Small-caliber gun bullet small-batch automatic assembling device and control method thereof

An assembly device, small batch technology, applied in the direction of ammunition, weapon accessories, offensive equipment, etc., can solve the problems of complex mechanism design and control method for automatic assembly of small caliber bullets and small batches, and achieve high quality of charge assembly, easy processing, The effect of meeting the consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

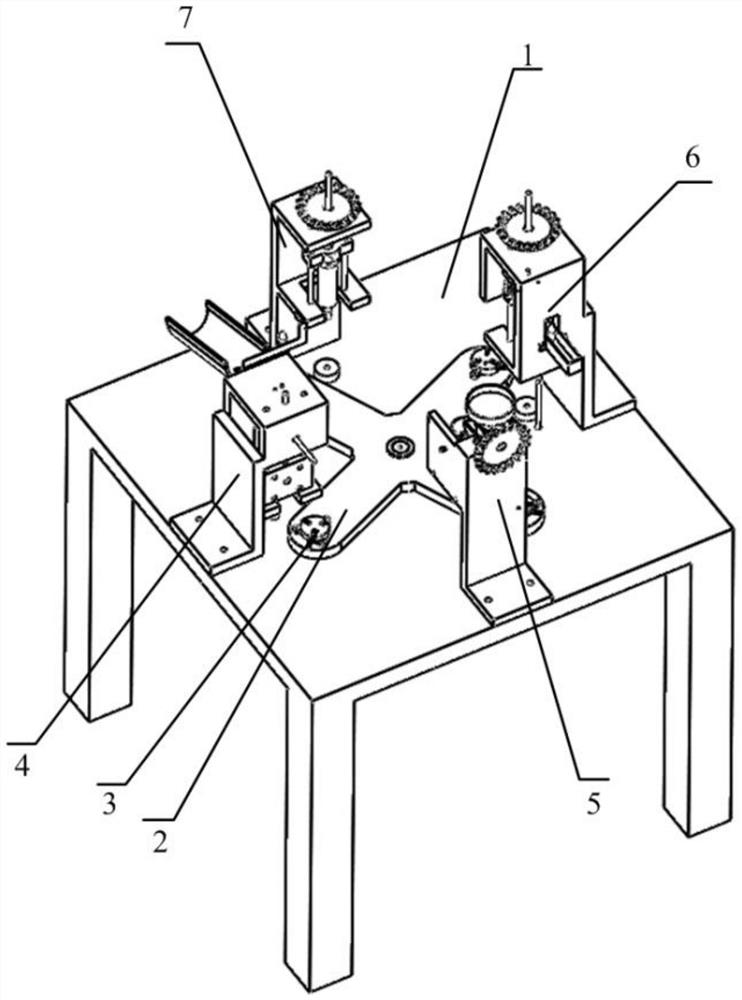

[0034] Such as Figure 1 to Figure 9 As shown, the automatic small-batch assembly device for small-caliber bullets of the present invention includes a workbench 1, a rotary disk 2, a shell grabbing disk 3 and mechanisms for realizing respective processes at four stations. The middle of the workbench 1 is connected by rotation; the four shell grabs 3 are fixed on the rotary disk 2 and connected by bolts; the mechanisms for realizing the respective processes include the feeding mechanism 4, the charging mechanism 5, The bullet pressing mechanism 6 and the mouth tightening mechanism 7, these four stations are fixed on the workbench 1 by bolts;

