Sealant additive online adding device and method

A technology of glue additives and additives, which is applied in the field of online addition of sealant additives, can solve the problems of short product warranty period, low production efficiency, and difficult detection of mixing adequacy, and achieve simple process and easy operation control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

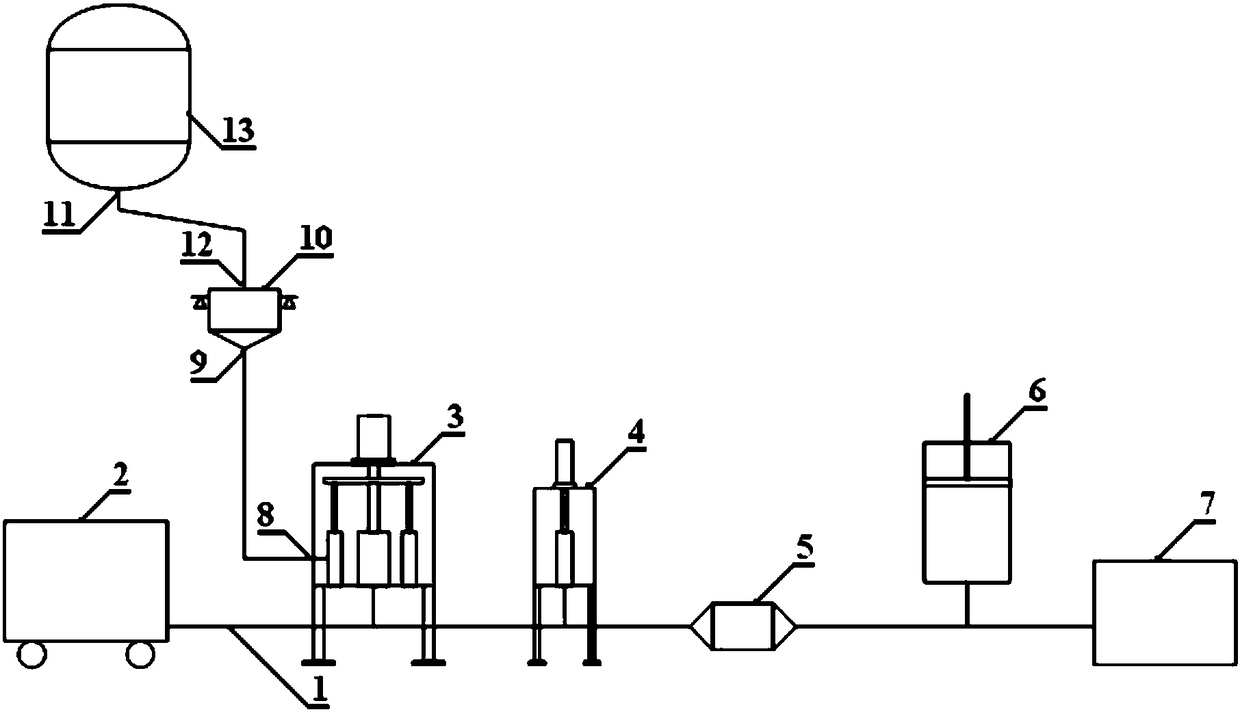

[0062] see figure 1 , figure 1 Schematic diagram of the structure of the device for adding sealant additives online provided by the embodiment of the present invention. Among them, 1 is the material conveying pipeline, 2 is the reaction cylinder, 3 is the multi-component mixer, 4 is the hydraulic station, 5 is the condenser, 6 is the buffer tank, 7 is the filling machine, 8 is the auxiliary agent inlet , 9 is the discharge port of the metering device, 10 is the metering tank, 11 is the discharge port of the storage tank, 12 is the feed port of the metering tank, and 13 is the storage tank.

[0063] The specific working process of the device for online addition of sealant additives provided in Example 1 is:

[0064] (1) Under the pressure provided by the press, the base material in the reaction tank is discharged, and enters the multi-component mixer through the material delivery pipeline; at the same time, according to the mass ratio of the auxiliary agent to the base materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com