Self-compacting concrete for CRTS III plate-type ballastless track filling layer and preparation method for self-compacting concrete

A technology of self-compacting concrete and slab-type ballastless track, which is applied in the field of building materials, can solve the problems of improving the fluidity of self-compacting concrete, maintaining time-volume stability of fluidity, shrinkage rate, durability and fine aggregate source, The long-term stability of the retention time and volume is not obvious, and the rheological properties of self-compacting concrete are changed to achieve strong internal bubble stability, small thixotropic changes over time, and improved various properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

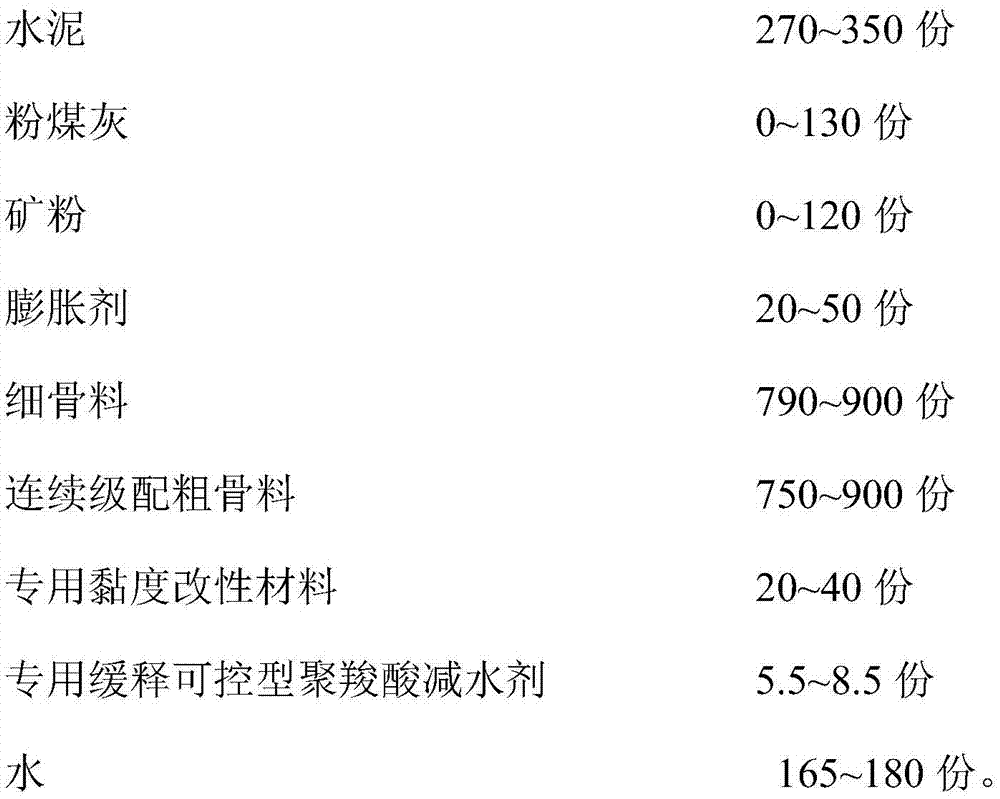

Method used

Image

Examples

Embodiment 1

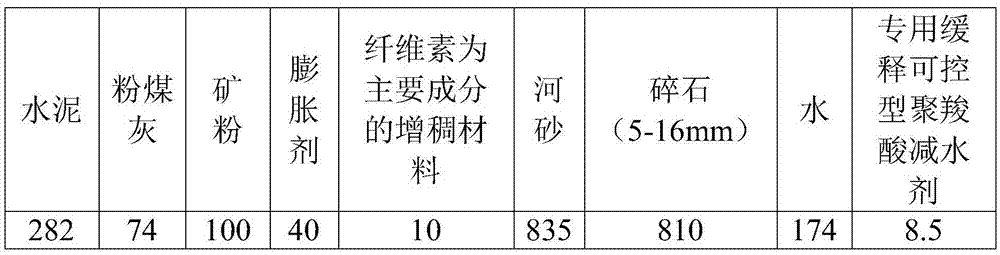

[0048] The fine aggregate is river sand with a fineness modulus of 2.6, the viscosity-modified material is a special viscosity-modified material, and the water-reducer is a special slow-release and controllable polycarboxylate water-reducer, which is used for the filling layer of CRTSⅢ plate ballastless track The proportion of self-compacting concrete is listed in Table 5.

