Patents

Literature

75results about How to "The process is simple and flexible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

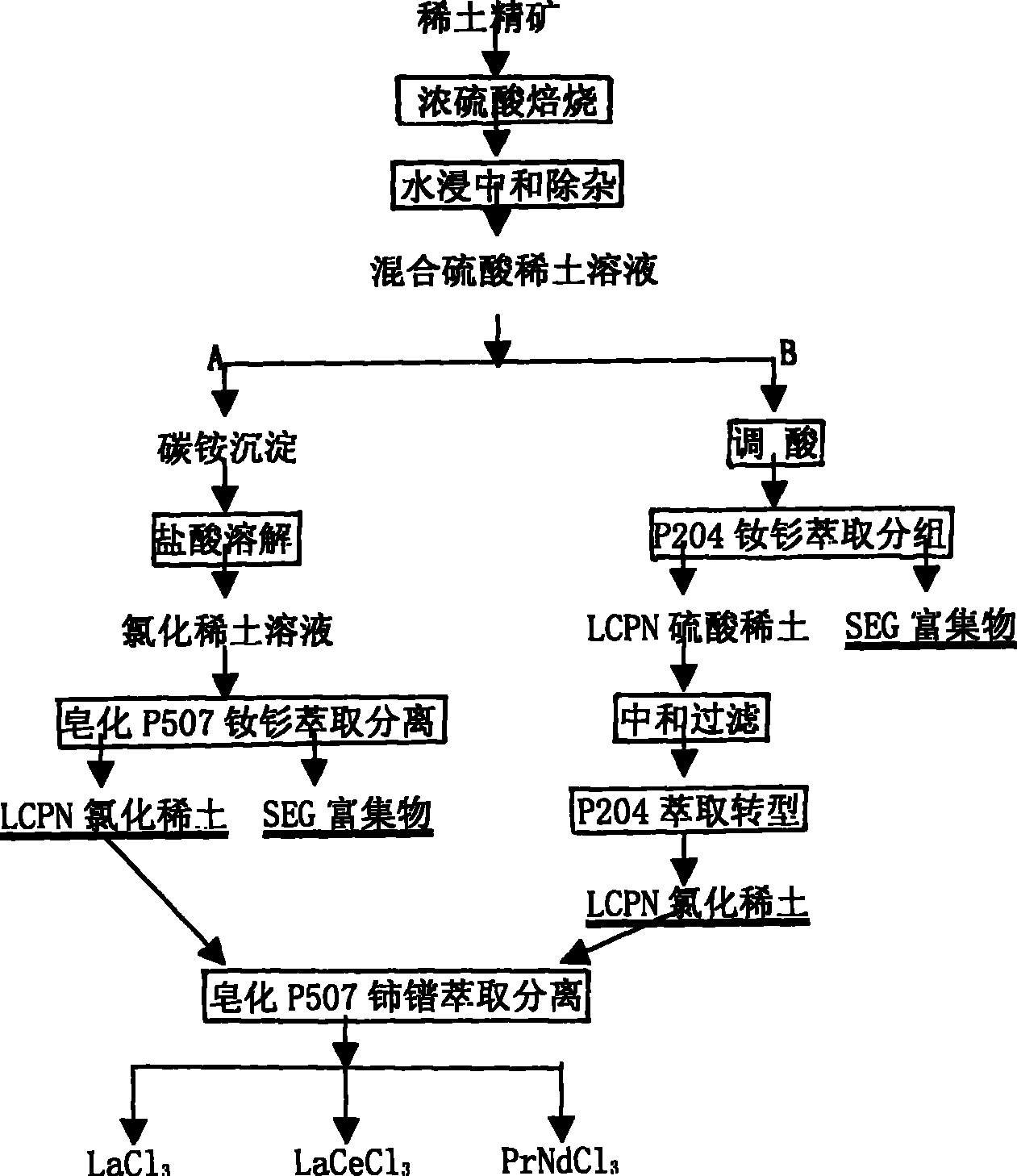

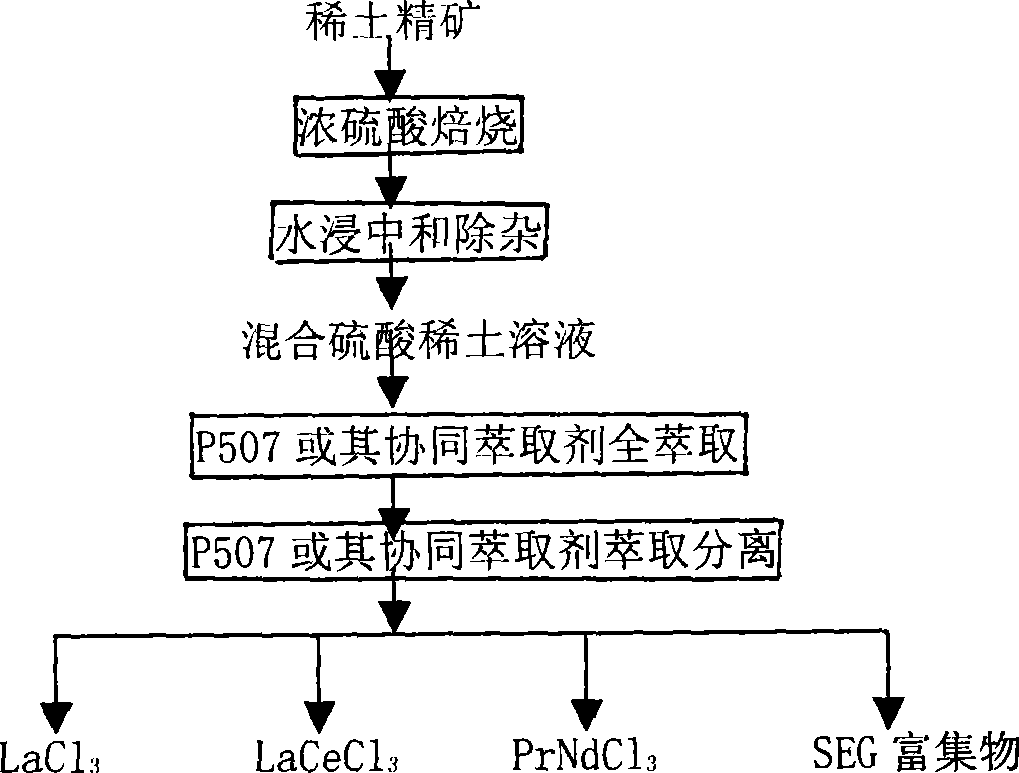

Process for solvent extraction separation purification of rare earth element

ActiveCN101319275AStripping is easyReduce acid and alkali consumptionProcess efficiency improvementRare-earth elementNitrate

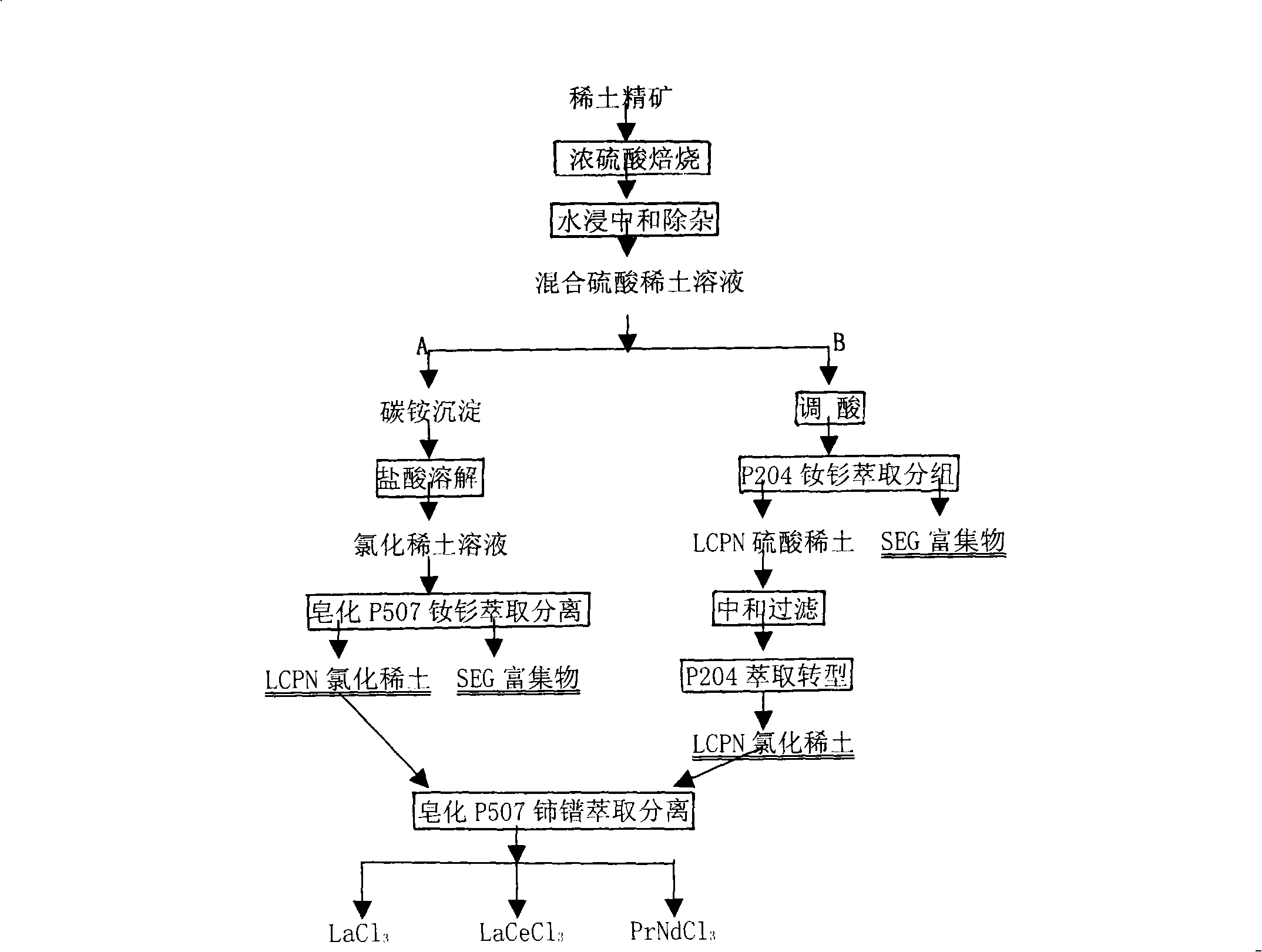

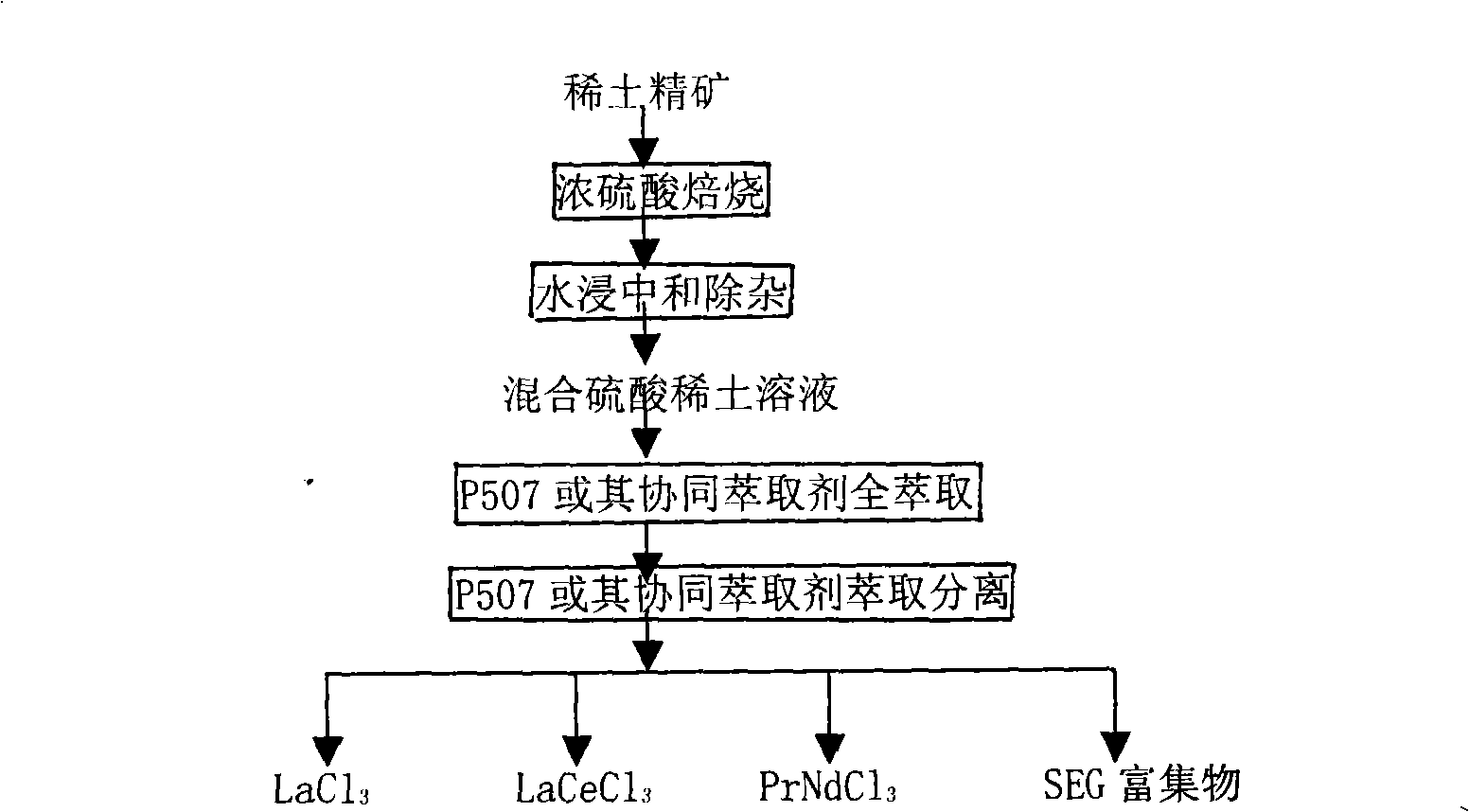

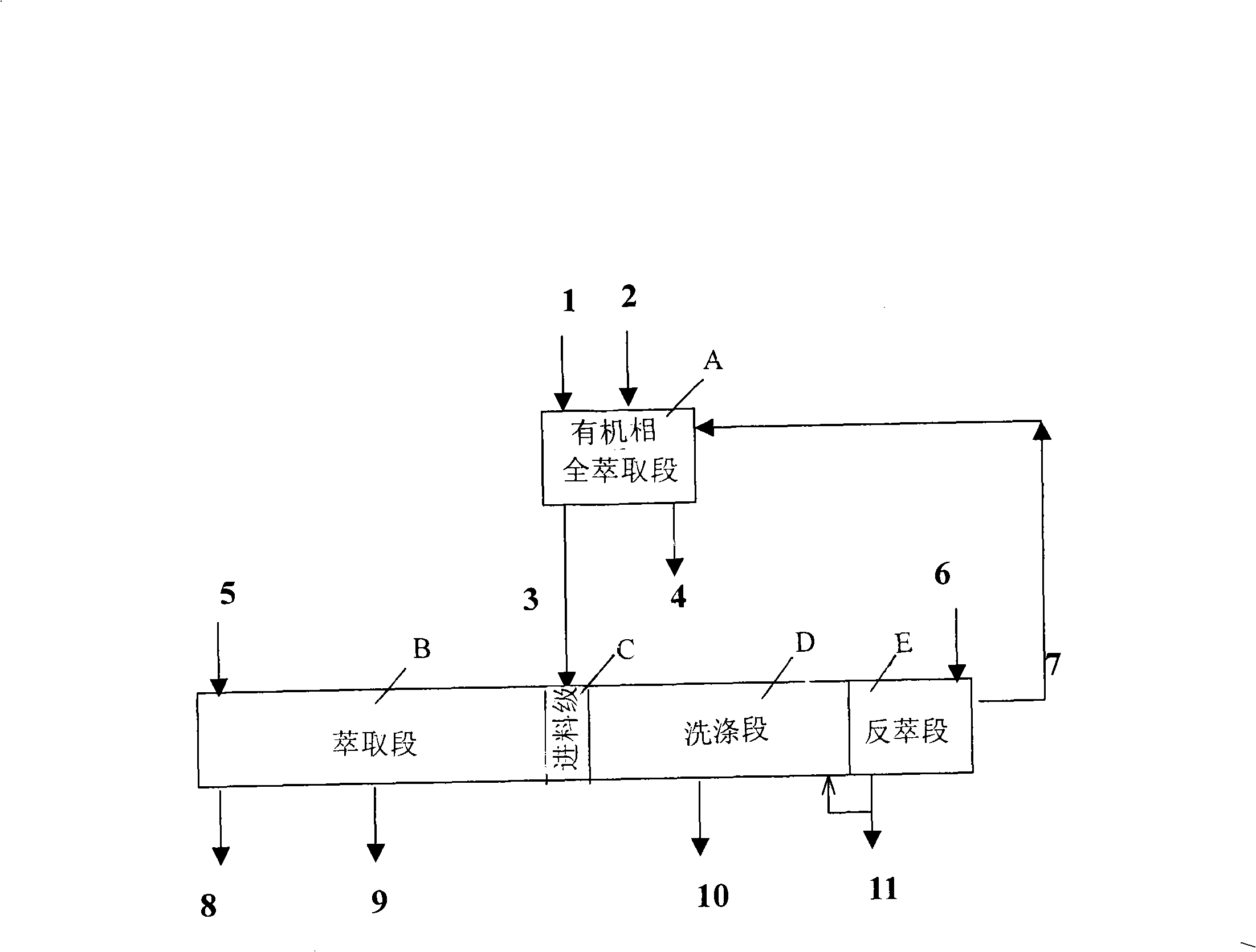

The invention provides a process method for separating and purifying rare earth elements by solvent extraction. The method takes a mixed rare earth sulfate solution obtained from a rare earth ore treated by sulphuric acid as a raw material, directly adopts a nonsaponifiable P507 extraction agent or a synergistic extraction agent containing the P507 to completely extract rare earth in a material liquid into an organic phase, and then takes the organic phase as a rare earth material liquid to extract, separate and purify the rare earth or directly backextract to produce mixed chlorinated rare earth or rare earth nitrate. The process method is simple and flexible, does not saponify the organic phase during the extraction and separation process, does not produce ammonia nitrogen waste water, is easy to backextract middle and heavy rare earths, and has less consumption of acid and base and low production cost.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Method for preparing acellular matrix

InactiveCN101274106AStrong decellularization specificityStrong specificityTissue regenerationProsthesisDiseasePhospholipase

The invention discloses a method of preparing acellular matrixes by using phospholipase. The method of the invention is characterized in that stand-by organ tissue is first pre-treated and then added into solution containing the phospholipase to prepare the acellular matrixes under a controlled condition; the prepared acellular matrixes are then washed. By adopting the preparation method of the invention, the obtained acellular matrix can have good physical property and biological function. Therefore, the preparation method in the invention is not only a great breakthrough in the tissue engineering, but also opens a new way for clinical treatment of diseases. The preparation method of the invention has the advantages of reliable theory, simple and flexible process technique, good product reproducibility and is very easy to be industrialized.

Owner:ZHONGSHAN OPHTHALMIC CENT SUN YAT SEN UNIV

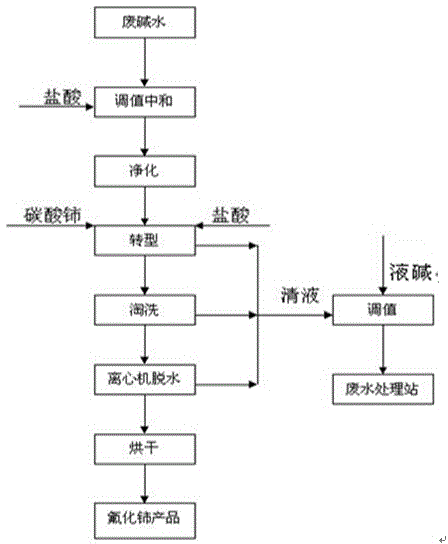

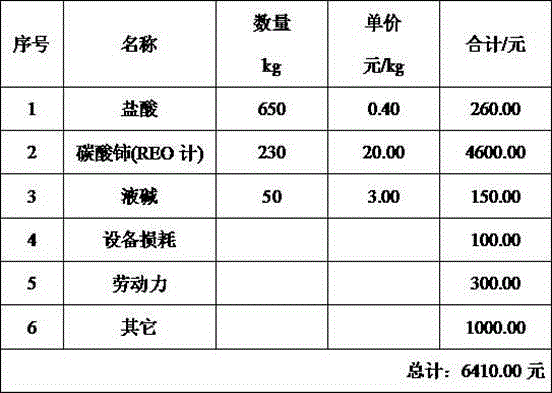

Method for fluorine removal of wastewater in bastnaesite hydrometallurgy

ActiveCN103979658AThe process is simple and flexibleEasy to operateWater contaminantsWaste water treatment from metallurgical processWastewaterHydrometallurgy

The invention relates to the field of bastnaesite hydrometallurgy, and in particular relates to a method for fluorine removal of wastewater in bastnaesite hydrometallurgy. A specific scheme comprises the following steps: A. regulating pH value of a fluorine-containing waste liquid to be acid through hydrochloric acid; B. adding cerium carbonate or lanthanum carbonate as well as hydrochloric acid to the waste liquid; C. adding a flocculant to the liquid obtained from reaction of the step B; and D. collecting a flocculating product. Through the method disclosed by the invention, chlorine in the wastewater is nearly completely turned into cerium fluoride; and therefore, the method not only reduces pollution but also facilitates operation.