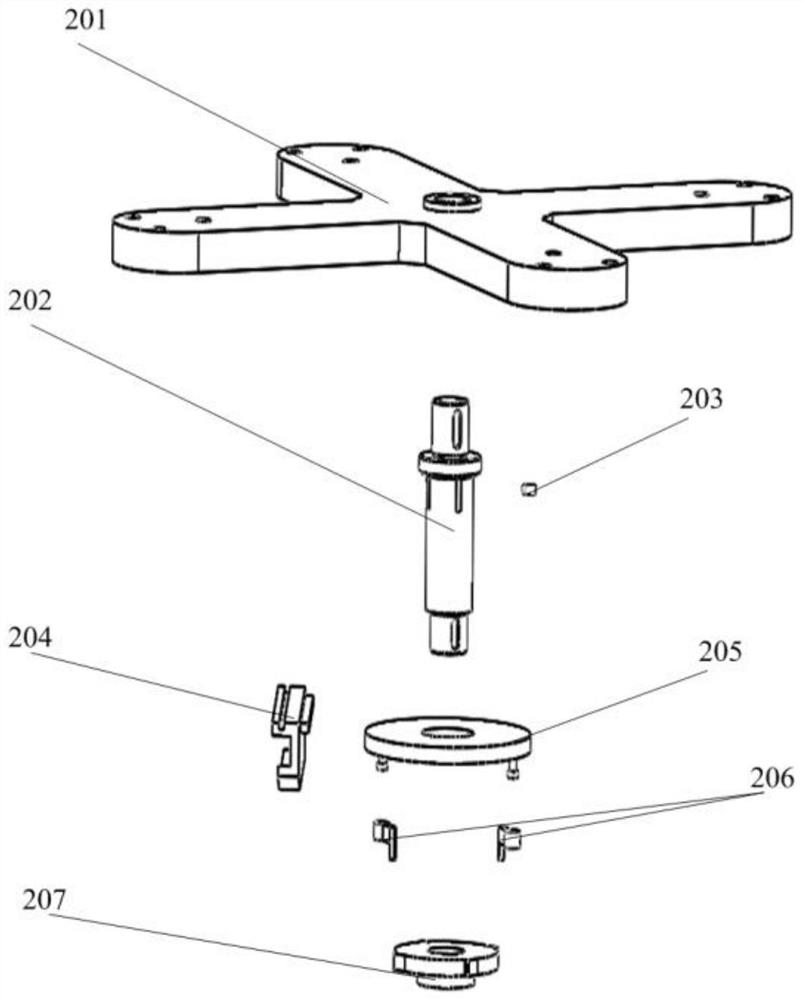

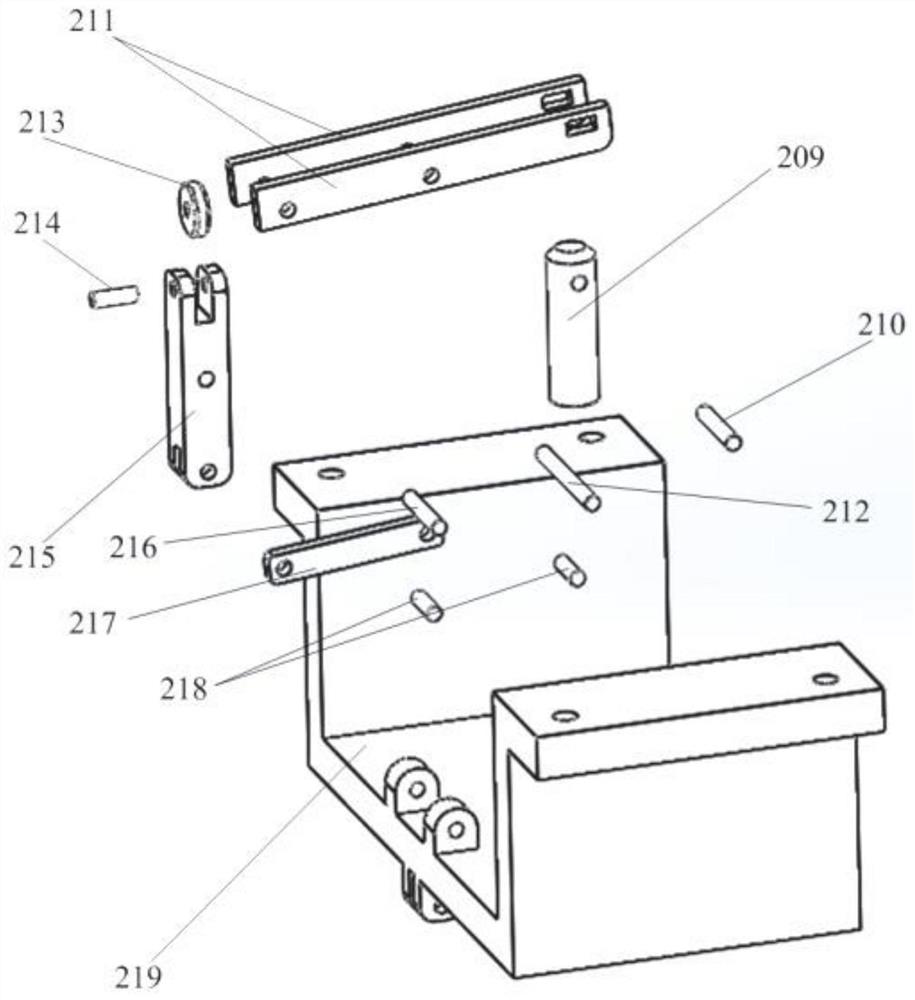

[0035] figure 2 and image 3 It is an exploded view of the rotary table 2 of the present invention, the rotary table 2 includes an index frame 201, a rotary table main shaft 202, a rotary table stop head 203, a rotar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com