Patents

Literature

61results about How to "Small fluctuations in product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High precision rare earth polishing powder and preparation thereof

ActiveCN101475777AEasy to control abrasion resistanceImprove control stabilityOther chemical processesPolishing compositions with abrasivesCerium oxalateGranularity

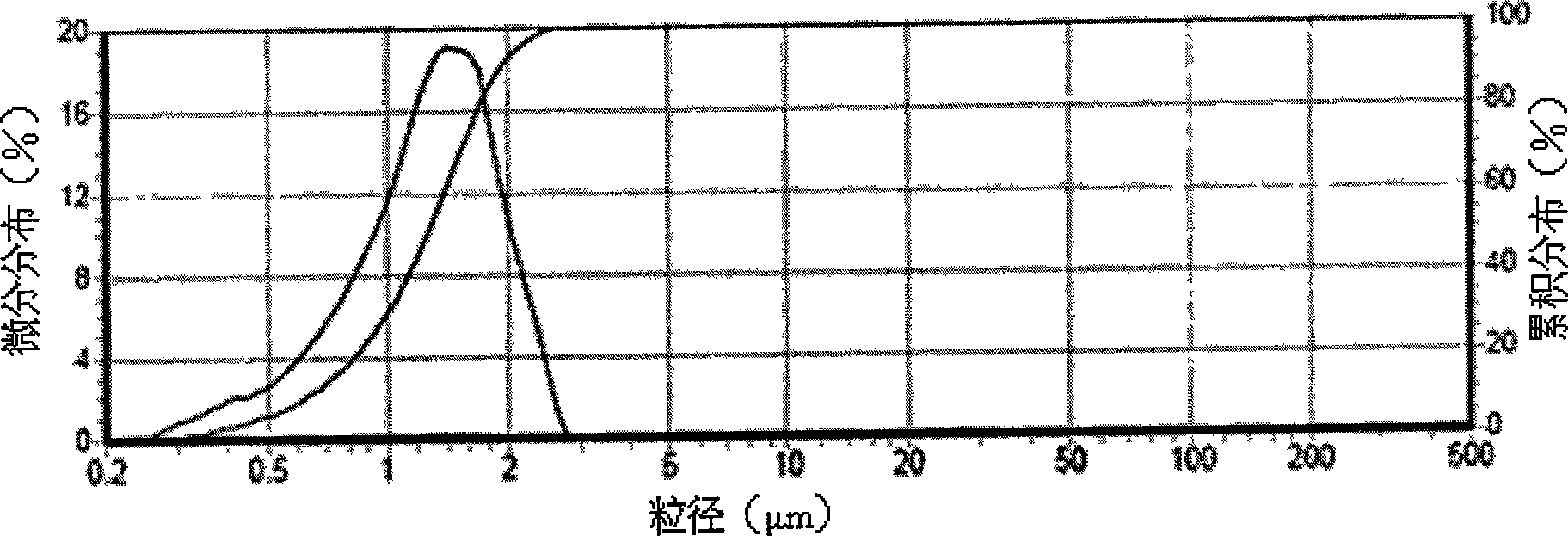

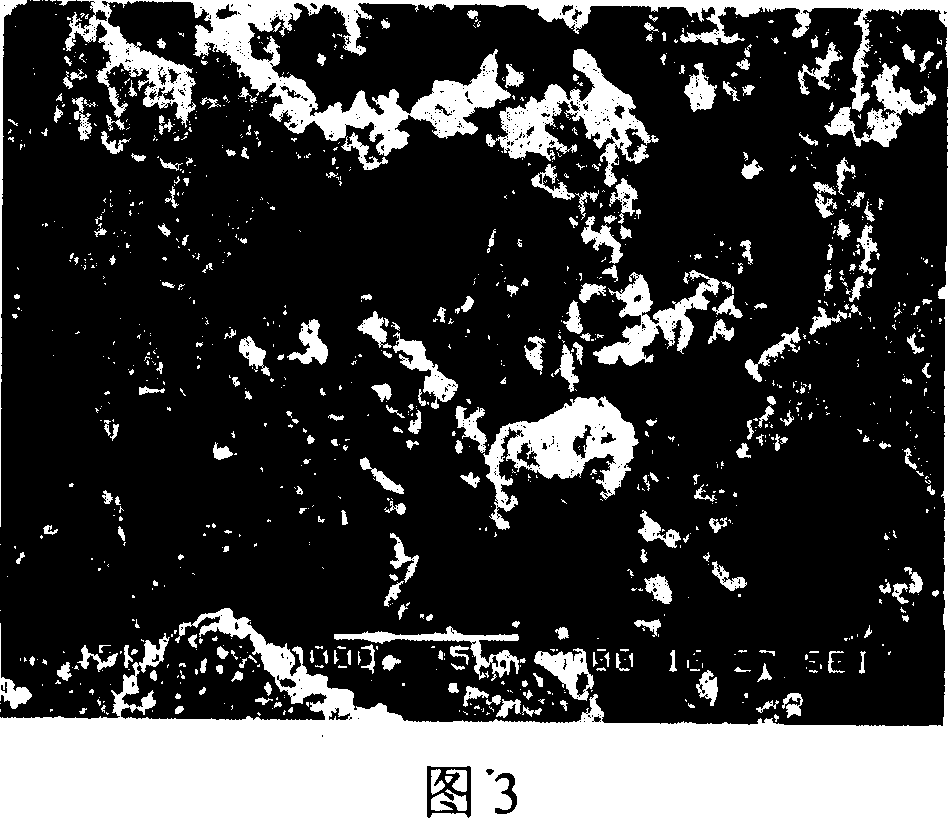

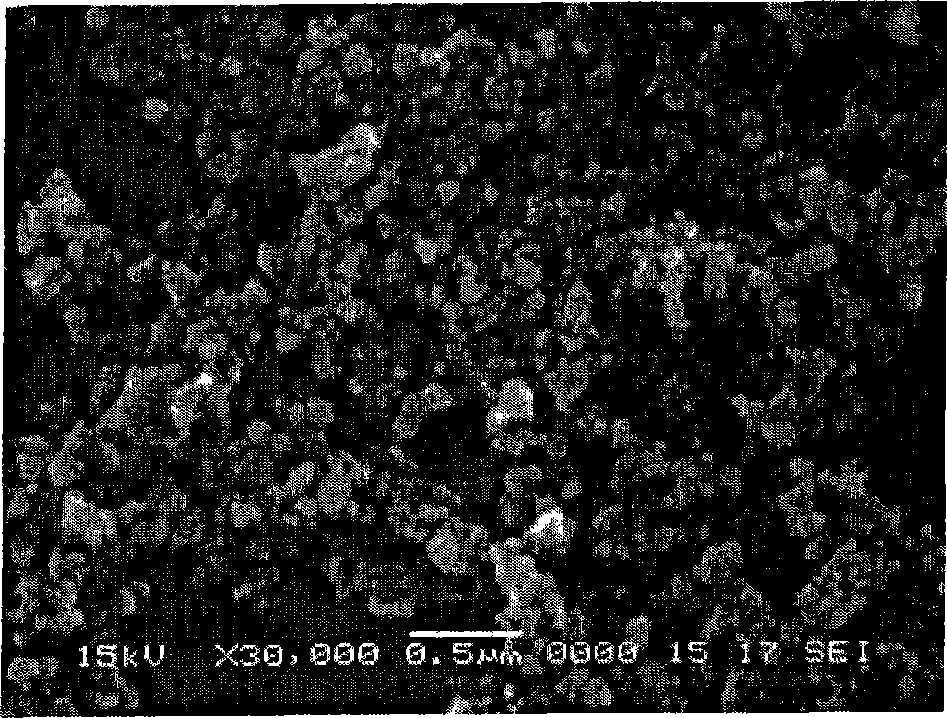

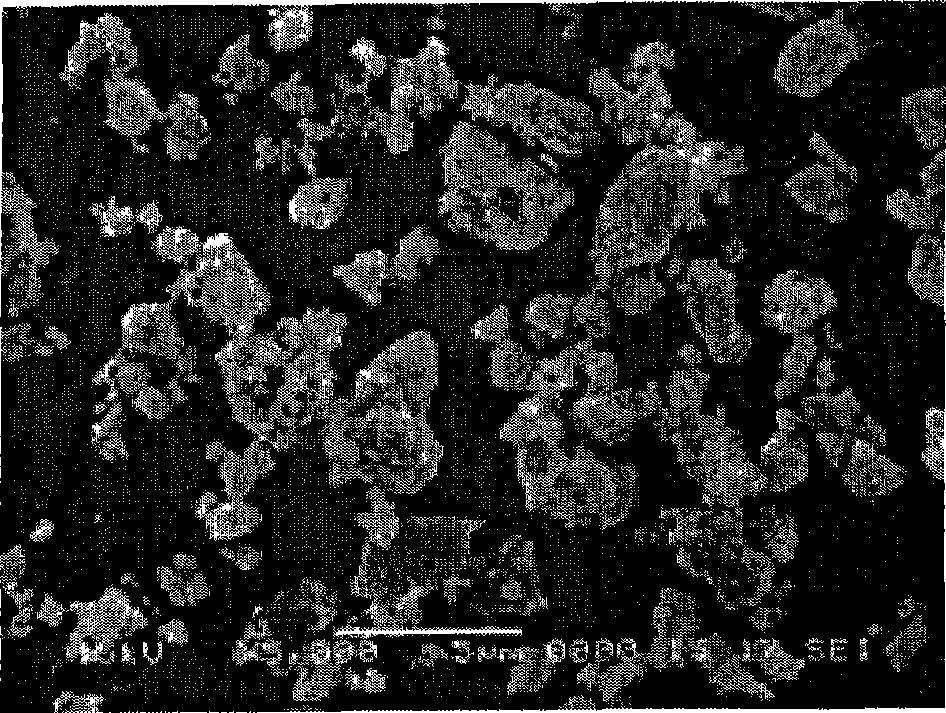

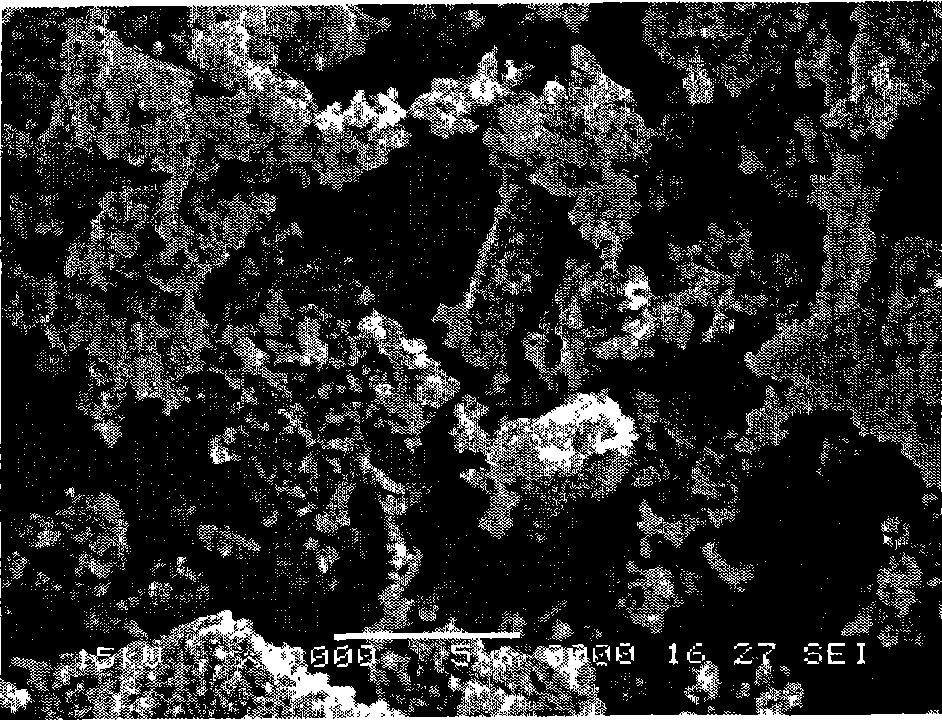

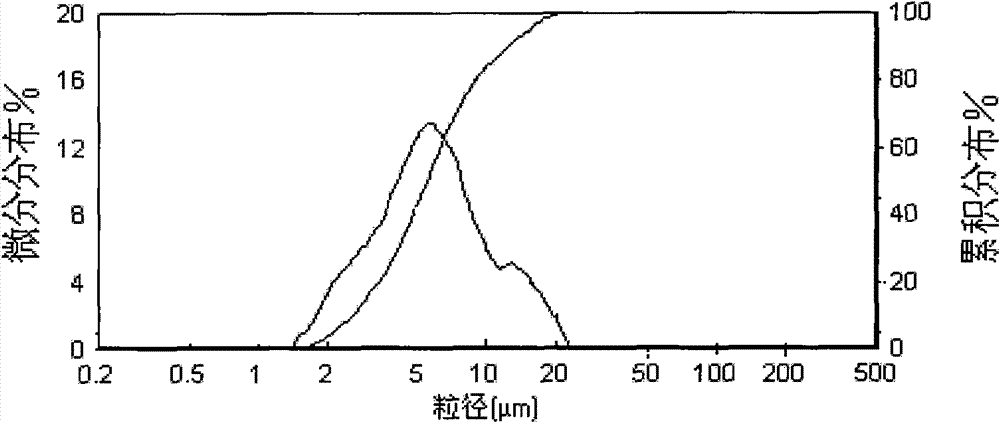

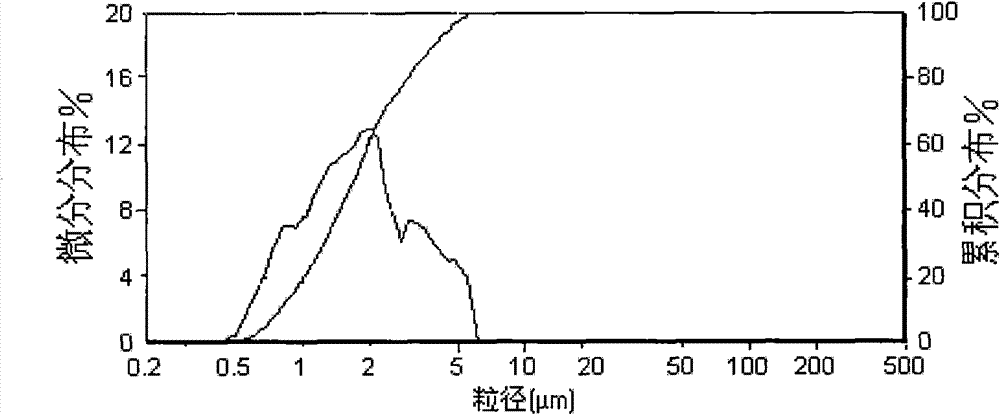

The invention discloses a high-precision rare-earth polishing powder and a method for preparing the same. The high-precision rare-earth polishing powder is characterized in that D50 particle diameter is between 0.5 and 1.80 mu m; the powder also meets the conditions that D10 is more than or equal to 0.5D50, D90 is less than or equal to 2D50, and D100 is less than or equal to 3D50; a cerium lanthanum nitrate or cerium lanthanum chloride solution is added to an ammonium oxalate solution with PH value of between 4.5 and 5.5 to generate monodisperse lanthanum cerium oxalate or lanthanum cerium praseodymium oxalate deposit; and the deposit is used as a crystal seed to prepare the high-precision rare-earth polishing powder. The high-precision rare-earth polishing powder prepared by the method does not need airflow pulverization and precise classification and has the characteristics of small median particle diameter and narrow granularity distribution range; the stability of the wearing resistance and polishing precision is easy to control; and the quality of a product has small fluctuation.