Owner:SICHUAN PROVINCE LESHAN CITY RUIFENG METALLURGY CO LTD

Making method for flexible dye sensitized solar battery nano crystal thin film

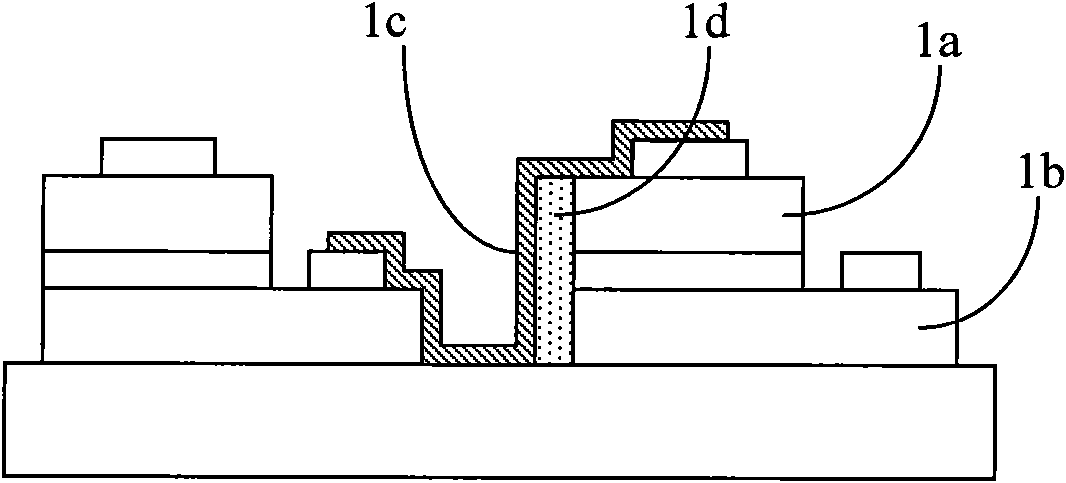

InactiveCN101127374AImprove battery efficiencyLow industrialization characteristicsLight-sensitive devicesElectrode manufacturing processesNanometreAirflow

The utility model belongs to field of solar battery, and relates to a manufacturing approach of flexible nanometer-crystalline film of dye sensitizing solar battery, which adopts nanostructured porous TiO2 powder as the material and forms the porous TiO2 film by depositing on a conducting substrate by vacuum deposition. The utility model is characterized in that a porous TiO2 film is made by vacuum cold coating, wherein the nanostructured porous TiO2 powder is accelerated by airflow and impacts on the substrate or the TiO2 coat at a high speed to speed up the combinations of the powder under the pressure of high speed impact at instantaneous high temperature rise; therefore the coat is combined well with the substrate and so are the grains in the coat. The film made by the above approach dose not need to go through high temperature process during manufacturing and after manufacturing, therefore is suitable for manufacture of flexible nanometer-crystalline film of dye sensitizing solar battery.

Owner:XI AN JIAOTONG UNIV

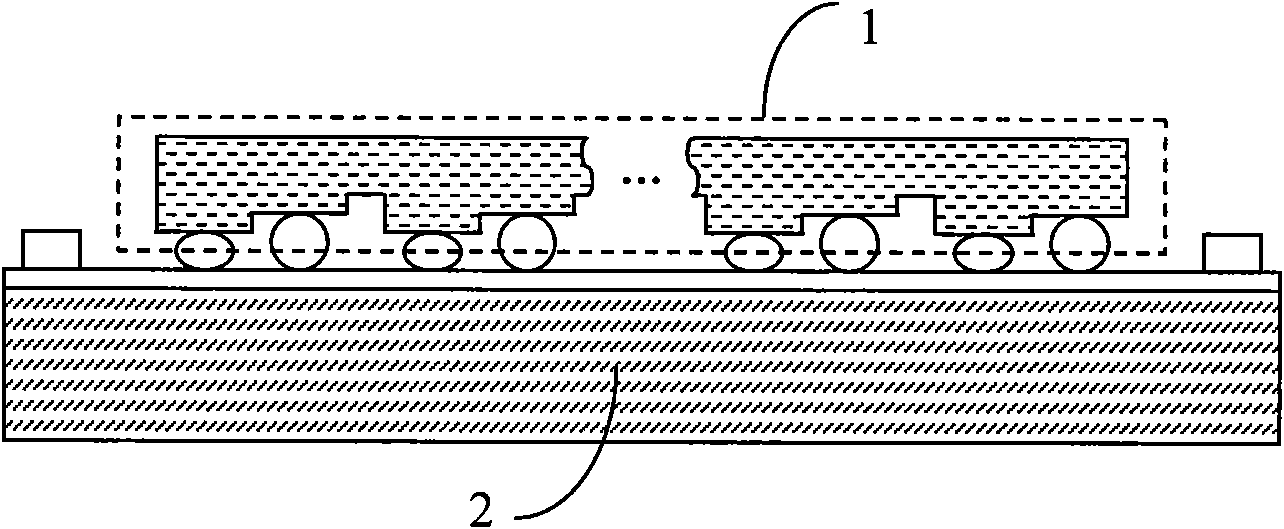

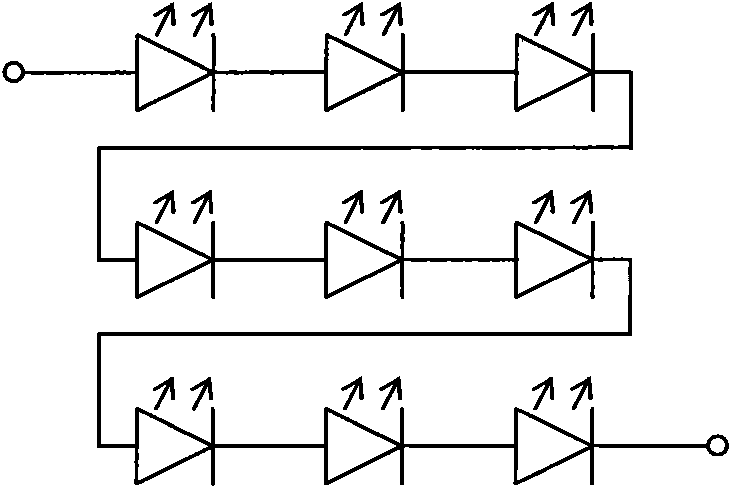

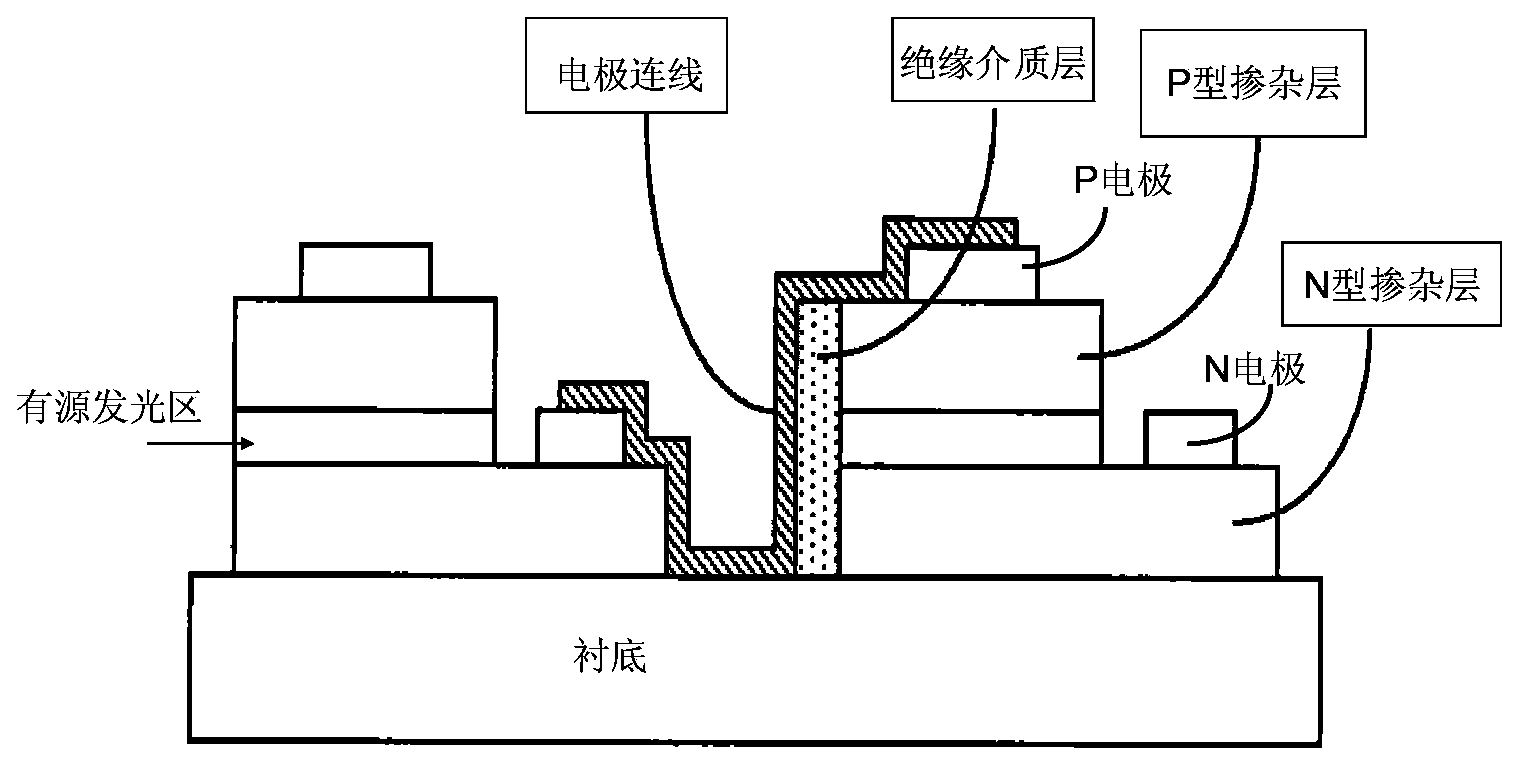

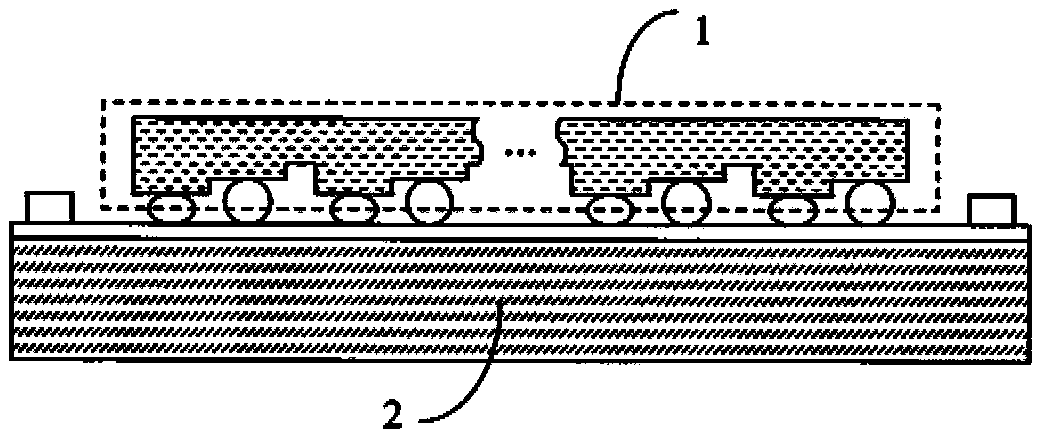

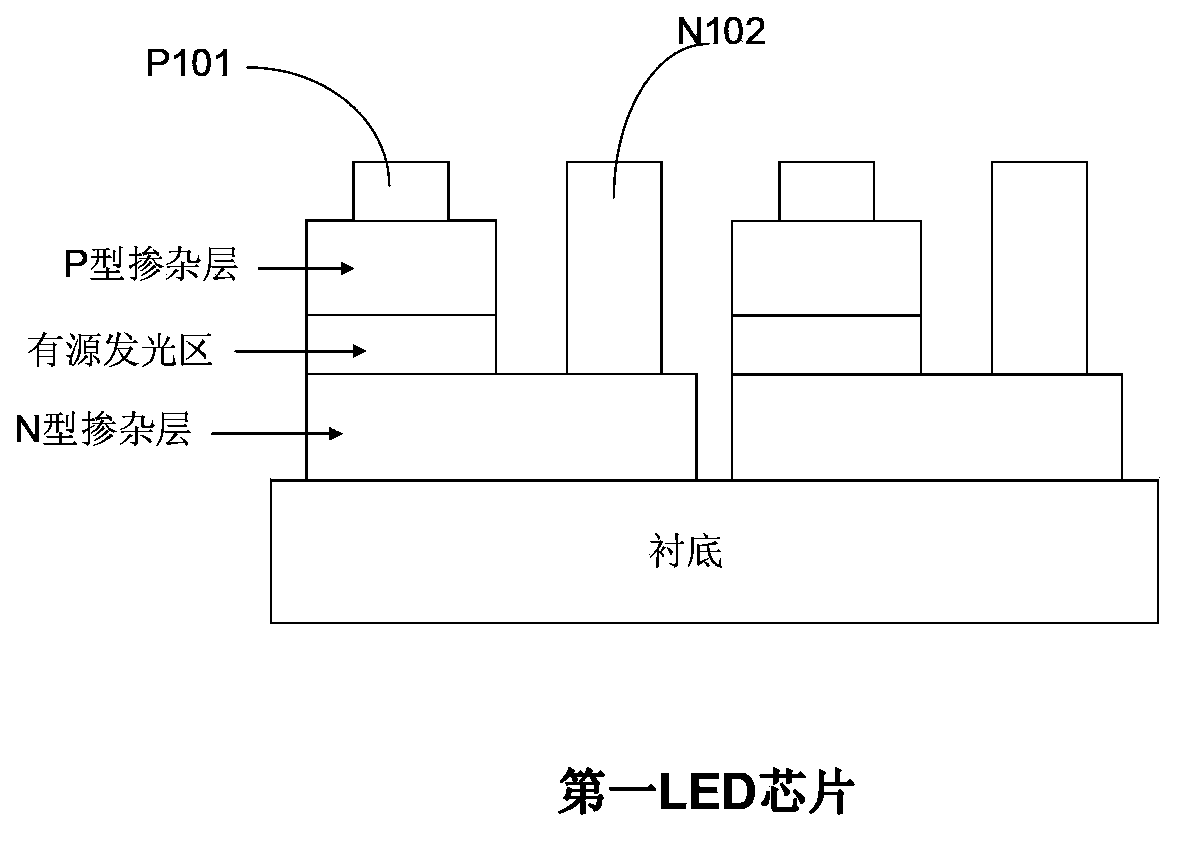

Luminescent device formed by inverted luminous cell array and manufacture method thereof

InactiveCN101982883AElimination of process difficultiesImprove production yieldSolid-state devicesSemiconductor devicesDevice formEngineering

The invention relates to a luminescent device formed by an inverted luminous cell array, which comprises an LED chip and a substrate. The LED chip is provided with a plurality of luminous cells which are insulated from each other, wherein each luminous cell is respectively provided with at least one of P poles and at least one of N poles. The upper surface of the substrate is provided with a metal wire layer. The LED chip is inverted on the substrate, the P poles and the N poles of each luminous cell on the LED chip are respectively and electrically connected with the metal wire layer on the substrate, and each luminous cell is connected with each other in series or in parallel by the metal wire layer. Compared with the prior art, the luminescent device replaces the metal wire on the LED chip with the metal wire layer on the substrate to realize that each luminous cell can be connected with each other in series or in parallel, thereby overcoming the technical difficulty that the wires among the luminous cells which are isolated from each other are hard to connect with each other in the normal technology. Furthermore, only by changing the design of the metal wire layer of the substrate, the luminescent device can realize the different designs such as the series connection, the parallel connection or the mixed connection, and is simple and flexible in technology relatively.

Owner:APT ELECTRONICS

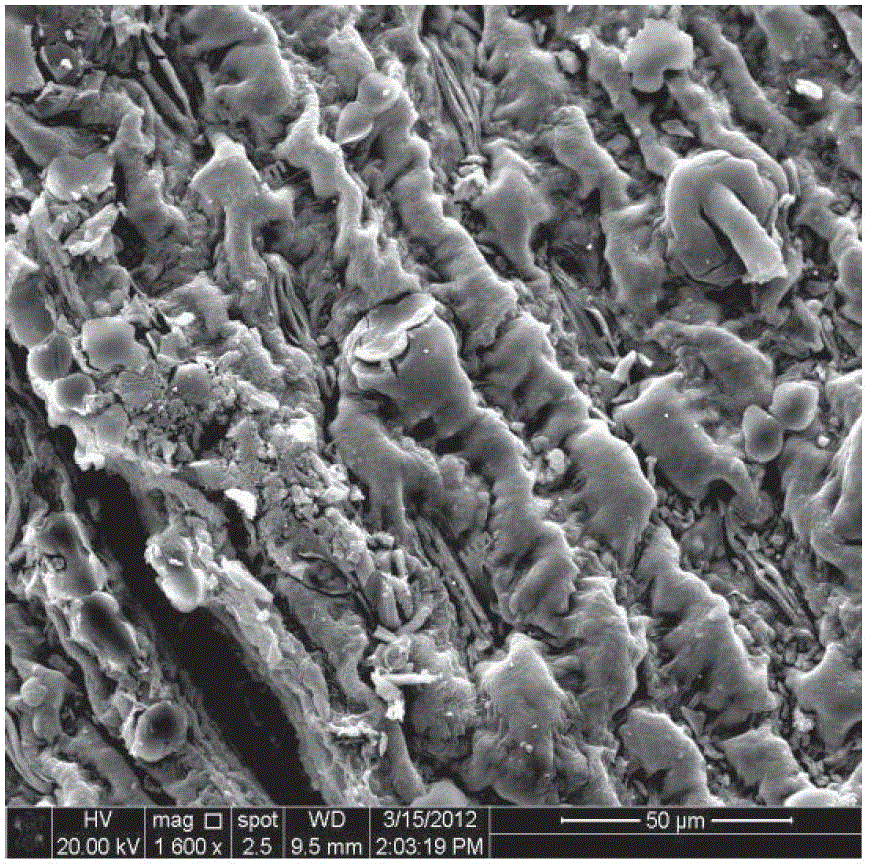

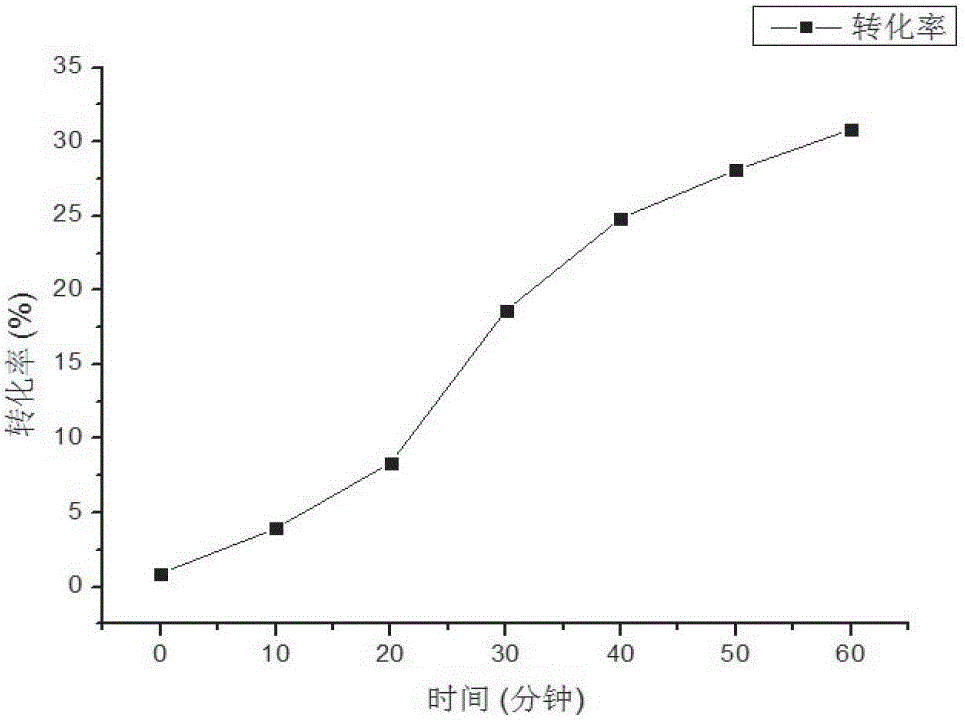

Method for preparing photocatalytic material with multi-component porous classification structure

InactiveCN102716740AImprove performanceThe process is simple and flexibleWater/sewage treatment by irradiationWater contaminantsElectrical conductorIntrinsics

The invention discloses a method for preparing a photocatalytic material with a multi-component porous classification structure. The method includes firstly, cleaning and treating surfaces of natural plant leaves, and soaking the natural plant leaves in metal precursor steeping liquor to obtain a metal oxide base material with a nanometer structure via hydrolysis and calcination; and secondly, steeping, drying and calcining the base material in precious metal precursor liquor to obtain the composite material with the multi-component porous classification structure. The invention further relates to photocatalytic composite material with the multi-component porous classification and application of the photocatalytic composite material. The method is simple and flexible in process and low in cost, precious metal is doped into the metal oxide intrinsic conductor nanometer material with the porous classification structure so as to obtain the photocatalyst material with excellent performances, and the photocatalyst material can effectively catalytically decompose organic pollutant in visible light.

