A brush for railway electric machine and its preparation method are provided

A technology for brushes and railways, which is applied in the manufacture of brushes, circuits, and current collectors. It can solve problems such as large contact resistance, uneven pull-out force, and high scrap rate, and achieve increased pull-out force, guaranteed stability, and reduced porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

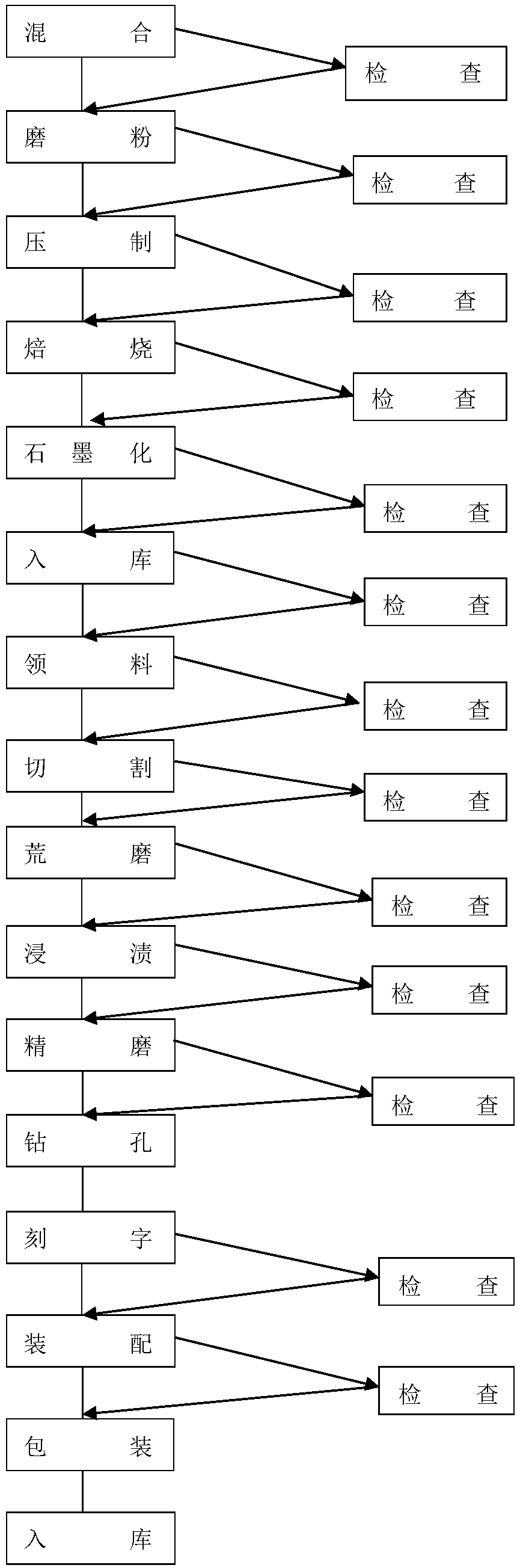

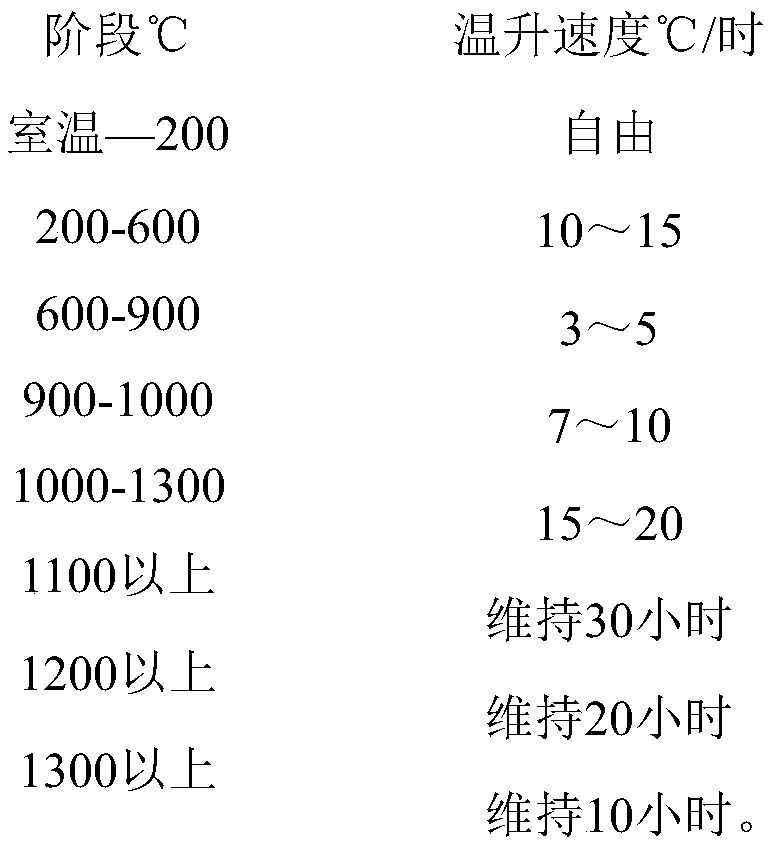

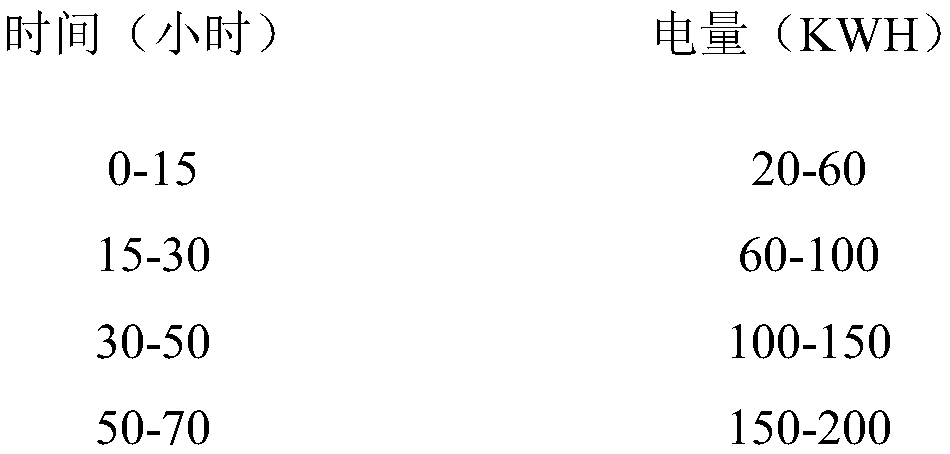

Method used

Image

Examples

Embodiment 1

[0057] The present embodiment provides a formula and a preparation method of a brush for railway motors, specifically as follows:

[0058] 1. Preparation method of modified asphalt: First, boil the medium-temperature asphalt into high-temperature asphalt with a softening point of 110°C-115°C, then stir sulfur into the high-temperature asphalt according to the mass ratio of sulfur and high-temperature asphalt at 1:3, and stir evenly , cooling, crushing, sampling, and grinding the asphalt blocks with a softening point less than 100°C into 25-mesh powder to obtain modified asphalt.

[0059] 2. Brush formula:

[0060] One-stage production process formula: carbon black, modified pitch and coal tar, and the obtained product is named as a one-stage product, wherein: the weight of carbon black is 100%, and the weight of modified pitch is 60% of the weight of carbon black, The weight of coal tar is 40% of carbon black weight, and the specific weight of each component is: 10 parts of c...

Embodiment 2

[0083] This embodiment provides a formula and preparation method of a brush for railway motors. The difference between this embodiment and Example 1 is that the formula of the brush is different. This embodiment adopts the following formula, and the processing technology is the same as that of Example 1.