Owner:上海华明高纳稀土新材料有限公司

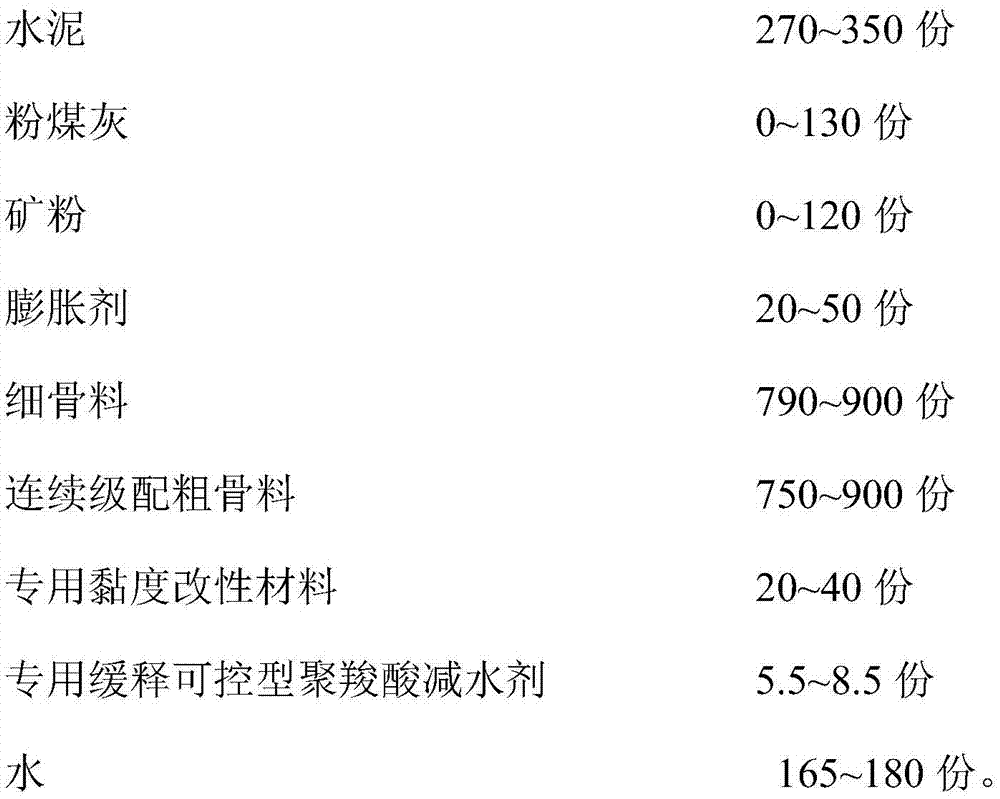

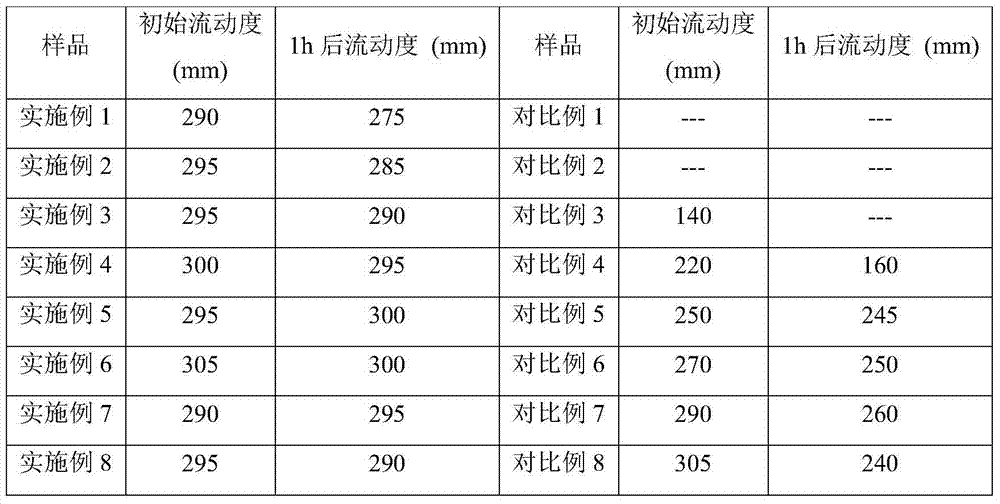

Self-compacting concrete for CRTS III plate-type ballastless track filling layer and preparation method for self-compacting concrete

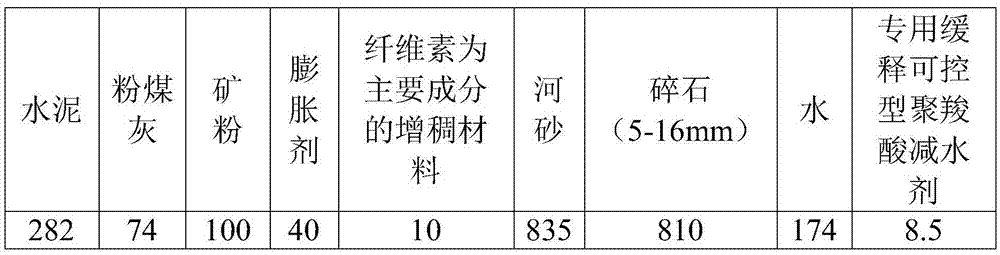

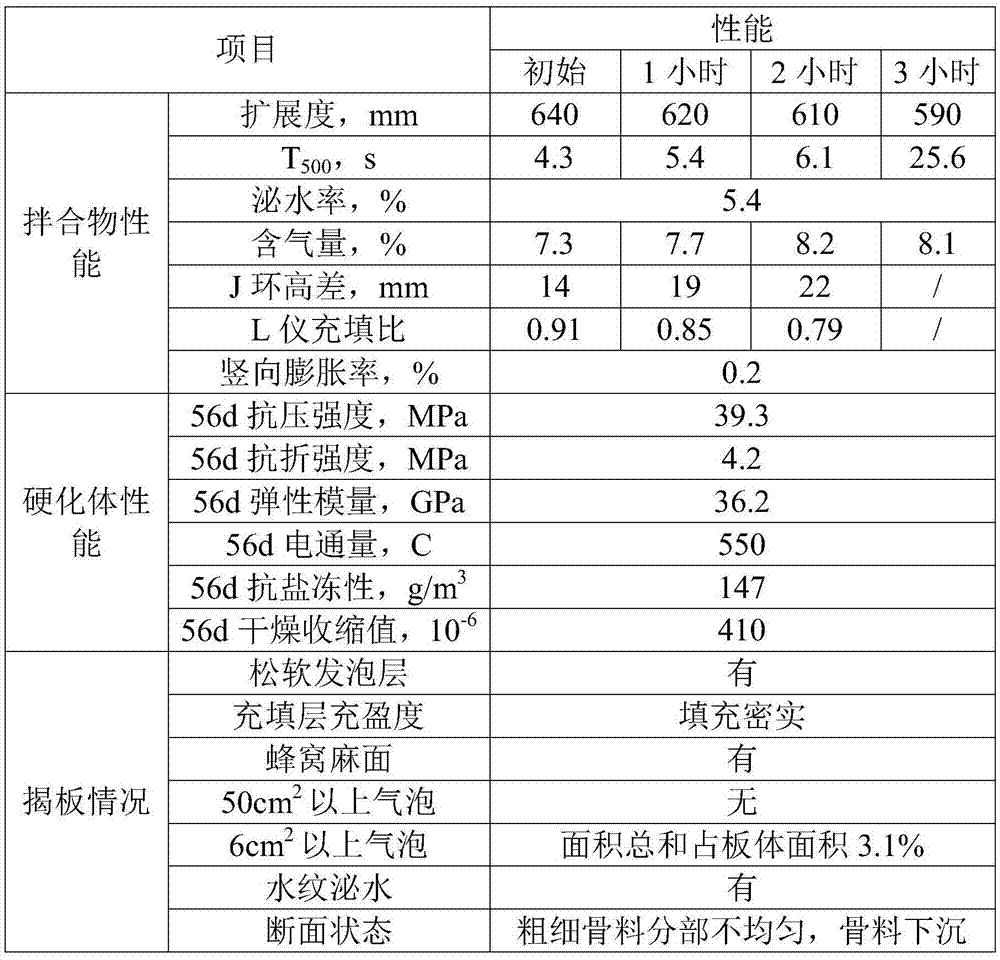

The present invention discloses a self-compacting concrete for CRTS III plate-type ballastless track filling layer. The concrete is prepared from the following raw materials in parts by weight: 270-350 parts of cement, 0-130 parts of coal fly ash, 0-120 parts of mineral powder, 20-50 parts of an expanding agent, 790-900 parts of fine aggregate, 750-900 parts of continuous gradation coarse aggregate, 20-40 parts specific viscosity modified materials, 5.5-8.5 parts of a specific sustained release controllable polycarboxylic acid water reducing agent and 165-180 parts of water. According to the invention, the specific viscosity modified materials and specific sustained release controllable polycarboxylic acid water reducing agent are used in combination to prepare the specific self-compacting concrete for filling layer with good flowability, strong volume stability, low sensitivity for water consumption, small thixotropic time change, low shrinkage and good longevity, thereby reducing theconstruction difficulty of the CRTS III plate-type filling layer and prolonging the sevice life of the ballastless track structure.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Production of high-cerium rare-earth polishing powder

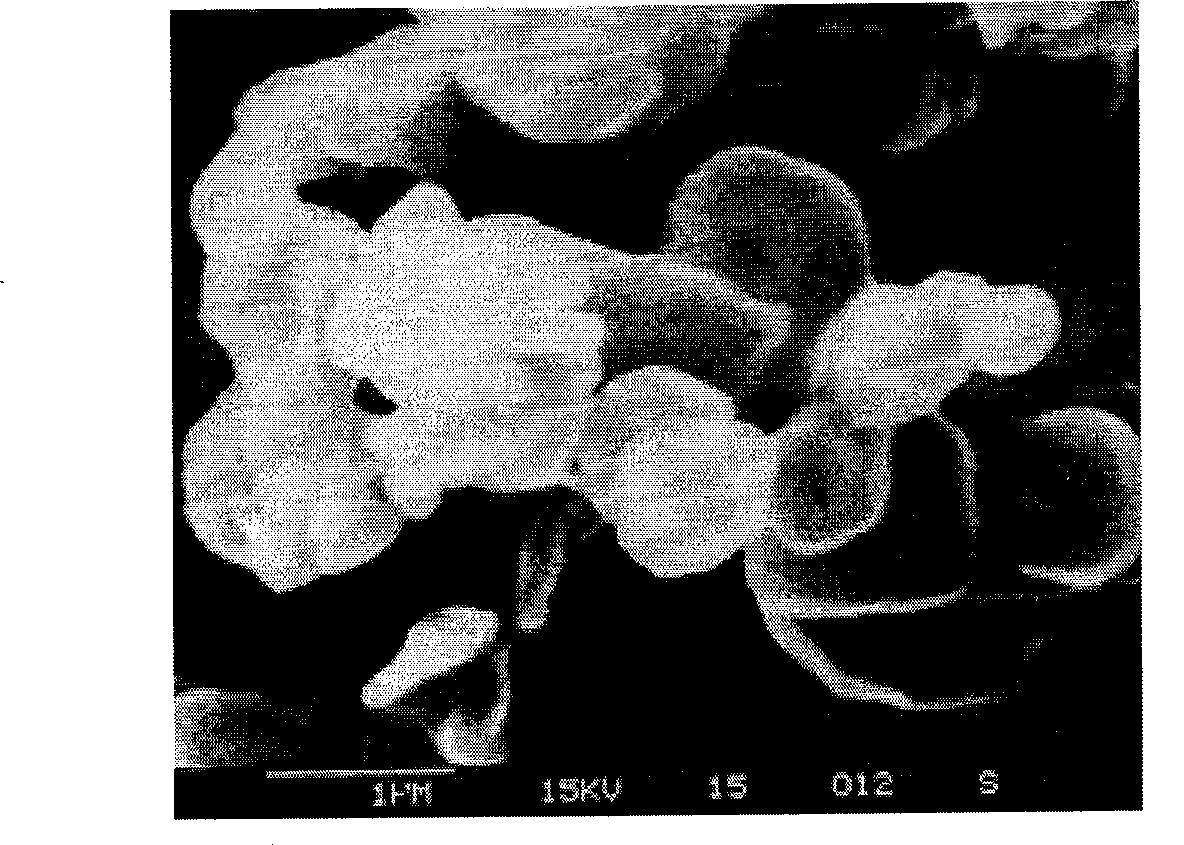

ActiveCN1939990AEasy to control abrasion resistanceImprove control stabilityPolishing compositionsCeriumSingle crystal

Production of cerium-enriched rare-earth polishing powder is carried out by preparing crystal seed, depositing to obtain lanthanum cerium carbonate, fluorating to obtain lanthanum cerium fluorine-carbonate, and calcining to obtain the final product. The grain diameter of single-crystal reaches to 1-2 micro. It's easy to control, has better abrasive resistance and grinding rate.

Owner:上海华明高纳稀土新材料有限公司

Production of high-cerium rare-earth polishing powder

Production of cerium-enriched rare-earth polishing powder is carried out by preparing crystal seed, depositing to obtain lanthanum cerium carbonate, fluorating to obtain lanthanum cerium fluorine-carbonate, and calcining to obtain the final product. The grain diameter of single-crystal reaches to 1-2 micro. It's easy to control, has better abrasive resistance and grinding rate.

Owner:上海华明高纳稀土新材料有限公司

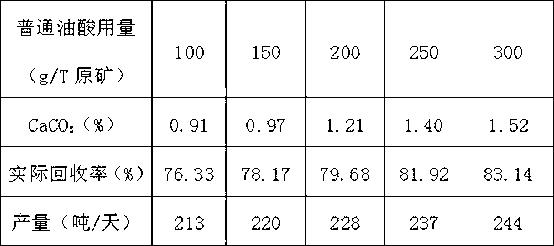

Fluorite mine flotation collecting agent

The invention discloses fluorite mine flotation collecting agent which is formed by mixing of the following raw materials by weight, namely 10-20 parts of oleic acid, 5-10 parts of number 2 oil, and 1-5 parts of kerosene. A preparing method of the agent comprises the steps that the oleic acid, the number 2 oil and kerosene are added into a stirring tank in sequence by the weight parts, and stirring is carried out under normal temperature and normal pressure for 0.5-1 hour until the materials are even. The collecting performance of the collecting agent is obviously better than that of existing collecting agent such as common oleic acid, temperature adaptive range is wide, lowest flotation pulp temperature can reach 5 DEG C, and the mineral dressing index is better than that of common oleic acid under the same temperature condition. The collecting agent is easy and convenient to prepare and use, safe, reliable and low in cost.

Owner:HUNAN XINYUAN MINING

Cigarette supplementary lean combined assembling method

ActiveCN101147623AAchieve leanMeet actual needsCigarette manufactureMaterial analysisSystems researchCombinatorial optimization

The present invention relates to an optimized combination method of cigarette auxiliary materials (including cigarette paper, forming paper, joint-wrapping paper and filter rod). Said method includes the following concrete contents: selecting and using orthogonal design to make experiment design, defining test index, defining test factor, selecting and defining horizontal range, making test scheme, test result treatment-range analysis and variance analysis, auxiliary materials combination regulation and optimization.