Owner:SHANGHAI JIAO TONG UNIV

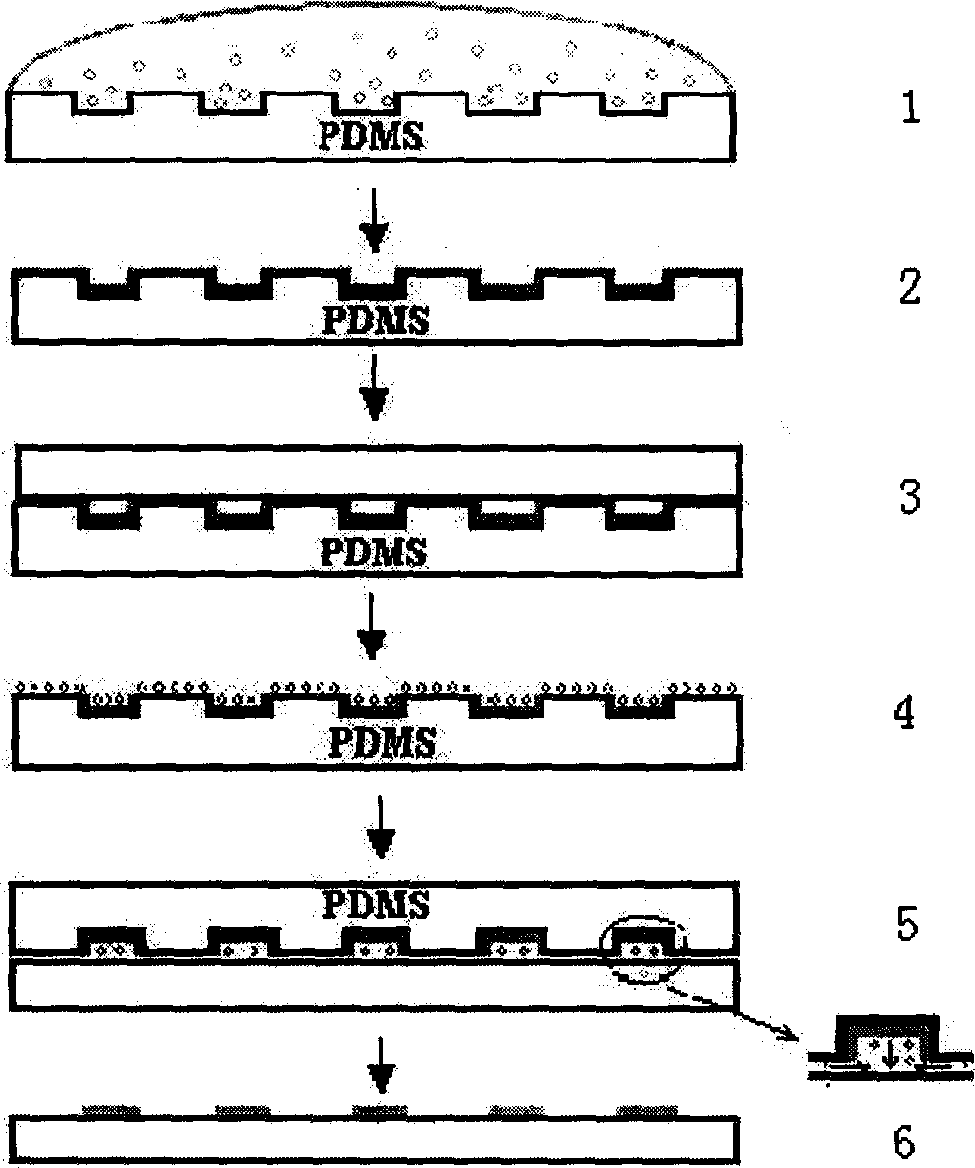

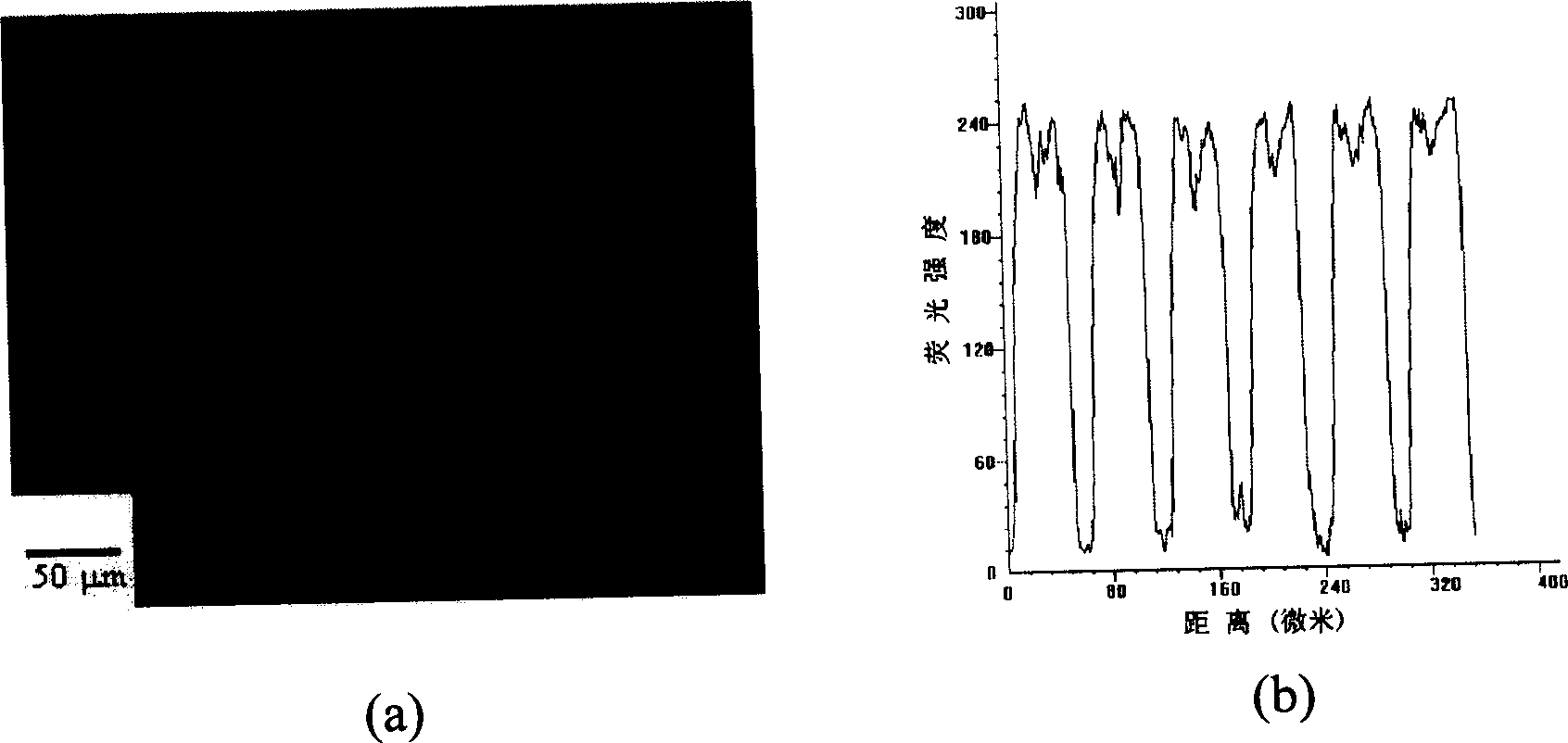

Method for fixing biological macro molecule pattern on polymer active surface by micro transfer technology

InactiveCN1425958AIncrease contrastImprove smoothnessCylinder pressesMicrobiological testing/measurementSurface patternChemical reaction

The microwave transfer process of fixing biological macromolecule pattern to the active surface of polymer includes selectively "mounting" biological macromolecule to the micro wells of polydimethyl siloxane stamp; forming one condensated water layer on the surface; dissolving biological macromolecule in water of the micro well and of transverse diffused area and producing chemical reaction in solution; and fixing biological macromolecule in pattern on the active surface of the polymer. The process is simple, flexible and repeatable, and the micro pattern has high contrast and fastness. The cheap process of fixing biological macromolecule in pattern is especially suitable for the less reaction activity biological moecule / active surface system. The present invention has excellent application foreground in constructing biological device, tissue engineering, cell biological research, etc. based on cells.

Owner:ZHEJIANG UNIV

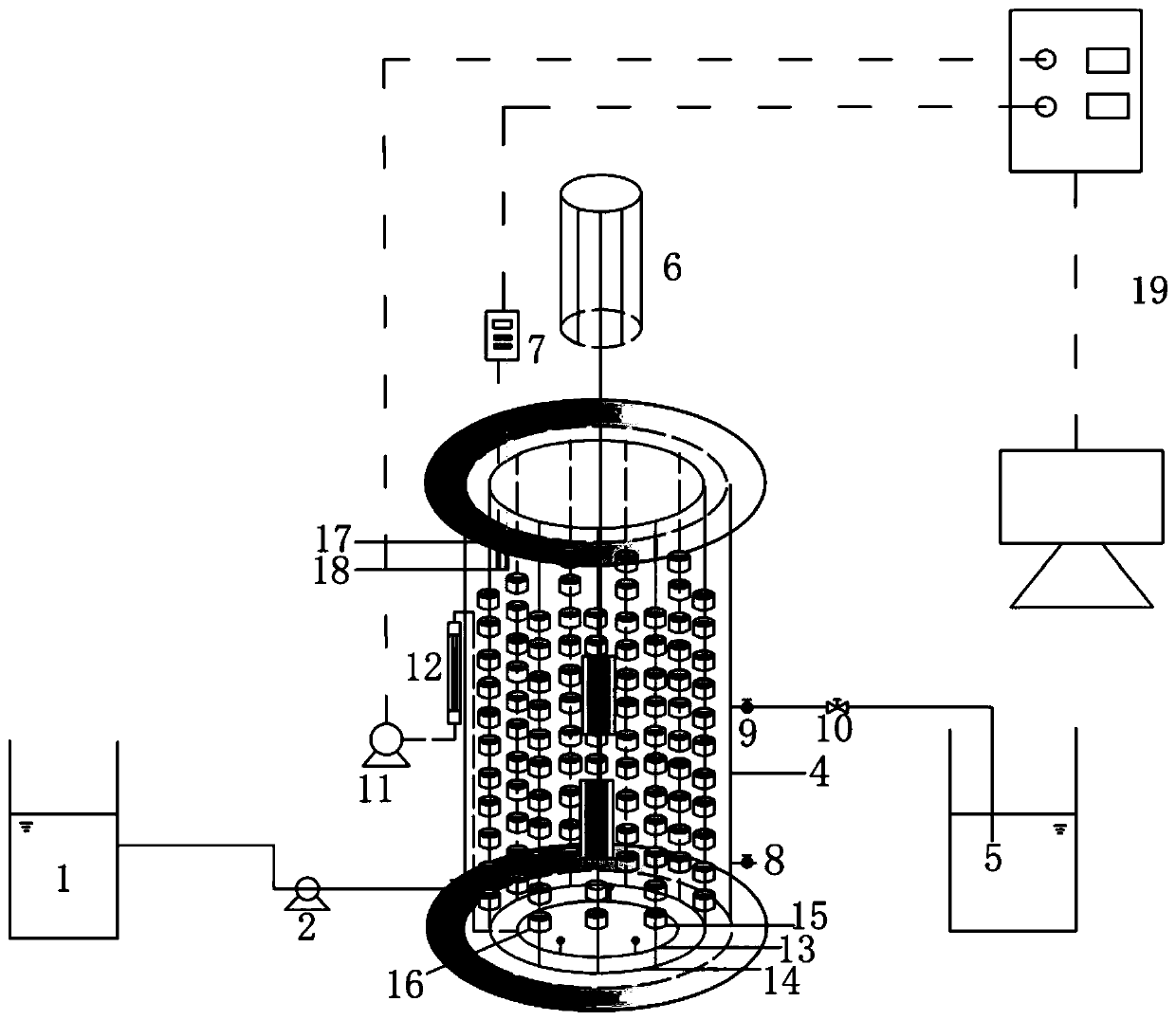

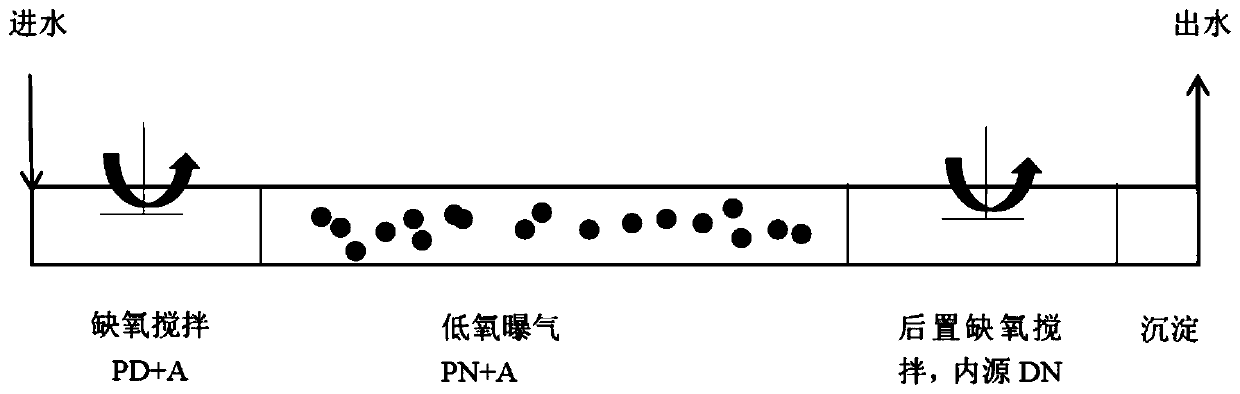

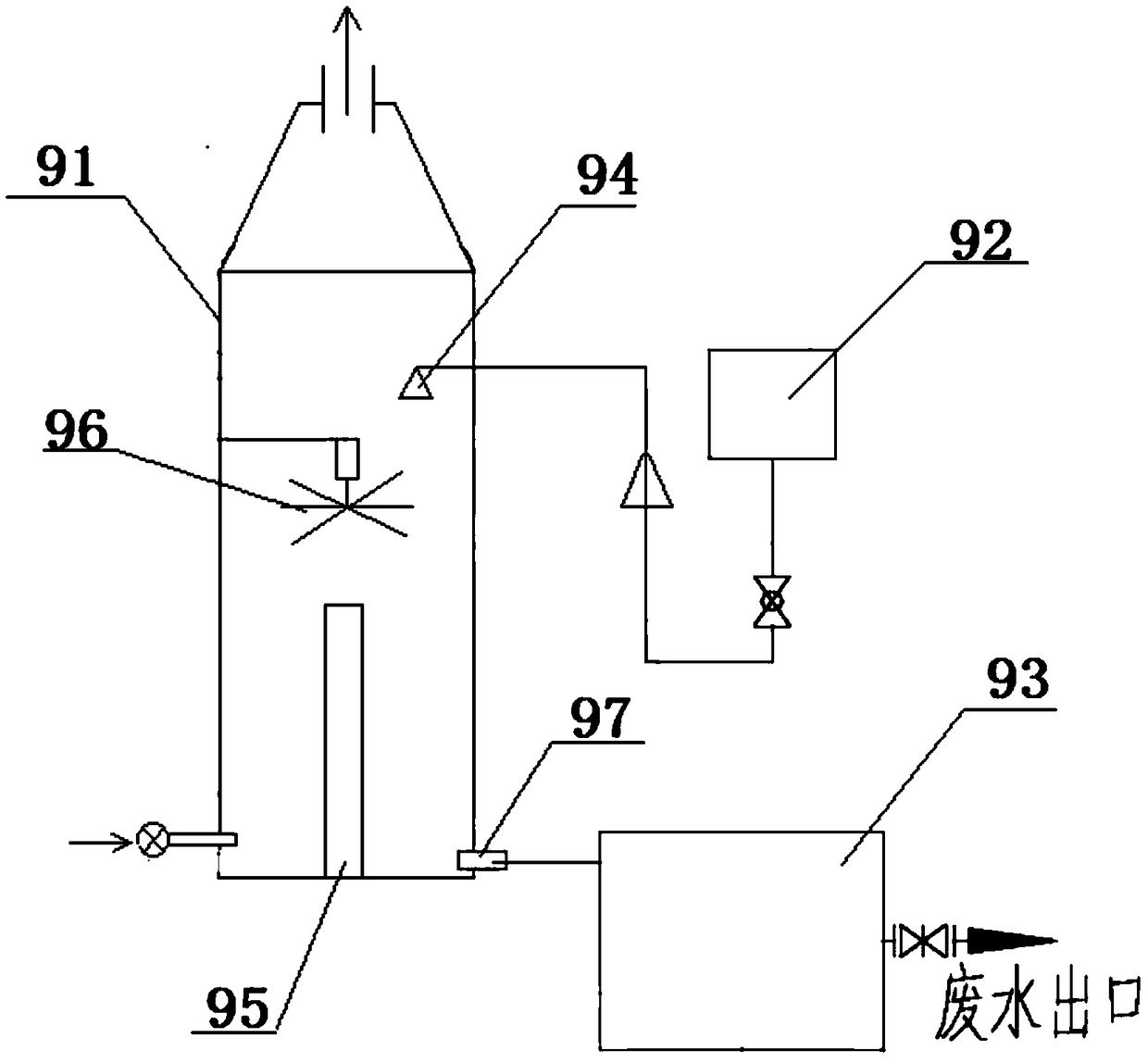

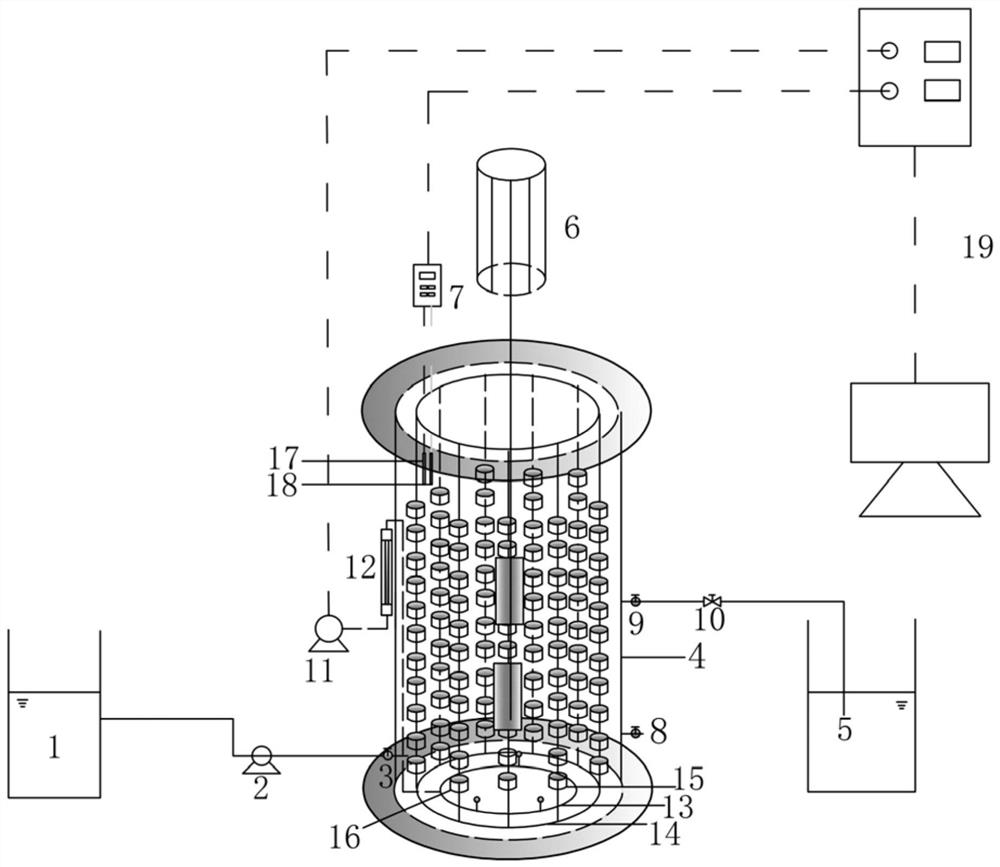

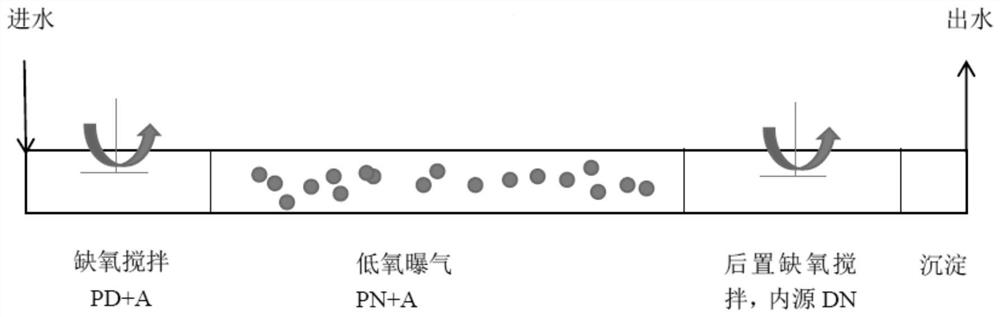

Device and method using integrated synchronous shortcut nitrification anammox coupling with shortcut denitrification to treat low-carbon-nitrogen-ratio city domestic sewage

ActiveCN110054294AMonitor Dissolved Oxygen ConcentrationPrevent over-aerationWater treatment parameter controlWater contaminantsWater dischargeLow oxygen

The invention relates to a device and method using integrated synchronous shortcut nitrification anammox coupling with shortcut denitrification to treat low-carbon-nitrogen-ratio city domestic sewageand belongs to the technical field of biological sewage treatment. The device comprises a raw city sewage tank, an SBR reactor, a blast aerator and a water discharge tank. At the beginning of reaction, the domestic sewage enters the SBR reactor, denitrifying bacteria use the carbon source in the domestic sewage to perform shortcut denitrification on residual NO3<-> of the previous cycle, the generated NO2<->-N and NH4<+>-N are synchronously removed through an anammox effect, residual organic matter is stored in the bodies of the denitrifying bacteria to synthesize PHA, low-oxygen aeration is performed after the reaction, integrated anammox reaction is performed on a biological membrane to remove NH4<+>-N and generate NO3<->-N, then stirring is performed, and the denitrifying bacteria use the PHA stored in the bodies to perform endogenous denitrification. The device and method has the advantages that NO2<-> accumulation is achieved in the form of shortcut nitrification and shortcut denitrification, N and COD of city sewage can be removed efficiently, the organic matter in the domestic sewage is sufficiently utilized, an external carbon source is not needed, aeration energy consumption is reduced, and deep denitrification is achieved.

