Preparation process of blank-similar type mud cosmetic clay and ceramic tile

A technology for cosmetic soil and ceramic tiles, applied in the field of ceramics, can solve problems such as the inconsistency of the temperature change trend, the flatness of the surface of the brick surface, and the wave deformation of all-tossing products, so as to reduce the fluctuation of product quality, stabilize product production, Formulated structure for uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with embodiment:

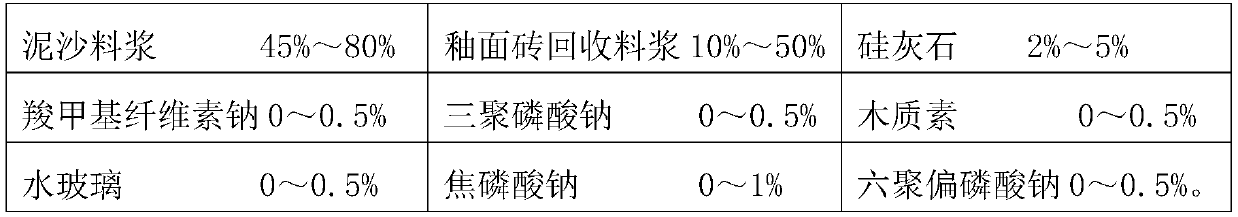

[0037] The high-temperature transparent glaze full-throwing body-type mud make-up soil is composed of the following components in parts by weight:

[0038]

[0039] The surface flatness of the prepared ceramic tiles is 0.1 mm convex and 0.2 mm concave.

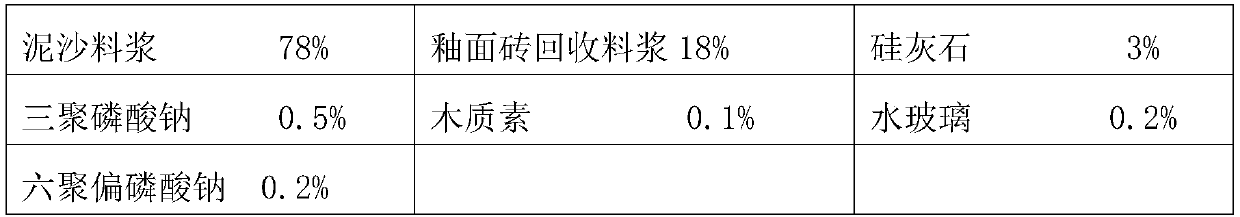

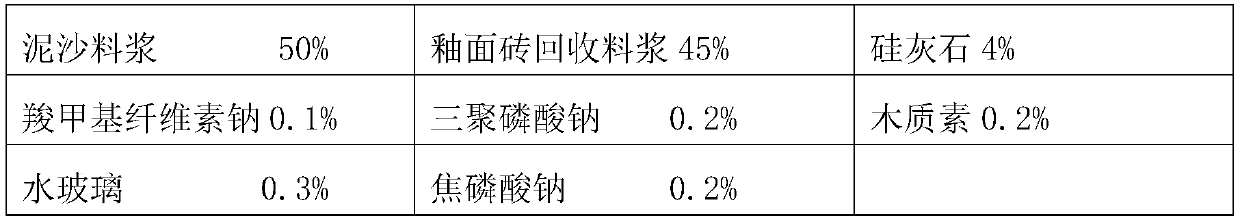

[0040] The low-temperature transparent glaze full-throwing body type mud make-up soil is composed of the following components in parts by weight:

[0041]

[0042] The surface flatness of the prepared ceramic tile is 0.3mm convex and 0.2mm concave.

[0043] In this example, the preparation process of the silt slurry is as follows: 28% of Jiangxi porcelain stone, 15% of Fengxin high-temperature sand, 10% of Fuzhou black mud, 14% of Fengcheng washed mud, 20% of Yichun lithium sand, magnesia 12% mud, 4% wollastonite, 0.5% sodium carboxymethyl cellulose, 0.25% lignin, 0.25% water glass formula weighing, enter the ball m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com