Owner:YUNNAN RES INST OF TOBACCO SCI

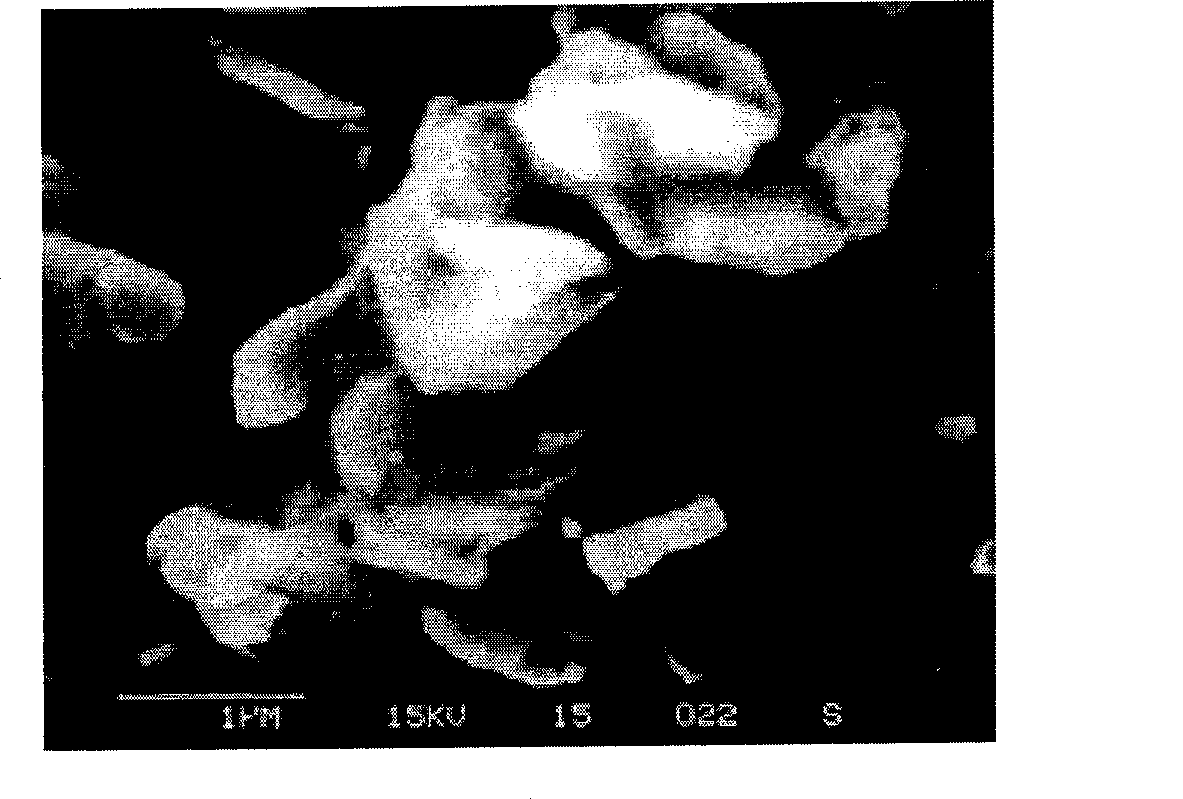

High accuracy aluminum oxide polishing powder and production method thereof

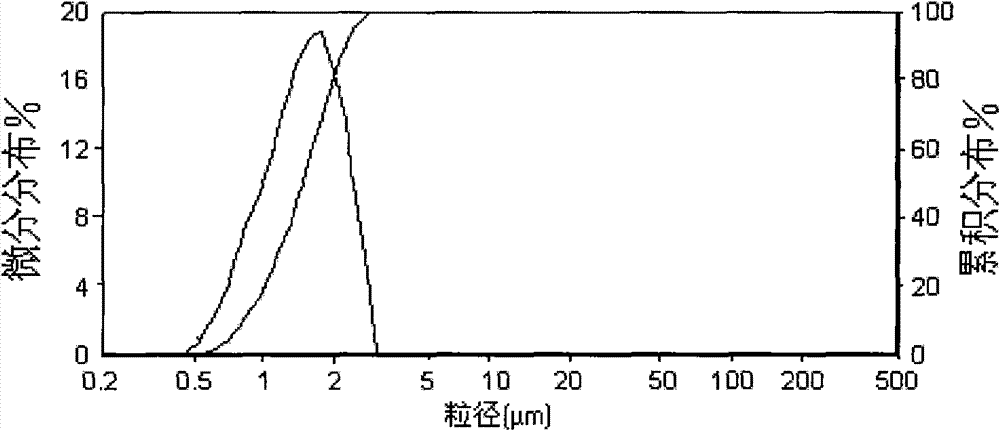

InactiveCN101824279AHigh polishing precisionSmall median diameterPolishing compositions with abrasivesAluminium oxides/hydroxidesLiquid-crystal displayGranularity

The invention discloses an aluminum oxide polishing powder and a production method thereof. The aluminum oxide polishing powder is characterized in that a D50 particle size is smaller than 2.0 microns and satisfies that D10 is no less than 0.5 times of D50, D90 is no more than 2 times of D50 and D100 is no less than 3 times of D50. The preparation method comprises the following steps of pulping raw materials of alpha-aluminum oxide with water, carrying out classification and obtaining a product. The aluminum oxide polishing powder has the advantages of small median particle diameter, narrow granularity distribution range, easy control of the polishing accuracy stability and small fluctuation of the product quality, can be used for accurate polishing processing of electronic product components including glasses for liquid crystal display screens, flat plane displays, optical elements, ultrathin glass substrates and glass magnetic discs and can also be used for preparing aluminum oxide polishing solution for polishing chemical machinery.

Owner:SHANGHAI GONA POWDER TECH

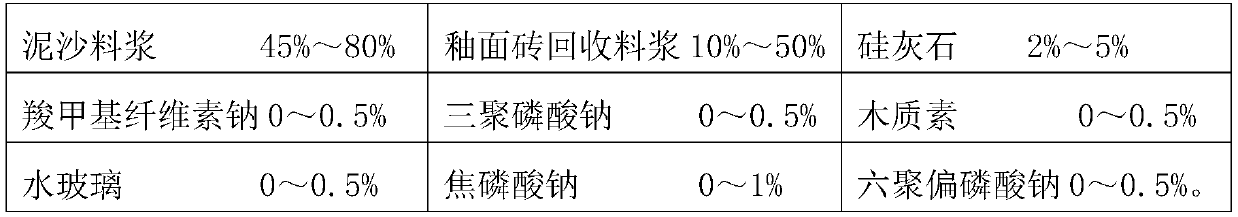

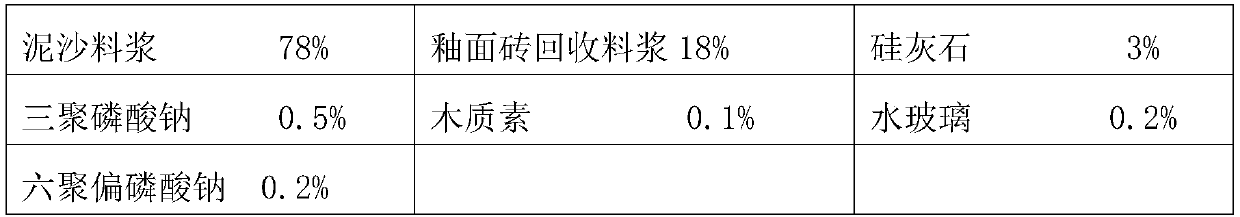

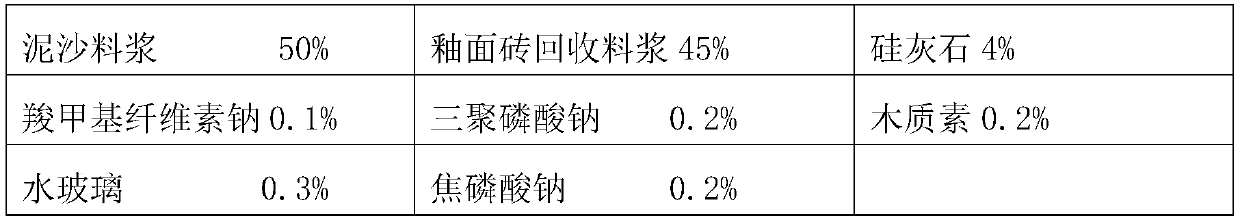

Preparation process of blank-similar type mud cosmetic clay and ceramic tile

The invention relates to a preparation process of blank-similar type mud cosmetic clay and a ceramic tile. The blank-similar type mud cosmetic clay comprises the following components in parts by weight: 45-80% of silt slurry; 10%-50% of glazed tile recycled slurry; 2% ~ 5% of wollastonite; 0-0.5% of sodium carboxymethyl cellulose; 0-0.5% of sodium tripolyphosphate; 0-0.5% of lignin; 0-0.5% of water glass; 0-1% of sodium pyrophosphate and 0-0.5% of sodium hexametaphosphate. The preparation process includes: (1) blank pressing, namely batch homogenizing of mineral raw materials; (2) blank body drying; (3) drying temperature of 100-280 DEG C, and drying time of 90-120 minutes; (4) applying of the blank-similar type mud cosmetic clay; (5) pattern decoration; (6) drenching of transparent glaze,the specific gravity is controlled to be 1.75-1.80, and the Engler Viscosity is controlled to be 30-40s; (7) firing, temperature is 1170-1190DEG C, and the time is 80-90 minutes; and (8) polishing and edging.

Owner:JIANGXI HEMEI CERAMICS +2

Process for producing soy protein for injection

ActiveCN101731442AGood water solubilityExcellent gel forming abilityProtein composition from vegetable seedsVegetable proteins working-upProtein solutionCompound (substance)

The invention provides a process for producing soy protein for injection. Degreased low-temperature soy bean meal is used as a raw material, and protein solution is obtained through the treatment of multiple chemical processes. The process comprises the following main production steps: extracting, acid precipitation, alkaline treatment, neutralization, sterilization and flash evaporation, pressure spray and drying. The process has the advantages of lower requirement for production conditions, simple and feasible operation, lower product quality fluctuation, broad market prospect after industrialization and the like.

Owner:山东万得福生物科技有限公司

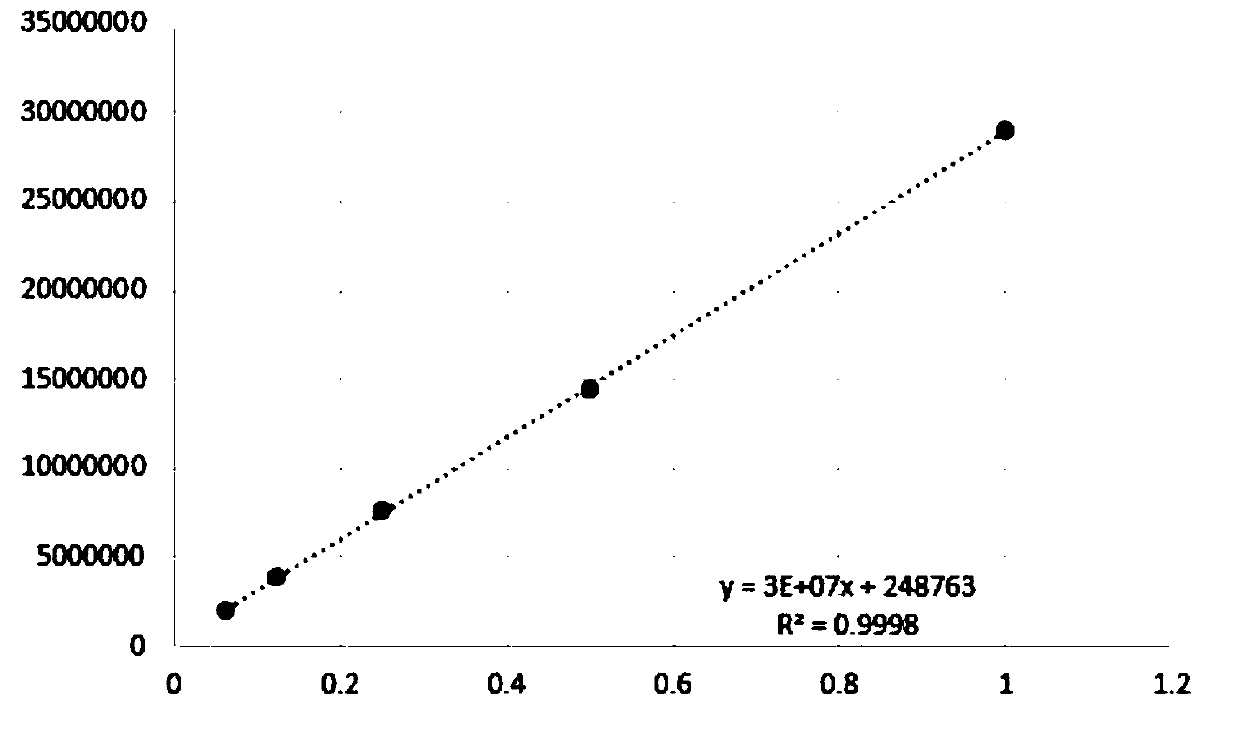

Epimedium compound product quality control and fingerprint spectrum detection method

ActiveCN110501445AGuaranteed stabilityGuaranteed accuracyComponent separationManufacturing computing systemsEpimediumMedicine

The invention discloses an epimedium compound product quality control and fingerprint spectrum detection method. According to the method, high performance liquid chromatography is used; the quality control of a product containing traditional Chinese medicine components, especially the stable control of the quality of a product containing a large quantity of non-traditional Chinese medicine components can be effectively realized; with step-by-step quality control realized, the quality fluctuation of the product can be reduced, and quality stability can be guaranteed. The method is simple and convenient and does not need additional instruments, standard substances and the like. With the method adopted, cost can be saved, and actual production can be benefitted.