Owner:BEIJING UNIV OF TECH

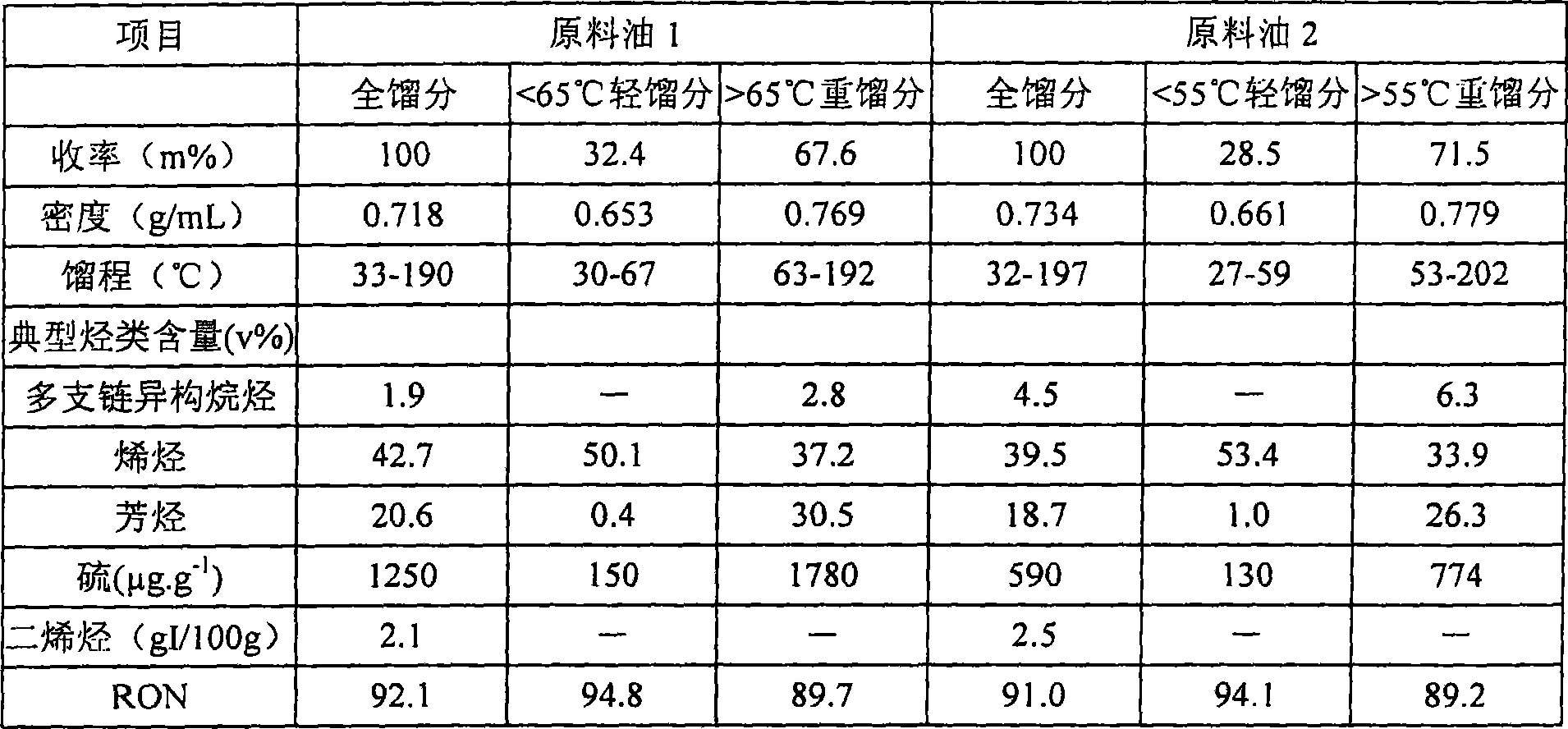

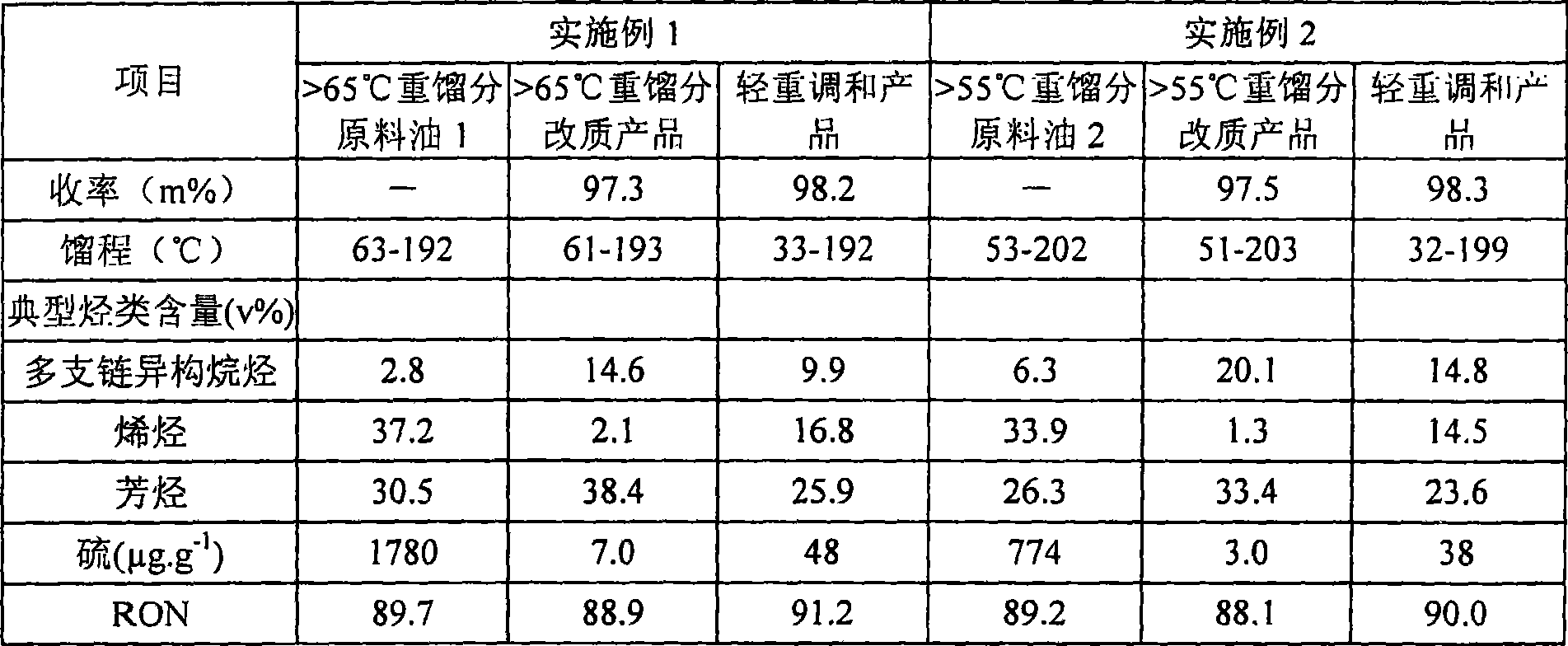

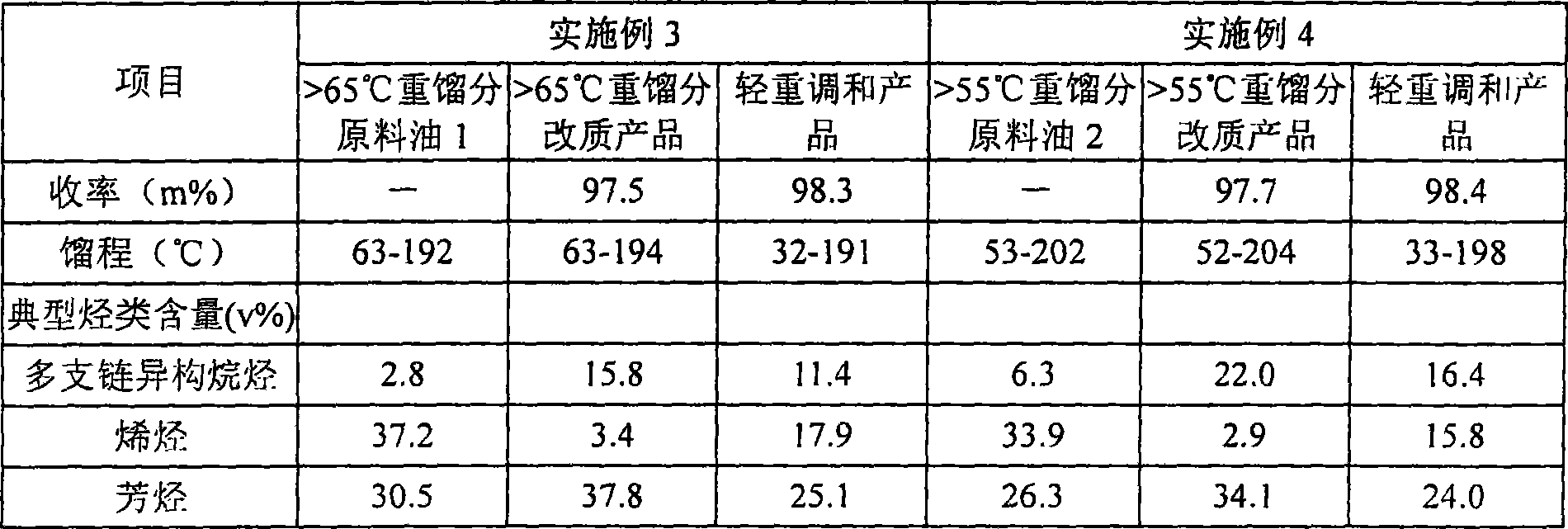

Hydrogenation modification method for faulty gasoline

ActiveCN101508911AAffect the service lifeSolve the problem of difficult removal of sterically hindered sulfidesTreatment with hydrotreatment processesHydrodesulfurizationSulfur

The invention relates to a hydro-upgrading method of poor gasoline. The invention provides a hydro-upgrading method of ultra-deep desulfurization and octane number preservation of poor gasoline, including the followings: poor full range gasoline is divided into light range gasoline and heavy range gasoline; the weight range gasoline is contacted with selective hydrobon catalyst in the first-stage reaction zone so that the reaction effluent in the second-stage reaction zone is contacted with desulfuration-hydrocarbon multibranched hydroisomeric catalyst and the reaction effluent in the third-stage reaction zone is contacted with supplementary desulfuration-hydrocarbon monobranched isomeric / aromatizing catalyst; and then the reaction effluent and the light range gasoline are mixed according to a proportion so as to obtain ultra clean gasoline product. The hydro-upgrading method is applied to hydro-upgrading for poor gasoline, particularly for ultra-high-sulfur and high-olefin poor catalytically cracked gasoline, can maintain or improve the product octane number and keep higher product liquid yield while greatly reducing the contents of olefin and sulfur, and can produce ultra clean gasoline of national IV or even higher standard.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

