Bastnaesite (bastnasite) separation method

A technology of bastnaesite and bastnaesite, which is applied in the field of bastnaesite (bastnaesite) separation method, can solve the problems of low equipment utilization efficiency, environmental pollution, high treatment cost, etc., and achieve improvement The effect of product value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

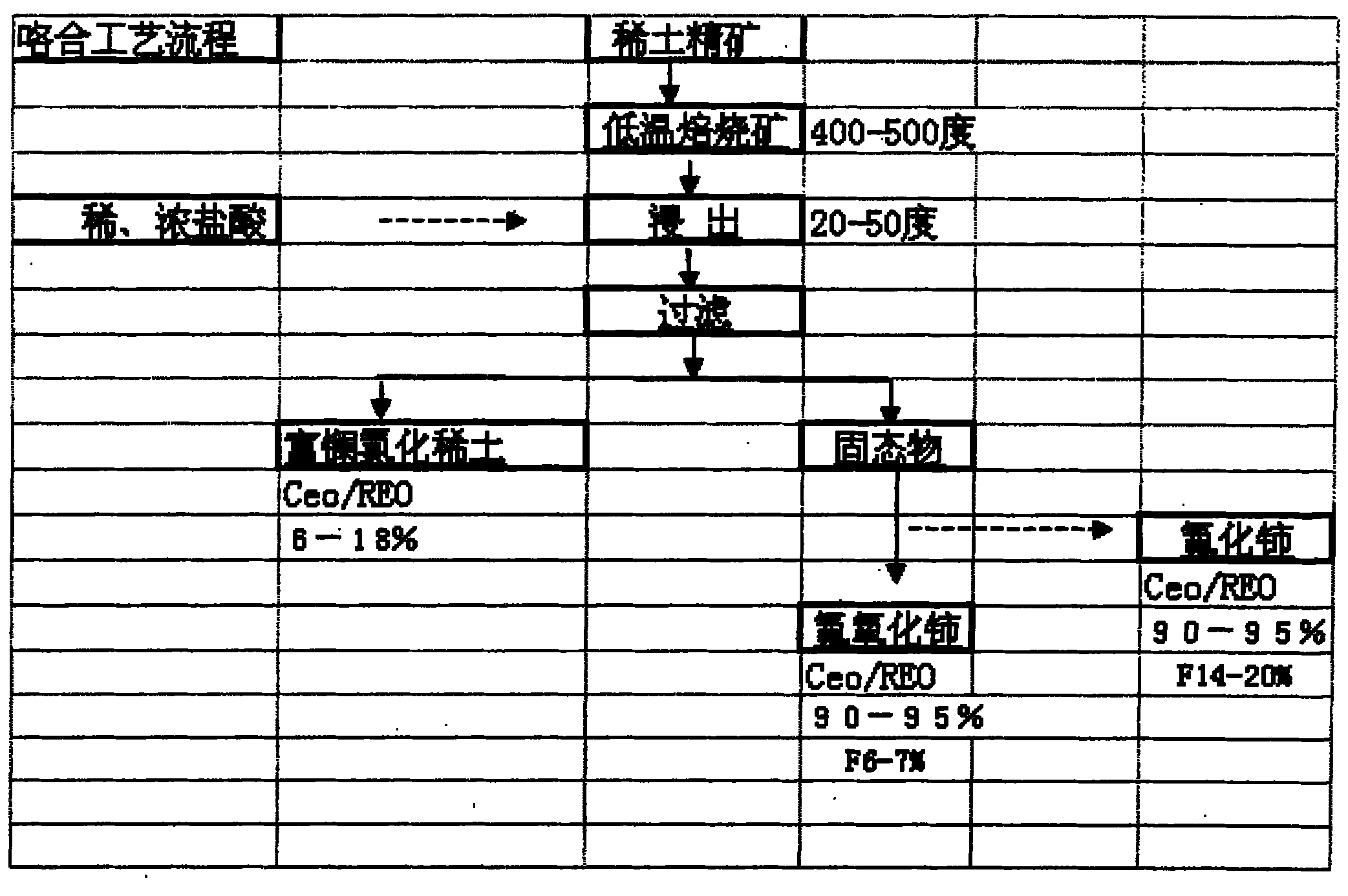

[0029] The bastnaesite (bastnaesite) rohe separation method comprises the following steps:

[0030] D. Low-temperature oxidation roasting of bastnaesite and bastnaesite at 400-500 degrees;

[0031] E. Use hydrochloric acid to directly dissolve the roasted concentrate at a low temperature of 20-50 degrees;

[0032] F, separating the dissolved rare earth solution and slag;

[0033] G. Separation of cerium fluoride and cerium oxyfluoride in the separation process

[0034] By roasting bastnaesite at low temperature and dissolving with low temperature hydrochloric acid, fluorine is used for directional bonding, and the content of cerium in the cerium-less lanthanum-rich rare earth chloride is 6-18% after optimal dissolution. The content of cerium in cerium fluoride and cerium oxyfluoride is not less than 90-95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com