A kind of preparation method of polycarboxylate superplasticizer synthesized at room temperature and wide temperature range

A technology of polycarboxylic acid and wide temperature range, which is applied in the field of building materials, can solve problems such as product quality fluctuations, and achieve the effects of small fluctuations in product performance, stable product performance, and high water-reducing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

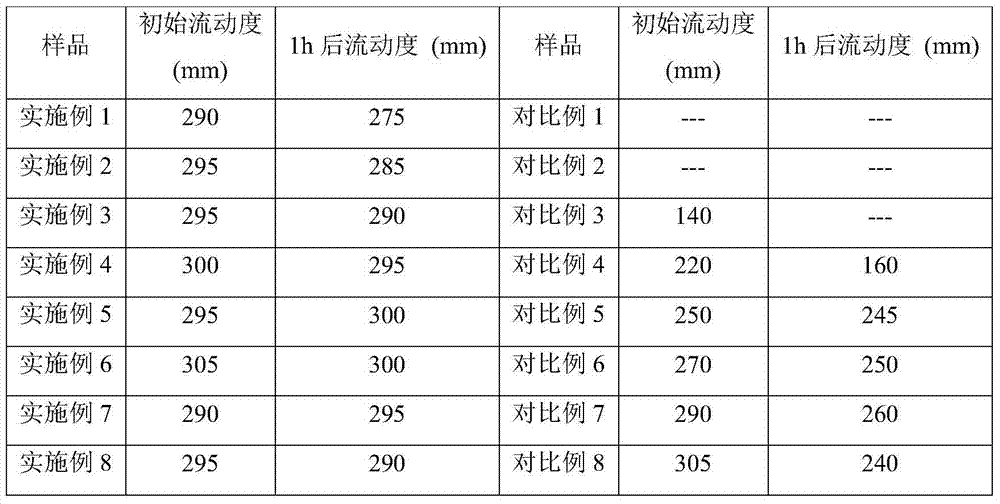

Examples

Embodiment 1

[0025] A preparation method for synthesizing a polycarboxylate water reducer in a wide temperature range at room temperature, the steps are as follows:

[0026] 1) In a 500ml four-necked flask equipped with a thermometer, a pH meter, a stirrer and a peristaltic pump flowmeter, add 160g of deionized water and 150g of methallyl alcohol polyoxyethylene ether in turn, stir until dissolved, and obtain a reactant solution ;

[0027]2) Measure the temperature of the reactant solution in the reaction kettle in step 1) to be 0° C., select hydrogen peroxide and azobisisobutylamidine hydrochloride as the oxidizing agent, and ferric gluconate and sodium dithionite as the reducing agent;

[0028] 3) Continue to add a mixed aqueous solution containing 3g of hydrogen peroxide and 1.5g of azobisisobutylamidine hydrochloride into the reactor (the amount of water in the solution should be just enough to dissolve the oxidant), and then add 5g of acrylic acid and an appropriate amount of sulfuric...

Embodiment 2

[0033] A preparation method for synthesizing a polycarboxylate water reducer in a wide temperature range at room temperature, the steps are as follows:

[0034] 1) In a 500ml four-necked flask equipped with a thermometer, a pH meter, a stirrer and a peristaltic pump flowmeter, add 160g of deionized water and 150g of methallyl alcohol polyoxyethylene ether in turn, stir until dissolved, and obtain a reactant solution ;

[0035] 2) Measure the temperature of the reactant solution in the reaction kettle in step 1) to be 5° C., select hydrogen peroxide and azobisisobutylamidine hydrochloride as the oxidizing agent, and ferric gluconate and sodium dithionite as the reducing agent;

[0036] 3) Continue to put 0.8g of hydrogen peroxide and 0.8g of azobisisobutylamidine hydrochloride mixed solution into the reaction kettle, then add 4g of acrylic acid and an appropriate amount of sulfuric acid, so that the initial pH of the reaction system is 3;

[0037] 4) Continue to drop the mixed...

Embodiment 3

[0041] A preparation method for synthesizing a polycarboxylate water reducer in a wide temperature range at room temperature, the steps are as follows:

[0042] 1) In a 500ml four-neck flask equipped with a thermometer, a pH meter, a stirrer and a peristaltic pump flowmeter, add 180g of deionized water and 150g of methallyl alcohol polyoxyethylene ether in turn, stir until dissolved, and obtain a reactant solution ;

[0043] 2) Measure the temperature of the reactant solution in the reaction kettle in step 1) to be 10°C, select hydrogen peroxide and azobisisobutylamidine hydrochloride as the oxidizing agent, and ferric gluconate and sodium dithionite as the reducing agent;

[0044] 3) Continue to put 1g of hydrogen peroxide and 0.5g of azobisisobutylamidine hydrochloride mixed solution into the reaction kettle, then add 3g of acrylic acid and an appropriate amount of sulfuric acid, so that the initial pH of the reaction system is 4;

[0045] 4) Continue to drip the mixed solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com