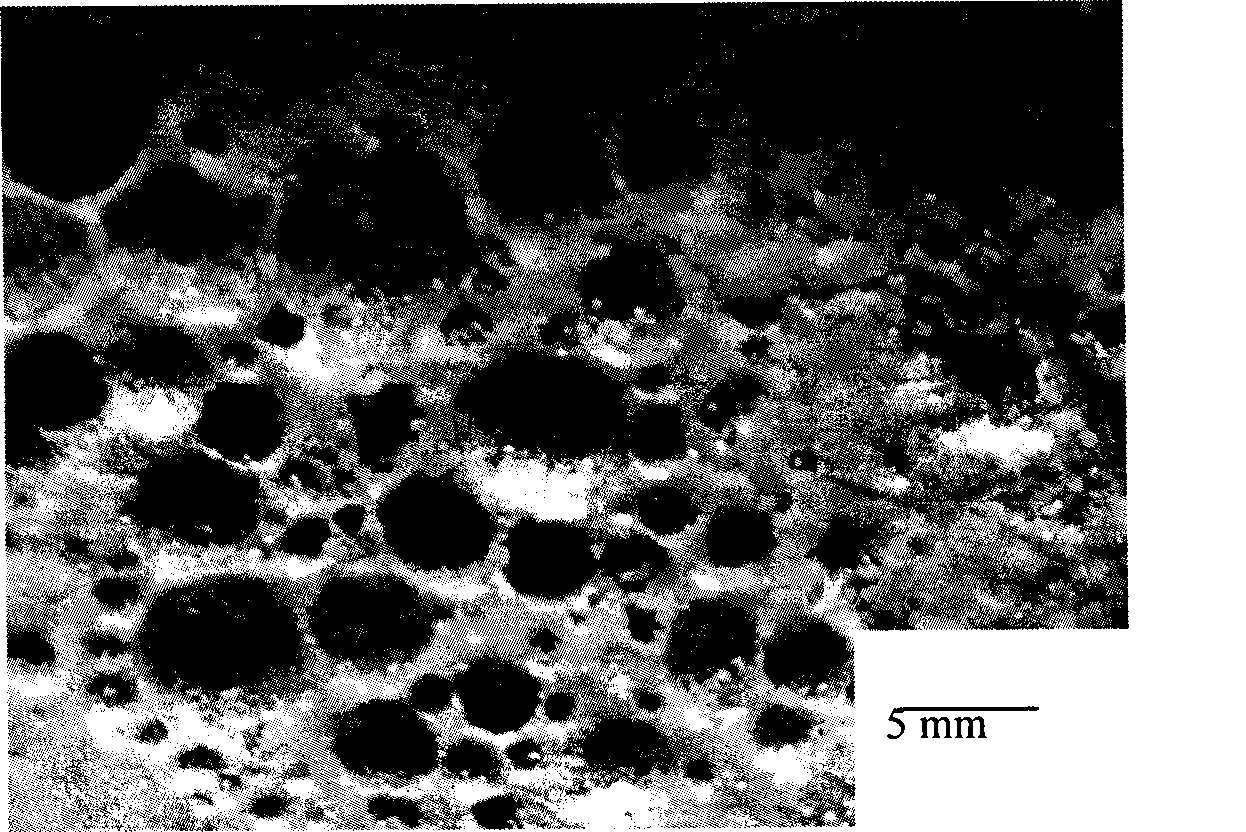

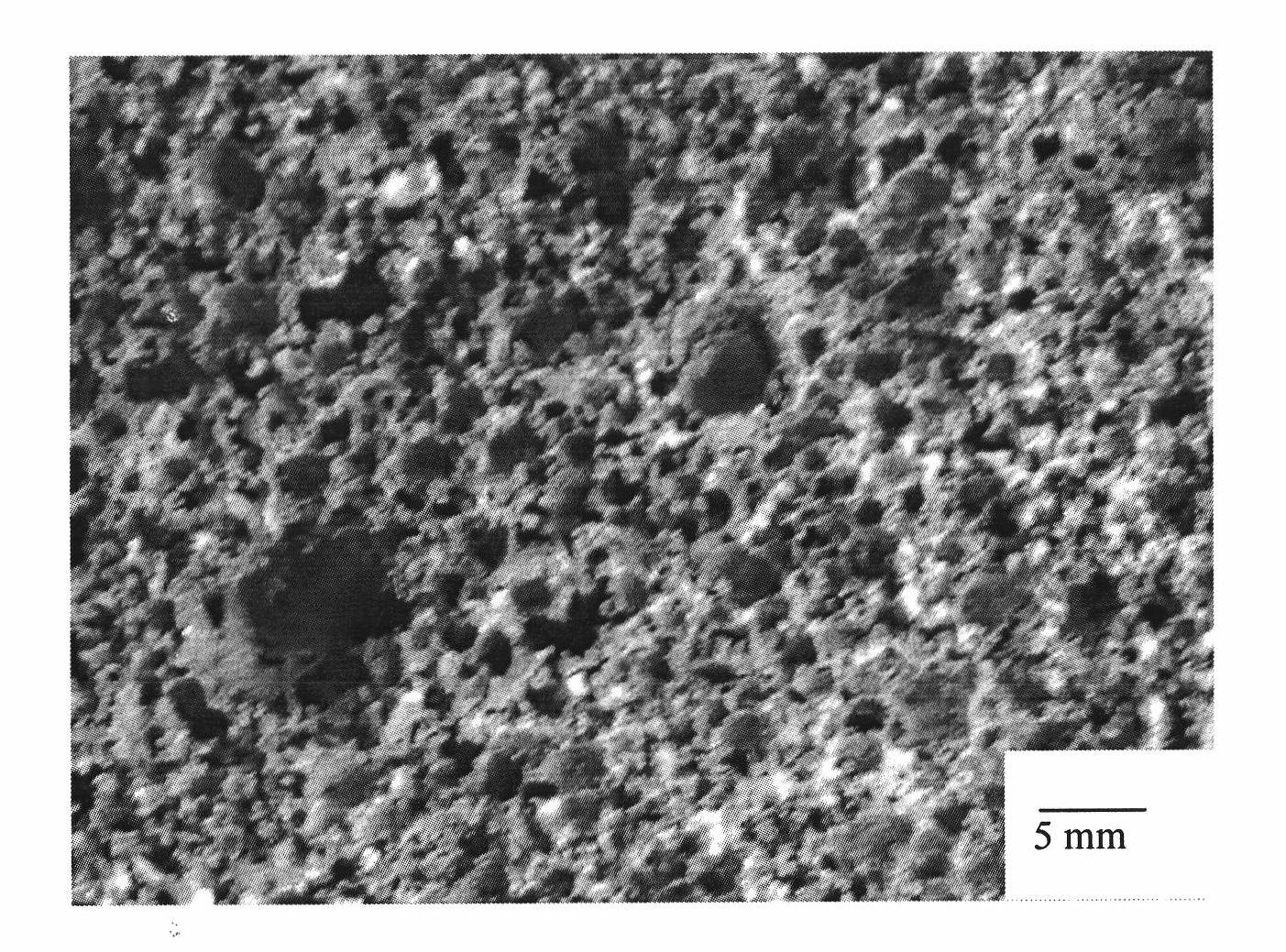

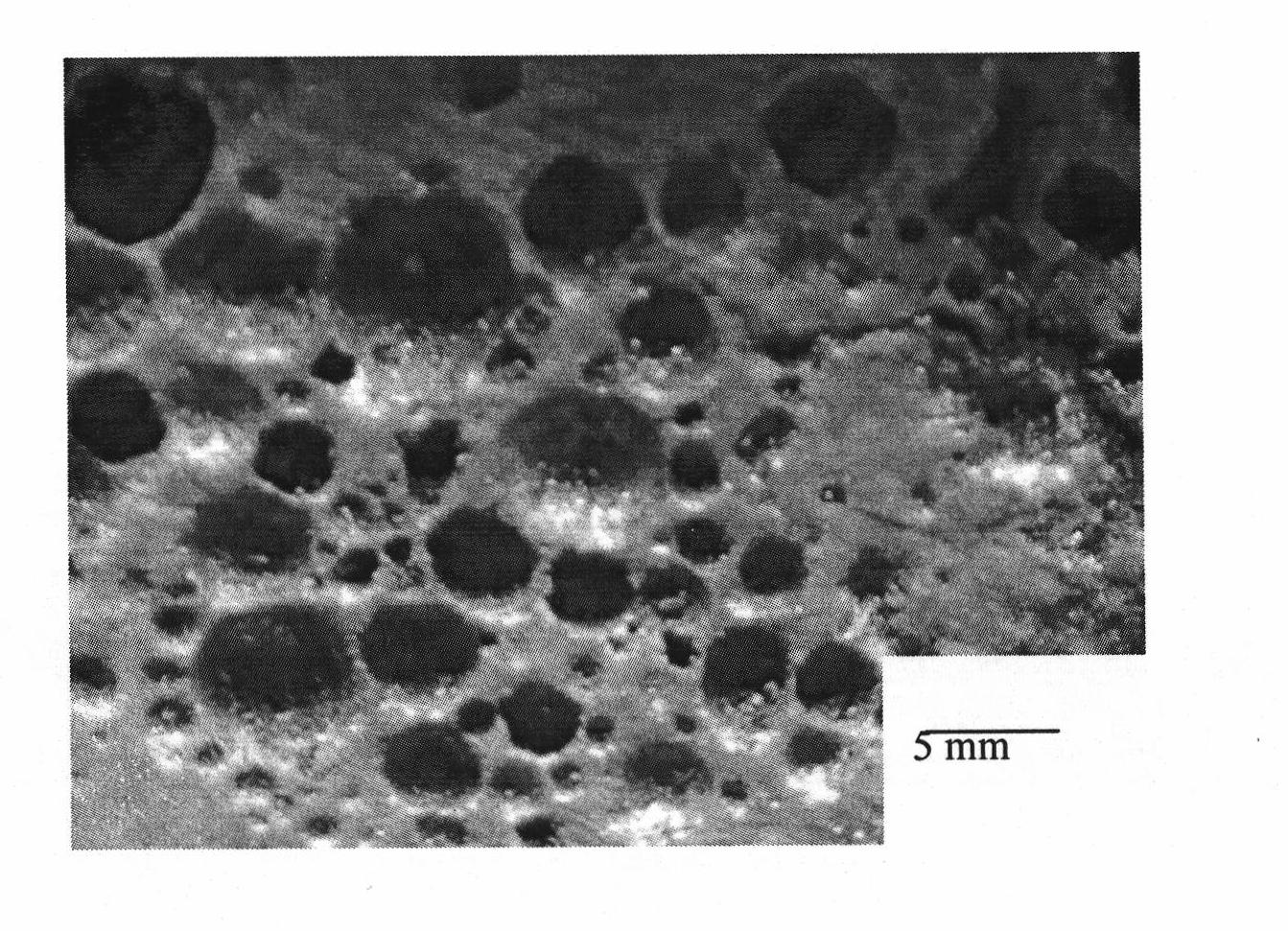

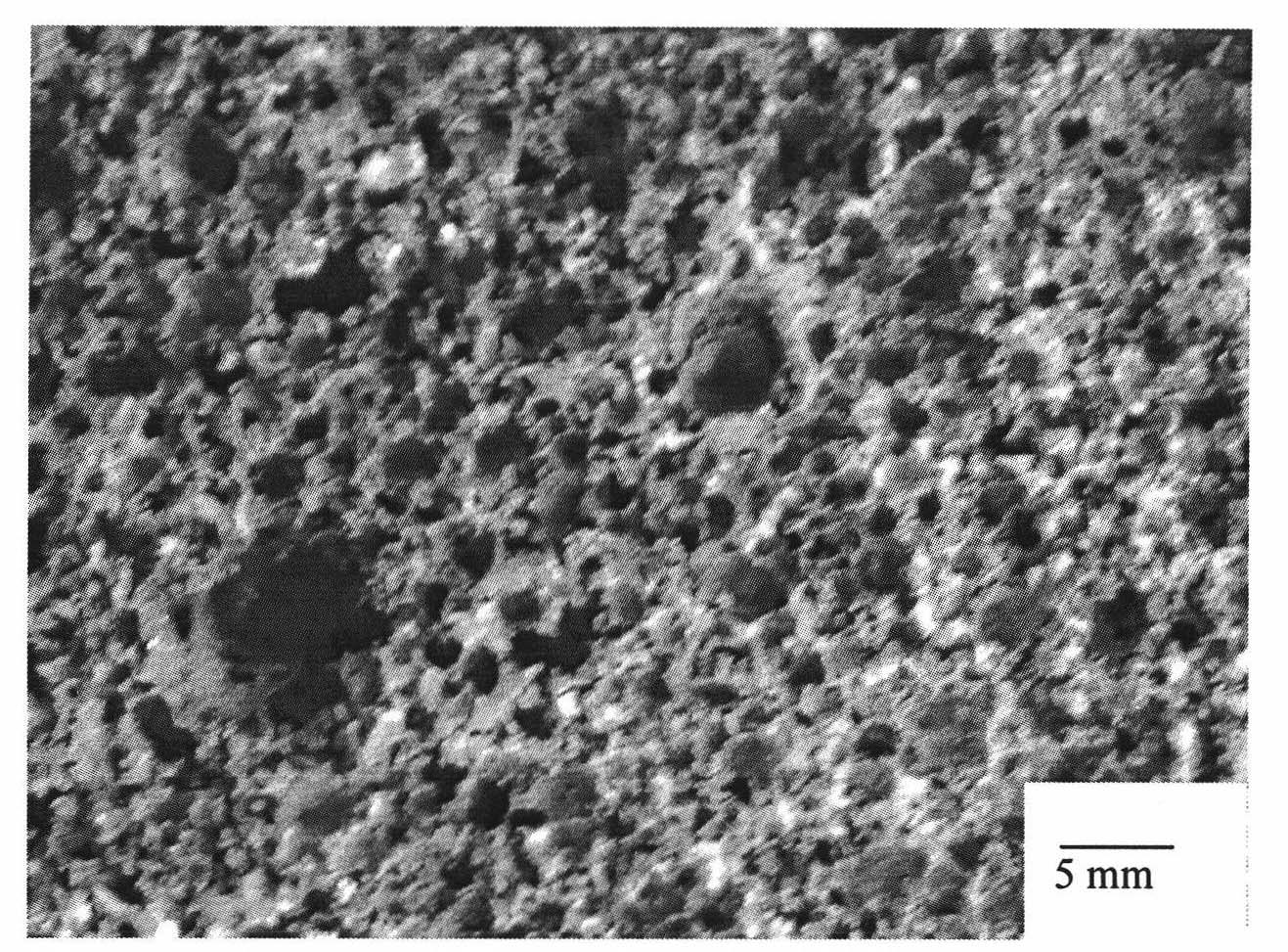

Preparation of foam magnesium alloy

The invention discloses a foam magnesium alloy preparing method, belonging to the field of the production of an alloy with open or closed pores. The method is particularly a method for preparing a magnesium alloy by means of foaming a powder entity and comprises the following steps: firstly, mixing 150-270-mesh pure magnesium powder and 250-400-mesh pure aluminum powder according to a mass ratio (pure magnesium powder : pure aluminum powder) ranging from 4:1 to 9:1 so as to obtain a metal powder mixture, uniformly mixing the metal powder mixture with 200-325-mesh TiH2 powder vesicant which accounts for 1.0-2.5 percent of the mass of the metal powder mixture, carrying out cold pressing and hot pressing on the mixture obtained from the previous step, and then obtaining a magnesium alloy foaming precast block; and then, under the protection of argon, preparing the foam magnesium alloy with an average aperture ranging from 1 mm to 5 mm by means of heating the foaming precast block in a mould. The method has the advantages of simple and flexible process, short period, high productive rate and no impurity; and the foam magnesium alloy prepared according to the method has a closed-pore structure and the advantages of high porosity, uniform pore structure distribution, regular pore shapes, wide application scope and good comprehensive performance.

Owner:HEBEI UNIV OF TECH

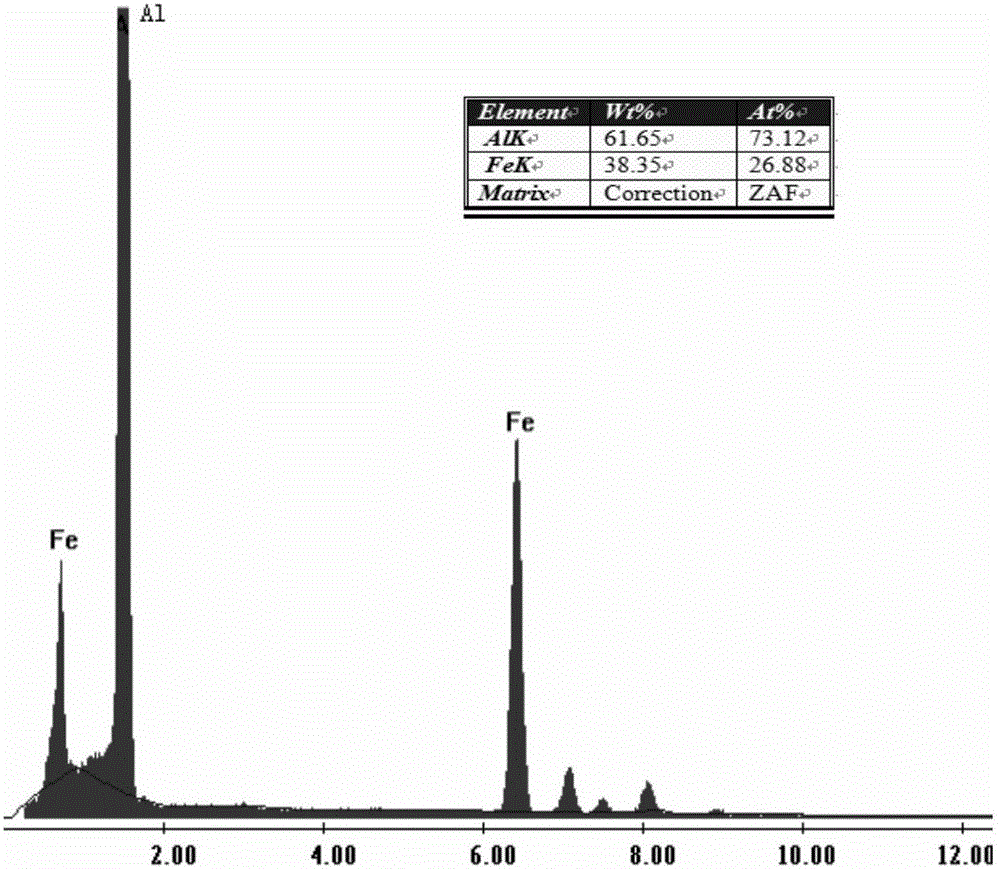

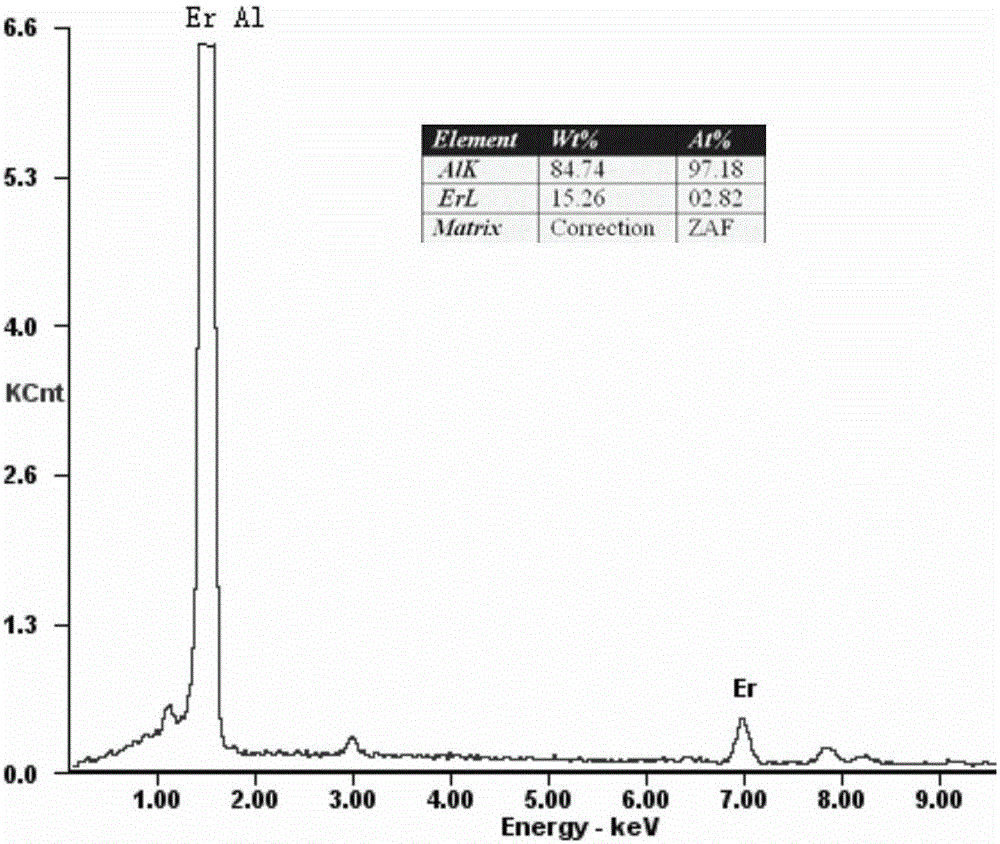

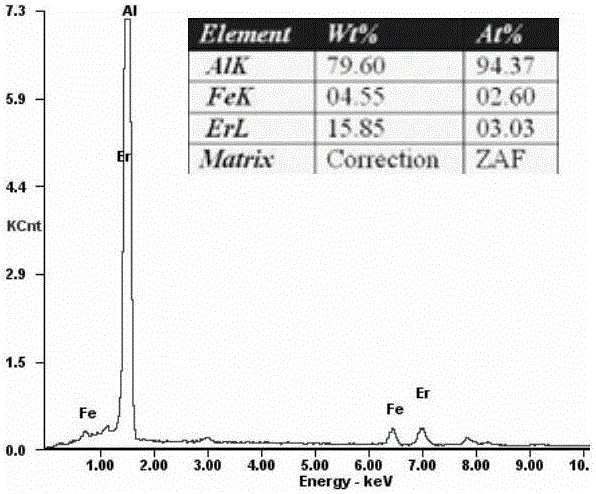

Light high-conductivity and heat-resistant aluminum conductor and preparation method thereof

ActiveCN105734353AImprove conductivityOo fullConductive materialMetal/alloy conductorsElectricityHeat resistance

The invention discloses a light high-conductivity and heat-resistant aluminum conductor and a preparation method thereof. The aluminum conductor is composed of, by weight, 0.035-0.06% of B, 0.1-0.2% of Zr, 0.1-0.3% of Er, inevitable impurities and the balance Al. The technological process comprises the steps of smelting, on-the-spot fast component analyzing, refining, rapid cooling casting, blank annealing, extruding and drawing. The added B element has the refining and modifying effects and mainly has the effect of promoting supersaturated solid solutions containing Zr and Er to separate out Al3(Er and Zr) ternary composite phases; the Al3(Er and Zr) composite phases are nano particles which are coherent with a matrix and have shell-core structures, are dispersed in the aluminum matrix and can greatly improve the electricity conductivity and the heat resistance of the aluminum conductor; the density of obtained monofilaments is smaller than or equal to 2.71 g / cm<3>, the electricity conductivity of the monofilaments is greater than or equal to 62%IACS, the short-time heat-resistance temperature of the monofilaments reaches 230 DEG C, the long-term heat-resistance temperature of the monofilaments reaches 210 DEG C, and the tensile strength of the monofilaments is greater than or equal to 165 MPa; the economic benefits are remarkable, the energy is greatly saved, and the environmental friendliness is high.

Owner:CENT SOUTH UNIV

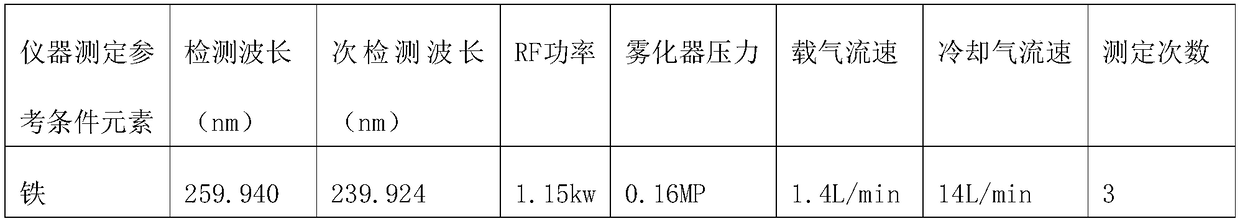

Determination method for magnets in iron ore

The invention discloses a determination method for magnets in iron ore. The method comprises steps as follows: firstly, after magnetic iron ore is crushed, manual repeated magnetic separation is performed, moisture of samples obtained after separation is evaporated to dryness, magnetic iron is enabled to be separated from iron and other impurities, magnets obtained after separation are dissolved by hydrochloric acid, a solution is prepared, the iron element of the solution enters an atomizing system of an inductively coupled plasma emission spectrometer in a form of aerosol, a target substanceis gasified and ionized in a plasma torch, a characteristic spectral line is radiated under excitation, concentration of iron in the solution is calculated according to the Lambert-Beer law, and magnet content of the ore is calculated. The method has no special requirement for nature and composition of the ore, and magnetite, hematite, specularite, limonite, siderite and common metallic ore are all suitable for the method. The method further has the advantages of high analysis speed, low cost, high efficiency, simple and flexible technological process, low energy consumption and the like, andthe application prospect is quite broad.

Owner:青海省核工业地质局核地质研究所 +1

Method for preparing composite electrode material, composite electrode material and battery

ActiveCN104425803AThe process is simple and flexibleLow costCell electrodesSecondary cellsIonDispersed media

The invention discloses a method for preparing a composite electrode material. The method comprises the following steps: activating hair, dispersing the hair in a dispersing medium, and adding a metal source solution for soaking so as to adsorb metal ions; and calcining the hair in an oxygen-containing atmosphere or an inert atmosphere, thereby obtaining the composite electrode material containing metal oxides or metal sulfides. The invention also discloses a composite electrode material prepared by the preparation method and a battery containing the composite electrode material. According to the method disclosed by the invention, the process is simple and flexible, and complicated and accurate process control is not needed. According to the method disclosed by the invention, the hair serves as a biological template, the hair resources are rich and readily available, hair residues and other wastes can be effectively utilized, wastes are changed into valuable materials, and the cost is low. According to the method disclosed by the invention, lots of chemical reagents are not needed, the method is environment-friendly, and sustainable development of the environment is promoted.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD +1

