Super-wide-breadth metallocene polyethylene greenhouse film resin composition and preparation method thereof

A technology of metallocene polyethylene and resin composition is applied in the field of resin composition for making ultra-wide shed film and its preparation field, which can solve the problems of excessive gelation, limited width, and many fish-eyes in the film, so as to improve the performance of the film. Melt strength, melt strength increase, effect of improving processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment and

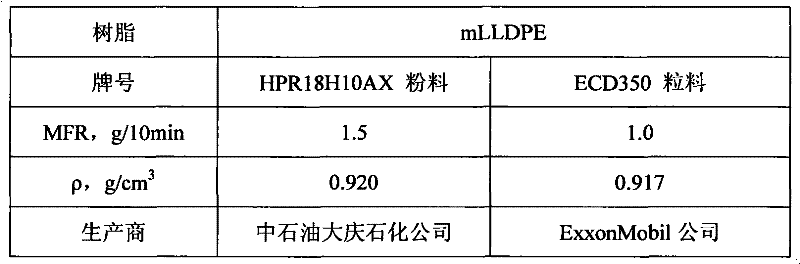

[0043] Embodiment and comparative example:

[0044] The following examples are cited to illustrate the inventive effect of the present invention, but the scope of protection of the present invention is not limited to these examples, and each component in the composition is calculated in parts by weight of the base resin mLLDPE.