Owner:甘肃琛蓝生物科技有限公司 +1

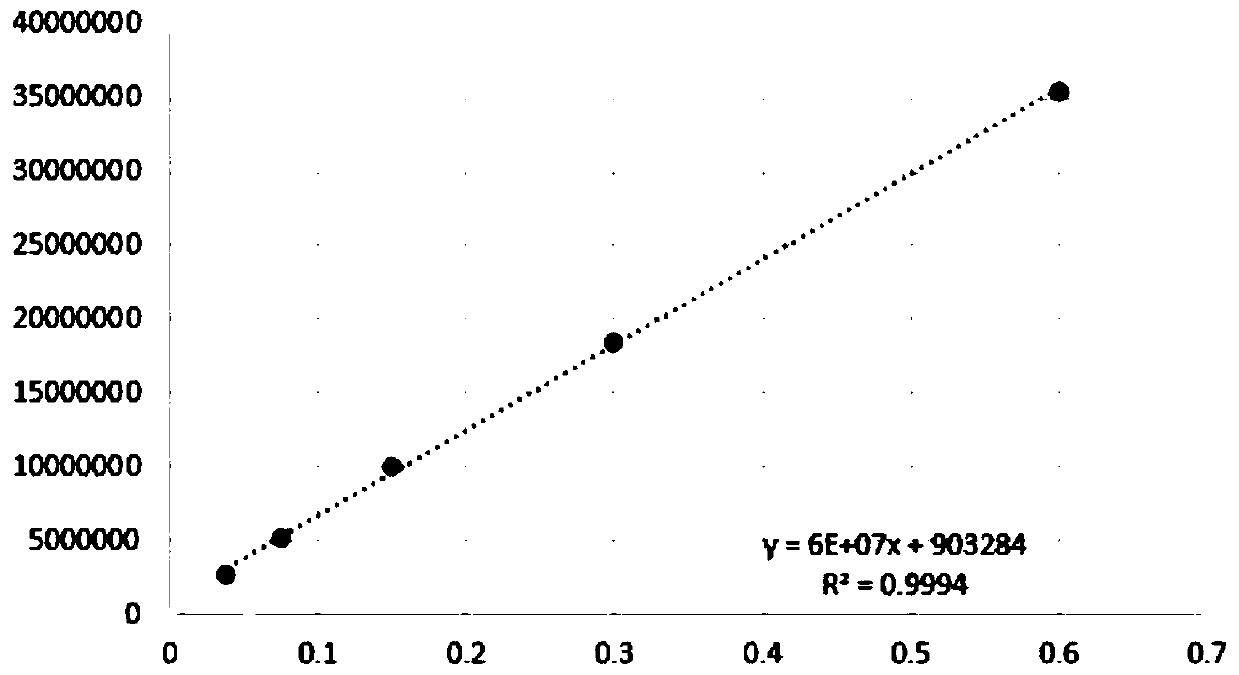

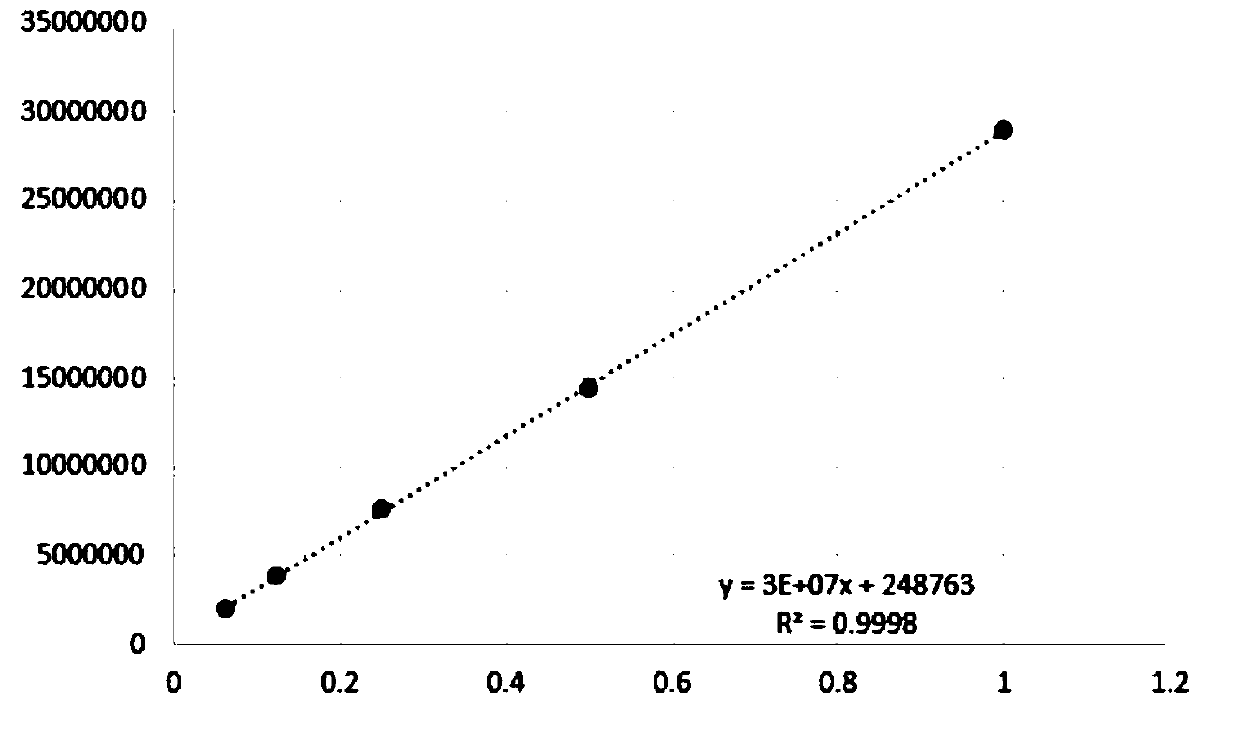

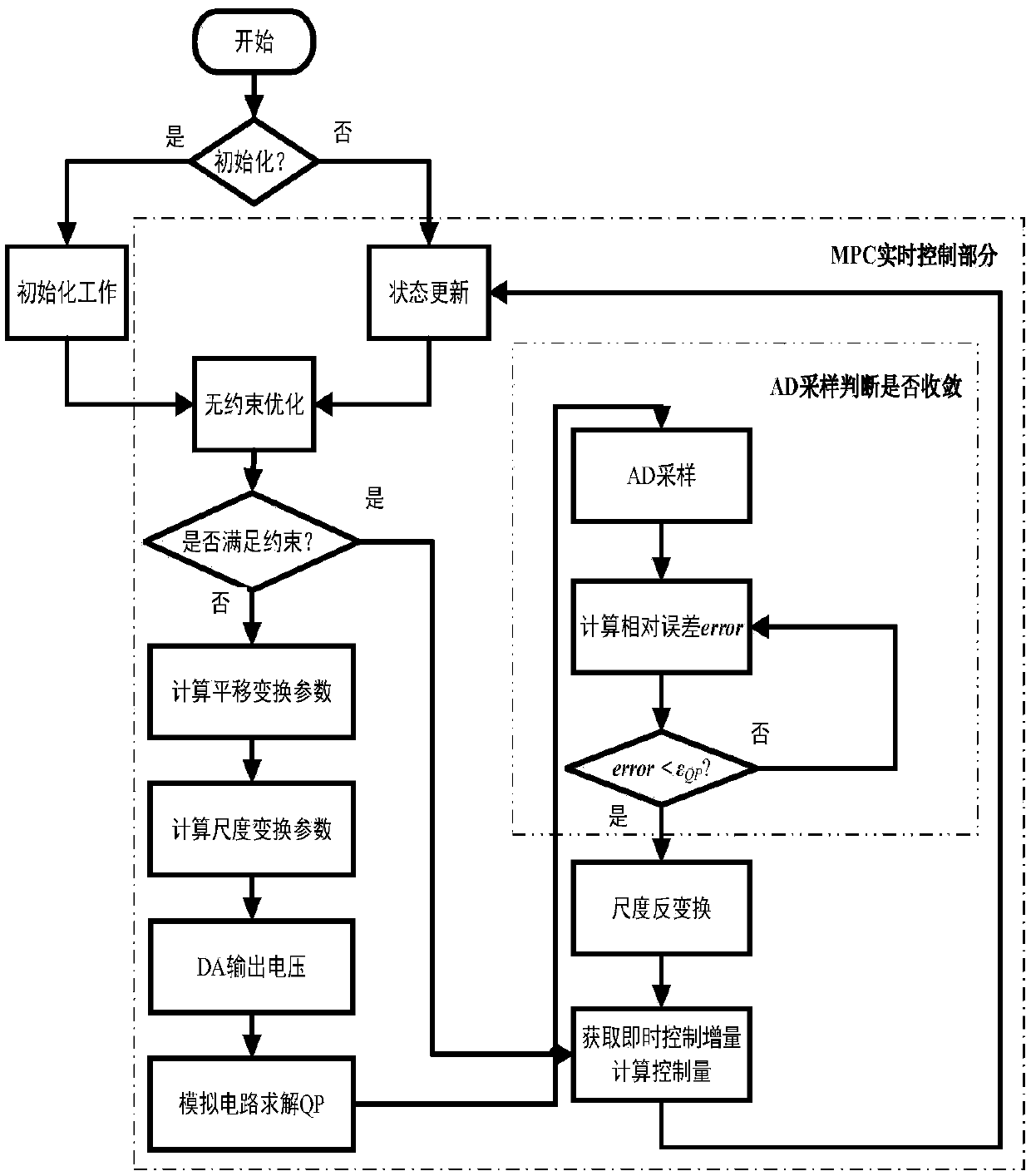

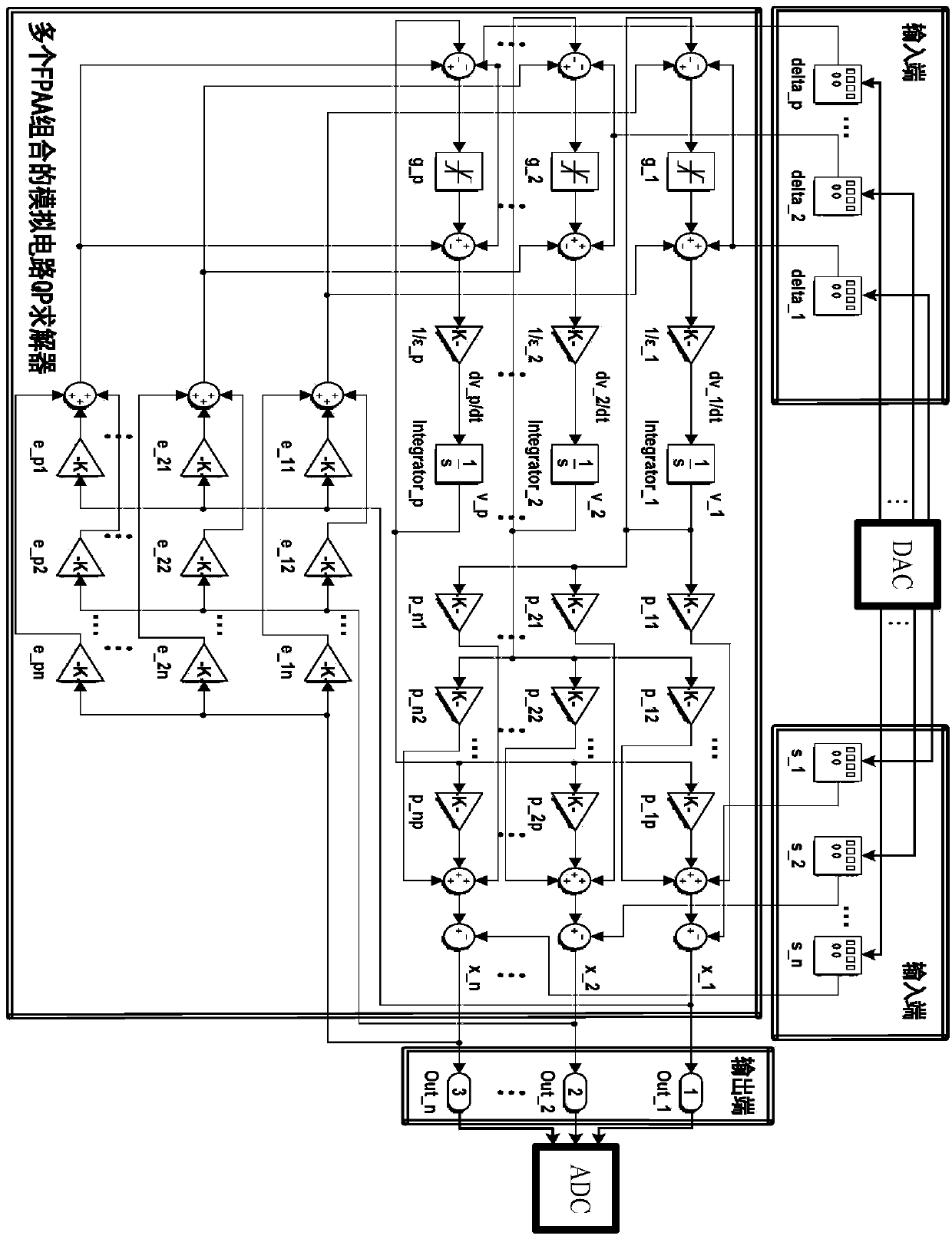

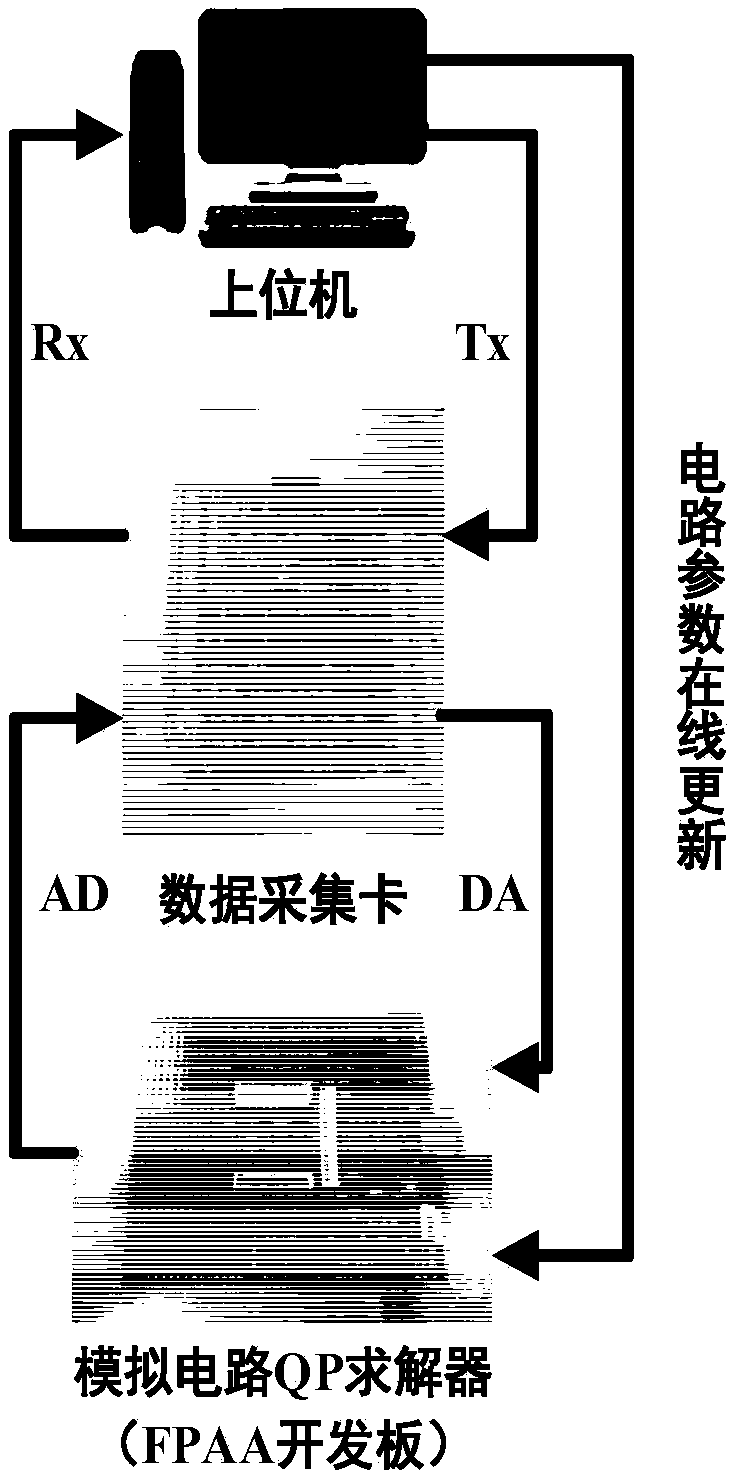

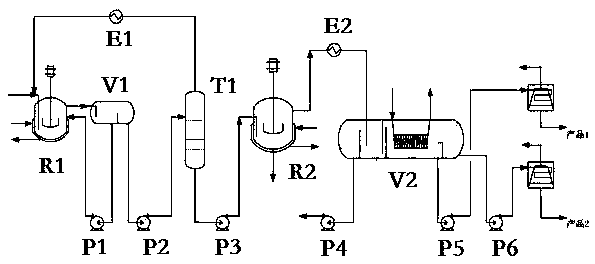

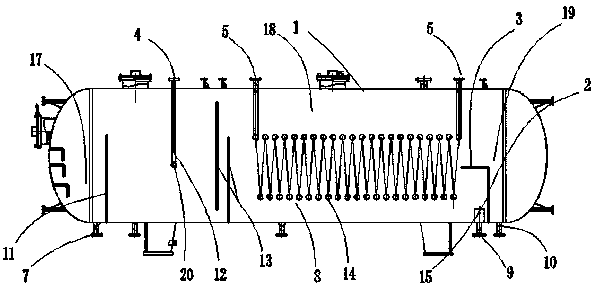

Rapid model prediction control method for air separation unit based on FPAA simulation neural network

ActiveCN108873701AIncrease control frequencyAvoid disadvantagesAdaptive controlAlgorithmUnconstrained optimization

The invention discloses a rapid model prediction control method for an air separation unit based on an FPAA simulation neural network. The method comprises two parts: offline calculation and online calculation. The offline calculation comprises the calculation of an MPC control parameter and the construction of an analog circuit QP solver; The online calculation comprises state updating, unconstrained optimization, calculation of translation transformation and scale transformation parameters, and QP solving of the analog circuit. The method employs a continuous neural network for solving a QPproblem, and has the natural parallelism. The method solves a problem that the analog circuit achieves the signal restriction of a continuous neural network through the translation transformation andscale transformation. On the basis, the circuit employs an FPAA for designing the analog circuit, thereby achieving the rapid solving of the QP in the MPC. Compared with an existing technology, the method effectively irons out the defects of a discrete neural network, and solves the problems in a better way that a conventional numerical method is low in MPC solving speed and is poorer in real-timeperformance.

