A method for recovering chromium from leather tanning wastewater

A waste water and tanning technology, applied in the field of chromium recovery, can solve the problems of low recovery rate, high cost, unfavorable chromium recovery and utilization, etc., and achieve the effects of improving chromium recovery rate, sufficient reaction, and saving recovery cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

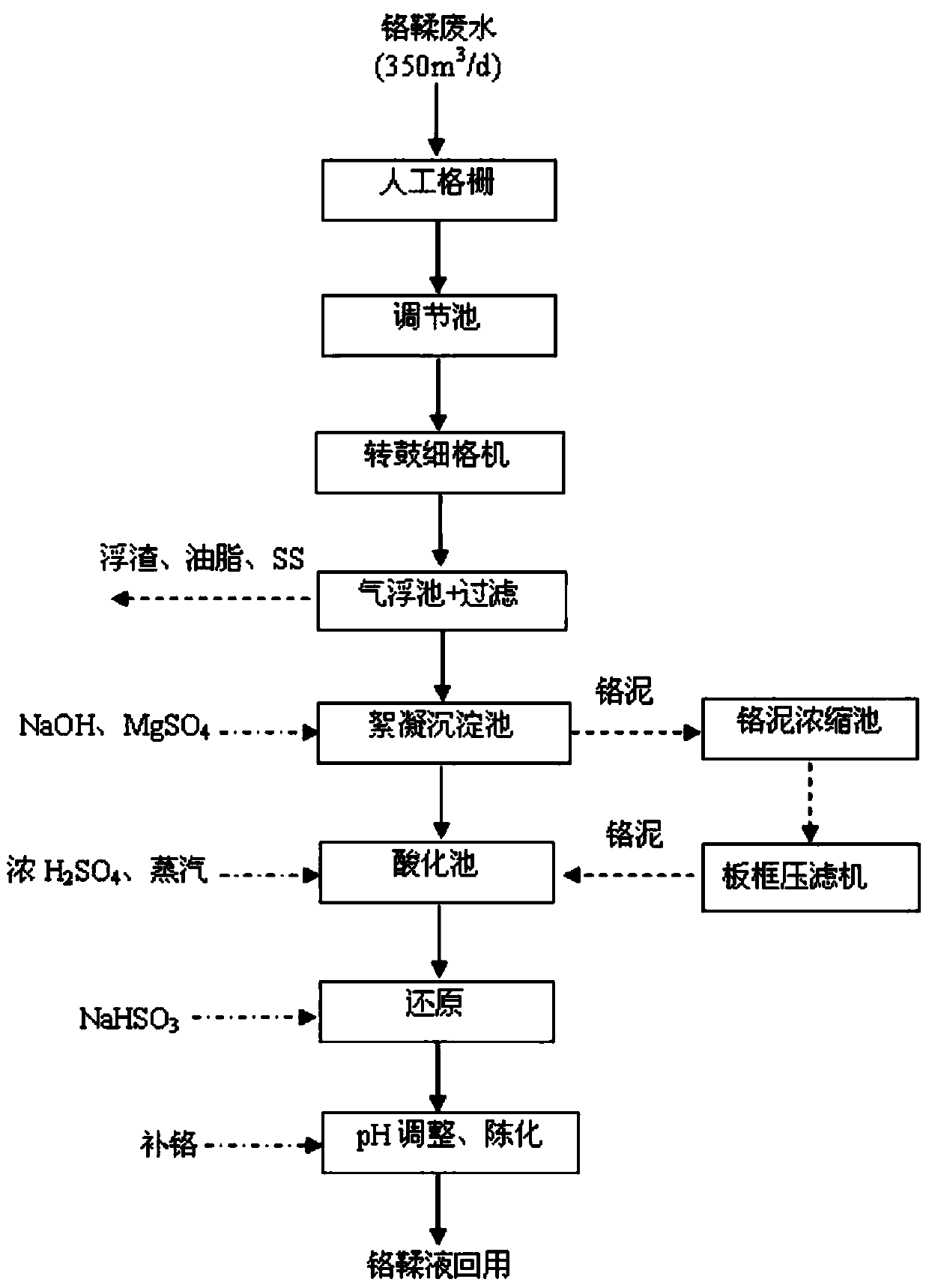

[0035] A method for recovering chromium from leather tanning wastewater. The sewage of the chromium recovery system comes from the tanning and retanning process. The chromium content of the wastewater is 2500-3000mg / L, and the designed treatment water volume is 350m 3 / d, pH value is 3.5~4.5, recovery process figure 1 ,Specific steps are as follows:

[0036] (1) Pretreatment: After the wastewater intercepts large floating objects through artificial grills and mechanical grilles, oil and other fine suspended solids and colloidal substances are further separated by pressurized dissolved air flotation, and then impurities are removed by self-cleaning mechanical filtration ; Fine grid gap 1mm, air bearing surface load 2.5m 3 / m 2 h, the air flotation separation time is 35min, the dissolved air water reflux ratio is 40%, and the self-cleaning filtration accuracy is 80μm;

[0037] (2) Precipitation and separation: add 20% NaOH solution and sedimentation aid MgSO to the effluent a...

Embodiment 2

[0045] A tannery processes 1 million pieces of raw cowhide annually, and produces 3000m of wastewater every day 3 / d, of which, the chrome tanning wastewater is about 300m 3 / d, Cr in wastewater 3+ Concentration is about 2000mg / L, pH is 4-5, adopt method of the present invention to process leather tanning chromium-containing wastewater and recycle the chrome sludge that produces, concrete steps are as follows:

[0046] (1) Pretreatment: Firstly, the raw water is pretreated by the drum grill machine, pressure dissolved air flotation machine and brush self-cleaning filter to remove impurities such as minced meat, grease, skin dregs, hair and suspended solids in the water , the mechanical grid is a drum type grid, and the gap between the grid bars is 1mm; the air flotation equipment is a pressure dissolved air flotation machine, and the surface load of the separation area is 2.5m 3 / m 2 h, the air flotation separation time is 35min, the dissolved air water reflux ratio is 40%;...

Embodiment 3

[0055] A method for reclaiming chromium from leather tanning wastewater, comprising the following steps:

[0056] (1) Pretreatment: remove impurities, grease, suspended matter and some organic matter in the leather tanning wastewater; the leather tanning wastewater first removes impurities through a mechanical grid, and then separates the grease, suspended matter and part of the organic matter through the air flotation equipment, and then Then remove the suspended matter in the liquid through a filter; wherein the mechanical grid is a drum type grid, and the gap between the grid bars is 1mm; the air flotation equipment is a pressure dissolved air flotation machine, and the surface load of the separation area is 2 ~ 3m 3 / m 2 h, the air flotation separation time is 30-40min, the dissolved air water reflux ratio is 30%-50%; the filter is a brush-type self-cleaning filter, the filtration accuracy is 80μm, and the water inlet pressure is 3kg / cm 2 ;

[0057] (2) Precipitation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com