distributes the material into the warehouse, and after the material fails, it can be discharged through the discharge system 10 at the lower part. A blanking stabilizer 9 is arranged in the warehouse to ensure that the blanking is smooth and the material layer is uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com