High concentration gradient microfluidic mixing chip with jet flow damaging function

A high-concentration, gradient technology, applied in mixers, laboratory utensils, chemical/physical/physicochemical processes, etc., can solve problems such as reducing fluid concentration, low test reliability, and inability to detect low-sensitivity probes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to solve the above-mentioned problems existing in the prior art, the applicant has conducted in-depth research and believes that the prior art has the following disadvantages:

[0016] 1. The size of the jet-type microfluidic mixing device is very small. Generally, the channel width is about 10um, and the formed jet is only 100nm, resulting in a very small detection area and high detection requirements. It is almost impossible to detect low-sensitivity probes, such as absorption and Raman. .

[0017] 2. The jet trajectory is determined by the experimental state, and the width is extremely narrow. Once the experimental state changes unpredictably, the jet will deviate from the predetermined trajectory, making it difficult to detect and the reliability of the experiment is low.

[0018] For this reason, the applicant proposes the following technical solutions.

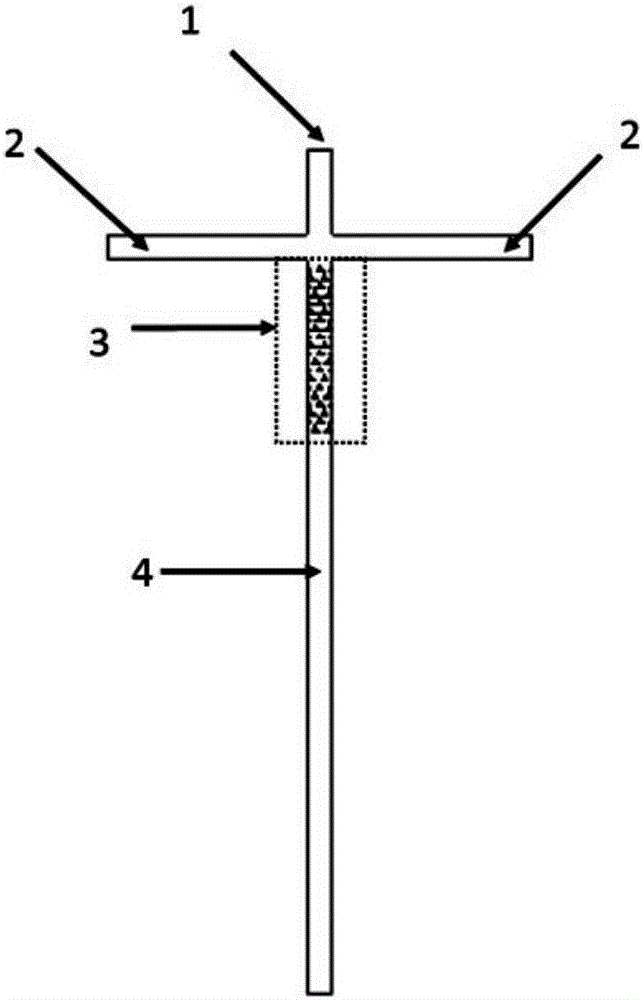

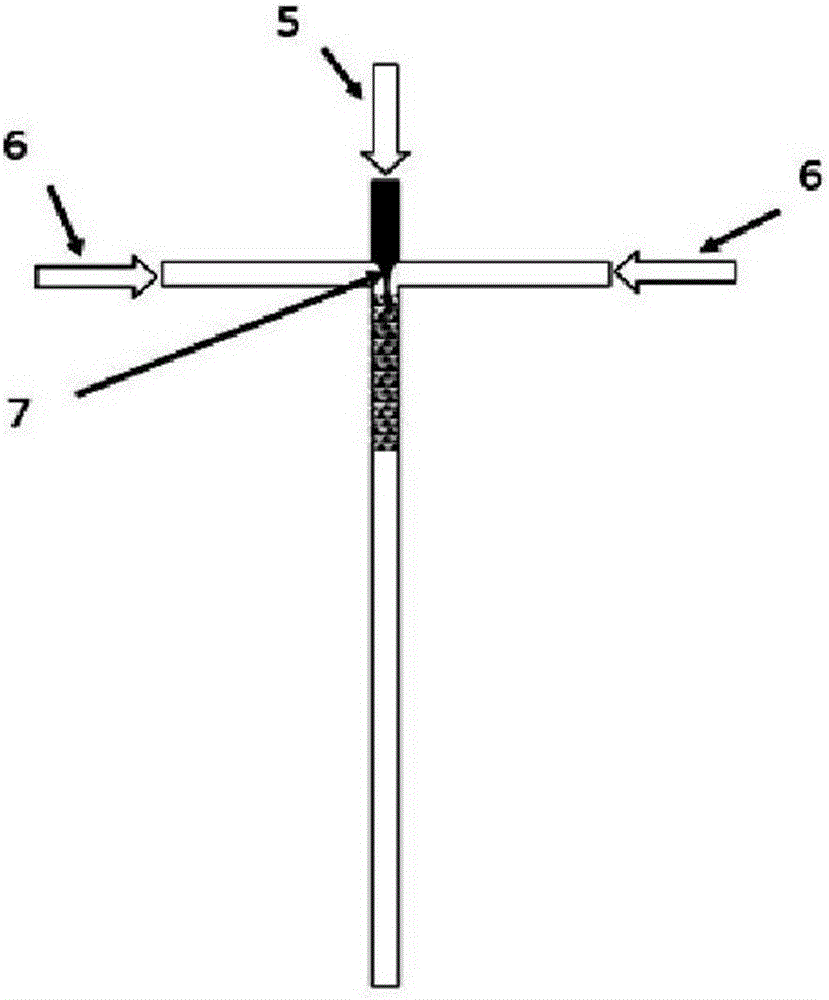

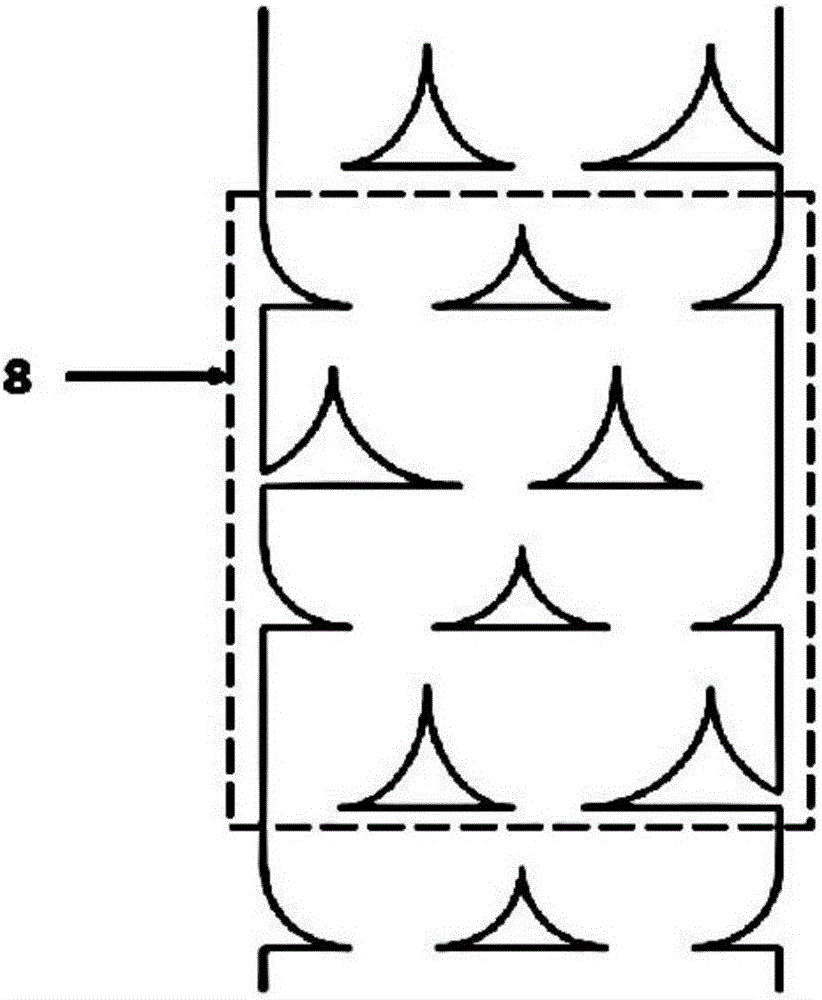

[0019] Such as figure 1 As shown, the jet-disrupting high-concentration gradient microfluidic mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com