Owner:ZHEJIANG UNIV

Method for simultaneously preparing polytetramethylene ether glycol with various specifications

The invention discloses a method for simultaneously preparing polytetramethylene ether glycol with various specifications. The method comprises the following steps: 1) adding tetrahydrofuran, then adding a heteropolyacid catalyst, and carrying out stirring and mixing for a reaction for 3-5 hours; 2) stopping stirring, carrying out standing to obtain a lower-layer catalyst phase and an upper-layerorganic phase, and replacing the upper-layer organic phase by tetrahydrofuran with a water content of less than 0.1%, so that the specific gravity of the heteropolyacid catalyst in the organic phase is adjusted to 1.8-2.0 g / cm<3>; 3) continuously introducing tetrahydrofuran, and after the reaction kettle is full of the polymerization liquid in, feeding the polymerization liquid into a sedimentation separation tank; 4) carrying out sedimentation for 1-3 hours in the sedimentation separation tank, and inputting the reaction liquid subjected to sedimentation separation into a tetrahydrofuran distillation tower; 5) adding an extracting agent and the reaction liquid subjected to sedimentation separation into a tetrahydrofuran distillation tower for carrying out mixing extraction; and 6) conveying the mixed liquid subjected to extraction to a polymer separator for separation. According to the preparation method disclosed by the invention, polytetramethylene ether glycol with different specifications can be prepared at a same time.

Owner:杭州三隆新材料有限公司

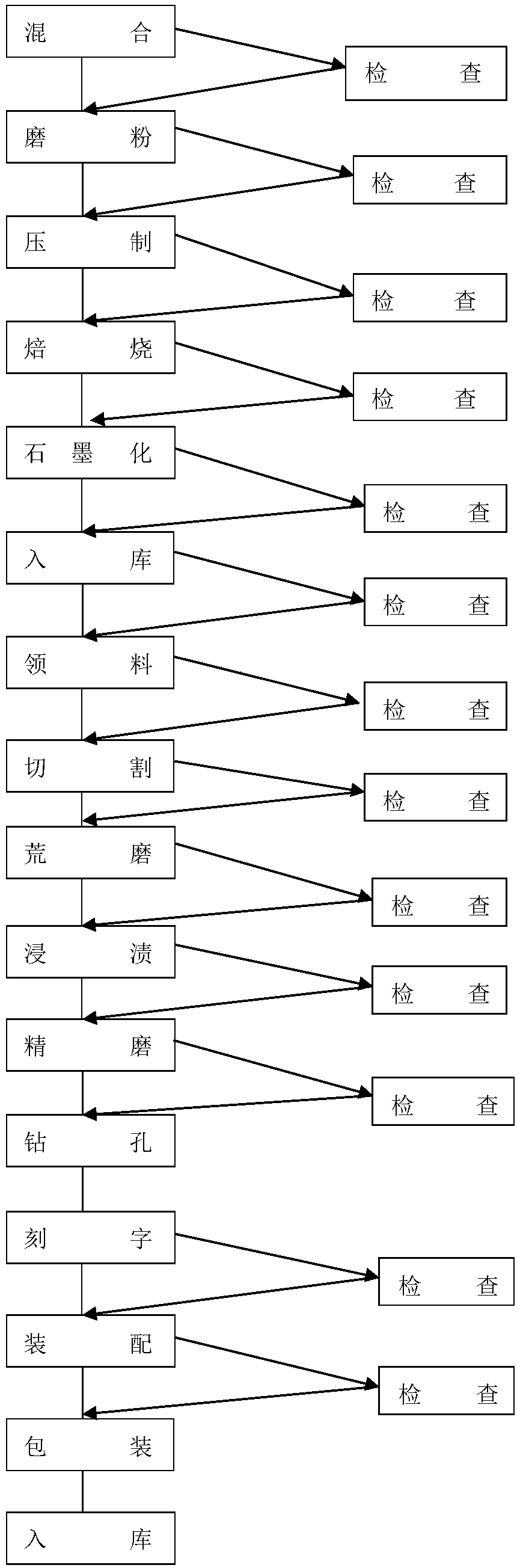

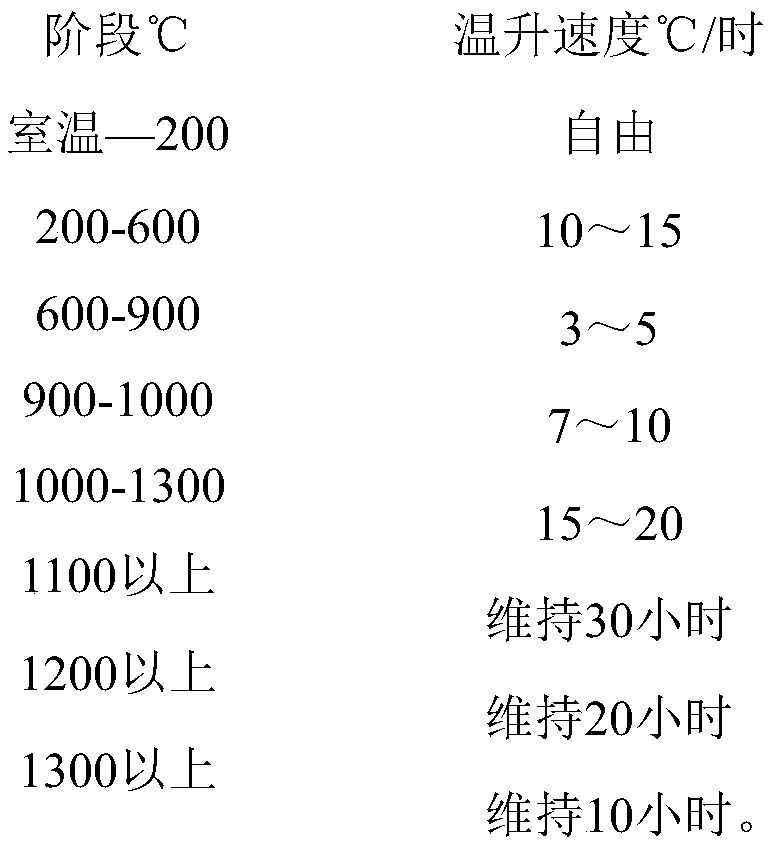

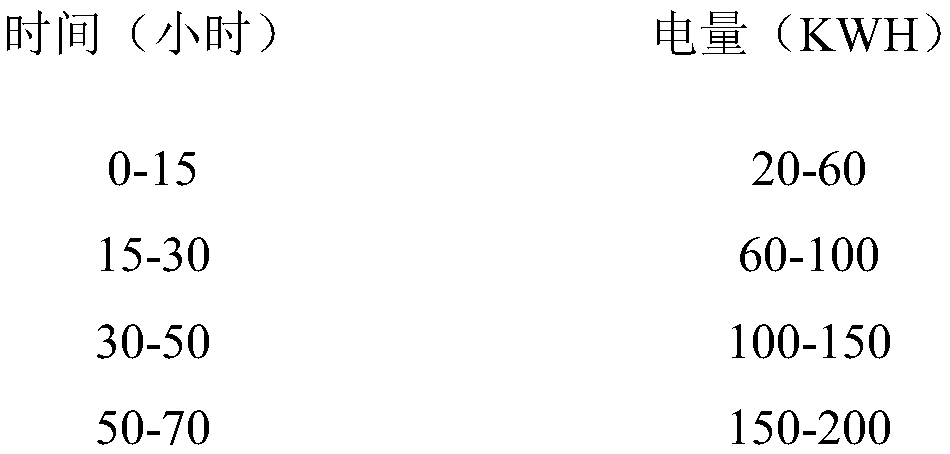

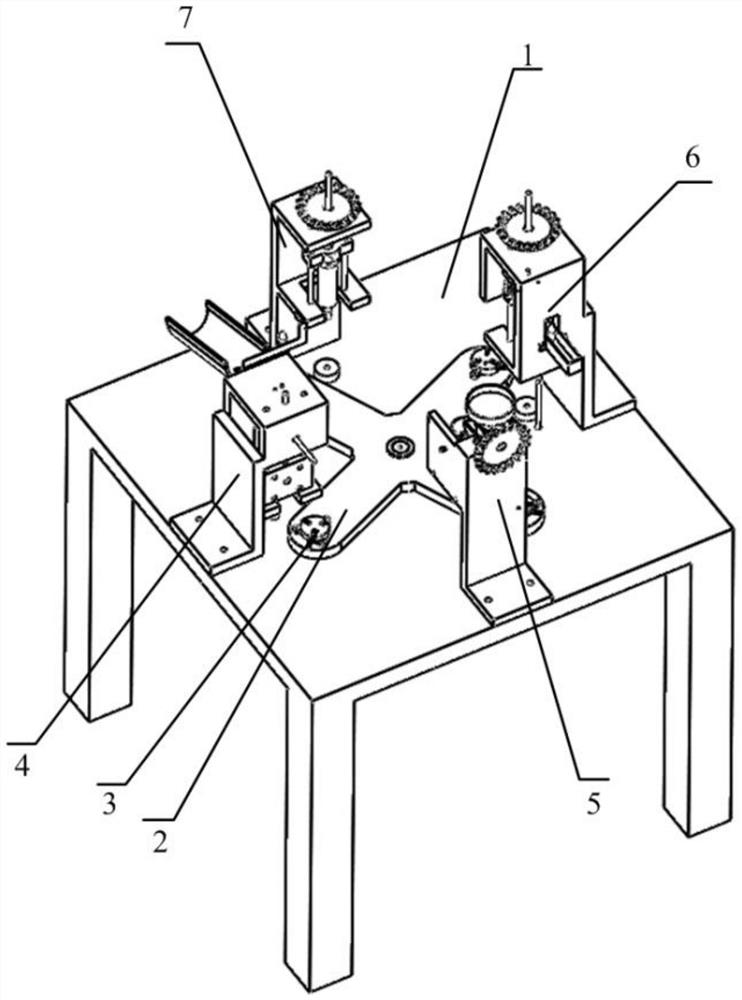

A brush for railway electric machine and its preparation method are provided

ActiveCN109004482AGuaranteed stabilitySolve the problem of brushing off braidsRotary current collectorBrushes manufacturePorosityWeight gaining

The invention discloses a railway electric motor brush and a preparation method thereof, belonging to the technical field of brush processing. The brush is prepared by two stages of production. One stage of production is prepared by heating and mixing carbon black, modified pitch and coal tar, roasting, and grinding to obtain a stage product after roasting is completed. Two-stage production is bymixing the first-stage product, carbon black, modified pitch and sulfur by heating, rolling, grinding, pressing, roasting, graphitizing, impregnating, finishing grinding, drilling and assembling to produce brushes. The invention also provides a preparation method of the electric brush. The performance uniformity of the electric brush is improved from 60% to 98%; The pull-out tension of the brush product can be increased by 2 to 3 times, up to 750kgf, the weight gain rate of the product is obviously increased, the weight gain rate is as high as 12%, the porosity is significantly reduced, and the porosity is up to 1%. The brush can meet the needs of the market. The brush is suitable for railway electric machines.

Owner:美尔森哈碳电碳(哈尔滨)有限公司

Zirconite tailing and coal gangue ceramic grinding ball and preparation method thereof

ActiveCN112374865ARealize resource utilizationReduce manufacturing costCeramic materials productionClaywaresCalciteDolomite

A disclosed zirconite tailing and coal gangue ceramic grinding ball is prepared from the following components in percentage by mass: 40-80 percent of zirconite tailings, 5-30 percent of coal gangue, 5-20 percent of aluminum oxide, 2-10 percent of feldspar, 1-5 percent of dolomite, 1-5 percent of talc, 1-5 percent of calcite, 1-5 percent of barium carbonate and 1-10 percent of quartz. The inventionfurther discloses a preparation method of the zirconite tailing and coal gangue ceramic grinding ball. The ceramic grinding ball prepared by taking the zirconite tailings and the coal gangue as mainraw materials is suitable for the related fields of mine metal mineral grinding, white mineral grinding, petroleum fracturing propping agents and the like, solid waste resource utilization is realized, and the production cost is greatly reduced.

Owner:江苏金石研磨有限公司

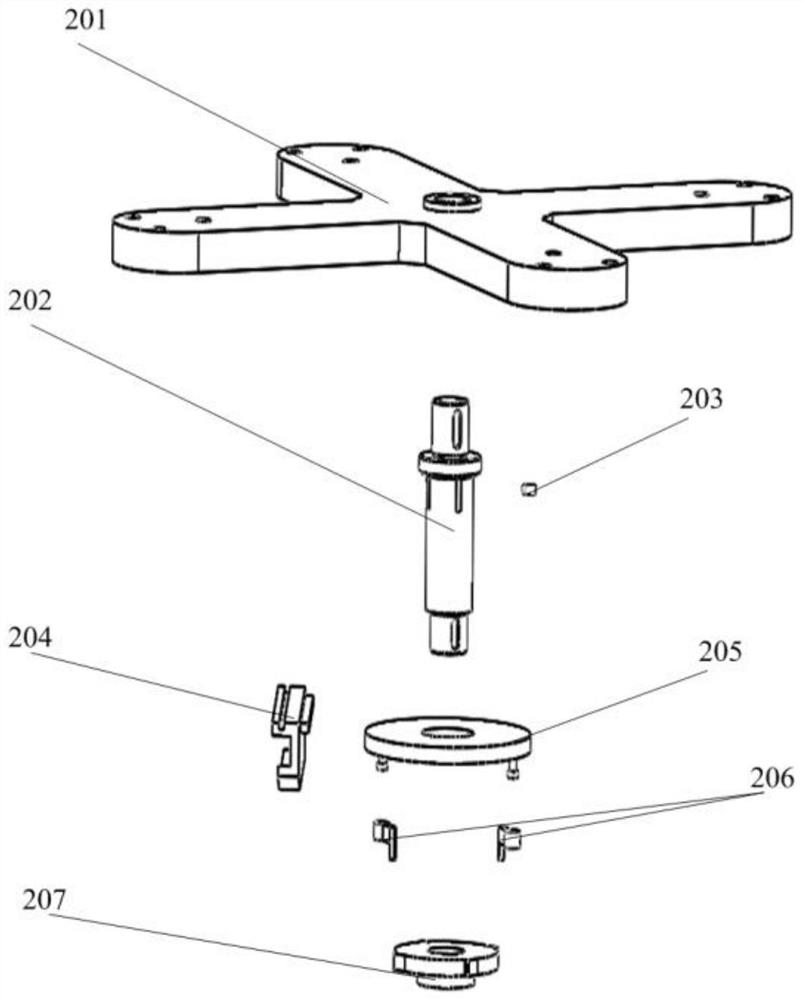

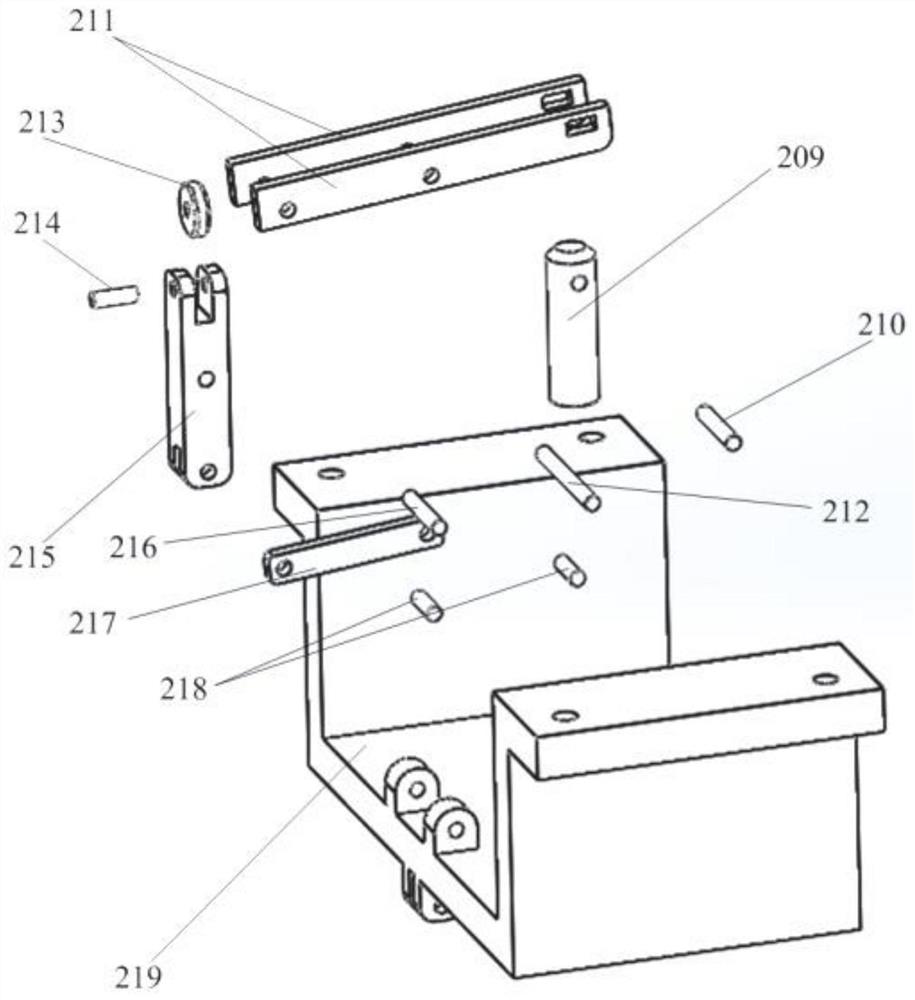

Small-caliber gun bullet small-batch automatic assembling device and control method thereof