[0049] Table 5 Proportion of self-compacting concrete for ballastless track filling layer (unit: kg / m 3 )

[0050]

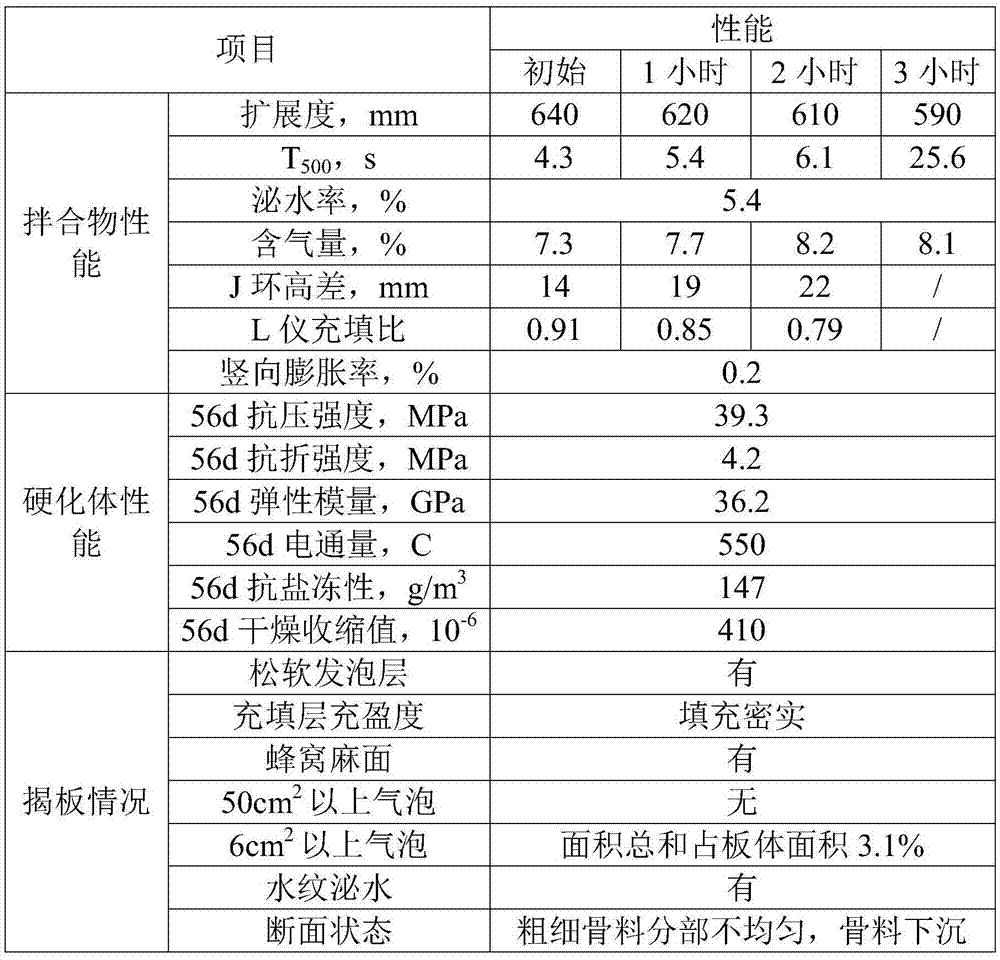

[0051] The ballastless track filling layer mixed with the ratio of Example 1 was transported to the site with self-compacting concrete. When the mixing water was added 150 minutes ago, the performance of the concrete was tested to meet the requirements of pouring construction. The filling layer pouring construction took 9 minutes. The slab time consumption is normal, and the peeling test shows that the performance of the self-compacting concrete is good, and the quality of the filling la...

Embodiment 2

[0055] The fine aggregate is artificial machine-made sand with a fineness modulus of 2.5, the viscosity-modified material is a special viscosity-modified material, the water reducer is a special slow-release and controllable polycarboxylate water reducer, and the CRTSⅢ plate ballastless track filling layer The proportion of self-compacting concrete is shown in Table 7.

[0056] Table 7 Proportion of self-compacting concrete for ballastless track filling layer (unit: kg / m 3 )

[0057]

[0058] The ballastless track filling layer mixed with the ratio of Example 2 was transported to the site with self-compacting concrete. When the mixing water was added 150 minutes ago, the performance of the concrete was tested to meet the requirements of pouring construction, and the pouring construction of the filling layer took 9.5 minutes. The filling time is normal, and the peeling test shows that the performance of the self-compacting concrete is good, and the quality of the filling la...

Embodiment 3

[0063] The fine aggregate is modified sea sand with a fineness modulus of 2.4, the viscosity modified material is a special viscosity modified material, the water reducer is a special slow-release and controllable polycarboxylate water reducer, and the CRTSⅢ plate ballastless track filling The ratio of self-compacting concrete for the layer is shown in Table 9.

[0064] Table 9 Proportion of self-compacting concrete for ballastless track filling layer (unit: kg / m 3 )

[0065]

[0066] The ballastless track filling layer mixed in Example 3 was transported to the site with self-compacting concrete. When the mixing water was added 150 minutes ago, the performance of the concrete was tested to meet the pouring construction requirements, and the filling layer pouring construction took 8.5 minutes. The filling time is normal, and the peeling test shows that the performance of the self-compacting concrete is good, and the quality of the filling layer is good. The performance of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com