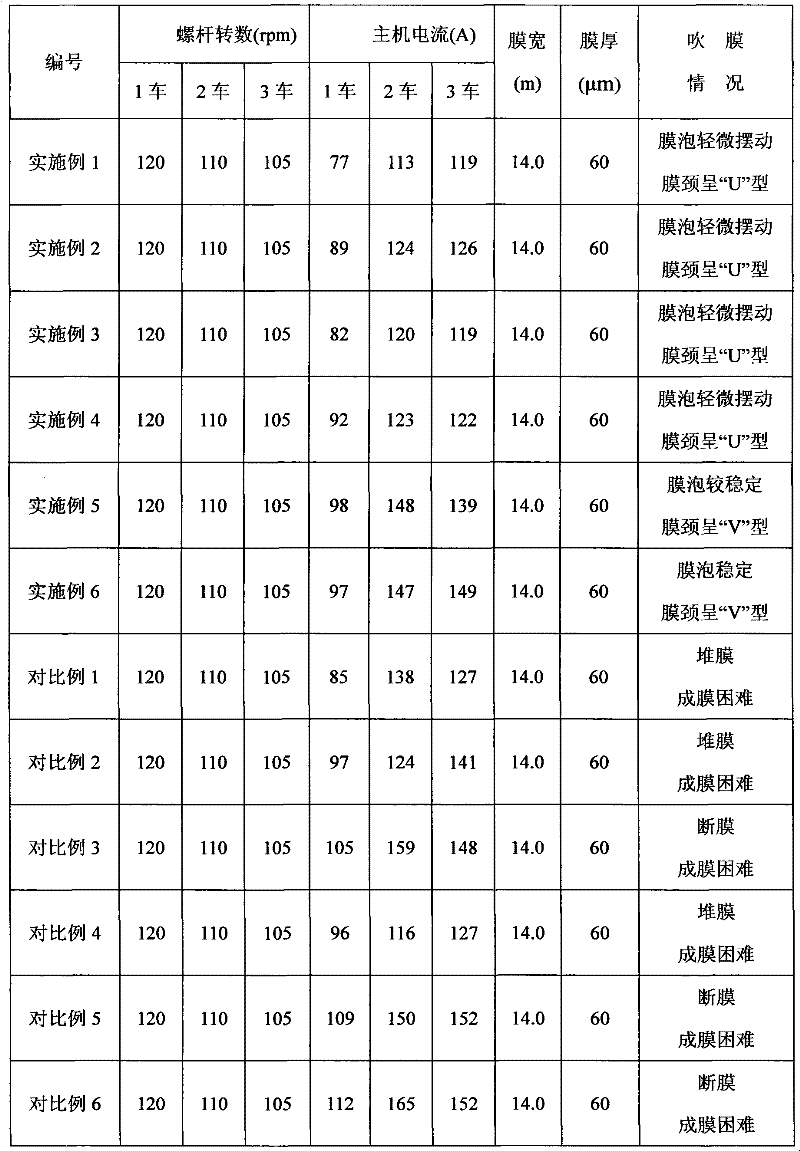

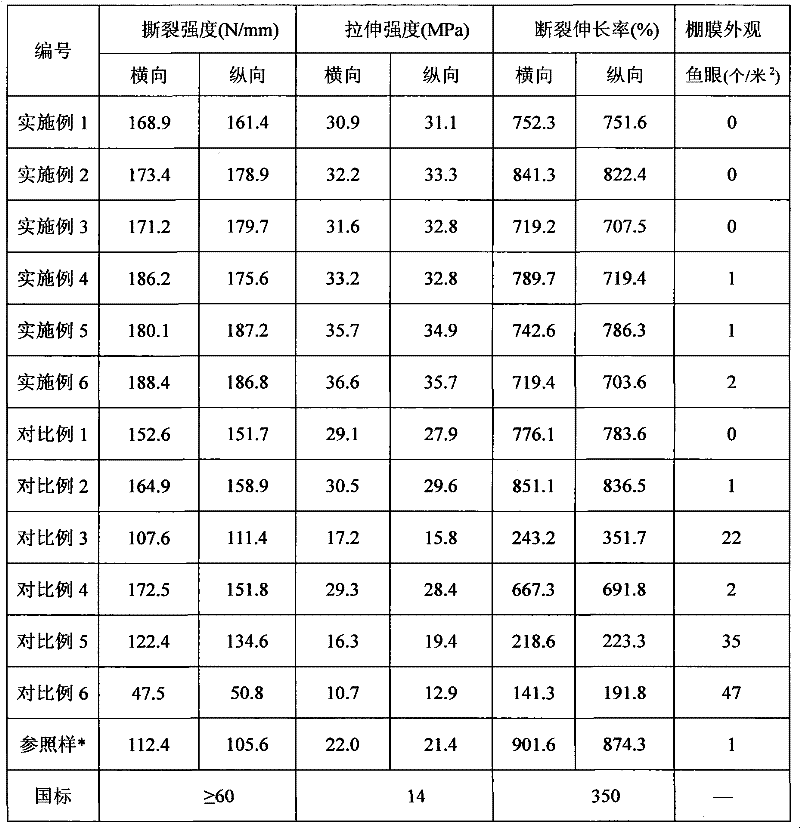

Embodiment 1

[0046] Mix 0.33 parts of TB and 0.025 parts of TBPA with 0.8 parts of acetone solvent, then add 5 parts of mLLDPE (HPR18H10AX) powder resin, 0.05 parts of antioxidant 1010, 0.15 parts of calcium stearate, and mix in a 10-liter high-speed mixer After 3 minutes, the premixed masterbatch is made, and the premixed masterbatch and 95 parts of mLLDPE (HPR18H10AX) powder resin are added to the extruder through the feeding port, and the barrel temperature is 155-210 ° C. After reacting for 2 minutes , and then prepare a solution of 0.012 parts of BPO and 0.04 parts of acetone solvent, add it dropwise into the plasticizing section of the extruder, and at a barrel temperature of 200-225 ° C, after extrusion for 17 seconds, cool and granulate to prepare combination. The composition is blown on a Φ120 three-layer composite blown film unit to produce an ultra-wide shed film (14m in width and 60 μm in thickness). The properties of the composition, the film blowing process conditions and the...

Embodiment 2

[0048] Mix 0.29 parts of TB and 0.03 parts of TBPA with 0.7 parts of xylene solvent, then add 5 parts of mLLDPE (ECD350) granular resin, 0.1 part of antioxidant 168, and 0.2 parts of zinc stearate in a 10-liter high-speed mixer After mixing for 3 minutes, make a premixed masterbatch, put the premixed masterbatch and 95 parts of mLLDPE (ECD350) powder resin into the extruder through the feeding port, and react for 2 minutes at the barrel temperature of 155-210°C Finally, prepare a solution of 0.015 parts of BPO and 0.05 parts of xylene solvent, add it dropwise into the plasticizing section of the extruder, and extrude it for 17 seconds at a barrel temperature of 200-225 ° C, then cool and granulate Compositions are prepared. The composition is blown on a Φ120 three-layer composite blown film unit to produce an ultra-wide shed film (14m in width and 60 μm in thickness). The properties of the composition, the film blowing process conditions and the properties of the shed film are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com