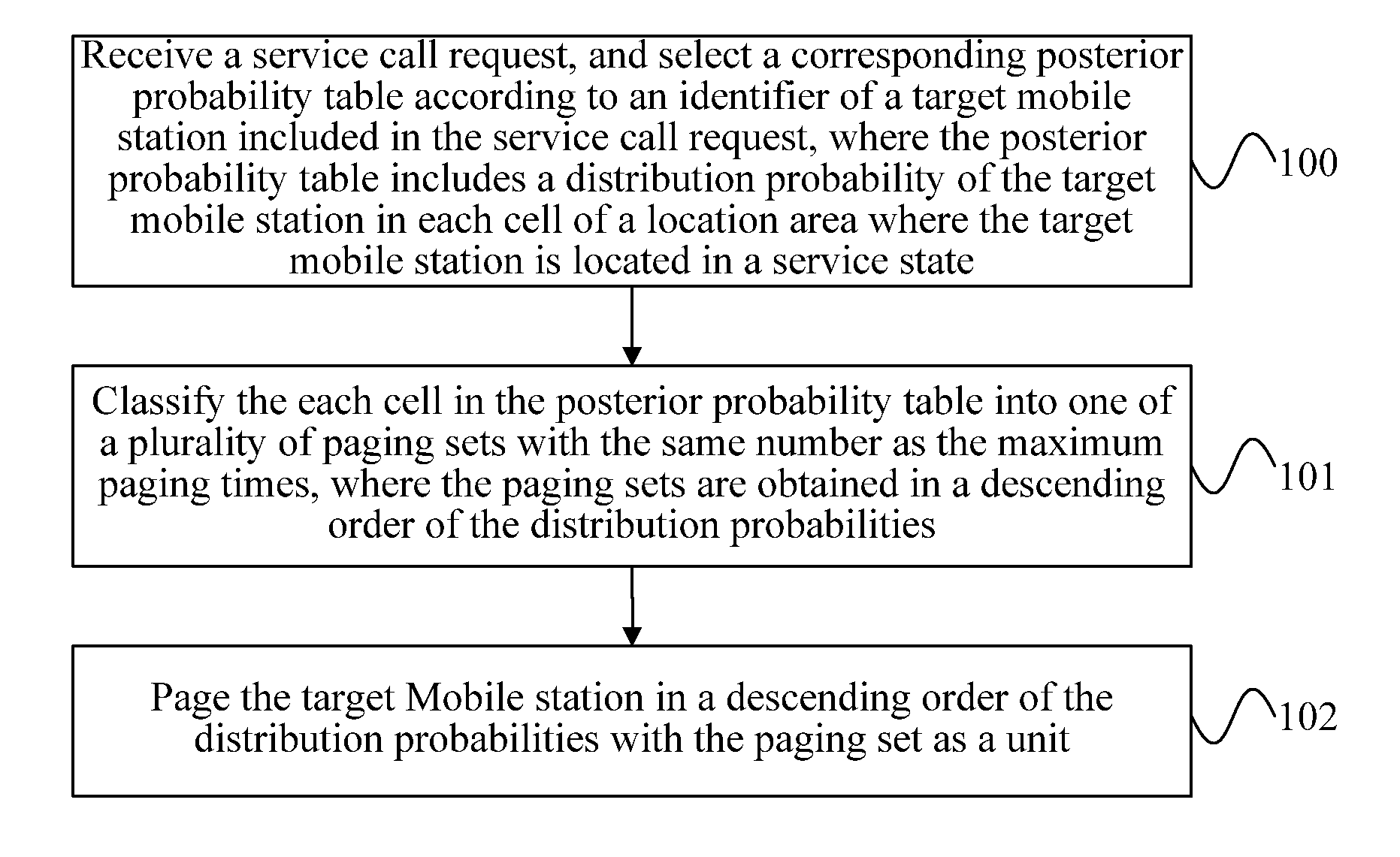

Mobile Station Paging Method and Mobile Call Center Device

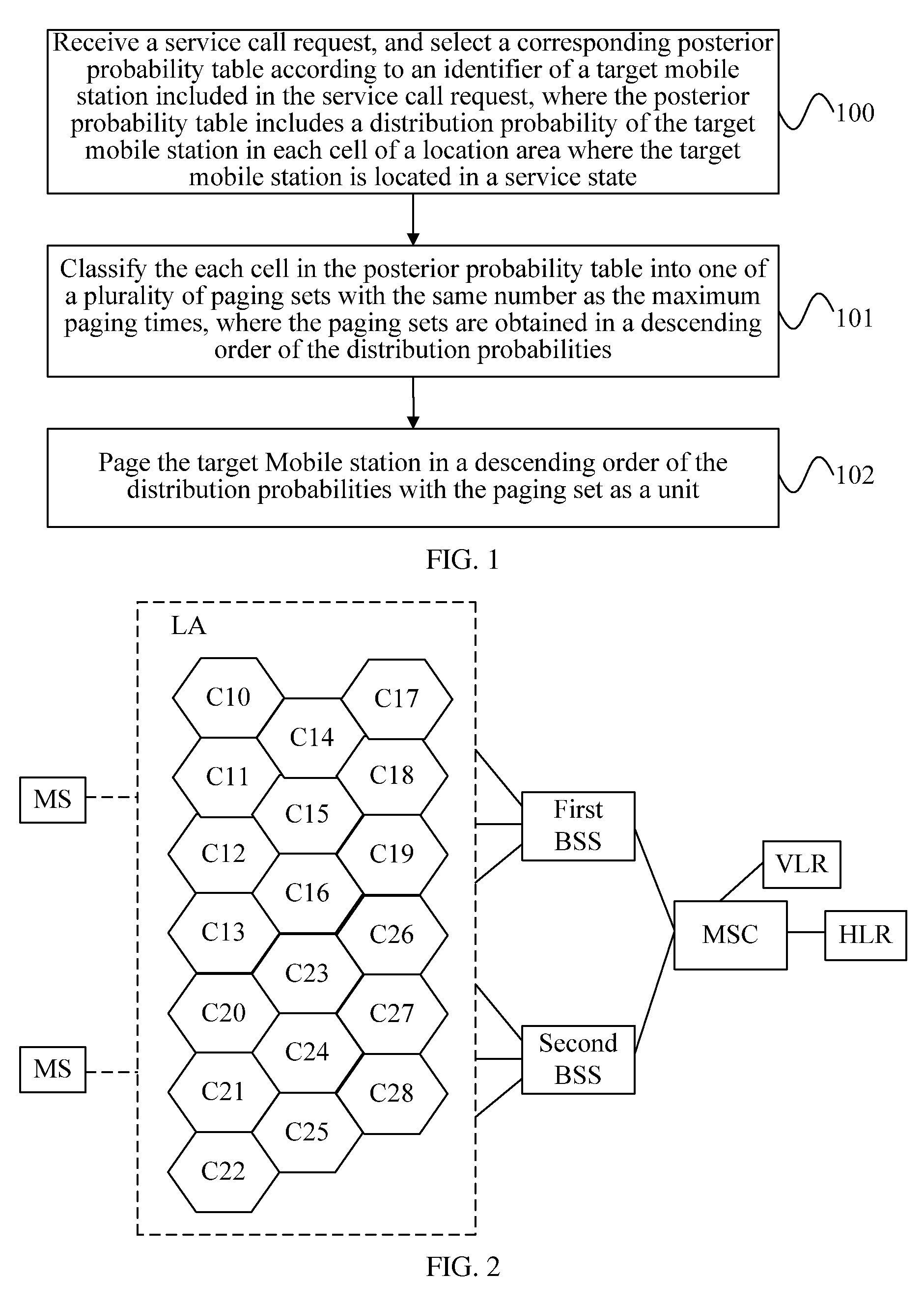

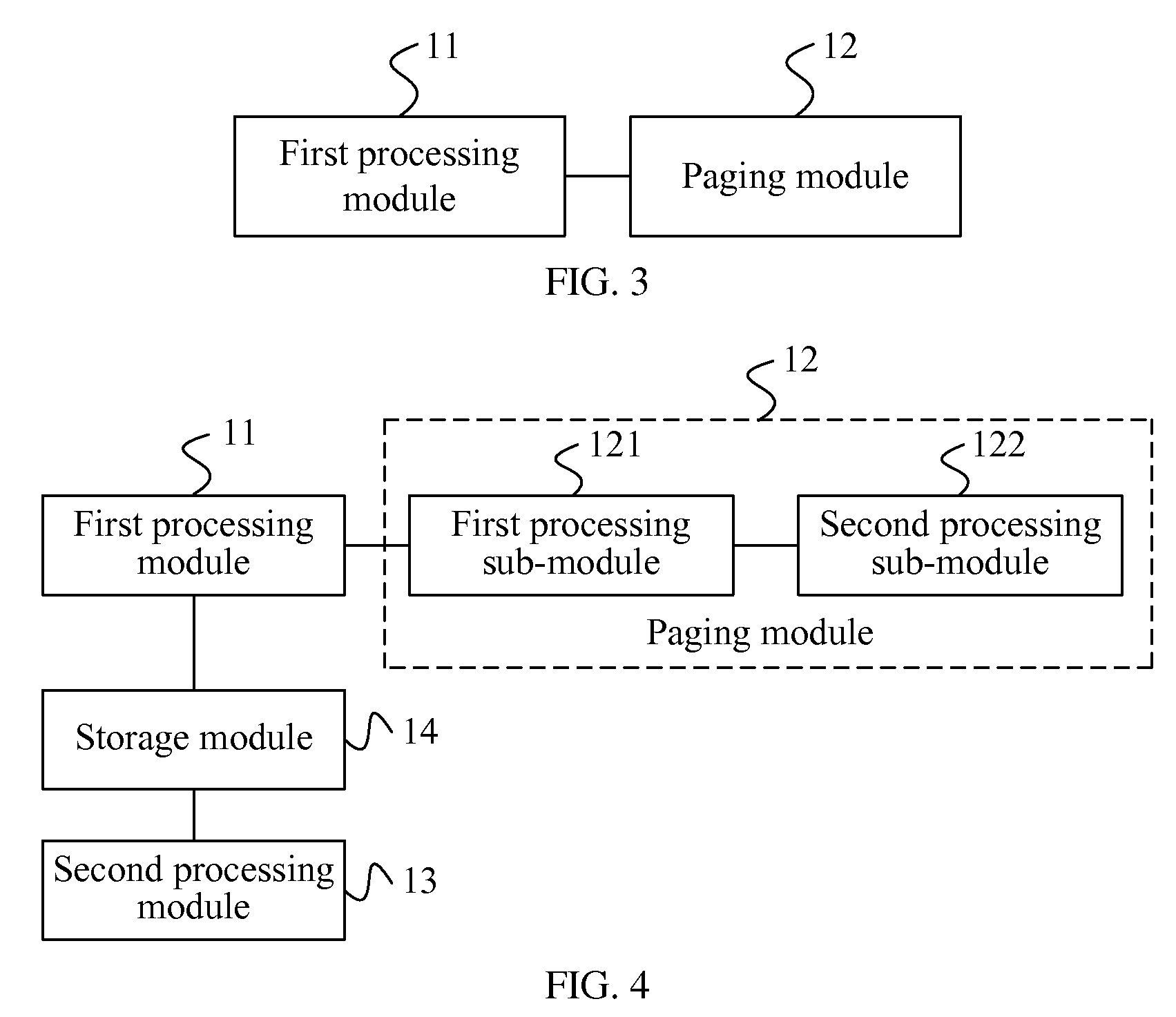

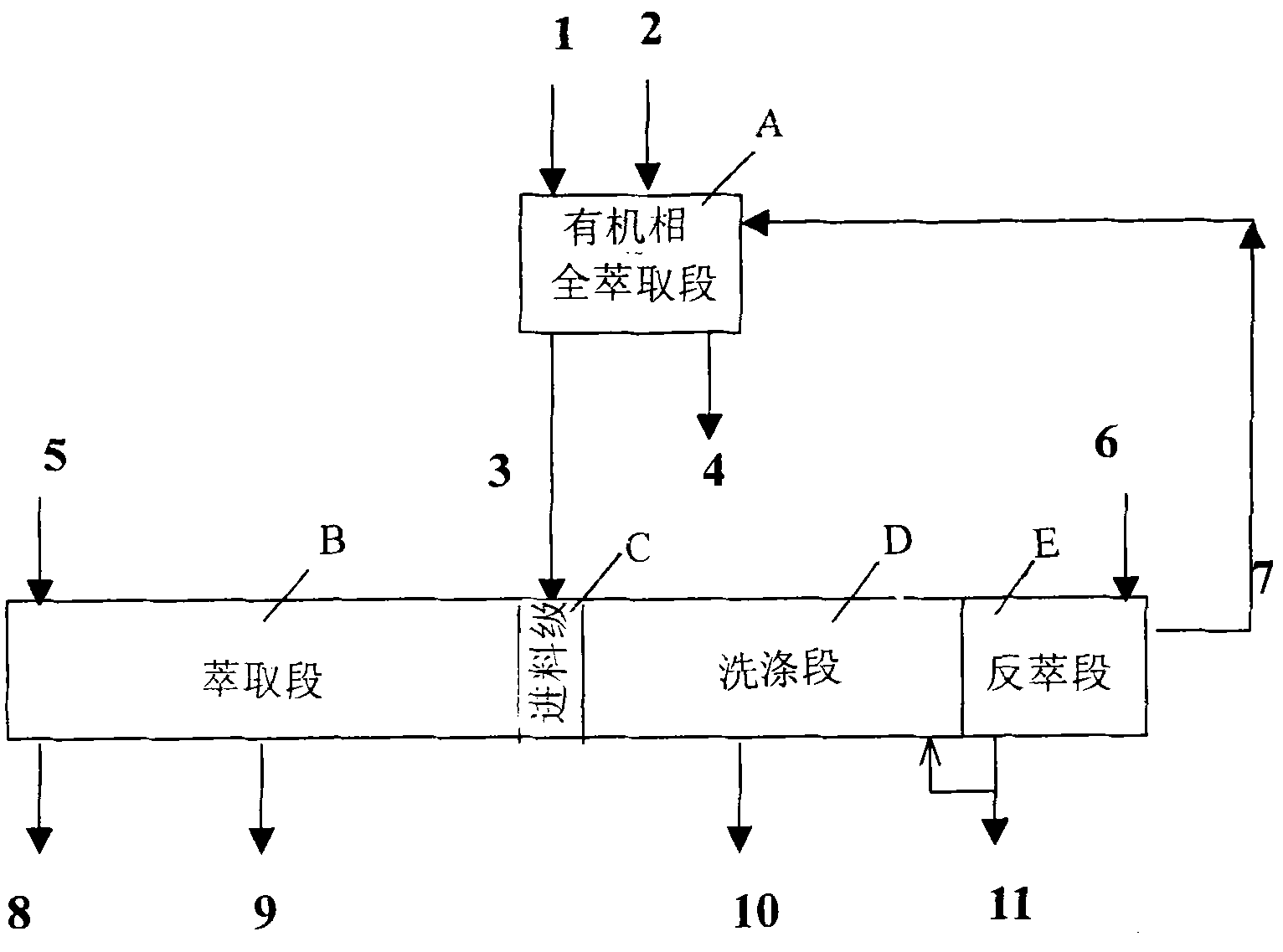

ActiveUS20120100871A1Save air interface resourcesThe process is simple and flexibleWireless communicationAir interfacePaging

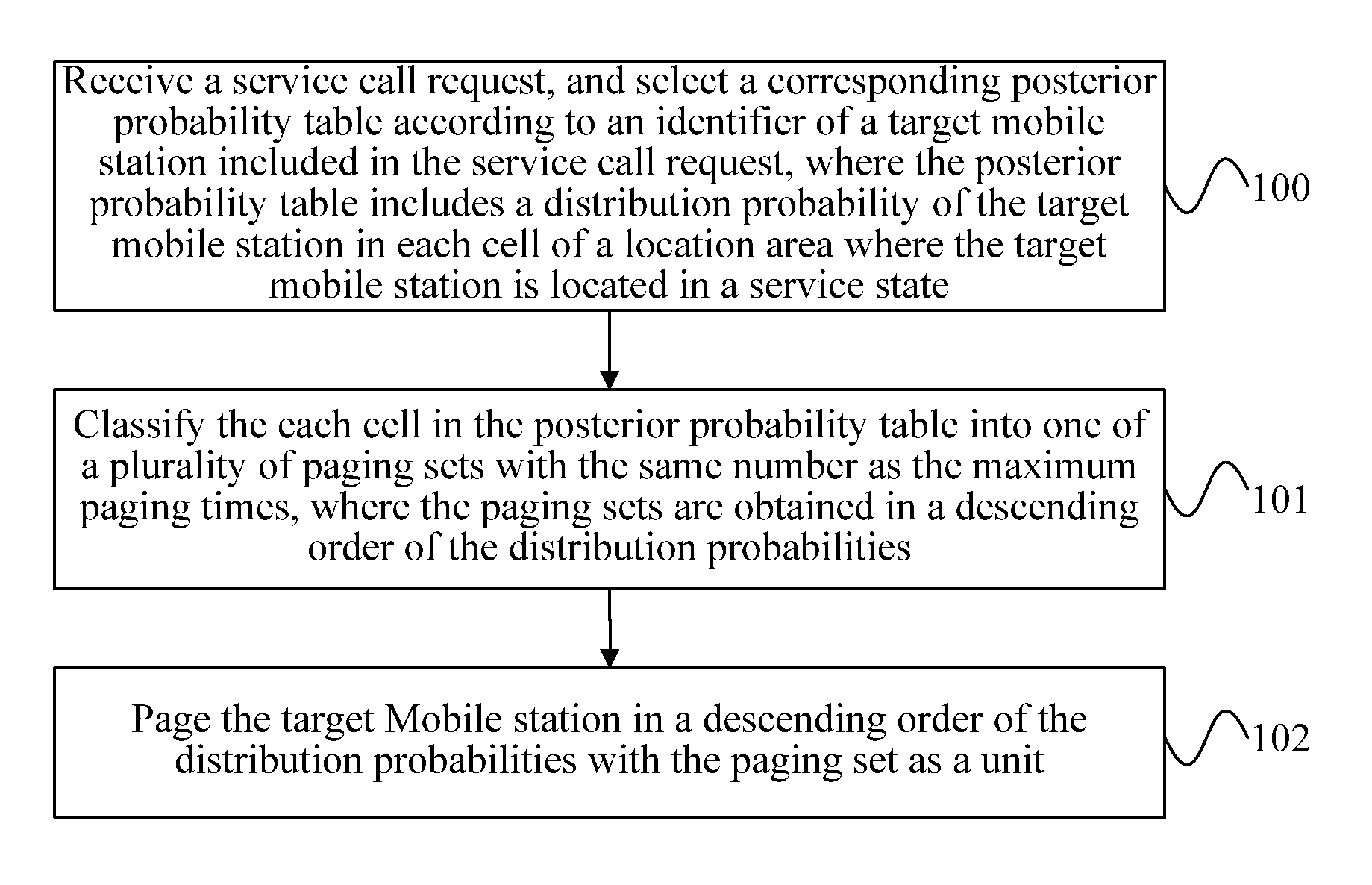

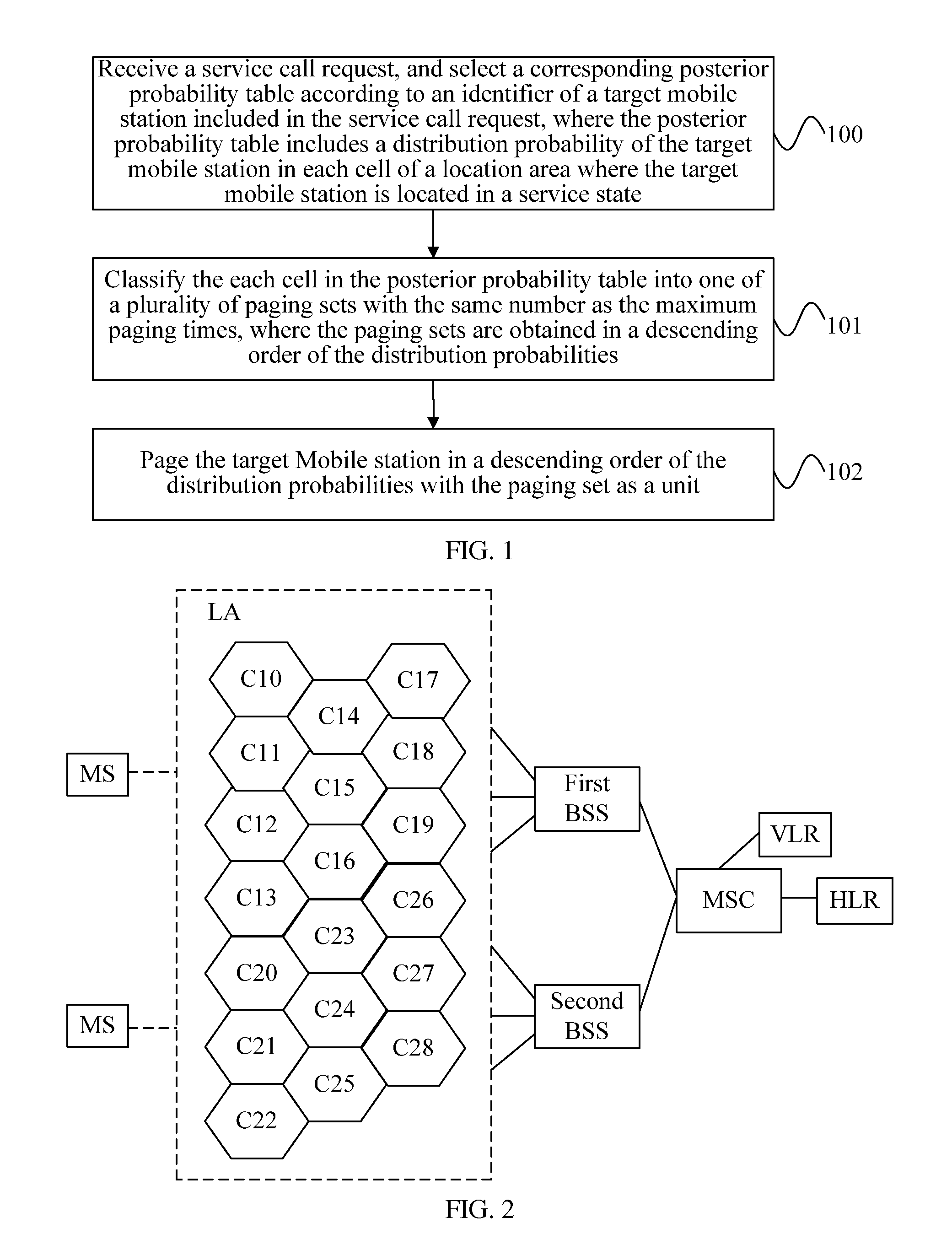

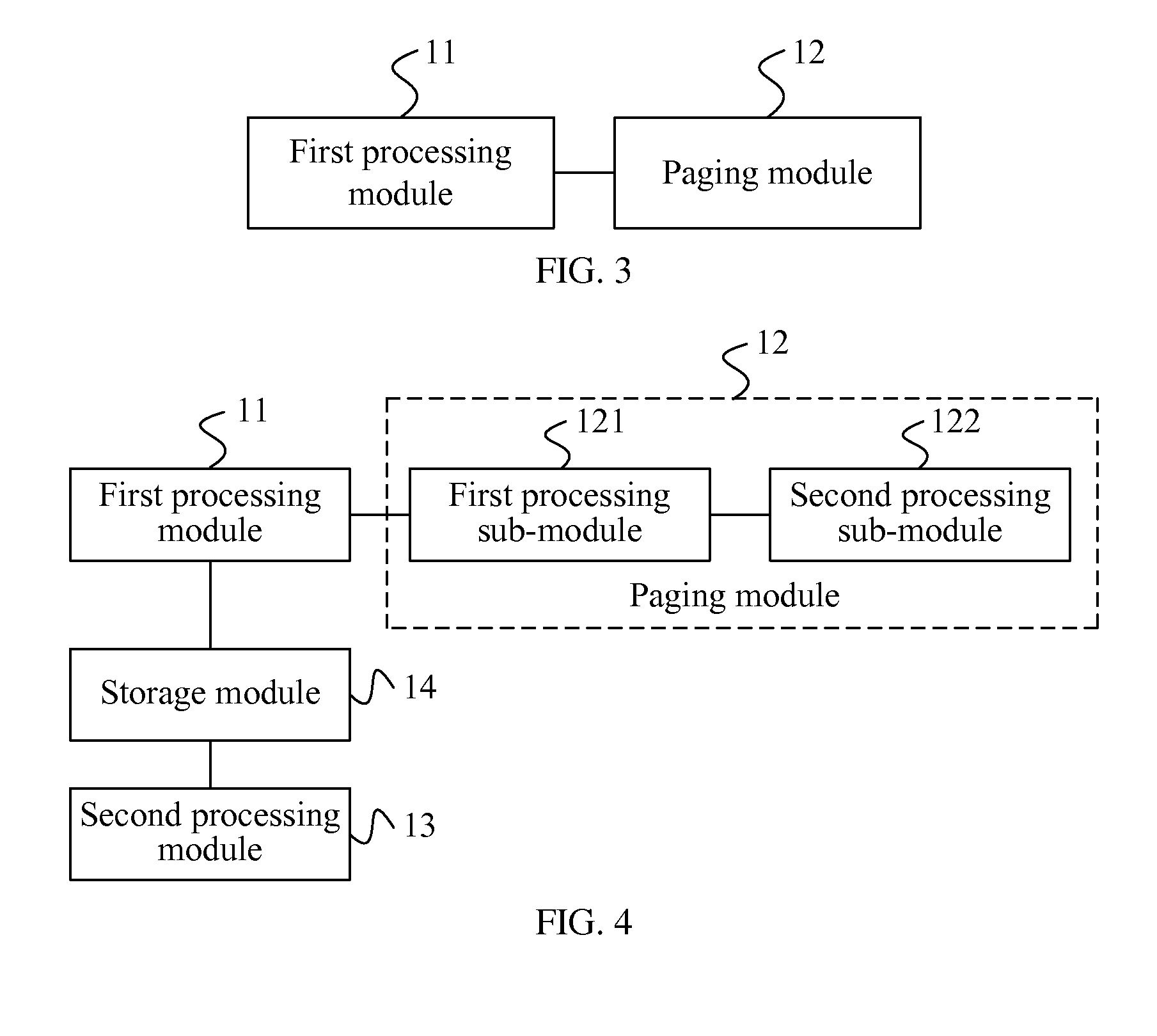

Embodiments of the present invention provide a mobile station paging method and a mobile call center device, The method includes: receiving a service call request, and selecting a corresponding posterior probability table according to an identifier of a target mobile station included in the service call request, where the posterior probability table includes a distribution probability of the target mobile station in each cell of a location area where the target mobile station is located in a service state; and selecting a cell to page the target mobile station according to the distribution probability. The paging is performed based on the distribution probability of a user in the each cell in the service state; the paging process is simple; and the application scenario is wide, thereby saving air interface resources while ensuring a paging efficiency.

