Method for improving tobacco material blending precision

A technology of tobacco materials and blending accuracy, which is applied in the fields of tobacco, tobacco preparation, food science, etc., can solve the problems of hysteresis in control and low moisture uniformity, and achieve low investment costs, reduce product quality fluctuations, and small investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

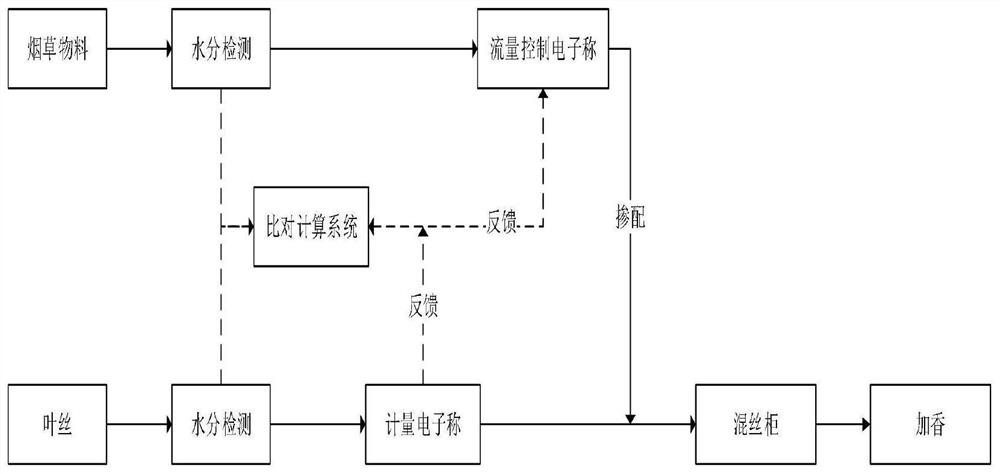

[0043] In order to facilitate those skilled in the art to understand and realize the present invention, the technical solution of the present invention is now further described in conjunction with the drawings and specific embodiments.

[0044] 1. After the leaf silk is tested for moisture, it will pass through the metering electronic scale, and the comparison calculation system will collect the following information: S 1-n , W T1 , W 1-n , L1-n .

[0045] S 1-n : The average value of leaf silk moisture detected by the moisture meter for the nth unit time (such as 2 minutes) of leaf silk.

[0046] W T1 : Cumulative amount of shredded dry matter since the beginning of the batch.

[0047] W 1-n : The cumulative amount of shredded leaves collected by the electronic scale at the nth unit time.

[0048] L 1-n : The average instantaneous flow rate collected by the electronic scale for the nth unit time of leaf silk.

[0049] 2. After the moisture content of the tobacco mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com