[0085] One-stage production process formula: carbon black, modified pitch and coal tar, and the obtained product is named as a one-stage product, wherein: the weight of carbon black is 100%, and the weight of modified pitch is 40% of the weight of carbon black, The weight of coal tar is 60% of the weight of carbon black, and the specific weight of each component is: 10 parts of carbon black, 4 parts of modified pitch, 6 parts of coal tar;

[0086] The two-stage production process formula: the first-stage product, carbon black, modified pitch and sulfur, wherein: the first-stage product is 80% by weight, and the carbon black is 20% by weight, and the to...

Embodiment 3

[0088] The invention provides a formula and a preparation method of an electric brush for railway motors, specifically as follows:

[0089] 1. Brush formula:

[0090] One-stage production process formula: carbon black, modified pitch and coal tar, and the obtained product is named as a one-stage product, wherein: the weight of carbon black is 100%, and the weight of modified pitch is 50% of the weight of carbon black. The weight of coal tar is 50% of the weight of carbon black; the specific weight of each component is: 5 parts of carbon black, 2.5 parts of modified pitch, 2.5 parts of coal tar;

[0091] Two-stage production process formula: first-stage product, carbon black, modified pitch and sulfur, wherein: the first-stage product is 70% by weight, and the carbon black is 30% by weight, and the total weight of the first-stage product and carbon black is 100% %, the weight of modified pitch is 40% of the total weight of the first-stage product and carbon black, and the weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com