Owner:HUAWEI TECH CO LTD

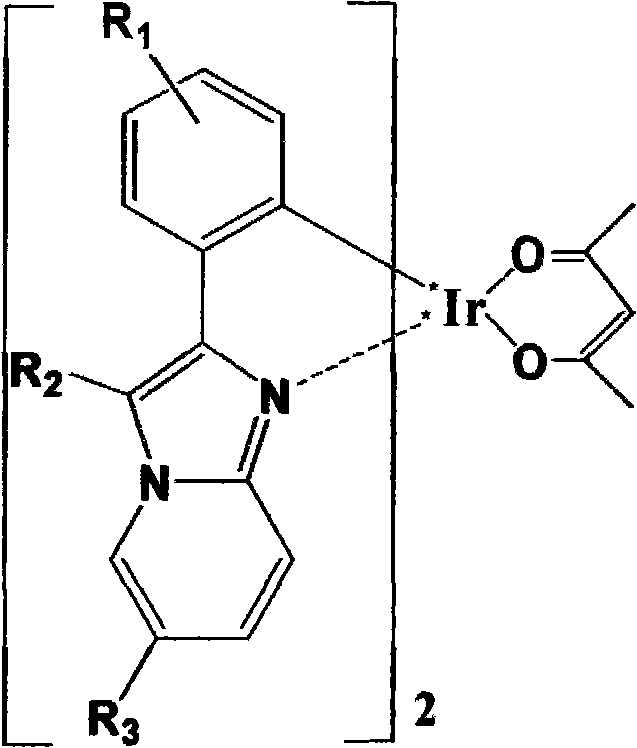

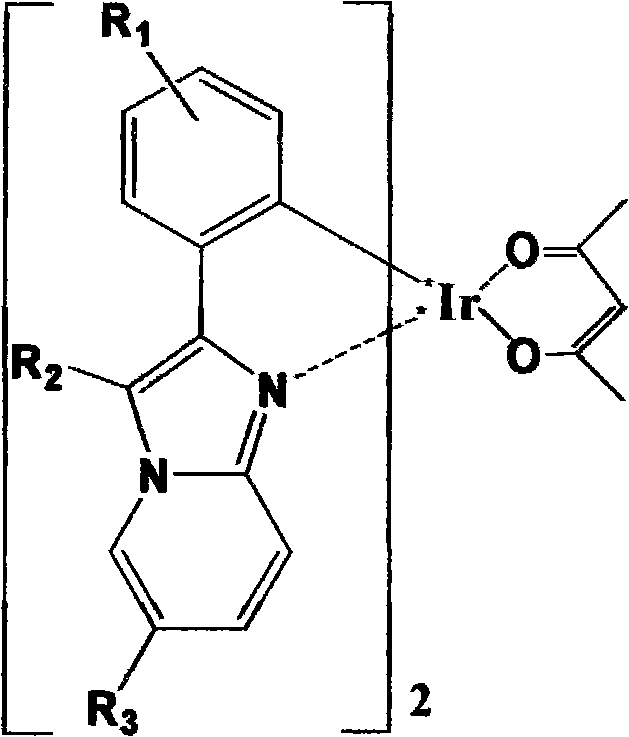

Phenyl-imidazopyridine type trivalent-iridium organometallic complex and organic electro-phosphorescent luminescent device thereof

InactiveCN101585855AImprove efficiencyIncrease brightnessGroup 8/9/10/18 element organic compoundsSolid-state devicesIridiumPeak value

The invention discloses a phenyl-imidazopyridine type trivalent-iridium organometallic complex and an organic electro-phosphorescent doped luminescent device based on the trivalent-iridium complex. The organic electro-phosphorescent material electroluminescent device has a layered doped structure, wherein a luminescent layer selects CBP as a matrix material and a series of Ir (III) complexes as dopant. The invention adopts a vacuum deposition process to prepare an electro-phosphorescent device with high performance, manufactures a PhOLED device with high efficiency and high brightness through the concentration of the Ir (III) complexes in a matrix, obtains green emission of which the electroluminescent spectrum peak value is between 511 and 540 nm through the structure modification of the Ir (III) complexes, improves the efficiency and brightness of the device, is flexible in manufacture process, and provides a good material for full-color display and illuminating application. And the material of the invention can be applied in single / full-color display and illuminating white-light devices.

Owner:XIAN RUILIAN NEW MATERIAL CO LTD

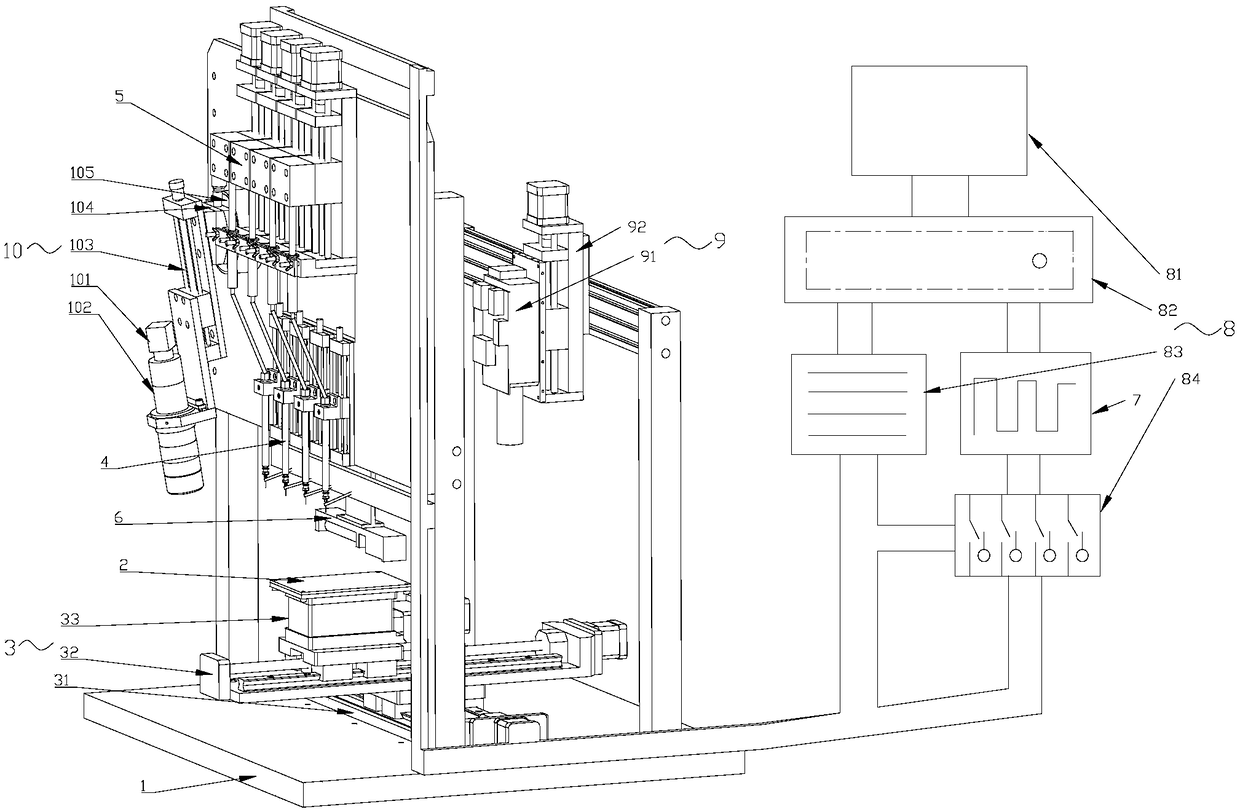

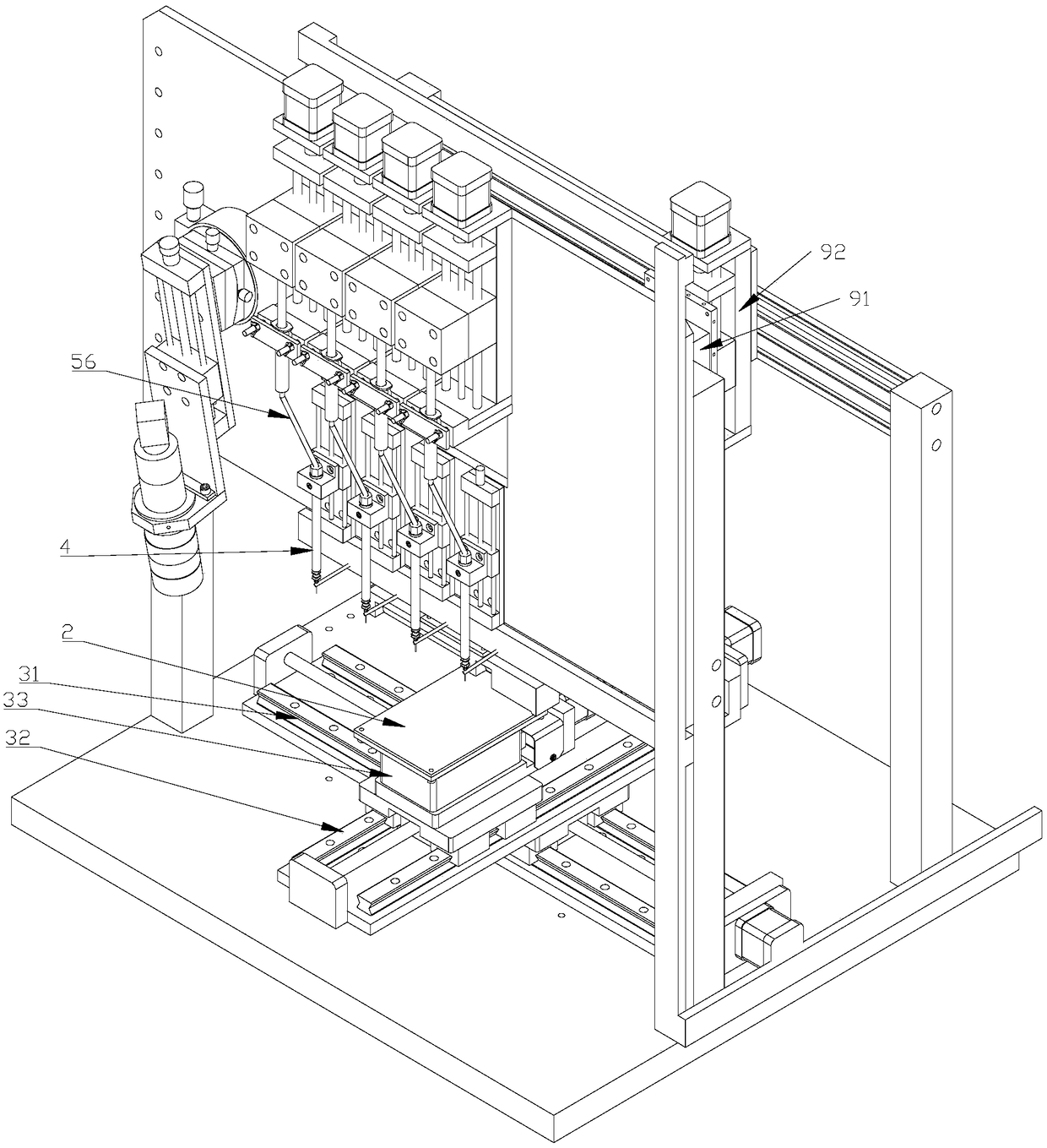

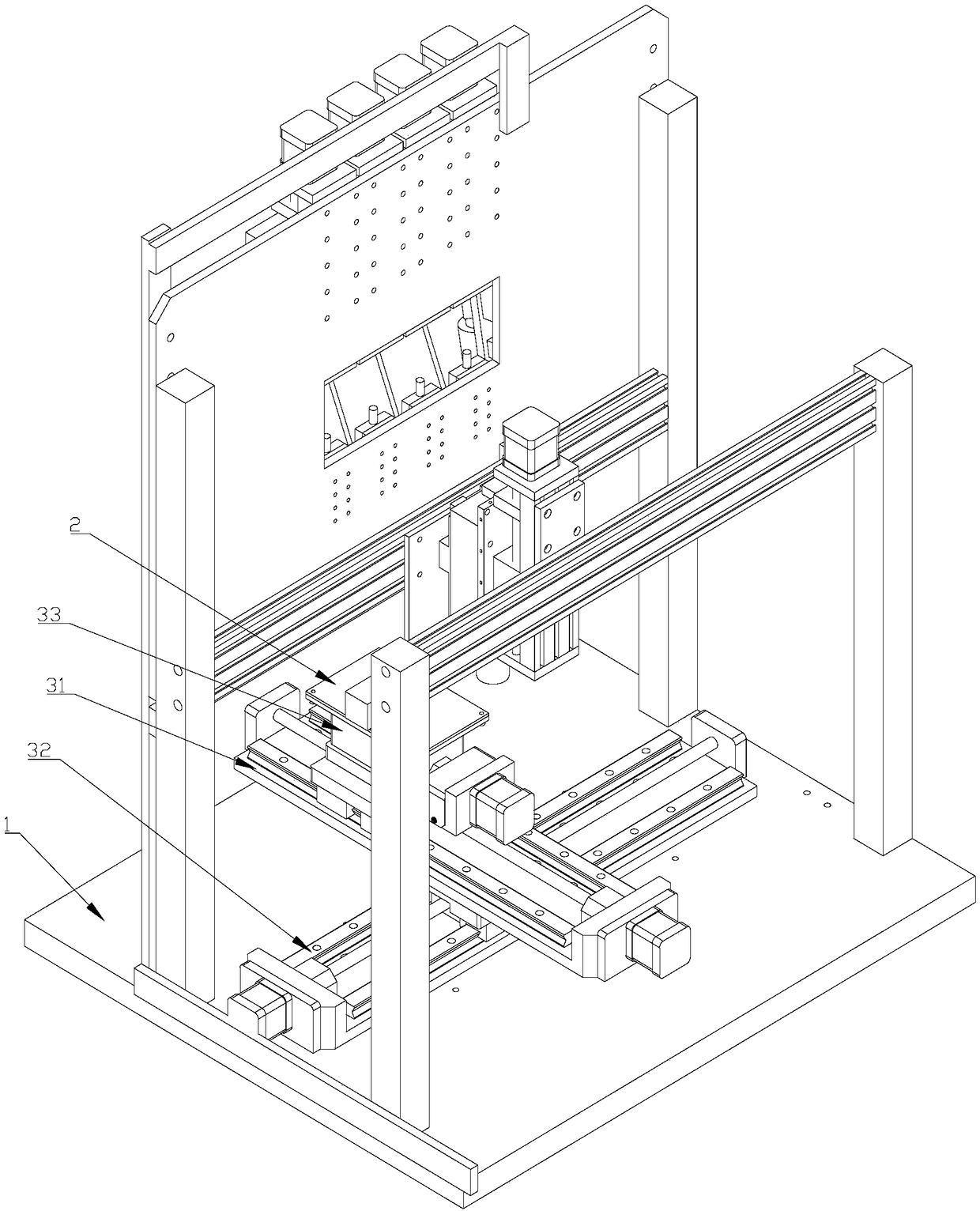

Multi-material 3D printing equipment based on electro-hydraulic-power coupling jet printing

ActiveCN109466061APrinting to achieveSuitable for pattern printingAdditive manufacturing apparatusCeramic shaping apparatusMulti materialPower coupling

The invention relates to multi-material 3D printing equipment based on electro-hydraulic-power coupling jet printing, and belongs to the technical field of 3D printing. The multi-material 3D printingequipment based on the electro-hydraulic-power coupling jet printing comprises a movable platform module, a workbench, a nozzle module, an injection pump module, a roller module and a control module;the material printed by the nozzle module can be a combination of various materials; the levelling of the liquid level of the printing material can be controlled by the roller module, and the thickness of each printing layer can be controlled through the combination of the movement of the roller module and the movement of the movable platform module; and the control module is used for controllingthe nozzle module, the movable platform and a relay contact to achieve the switching of the printing materials. According to the multi-material 3D printing equipment based on the electro-hydraulic-power coupling jet printing, printing of various materials can be realized, the switching speed of different printing materials is high, and the manufacturing cost of the nozzle module is low which is beneficial to reducing the cost of the whole machine.