PendingCN112577374ASimple structureMeet the needs of high consumptionAmmunitionMan machineEngineering

The invention relates to a small-caliber gun bullet small-batch automatic assembling device which comprises a workbench, a rotary table and multiple bullet shell grabbing discs, wherein the rotary table is rotationally connected with the workbench, and the multiple bullet shell grabbing discs are sequentially fixed to the rotary table. The small-caliber gun bullet small-batch automatic assemblingdevice further comprises a feeding mechanism, a charging mechanism, a bullet pressing mechanism and an opening tightening mechanism, wherein the feeding mechanism, the charging mechanism, the bullet pressing mechanism and the opening tightening mechanism are fixed to the workbench and sequentially and fixedly connected in the circumferential direction of the workbench. According to the small-caliber gun bullet small-batch automatic assembling device, the motions of all stations in the gun bullet assembling process can be accomplished in sequence. Rotary assembly is adopted by the small-calibergun bullet small-batch automatic assembling device, compared with direct-feed assembly, the rotary assembly is higher in efficiency and smaller in the occupied area, and the rotary assembly is suitable for indoor application. According to gun bullets with different calibers, related parts are modularly designed so that an assembling system can be quickly adjusted to assemble the gun bullets withdifferent specifications. The different gun bullets can be rapidly and efficiently assembled by the device in a small-batch mode, man-machine separation and automatic assembly are achieved, and the safety, the reliability and the economy of the assembling process are effectively improved.

Owner:JIANGSU SMARTWALK INTELLIGENCE TECH CO LTD

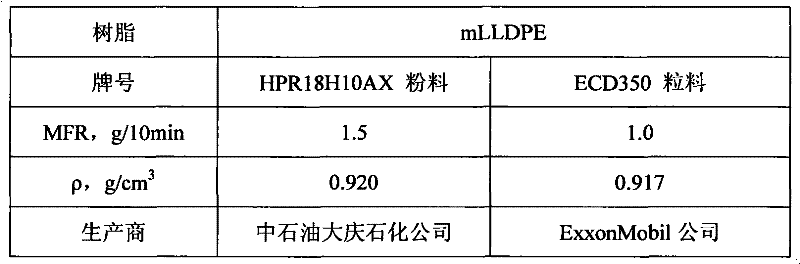

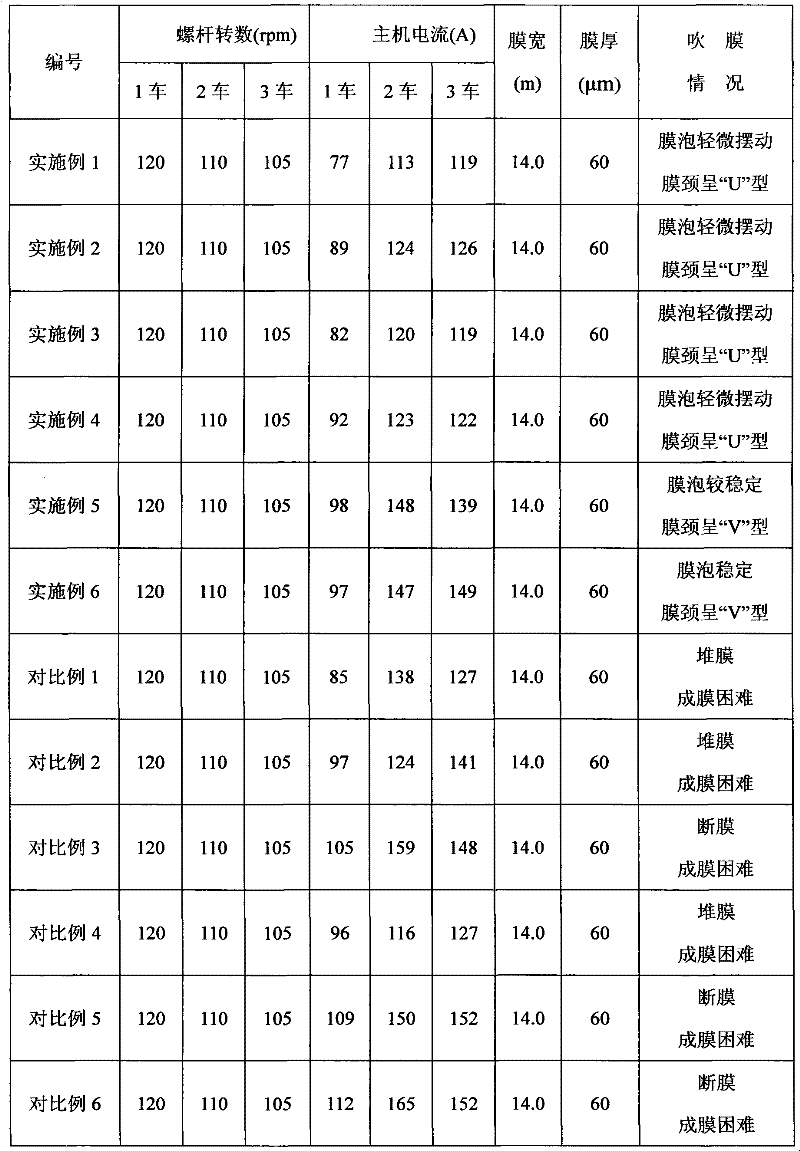

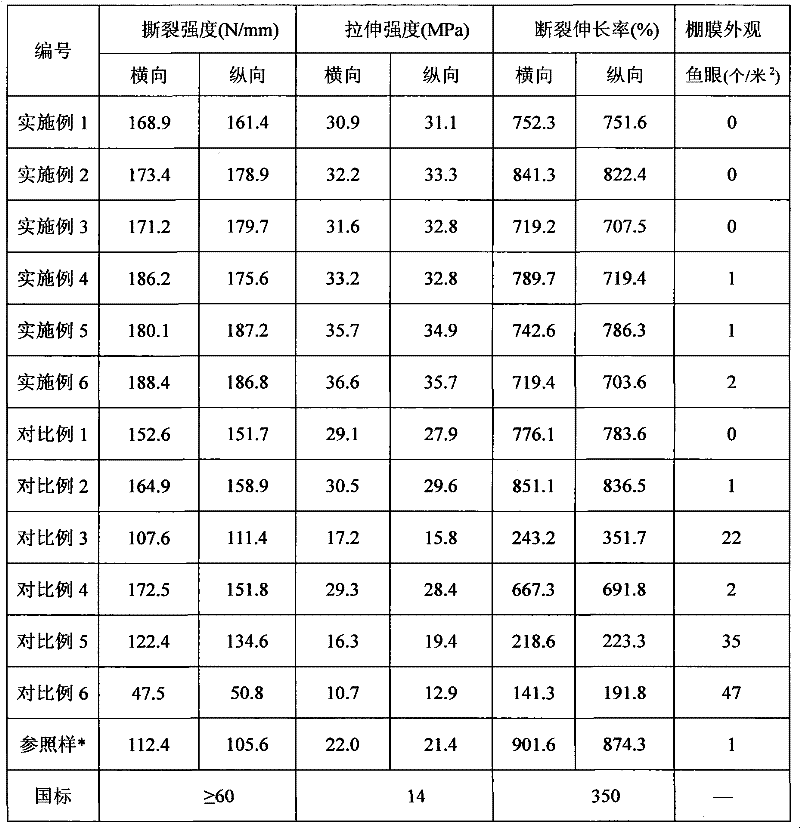

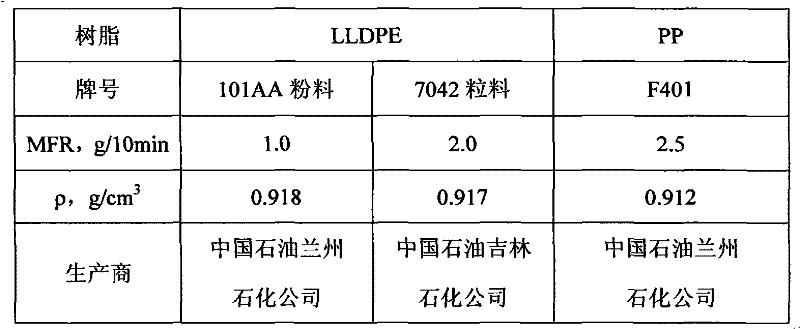

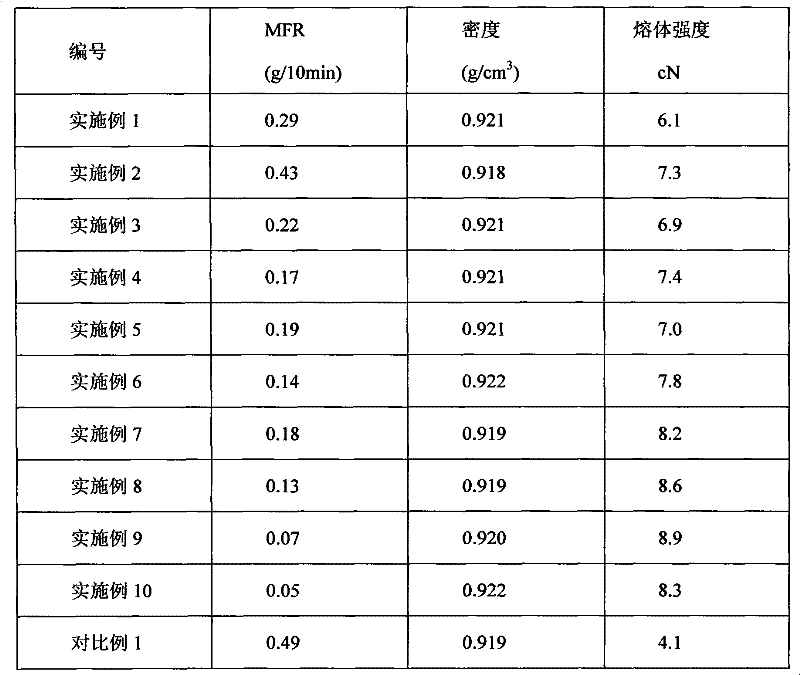

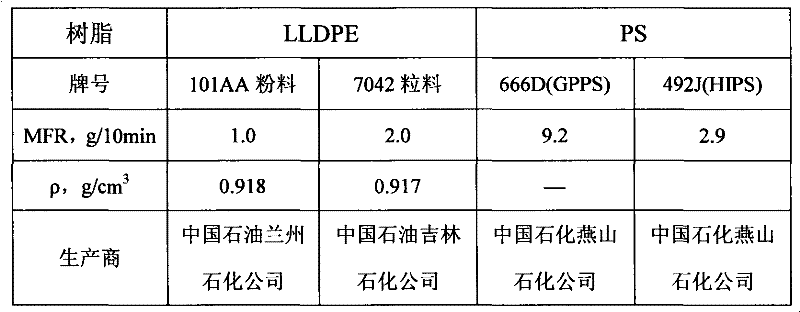

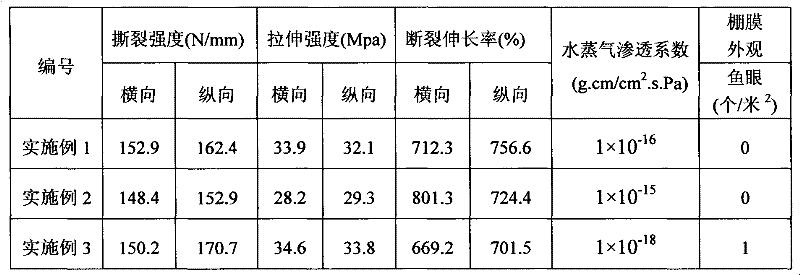

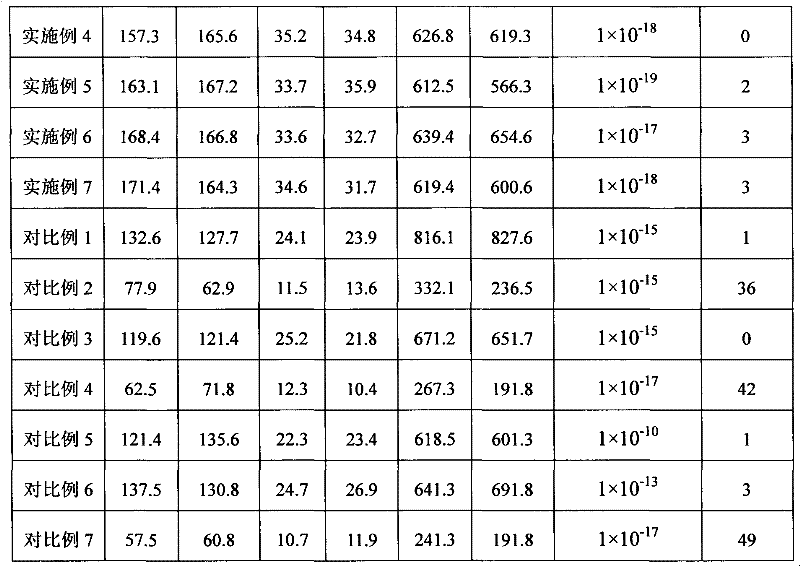

Super-wide-breadth metallocene polyethylene greenhouse film resin composition and preparation method thereof

The invention discloses a metallocene polyethylene greenhouse film resin composition, which comprises the following components based on metallocene linear low-density polyethylene (mLLDPE) being 100% by weight: 1) mLLDPE, wherein the flow rate of mLLDPE melt is 0.5-10 g / 10 minutes; 2) 0.11-0.37% of compound cross-linking agent composed of 1,1-dimethylethyl-hydrogen peroxide and tert-butyl peroxyacetate; and 3) 0.011-0.027% of dibenzoyl peroxide. The strength of the greenhouse film resin composition melt is increased by more than 2 times as compared with that of mLLDPE, and high-strength little-fisheye super-wide-breadth greenhouse film (breadth not less than 14m and thickness not less than 60 mu m) can be prepared by blowing the greenhouse film resin composition without adding any other substances. The invention further discloses a preparation method of the composition.

