Polyethylene geomembrane resin composition and preparation method thereof

A technology of resin composition and geomembrane, which is applied in the field of polyethylene resin composition, can solve the problem of "fish eyes" in the film, and achieve the effects of significant reinforcement effect, improved melt strength, and controllable crosslinking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

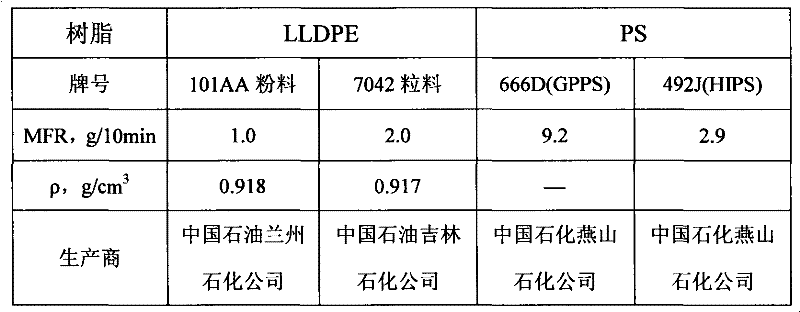

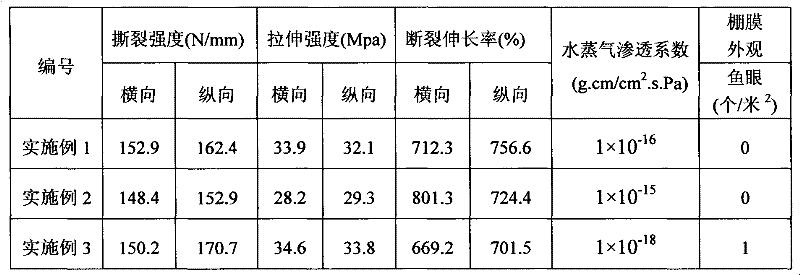

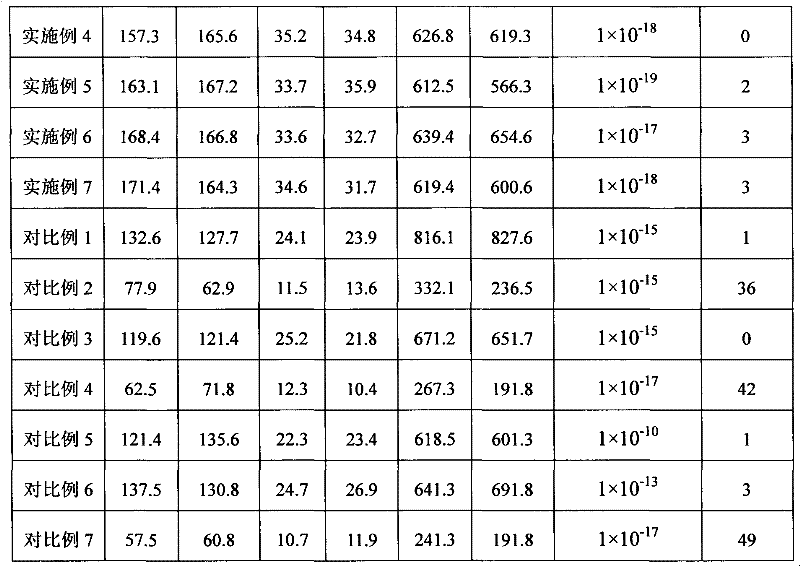

Embodiment 1

[0053] (1) Preparation of LLDPE-g-PS: Take 0.8 parts of DCP and 1.6 parts of acetone and mix them in a beaker, then mix the mixed solution with 100 parts of LLDPE (101AA), 15 parts of PS (666D) and 0.15 parts of anti Put oxygen agent 1010 and 0.15 parts of calcium stearate into a 10L high-speed mixer together, mix at high speed for 5 minutes, and put the mixed material into a Φ67 twin-screw extruder at a reaction temperature of 170-220°C and a reaction time of 9 minutes. Melt-grafting reaction was carried out under , cooled and granulated to obtain LLDPE-g-PS (grafting rate: 3.9%).

[0054] (2) Preparation of polyethylene geomembrane resin composition: Mix 0.43 parts of TB and 0.03 parts of TBPB with 0.9 parts of acetone solvent, then add 5 parts of LLDPE (101AA), and mix in a 10-liter high-speed mixer for 3 minutes to prepare Premix masterbatch, take out 15 parts of LLDPE-g-PS and premix masterbatch, 95 parts of LLDPE (101AA), 0.1 part of antioxidant 1010, 0.1 part of calcium...

Embodiment 2

[0056] (1) Preparation of LLDPE-g-PS: Take 1.1 parts of TBPA and 2.6 parts of acetone and mix them in a beaker, then mix the mixed solution with 100 parts of LLDPE (7042), 22 parts of PS (492J) and 0.1 part of anti Put oxygen agent 1010 and 0.1 part of zinc stearate together in a 10L high-speed mixer, mix at high speed for 5 minutes, and put the mixed material into a Φ67 twin-screw extruder at a reaction temperature of 170-220°C and a reaction time of 9 minutes. Melt-grafting reaction was carried out under , cooled and granulated to obtain LLDPE-g-PS (grafting rate: 5.2%).

[0057] (2) Preparation of polyethylene geomembrane resin composition: After mixing 0.41 parts of TB and 0.05 parts of TBPB with 1.1 parts of xylene solvent, then add 7 parts of LLDPE (7042), and mix in a 10-liter high-speed mixer for 3 minutes to prepare into a premix masterbatch, take out 19 parts of LLDPE-g-PS (grafting rate: 5.2%) and premix masterbatch and 93 parts of LLDPE (7042) and 0.25 parts of ant...

Embodiment 3

[0059] (1) The preparation of LLDPE-g-PS is completely the same as in Example 1.

[0060] (2) Preparation of polyethylene geomembrane resin composition: Mix 0.38 parts of TB and 0.07 parts of TBPB with 0.9 parts of toluene solvent, then add 5 parts of LLDPE (101AA), and mix in a 10-liter high-speed mixer for 3 minutes to prepare Premix masterbatch, take out 22 parts of LLDPE-g-PS (graft rate: 3.9%) and premix masterbatch and 95 parts of LLDPE (101AA) and 0.15 part of antioxidant 1010, 0.05 part of calcium stearate from the feeding port Add them together into the extruder, and react for 2 minutes under the condition of the cylinder temperature of 165-200°C, and finally prepare a solution of 0.021 parts of BPO and 0.05 parts of toluene solvent, and drop them into the plasticizing section of the extruder. The cylinder temperature is 200-230° C., after extrusion reaction for 17 seconds, cooling and granulation to prepare polyethylene geomembrane resin composition. The composition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com