Praseodymium-doped cerium fluoride/attapulgite up-conversion composite photocatalytic material and preparation method and application thereof

A composite photocatalysis and attapulgite technology, which is applied in the field of praseodymium doped cerium fluoride/attapulgite up-conversion composite photocatalytic material and its preparation, can solve the problems of low utilization rate of sunlight and the like, and achieves reduction of photogenerated electrons and empty space. The compounding of holes, improving the utilization rate, and overcoming the effect of uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) 0.26g Pr(NO 3 ) 3 ·6H 2 O, 0.61g Ce(NO 3 ) 3 ·6H 2 O, 0.16g NH 4 F, 0.90g of ATP was added into deionized water and ultrasonically dissolved, the pH of the system was adjusted to 4-5, and the beaker was shaken to make it evenly mixed. Then transfer it to a microwave hydrothermal kettle for microwave hydrothermal heating, set the temperature to 160°C, and set the time to 70min;

[0024] (2) Centrifuge the sample prepared in step (1) with a centrifuge, and then wash it with water. Then the sample is dried and ground to obtain the praseodymium-doped cerium fluoride / attapulgite up-conversion composite photocatalytic material 40%Pr 0.3 Ce 0.7 f 3 / ATP.

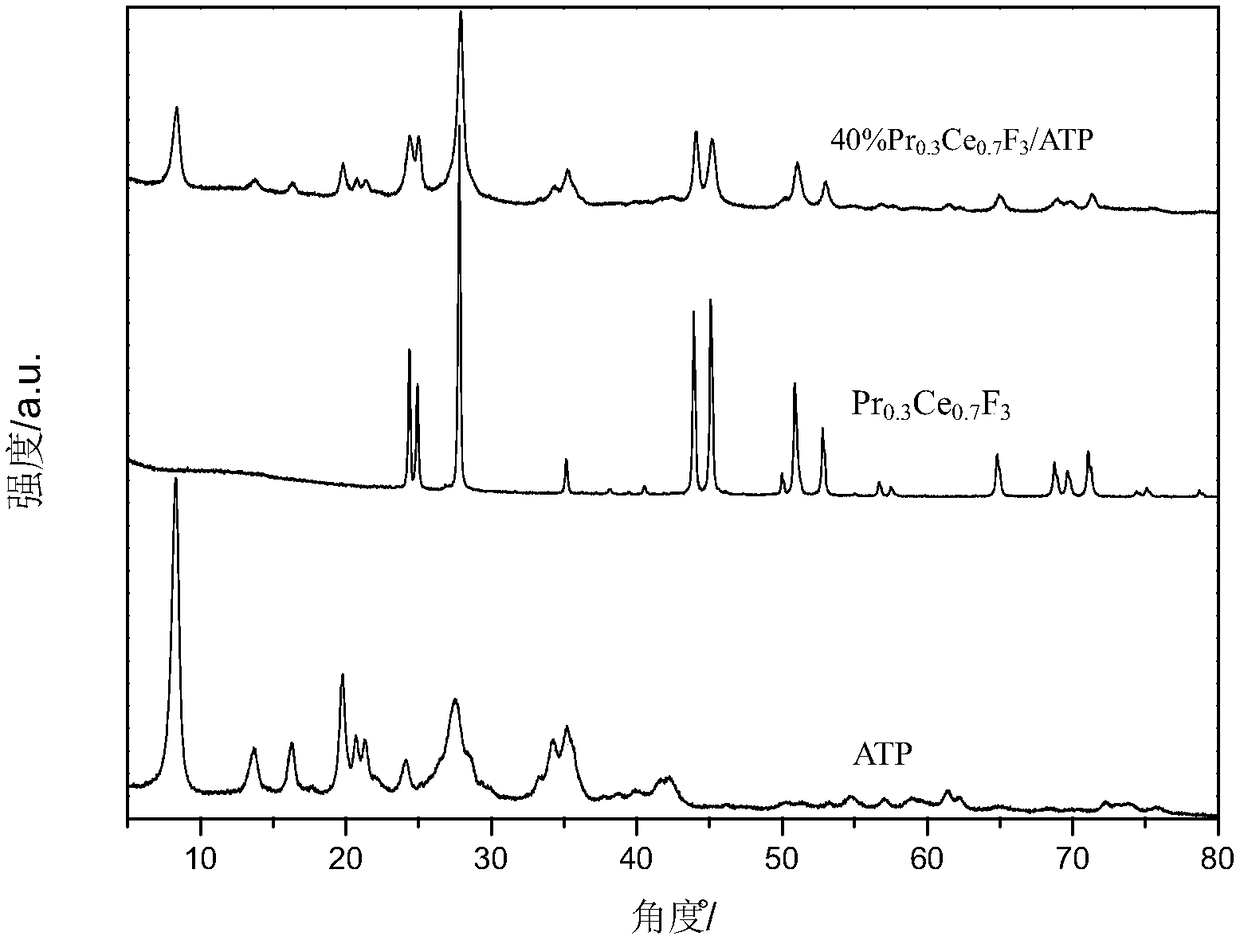

[0025] The obtained sample is characterized by X-ray powder diffraction to characterize its structure and composition, and utilizes a transmission electron microscope to observe the TEM picture of the sample, and the 40% Pr prepared according to the process of Example 1 0.3 Ce 0.7 f 3 The XRD pattern of / ATP...

Embodiment 2

[0031] (1) 0.09g Pr(NO 3 ) 3 ·6H 2 O, 0.78g Ce(NO 3 ) 3 ·6H 2 O, 0.20g NH 4 F, 1.92g ATP was added into deionized water and ultrasonically dissolved, the pH of the system was adjusted to 4-5, and the beaker was shaken to make it evenly mixed. Then transfer it to a microwave hydrothermal kettle for microwave hydrothermal heating, set the temperature to 160°C, and set the time to 70min;

[0032] (2) Centrifuge the sample prepared in step (1) with a centrifuge, and then wash it with water. Then the sample is dried and ground to obtain the praseodymium-doped cerium fluoride / attapulgite up-conversion composite photocatalytic material 20%Pr 0.1 Ce 0.9 f 3 / ATP.

[0033] Subsequent testing is as in Example 1, and the desulfurization rate is 87%.

Embodiment 3

[0035] (1) 0.34g Pr(NO 3 ) 3 ·6H 2 O, 0.52g Ce(NO 3 ) 3 ·6H 2 O, 0.13g NH 4 F, 1.75g ATP was added into deionized water and ultrasonically dissolved, and the pH of the system was adjusted to 4-5, and the beaker was shaken to make it evenly mixed. Then transfer it to a microwave hydrothermal kettle for microwave hydrothermal heating, set the power to 400W, set the temperature to 160°C, and set the time to 70min;

[0036] (2) Centrifuge the sample prepared in step (1) with a centrifuge, and then wash it with water. Then the sample is dried and ground to obtain the praseodymium-doped cerium fluoride / attapulgite up-conversion composite photocatalytic material 20%Pr 0.4 Ce 0.6 f 3 / ATP.

[0037] Subsequent testing is as in Example 1, and the desulfurization rate is 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com