Owner:PETROCHINA CO LTD

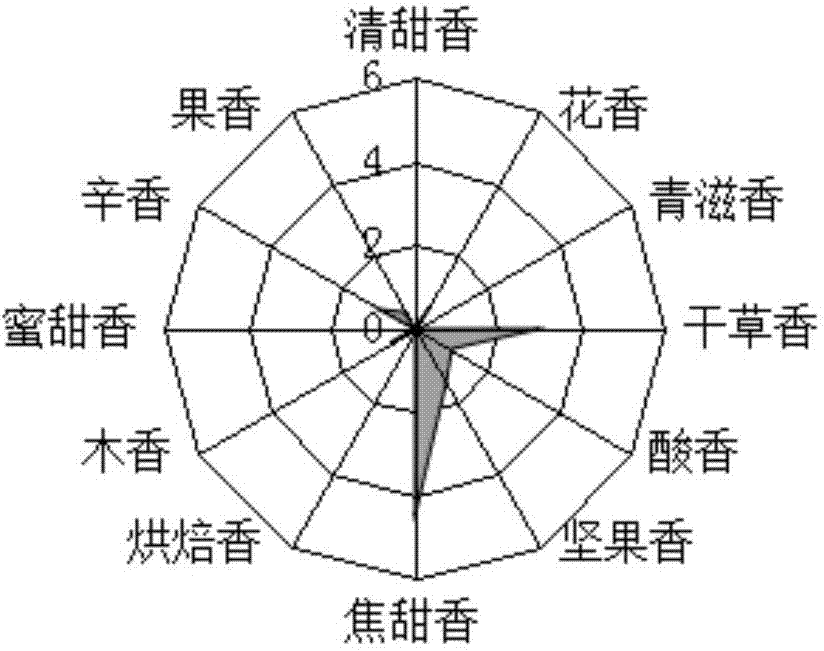

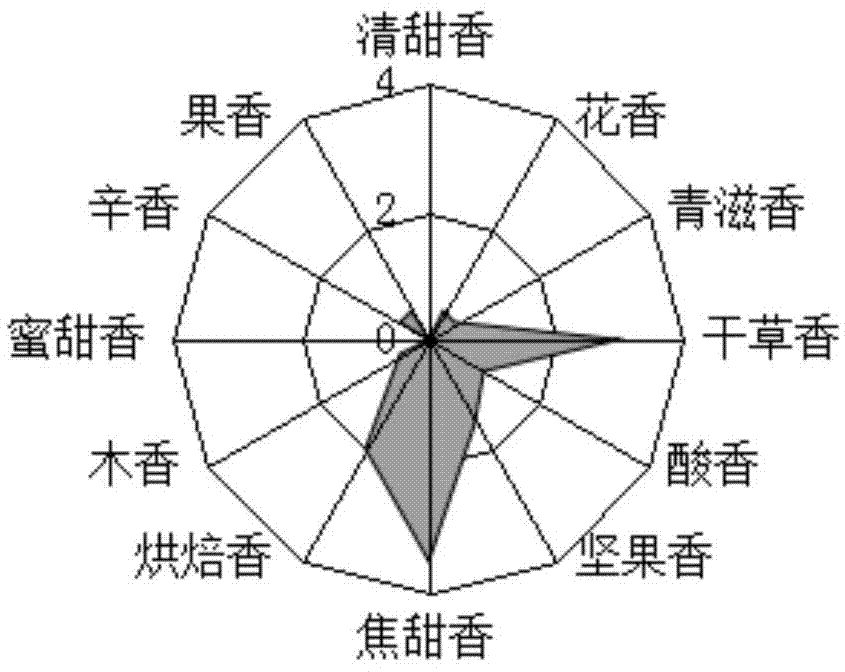

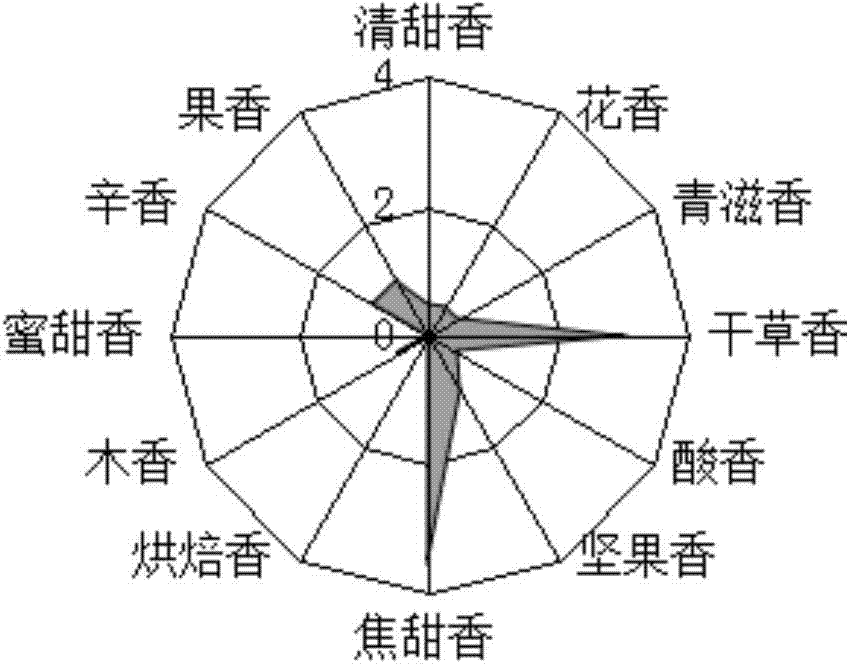

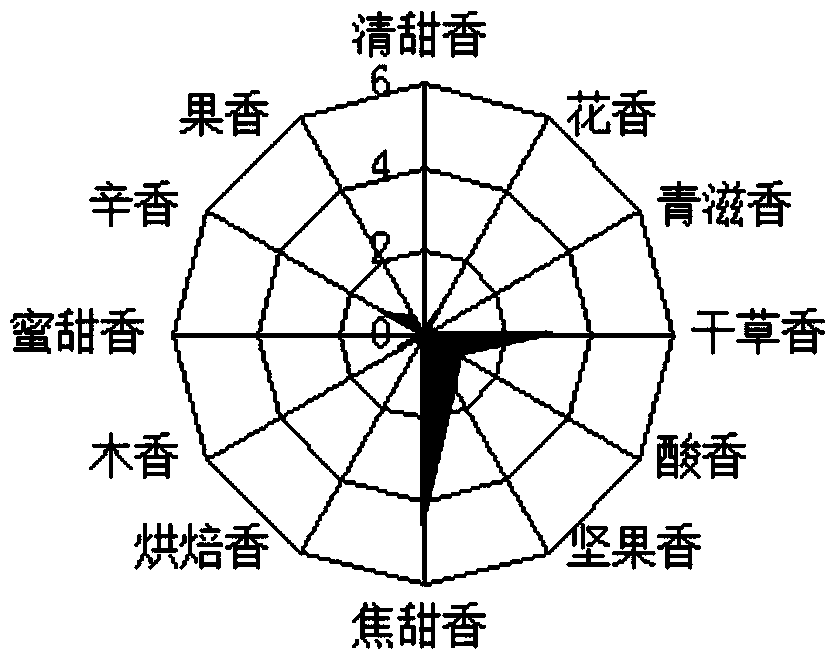

Essence highlighting sweet scorched aroma style characteristic, and application thereof in cigarettes

ActiveCN104745305AEasy to addSuitable for large-scale productionTobacco preparationEssential-oils/perfumes3-oxo-alpha-ionolKetone

The invention discloses an essence highlighting a sweet scorched aroma style characteristic. The essence comprises the following components by weight percent: 0.14-0.60wt% of furfuryl alcohol, 0.02-0.14wt% of 5-methyl furfuraldehyde, 0.12-0.40wt% of 6-methyl-5-heptenyl-2-one, 0.06-0.16wt% of crocein aldehyde, 0.05-0.30wt% of 3-oxo-alpha-ionol, 4.27-8.25wt% of solanone, 1.78-3.07wt% of cembratrienediol, 0.54-1.50wt% of linoleic acid, 60-70wt% of propylene glycol and 16-30wt% of ethanol. The essence provided by the invention assists in stabilizing cigarette style characteristic. With the essence, product quality fluctuation caused by tobacco quality difference can be reduced.

Owner:CHINA TOBACCO YUNNAN IND

Polyethylene greenhouse film resin composition with high intensity and ultra-broad width, and its preparation method

The invention discloses a polyethylene greenhouse film resin composition with high intensity and ultra-broad width and its preparation method, by referring linear low density polyethylene in weight percent, the resin composition comprises: 1) 100% of LLDPE; 2) 0.12%-0.45% of compound crosslinking auxiliary agent (1,1-hydroxyphenyl-hydrogen peroxide and 2,5-dimethyl-2,5-di-tert-butyl peroxide hexane); 3) 0.015%-0.032% of dibenzoyl peroxide; 4) 15%-37% of PP / LLDPE blended grafted polymer. According to the invention, the composition is capable of steadily blowing the ultra-broad width greenhousefilm (broad width is greater than or equal to 14m, the thickness is greater than or equal to 80 mum) on a general film blowing machine group, and the tear strength of film product is high, the product has no fish eye on the appearance, the polyethylene greenhouse film resin composition is capable of resisting 8-9 grade sand storm, and is especially suitable for laying in central and western regions in which the sandstorm occurs frequently. The present invention also discloses a preparation method of the resin composition.

Owner:PETROCHINA CO LTD

Method for preparing dried tofu based on twin-screw extruder

InactiveCN108684825AFine surface structureSmooth surface structureCheese manufactureEnvironmental resistanceProcess engineering

The invention provides a method for preparing dried tofu based on a twin-screw extruder. The method comprises a pulverizing stage, a material feeding stage, a mixing stage, a vacuum charging stage, anextruding and aging stage, a cooling stage and a sterilizing stage. Based on the twin-screw extruder, the methods of expanding by extruding, pulverizing by a press roll and the like improve the blending property, mouthfeel and eating quality of isolated protein. According to the preparation method provided by the invention, by application of corresponding processes and formula adjustment, the blending property, palatability and digestibility of the isolated protein are improved. A production process provided by the invention is applicable to continuous industrial production of whole grain nutritional dried tofu by extruding and has high degree of automation, energy saving and environmental protection, the moisture content of materials in the process is relatively low, the energy consumption for re-drying is reduced, the energy utilization rate is high and the production process conforms to the human sustainable development strategy (the energy consumption of like products is only 25-40% of a traditional method).

Owner:合达信科技集团有限公司

High accuracy aluminum oxide polishing powder and production method thereof

InactiveCN101824279BHigh polishing precisionSmall median diameterPolishing compositions with abrasivesAluminium oxides/hydroxidesLiquid-crystal displayGranularity

The invention discloses an aluminum oxide polishing powder and a production method thereof. The aluminum oxide polishing powder is characterized in that a D50 particle size is smaller than 2.0 microns and satisfies that D10 is no less than 0.5 times of D50, D90 is no more than 2 times of D50 and D100 is no less than 3 times of D50. The preparation method comprises the following steps of pulping raw materials of alpha-aluminum oxide with water, carrying out classification and obtaining a product. The aluminum oxide polishing powder has the advantages of small median particle diameter, narrow granularity distribution range, easy control of the polishing accuracy stability and small fluctuation of the product quality, can be used for accurate polishing processing of electronic product components including glasses for liquid crystal display screens, flat plane displays, optical elements, ultrathin glass substrates and glass magnetic discs and can also be used for preparing aluminum oxide polishing solution for polishing chemical machinery.

Owner:SHANGHAI GONA POWDER TECH

Preparation method of brewing powder based on twin-screw extruder

InactiveCN108567110AImprove brewing characteristicsGood brewabilityFood shapingCooking & bakingEngineering

The invention provides a preparation method of brewing powder based on a twin-screw extruder. The preparation method comprises a crushing stage, a feeding stage, a mixing stage, a vacuum feeding stage, an extrusion curing stage, a pre-drying stage, a tableting stage and a second baking stage. According to the invention, the brewing characteristics, mouthfeel and edible quality of whole grain are improved based on extrusion expansion, roller crushing, etc. of the twin-screw extruder; based on the preparation method and through corresponding process and formula adjustment, the brewing characteristics, palatability and digestibility of whole grain are enhanced; the production process provided by the invention is suitable for continuous industrial production of extruded whole grain nutrition powder; the preparation method has a high degree of automation and has effects of energy conservation and environmental protection;as a material process has relatively low moisture,the energy consumption of re-drying is relatively low, the energy utilization rate is high, and the preparation method is in line with human sustainable development strategy (the energy consumption is only 25%-40% of that of a traditional preparation method of similar products).

Owner:合达信科技集团有限公司

A kind of preparation method of polycarboxylate superplasticizer synthesized at room temperature and wide temperature range

The invention discloses a preparation method of synthesis of a polycarboxylate superplasticizer at room temperature in wide temperature range. The preparation method comprises the steps of 1) mixing polyether macromonomer with water to obtain a reactant solution; 2) measuring temperature of the reactant solution, and selecting an oxidizing agent and a reducing agent according the temperature of the reactant solution; 3) putting an oxidant solution into the reactant solution, then dropwise adding comonomer and the reducing agent, keeping the pH value of a reaction system to 2 to 12 by using acid or alkali according the temperature of the reaction system, the dripping time of the comonomer is 0.5 to 1.5h, the dripping time of the reducing agent is 0.5 to 2h, continuously reacting for 0.5 to 1h after dripping, so as to obtain the polycarboxylate superplasticizer. According to the preparation method disclosed by the invention, the fluctuation of product quality caused by the change of environment temperature and the temperature rise in a reaction process is avoided when the polycarboxylate superplasticizer is synthesized at room temperature, and a high-performance polycarboxylate superplasticizer with high water-reducing rate, good slump loss resistant property and stable product performance can be synthesized between 0 to 50 DEG C.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

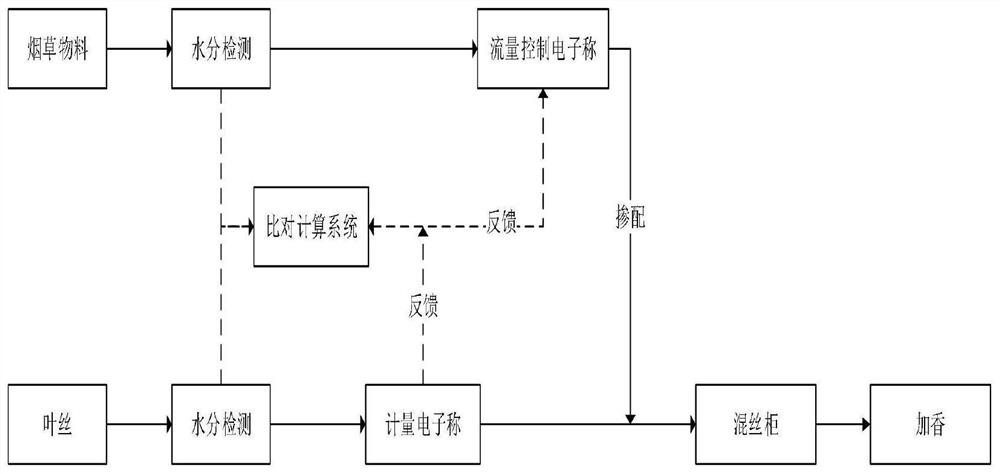

Method for improving tobacco material blending precision

InactiveCN112841696ASmall storage environment requirementsLess investmentTobacco preparationProcess engineeringIndustrial engineering

The invention discloses a method for improving the tobacco material blending precision, and belongs to the field of tobaccos. The method comprises the following steps: comparing and calculating tobacco material and cut tobacco moisture, quantitatively controlling the instantaneous blending flow of the tobacco material, and keeping the instantaneous blending proportion of the dry matter content of the tobacco material consistent with the cut tobacco formula proportion so as to improve the tobacco material blending precision, thereby achieving the purpose of improving the tobacco shred formula precision. According to the method, the instant blending proportion of the dry matter content of the tobacco materials in each batch can be kept consistent with the cut tobacco formula proportion, the batch accumulative blending precision can be monitored in real time, and meanwhile, the dry matter content blending proportion fluctuation caused by material moisture fluctuation and the like of different batches is reduced, so that the blending precision of the tobacco materials is improved, the tobacco shred formula precision is improved, and product quality fluctuation is reduced. Compared with other methods, the method has the advantages that the investment cost is low, and the method is simple and efficient.

