Method for simultaneously preparing polytetramethylene ether glycol with various specifications

A technology of polytetramethylene ether glycol and specifications, which is applied in the field of preparation of polytetramethylene ether glycol, can solve the problems of inability to produce PTMEG of various specifications at the same time, reduce waste of transition materials and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

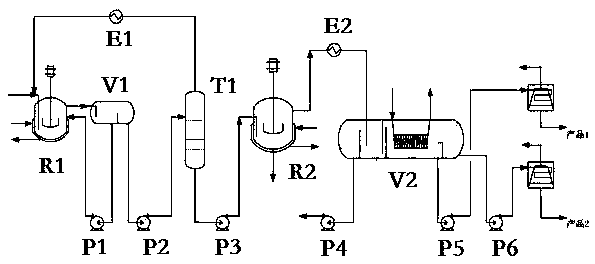

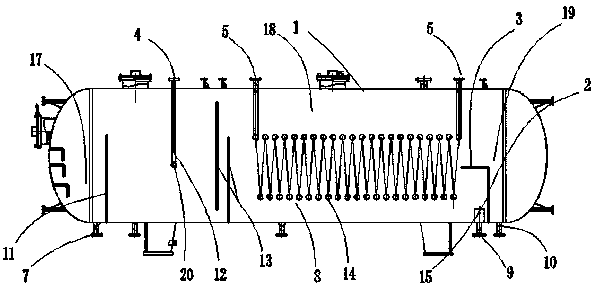

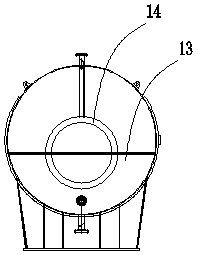

[0034] As shown in accompanying drawing 01, the present invention discloses a method for simultaneously preparing polytetramethylene ether glycol of various specifications, comprising:

[0035] 1) Add tetrahydrofuran with a liquid level of about 30% into the reactor R1, and then add a certain amount of heteropoly acid catalyst. The amount of catalyst added is based on actual needs, and the amount of catalyst can be controlled at 20% of the entire reaction liquid. When adding the heteropolyacid catalyst and tetrahydrofuran into R1, tetrahydrofuran should be added first, and then the catalyst should be added, and the catalyst should be added while stirring. The temperature of the reaction kettle was controlled at 50°C; the catalyst was stirred for 3 hours to completely dissolve the catalyst.

[0036] 2) When the stirring is stopped, the catalyst settles in the lower part of the reactor R1, forming an obvious lower catalyst phase and an upper organic phase. Replace the organic p...

Embodiment 2

[0043] The invention discloses a method for simultaneously preparing polytetramethylene ether glycol of various specifications, comprising:

[0044] 1) Add tetrahydrofuran with a liquid level of about 30% into the reaction kettle R1, and then add a certain amount of heteropoly acid catalyst. The amount of catalyst added is based on actual needs. In this example, the amount of catalyst is controlled at 33% of the entire reaction liquid . When adding the heteropolyacid catalyst and tetrahydrofuran into R1, tetrahydrofuran should be added first, and then the catalyst should be added, and the catalyst should be added while stirring. The temperature of the reaction kettle was controlled at 55° C. and stirred for 5 hours to completely dissolve the catalyst.

[0045] 2) When the stirring is stopped, the catalyst settles in the lower part of the reactor R1, forming an obvious lower catalyst phase and an upper organic phase. Replace the organic phase in the reactor R1 with tetrahydro...

Embodiment 3

[0051] The invention discloses a method for simultaneously preparing polytetramethylene ether glycol of various specifications, comprising:

[0052] 1) Add tetrahydrofuran with a liquid level of about 30% into the reactor R1, and then add a certain amount of heteropoly acid catalyst. The amount of catalyst added is based on actual needs, and the amount of catalyst can be controlled at 45% of the entire reaction liquid. When adding the heteropolyacid catalyst and tetrahydrofuran into R1, tetrahydrofuran should be added first, and then the catalyst should be added, and the catalyst should be added while stirring. The temperature of the reaction kettle was controlled at 50° C.; it was stirred for 4 hours to completely dissolve the catalyst.

[0053] 2) When the stirring is stopped, the catalyst settles in the lower part of the reactor R1, forming an obvious lower catalyst phase and an upper organic phase. Replace the organic phase in the reactor R1 with tetrahydrofuran (moisture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com