A regulator for enhancing the burnt-sweet flavor of tobacco leaves and its method for treating tobacco

A regulator and tobacco coke technology, which is applied in the fields of tobacco processing, tobacco preparation, etc., can solve the problems of unstable tobacco leaf quality of charred and sweet tobacco leaves, the great difference in the natural flavor of flavored flue-cured tobacco, and the inability to meet urgent needs, etc. Achieve the effects of improving the solubility, reducing product quality fluctuations, and enhancing the style of burnt sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

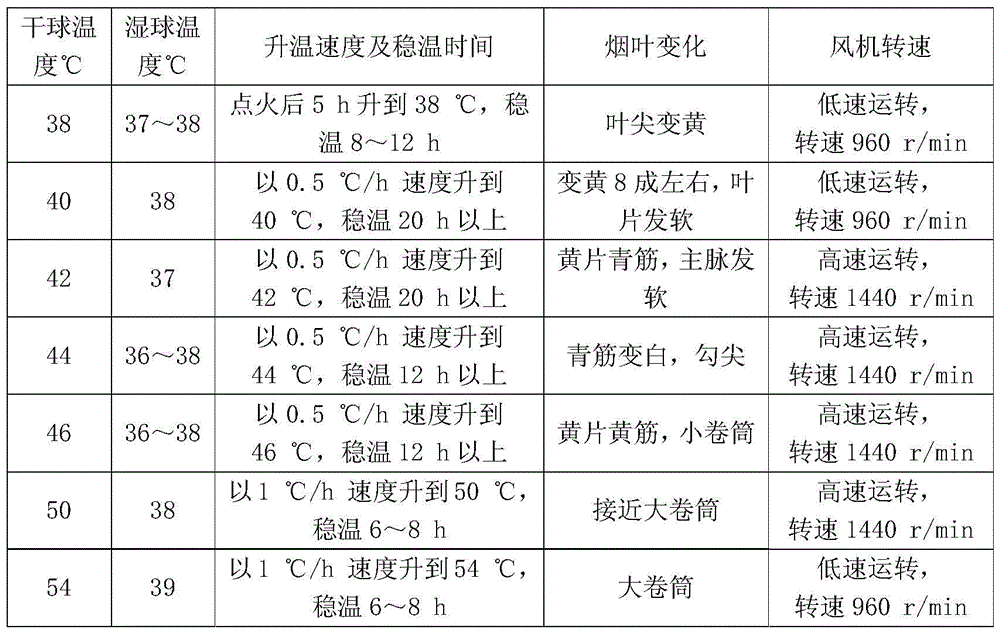

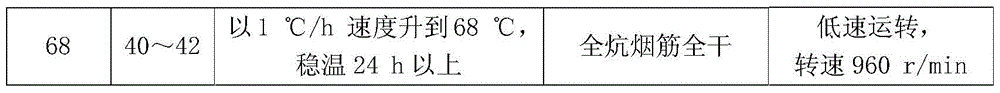

Method used

Image

Examples

Embodiment 1

[0025] A regulator for enhancing the pyrosweet flavor of tobacco leaves, comprising the following raw materials by weight: 2.66 L-aspartic acid, 3.10 L-histidine, 0.56 L-proline, 0.66 L-isoleucine, Potassium hydroxide 2.51, sucrose ester 3.00.

[0026] The method for processing tobacco leaves using the above-mentioned regulator for enhancing the burnt-sweet flavor of tobacco leaves, comprising the following steps:

[0027] (1) Configuration of regulator stock solution

[0028] Potassium hydroxide was dissolved in 200 parts by weight of water to obtain a potassium hydroxide solution. The dissolution process could be accelerated by heating and stirring. After cooling, L-aspartic acid, L-histidine, L-proline Amino acid and L-isoleucine were added to the potassium hydroxide solution, stirred to react, and the reaction formed amino acid potassium salt. After fully reacted, 800 parts by weight of water and sucrose ester were added, and the stirring was continued until all solid sub...

Embodiment 2

[0038] A regulator for enhancing the pyrosweet flavor of tobacco leaves, comprising the following raw materials in parts by weight: L-aspartic acid 2.00, L-histidine 2.32, L-proline 0.46, L-isoleucine 0.52, Potassium hydroxide 2.13, sucrose ester 2.50.

[0039] The method for processing tobacco leaves using the above-mentioned regulator for enhancing the burnt-sweet flavor of tobacco leaves, comprising the following steps:

[0040] (1) Configuration of regulator stock solution

[0041] Potassium hydroxide was dissolved in 200 parts by weight of water to obtain a potassium hydroxide solution. The dissolution process could be accelerated by heating and stirring. After cooling, L-aspartic acid, L-histidine, L-proline Amino acid and L-isoleucine were added to the potassium hydroxide solution, stirred to react, and the reaction formed amino acid potassium salt. After fully reacted, 800 parts by weight of water and sucrose ester were added, and the stirring was continued until all ...

Embodiment 3

[0048] A regulator for enhancing the pyrosweet flavor of tobacco leaves, comprising by weight the following raw materials: L-aspartic acid 3.32, L-histidine 3.88, L-proline 0.69, L-isoleucine 0.77, Potassium hydroxide 3.46, sucrose ester 3.50.

[0049] The method for processing tobacco leaves using the above-mentioned regulator for enhancing the burnt-sweet flavor of tobacco leaves, comprising the following steps:

[0050] (1) Configuration of regulator stock solution

[0051]Potassium hydroxide was dissolved in 200 parts by weight of water to obtain a potassium hydroxide solution. The dissolution process could be accelerated by heating and stirring. After cooling, L-aspartic acid, L-histidine, L-proline Amino acid and L-isoleucine were added to the potassium hydroxide solution, stirred to react, and the reaction formed amino acid potassium salt. After fully reacted, 800 parts by weight of water and sucrose ester were added, and the stirring was continued until all solid subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com