Owner:HONGTA TOBACCO GRP

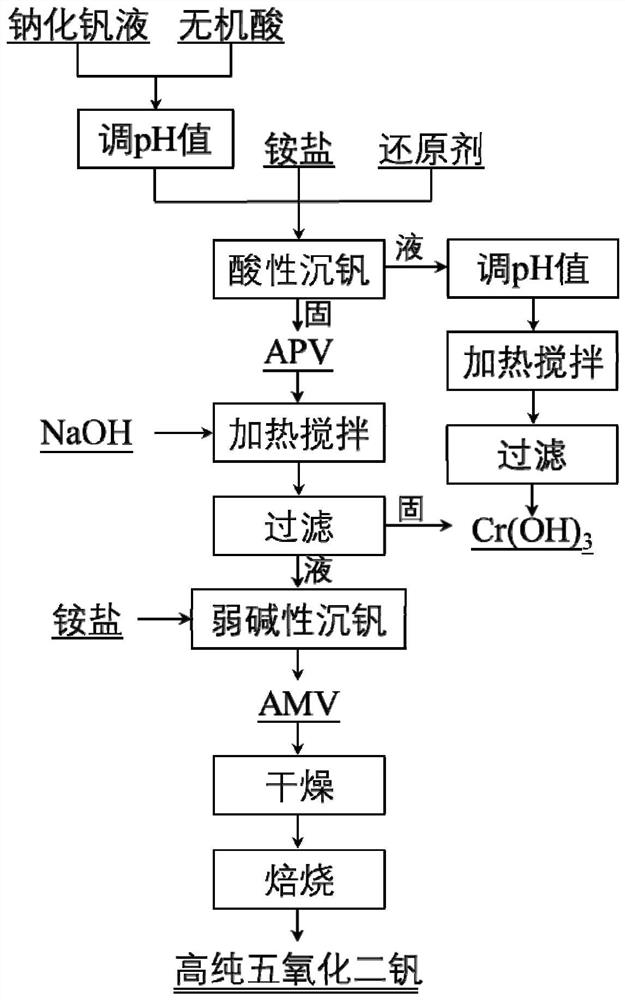

Method for preparing high-purity vanadium pentoxide by reducing and precipitating sodium vanadium solution

PendingCN114275815ANo pollution in the processSimple processVanadium oxidesProcess efficiency improvementChemical industryVanadium atom

The invention relates to the technical field of vanadium chemical industry and high-purity vanadium pentoxide preparation, in particular to a method for preparing high-purity vanadium pentoxide through reduction precipitation of a sodium vanadium solution. The method comprises the following steps: providing a sodium vanadium solution, adding an acid and a reducing agent, adjusting the pH value to 2-3, then adding a first ammonium salt, carrying out a reaction, after the reaction is finished, filtering to obtain a vanadium precipitation filter cake, pulping and washing the filter cake with deionized water, and then drying; dissolving the dried product in a sodium hydroxide solution, controlling the final pH value to be 10.5-12, stirring for reaction, filtering to obtain a grey green filter cake and a colorless vanadium solution, adding a second ammonium salt into the colorless vanadium solution, filtering, washing and drying after the reaction is finished to obtain a white solid, and roasting the white solid to obtain vanadium pentoxide. According to the method for preparing the high-purity vanadium pentoxide by reducing and precipitating the sodium vanadium solution, the high-purity vanadium pentoxide with the purity of 99.99 wt% or above can be prepared.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Polyethylene geomembrane resin composition and preparation method thereof

ActiveCN102408615AImprove melt strengthFor high demands on melt strengthCross-linkLinear low-density polyethylene

The invention discloses a polyethylene geomembrane resin composition. Taking the weight of linear low density polyethylene (LLDPE) as 100%, the resin composition comprises: LLDPE fusant, wherein the flow rate of the fusant is 0.5-10 g / 10min; (2) 0.17%-0.51% of a complex cross-linking additive composed of 1,1-dimethylethyl-hydrogen peroxide and peroxide tert-butyl benzoate; (3) 0.017%-0.032% of benzoyl peroxide (BPO); and (4) 11%-35% of LLDPE-g-PS graft copolymer. With the adoption of the composition, the gradually enlarging of an LLDPE microcrosslinking structure is realized, the occurrence of gelling is avoided, and broad-width geomembrane with few fish eyes, high strength and good barrier property can be stably produced by blowing without any mixing, wherein the thickness of the geomembrane is thicker than or equal to 0.5 mm, and the breadth of the geomembrane is 5-8 mm. The application of the LLDPE in the fields, such as agriculture, water conservancy, transportation, environmentalprotection and port construction and the like is enlarged. The invention further discloses a preparation method of the resin composition.

Owner:PETROCHINA CO LTD

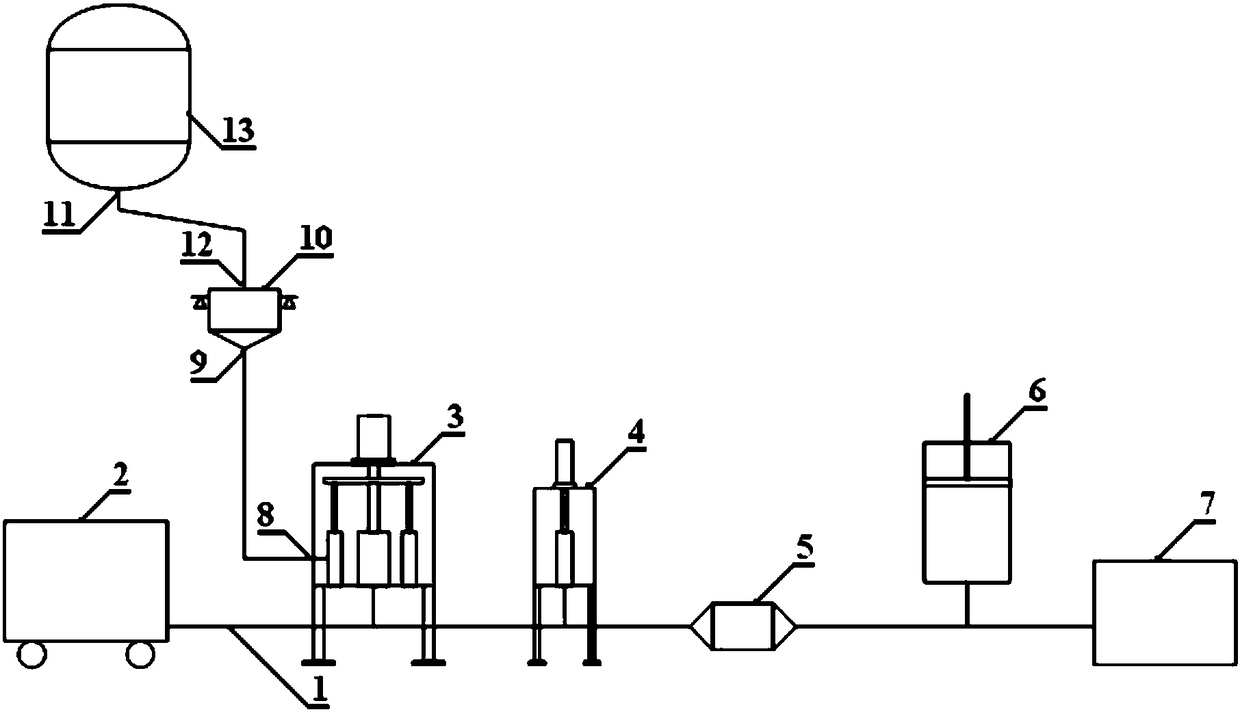

Sealant additive online adding device and method

PendingCN108465435ASimple processControllableTransportation and packagingMixer accessoriesProcess engineeringSealant

The invention provides a sealant additive online adding device. The sealant additive online adding device comprises a material conveying pipeline, a reaction cylinder, a mixing device, a superchargingdevice, a condensing unit, a buffer device, a filling machine, a metering device and an additive storage tank, wherein the reaction cylinder, the mixing device, the supercharging device, the condensing unit, the buffer device and the filling machine are sequentially arranged on the material conveying pipeline; the mixing device is further provided with an additive feed port; a discharge port of the metering device is connected with the additive feed port of the mixing device; a discharge port of the additive storage tank is connected with a feed port of the metering device; and the mixing device is a multi-component mixing machine. Compared with the prior art, the provided device is sequentially provided with the reaction cylinder, the mixing device, the supercharging device, the condensing unit, the buffer device and the filling machine on the material conveying pipeline, the high temperature filling is avoided, the guarantee period of a product is prolonged, the energy consumption is reduced; moreover, an additive is added online, so that the additive is stably mixed with a base stock, the quality fluctuation of the product is small, and the production efficiency is high.

Owner:HANGZHOU ZHIJIANG NEW MATERIAL CO LTD +1

A flavor highlighting the characteristics of burnt-sweet aroma and its application in cigarettes

ActiveCN104745305BEasy to addSuitable for large-scale productionTobacco preparationEssential-oils/perfumes3-oxo-alpha-ionolFood flavor

The invention discloses an essence highlighting a sweet scorched aroma style characteristic. The essence comprises the following components by weight percent: 0.14-0.60wt% of furfuryl alcohol, 0.02-0.14wt% of 5-methyl furfuraldehyde, 0.12-0.40wt% of 6-methyl-5-heptenyl-2-one, 0.06-0.16wt% of crocein aldehyde, 0.05-0.30wt% of 3-oxo-alpha-ionol, 4.27-8.25wt% of solanone, 1.78-3.07wt% of cembratrienediol, 0.54-1.50wt% of linoleic acid, 60-70wt% of propylene glycol and 16-30wt% of ethanol. The essence provided by the invention assists in stabilizing cigarette style characteristic. With the essence, product quality fluctuation caused by tobacco quality difference can be reduced.

Owner:CHINA TOBACCO YUNNAN IND

A rare earth electrolyzer repair paste and non-stop repair method

The invention provides a rare earth electrolytic cell repair paste and a non-stop repair method, which relate to the technical field of rare earth electrolysis, and include a binder and a dry material at a ratio of 1:3 in parts by weight; wherein the dry material includes The following components in parts by weight: 20-27 parts of graphite powder, 51-55 parts of anthracite powder and 18-26 parts of rare earth fluoride powder; , form a protective layer with a dense structure, and its own oxidation consumption is slow, and it has strong corrosion resistance to the fluoride salt melt in the rare earth electrolytic cell. Due to the existence of the repair paste, the upper edge of the graphite tank is isolated from the air to avoid Or delay the further oxidation loss of the upper edge of the graphite tank body, effectively prolonging the service life of the graphite tank of the rare earth electrolytic tank.

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

Metal hydroxide halogen-free anti-flaming polyolefin composition and preparation method thereof

The present invention discloses one kind of no-halogen fireproof composite material of metal hydroxide and polyolefin and its preparation process. The no-halogen fireproof composite material consists of metal hydroxide 40-60 weight portions, polyolefin 30-60 weight portions, interface modifier 0.1-5 weight portions, synergistic fire retardant 0-10 weight portions and antioxidant 0.1-2 weight portions. It is prepared through the first pre-treating metal hydroxide with the interface modifier, and the subsequent mixing and extruding all the materials. The no-halogen fireproof composite material has high fireproof performance and excellent mechanical performance, and may be used in electric wire and cable, pipe and rod.

Owner:SOUTH CHINA UNIV OF TECH

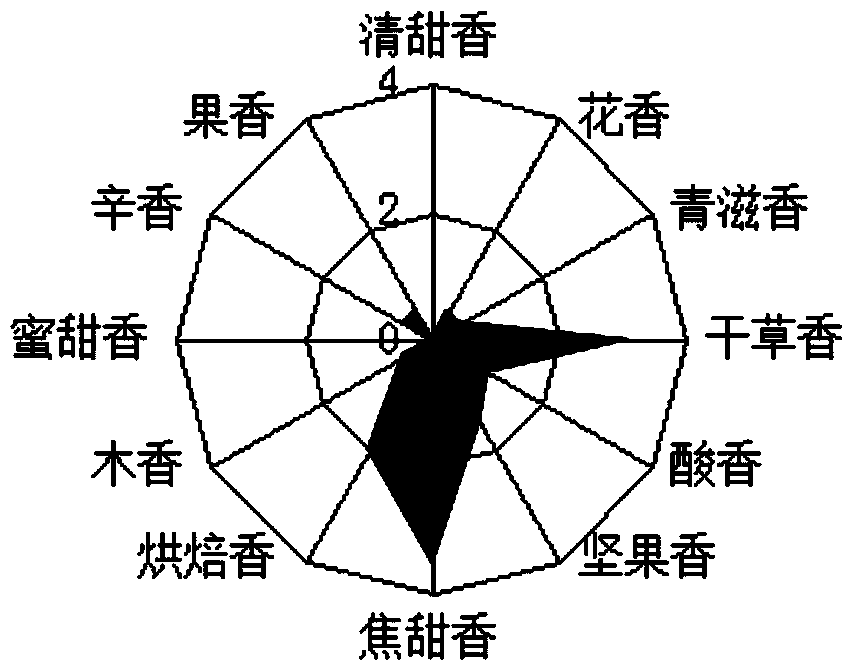

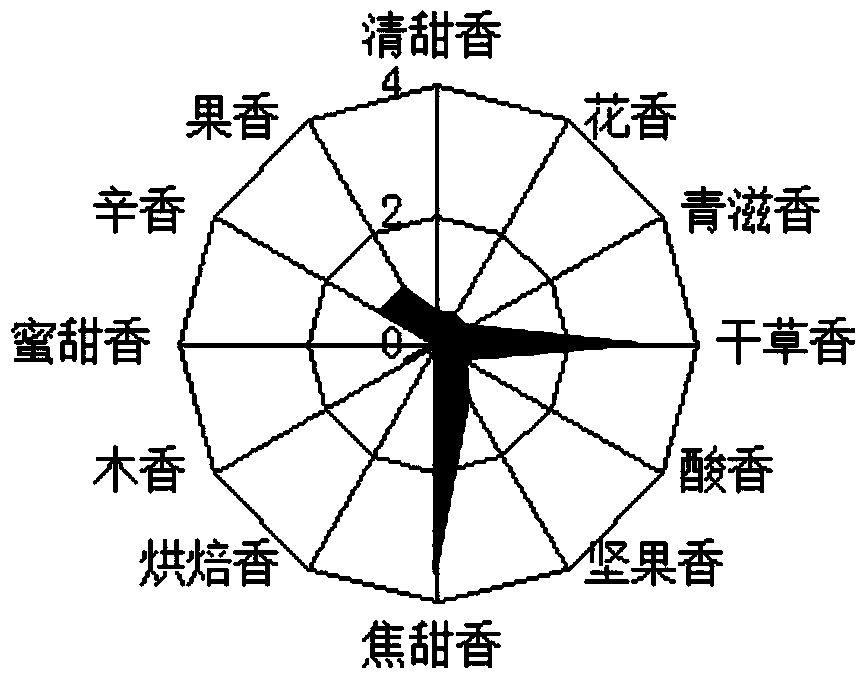

A regulator for enhancing the burnt-sweet flavor of tobacco leaves and its method for treating tobacco

InactiveCN105476058BImprove the problem of low solubilityImprove solubilityTobacco preparationTobacco treatmentMaillard reactionSolubility

The invention discloses a regulating agent capable of enhancing the sweet aroma of tobacco leaves. The regulating agent is prepared from the following raw materials in parts by weight: 2.00-3.32 parts of L-aspartic acid, 2.32-3.88 parts of L-histidine, 0.46-0.69 part of L-proline, 0.52-0.77 part of L-isoleucine, 2.13-3.46 parts of potassium hydroxide, and 2.50-3.50 parts of sucrose ester. The invention further provides a method for processing the tobacco leaves by adopting the regulating agent capable of enhancing the sweet aroma of the tobacco leaves. The method comprises the steps of preparation of regulating agent stock solution, pretreatment on the tobacco leaves, baking of the tobacco leaves, and the like. According to the method provided by the invention, after L-aspartic acid, L-histidine, L-proline and L-isoleucine have cation exchange reaction with potassium hydroxide, amino acid potassium salt is formed, and the solubility of the amino acid potassium salt is relatively high, so that the problem that the solubility of amino acid is relatively low is effectively improved, further, the absorption by the tobacco leaves is facilitated, the occurrence of Maillard reaction is promoted, the number of the products of the Maillard reaction greatly increases, therefore, the sweet aroma of the tobacco leaves is effectively enhanced, and the fluctuation of product quality caused by environmental deviation is reduced.

Owner:INST OF TOBACCO ANHUI ACADEMY OF AGRI SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com