Rich cerium rare earth polishing powder and preparation method thereof

A technology of cerium-rich rare earths and cerium-rich mixed rare earths, which is applied in the direction of polishing compositions containing abrasives, etc., can solve problems such as unstable product quality, difficulty in control, and environmental pollution, and achieve narrow particle size distribution range, small pollution, and high composition uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Get 50g / l lanthanum cerium chloride solution (CeO -2 / TREO=65.7%, La 2 o -3 / TREO=34.2%, Pr 6 o 11 / TREO≤0.1%, Nd 2 o 3 / TREO≤0.1%) 2000ml and 50g / l cerium chloride solution 500ml, preheat at 50℃ for 0.5h. Add ammonium bicarbonate solution preheated at 50°C for 0.5h to pH = 7, stop the dropwise addition, age at 40°C for 2h after the reaction is complete, and filter to obtain lanthanum cerium carbonate and cerium carbonate for use.

[0033] Add 21ml of hydrofluoric acid (40%) to the cerium carbonate after mixing with water, react at 50°C for 0.5h, then age at 50°C for 2h, filter, and pre-calcine at 350°C for 2.5h to obtain cerium fluoride.

[0034] Cerium fluoride was mixed with the prepared lanthanum cerium carbonate, slurried, ball milled for 0.5h, and spray-dried at 150°C. Then it was roasted at a heating rate of 6°C / min, kept at 500°C for 0.5h, and then fired at 900°C for 5h. That is, the cerium-rich rare earth polishing powder is obtained.

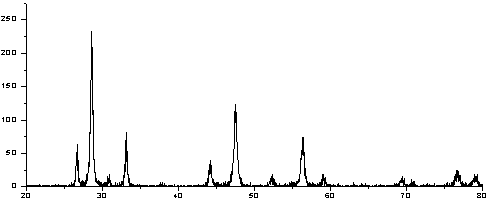

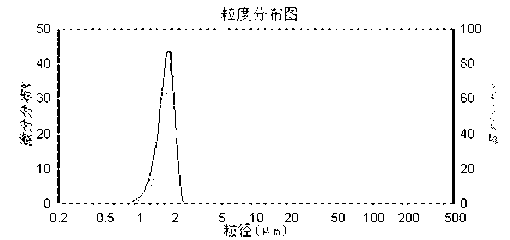

[0035] Its spec...

Embodiment 2

[0038] Get 80g / l lanthanum cerium chloride solution (CeO -2 / TREO=64.3%, La 2 o -3 / TREO=33.2%, Pr 6 o 11 / TREO=2.4%, Nd 2 o 3 / TREO≤0.1%) 1250ml and 100g / l cerium chloride solution 220ml, preheat at 50℃ for 0.5h. Add dropwise 0.9 mol / l ammonium bicarbonate solution preheated at 50°C for 0.5 h, stop at pH=6.5, and stir until the reaction is complete. Aged at 40°C for 2h, filtered to obtain lanthanum cerium carbonate and cerium carbonate.

[0039] Add water to the prepared cerium carbonate, add 18.5ml of HF (40%), react at 40°C, filter, and pre-calcine at 300°C for 2.5h to obtain cerium fluoride.

[0040] Cerium fluoride was mixed with prepared lanthanum cerium carbonate, slurried, ball milled for 0.5h, filtered, and spray-dried at 150°C. Then calcined at a heating rate of 6°C / min and calcined at 950°C for 5h to obtain cerium-rich red rare earth polishing powder.

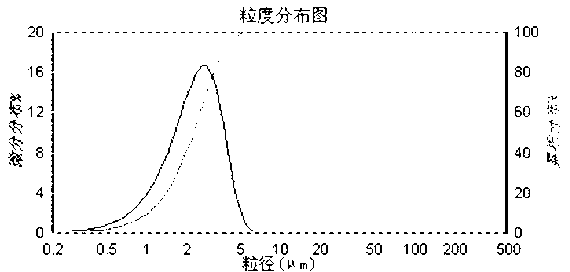

[0041] The measured specific surface area is 5.903m 2 / g,D 50 =2.28μm, D 100 =7.51 μm.

[0042] figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com