Owner:XIAMEN UNIV

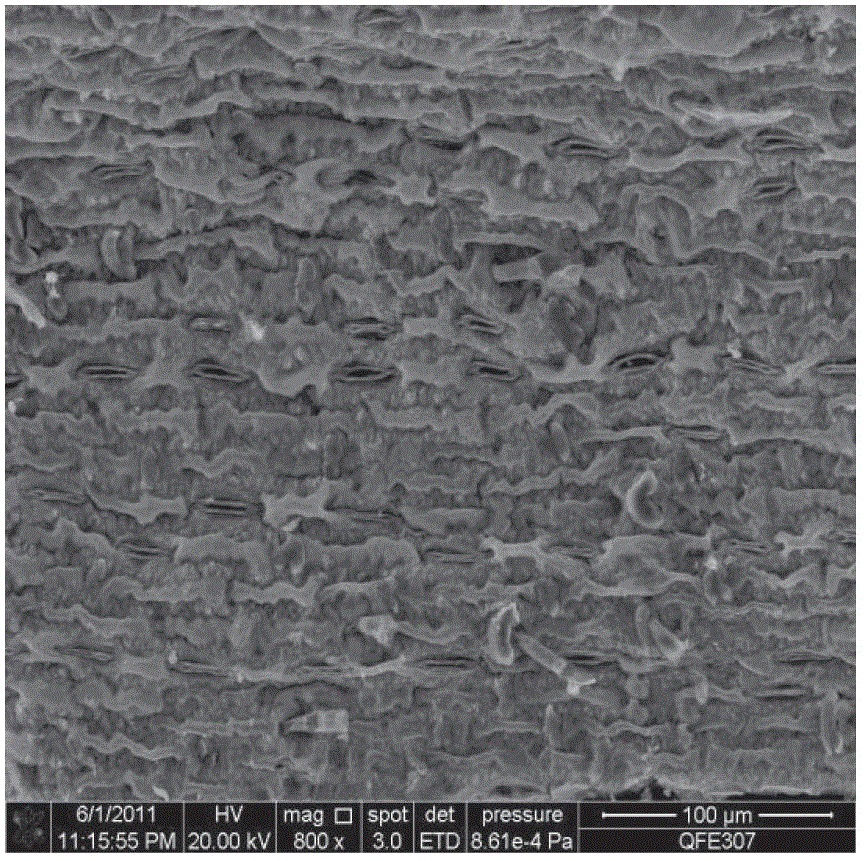

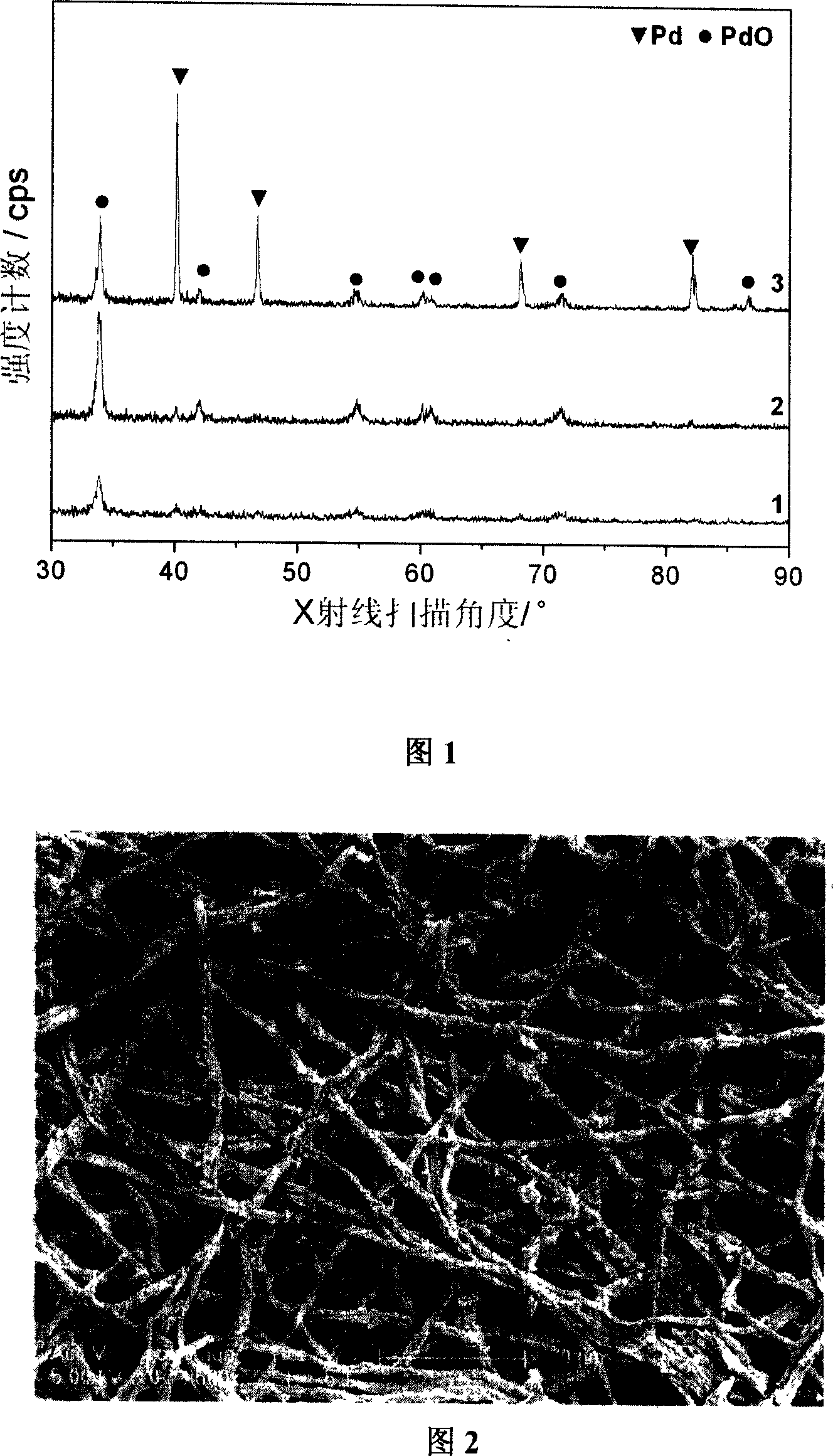

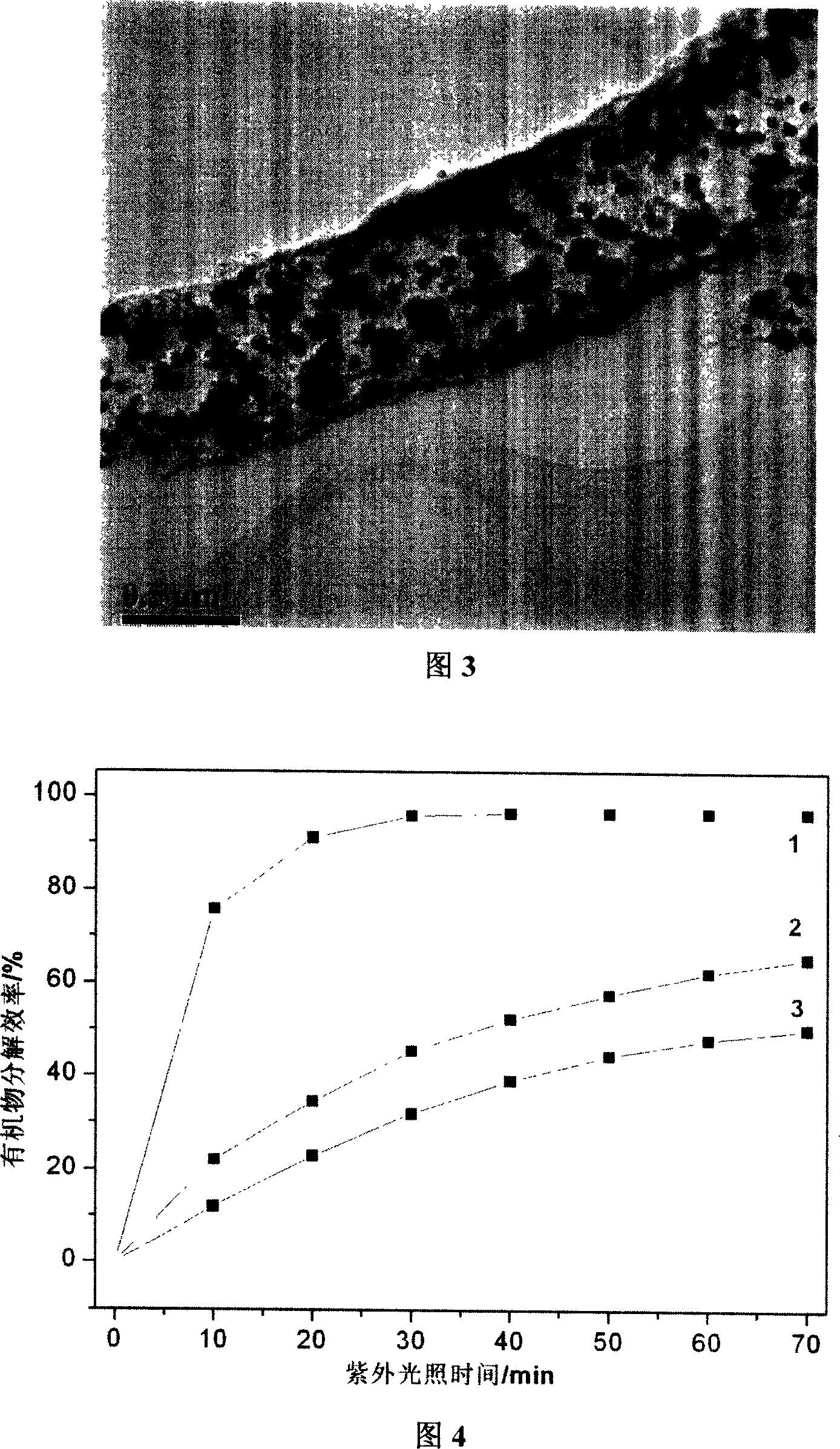

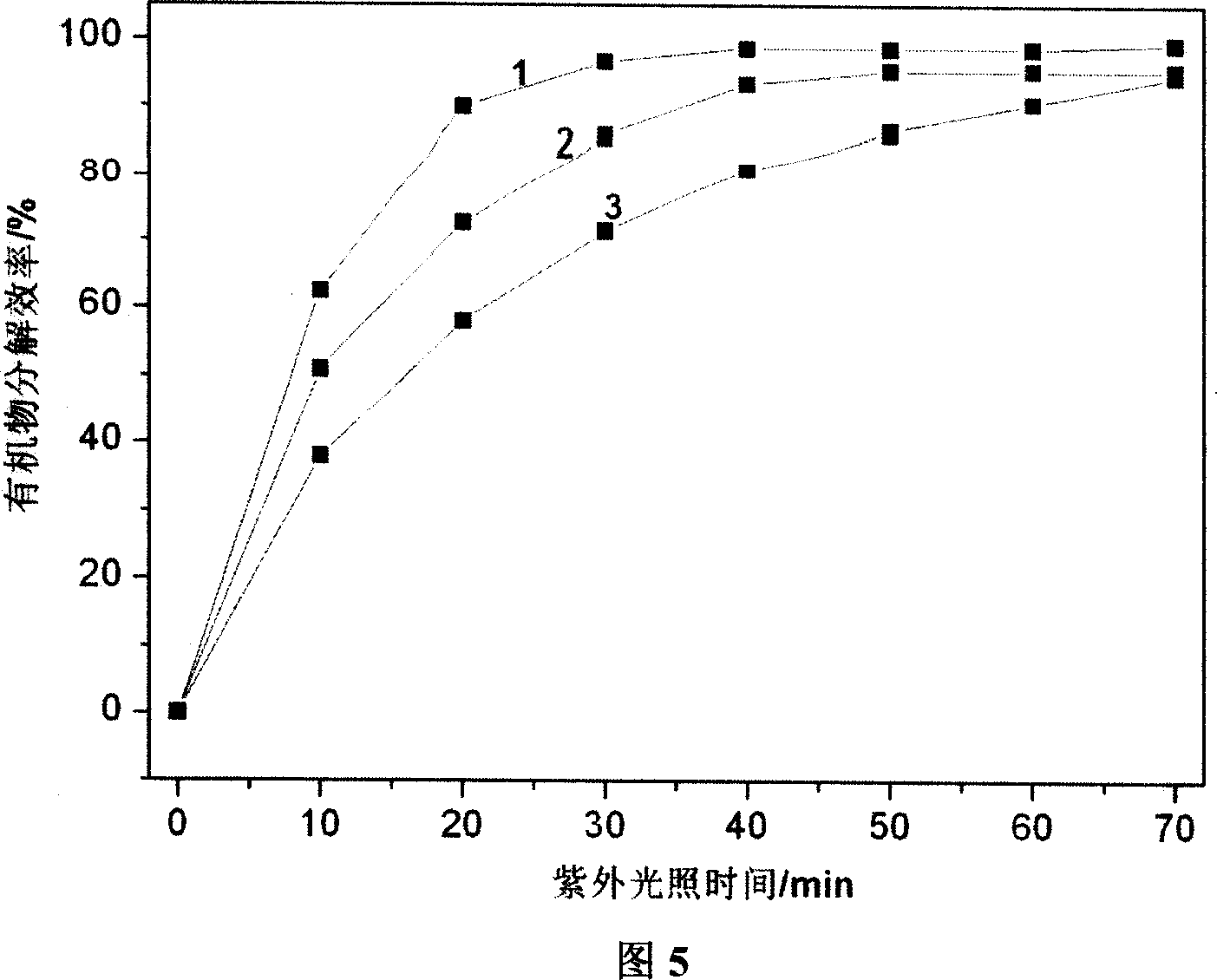

Preparation method of biologic morphologies three dimensional network structure Pd system nano-photocatalyst material

InactiveCN101007276AThe process is simple and flexibleLow cost of preparationCatalyst carriersCatalyst activation/preparationPalladiumBiological materials

The invention involves a biological shape three-dimensional network structure palladium nano-photocatalytic materials preparation method. It makes use of dipping optimum biological materials self-deacidizing technique and uses the bird eggshell film as biological template materials; it prepares three-dimensional network tubular hierarchy Pd / PdO photocatalytic composite material with excellent performance through dipping optimization in palladium salt solution and combining with roasting dispose, controls the component and construction of prepared composite material through adjusting the dipping optimization process and heat treatment process, the prepared photo-catalytic materials are combined by PdO with full crystallization and metal Pd nanometer particles uniformly, and combines special three-dimensional network intercommunicating tube construction orderly, and the metal nanometer particles loads and inserts on tube inner wall uniformly. The art of the invention method is simple, cost is low and the prepared material has excellent photo-catalytic properties.

Owner:SHANGHAI JIAO TONG UNIV

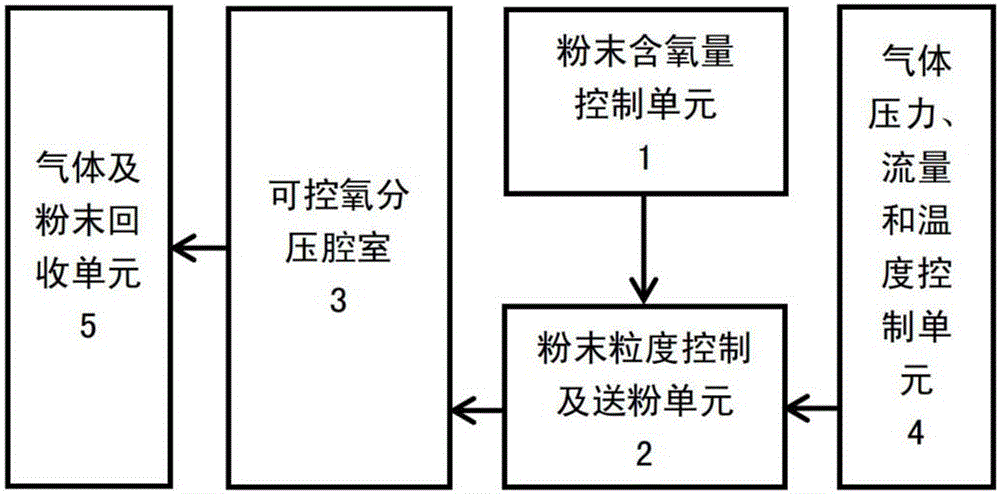

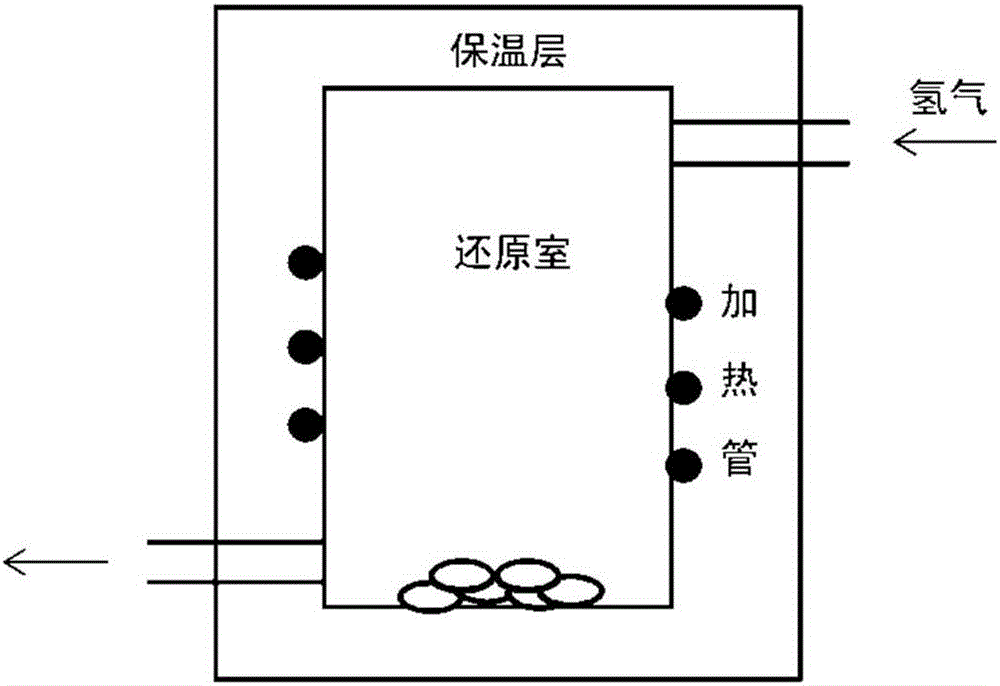

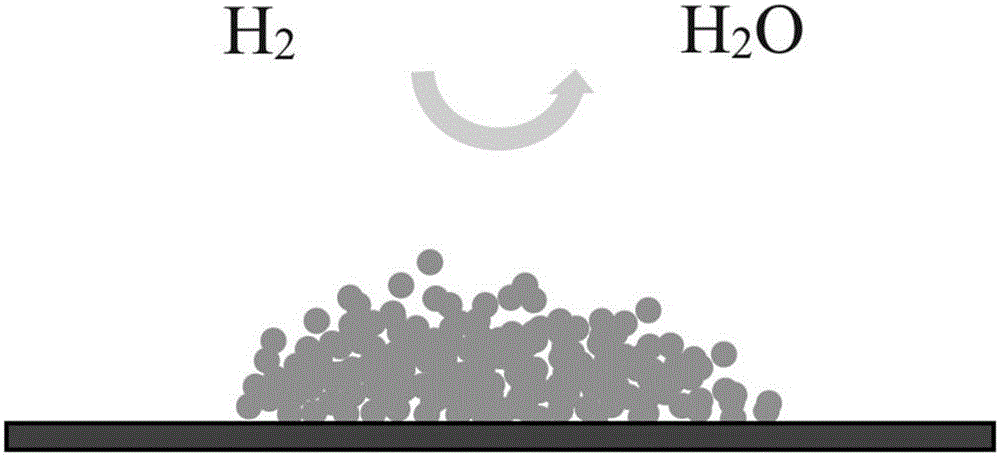

Method for preparing copper film through controlled atmosphere cold spraying

ActiveCN106367750AThe process is simple and flexibleGood controllabilityPressure inorganic powder coatingSpray nozzleCopper oxide

The invention discloses a method for preparing a copper film through controlled atmosphere cold spraying. The method comprises the steps that firstly, original copper powder is conveyed into a powder oxygen content control unit, copper oxide on the surfaces of copper powder particles is reduced into copper, and the oxygen content of the copper powder is reduced; secondly, the copper powder treated through the powder oxygen content control unit is conveyed into a powder granularity control and powder feeding unit, the input copper powder is scattered and screened, and the granularity of the output copper powder particles is controlled within the set range; thirdly, the copper powder treated in the second step is conveyed into a cold spraying nozzle in a controlled oxygen partial pressure cavity; and fourthly, the speed and temperature of the copper powder particles are regulated and controlled through a gas pressure, flow and temperature control unit, and the copper powder particles in the controlled oxygen partial pressure cavity collide with base body depositions to form the copper film. The film obtained through the method is dense in structure and low in oxygen content, the conductivity is not lower than 80% that of corresponding component dense block materials, and the film is superior to a traditional electrolysis or copper electroplating film in the aspects of environment protection and cost.

Owner:XI AN JIAOTONG UNIV

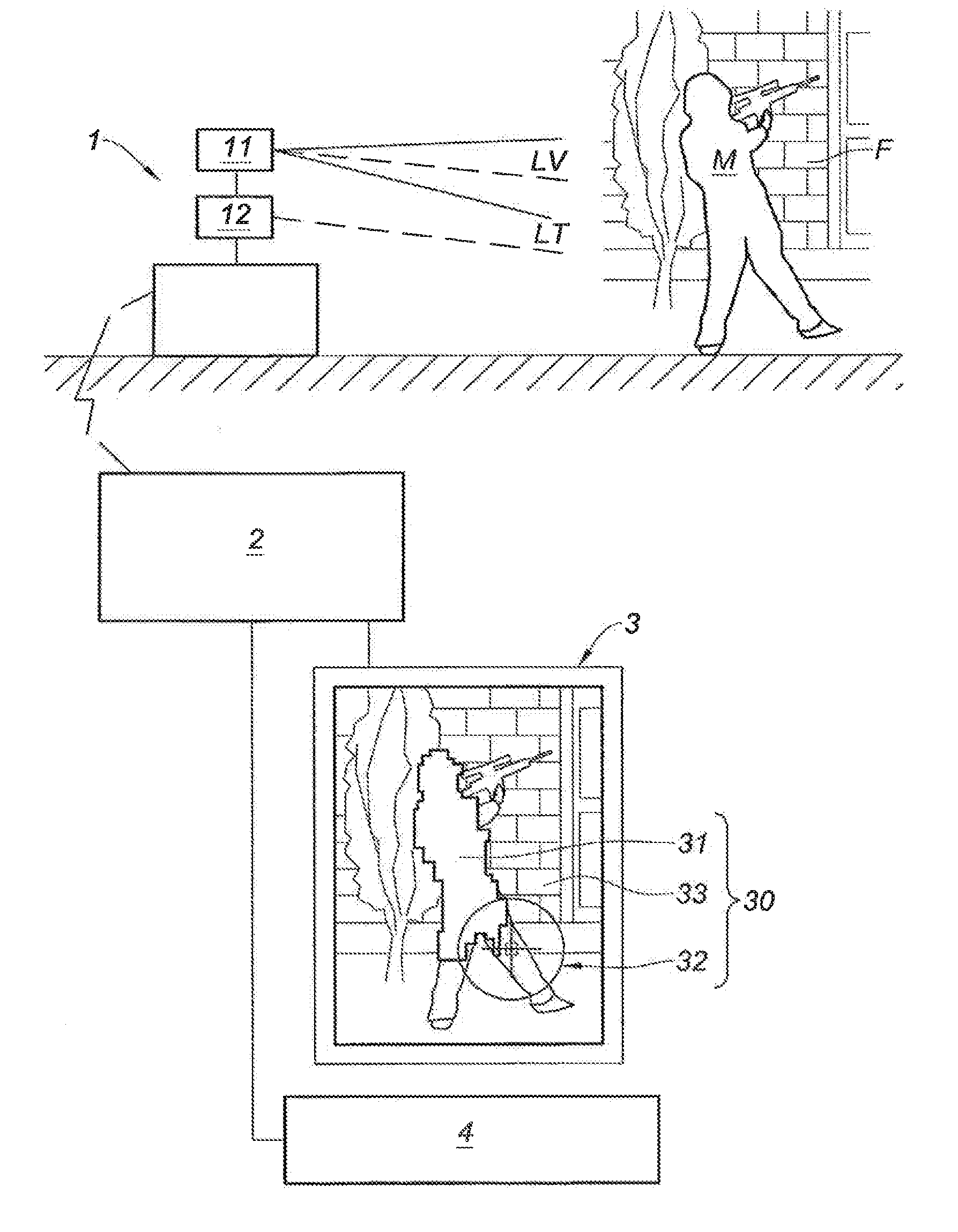

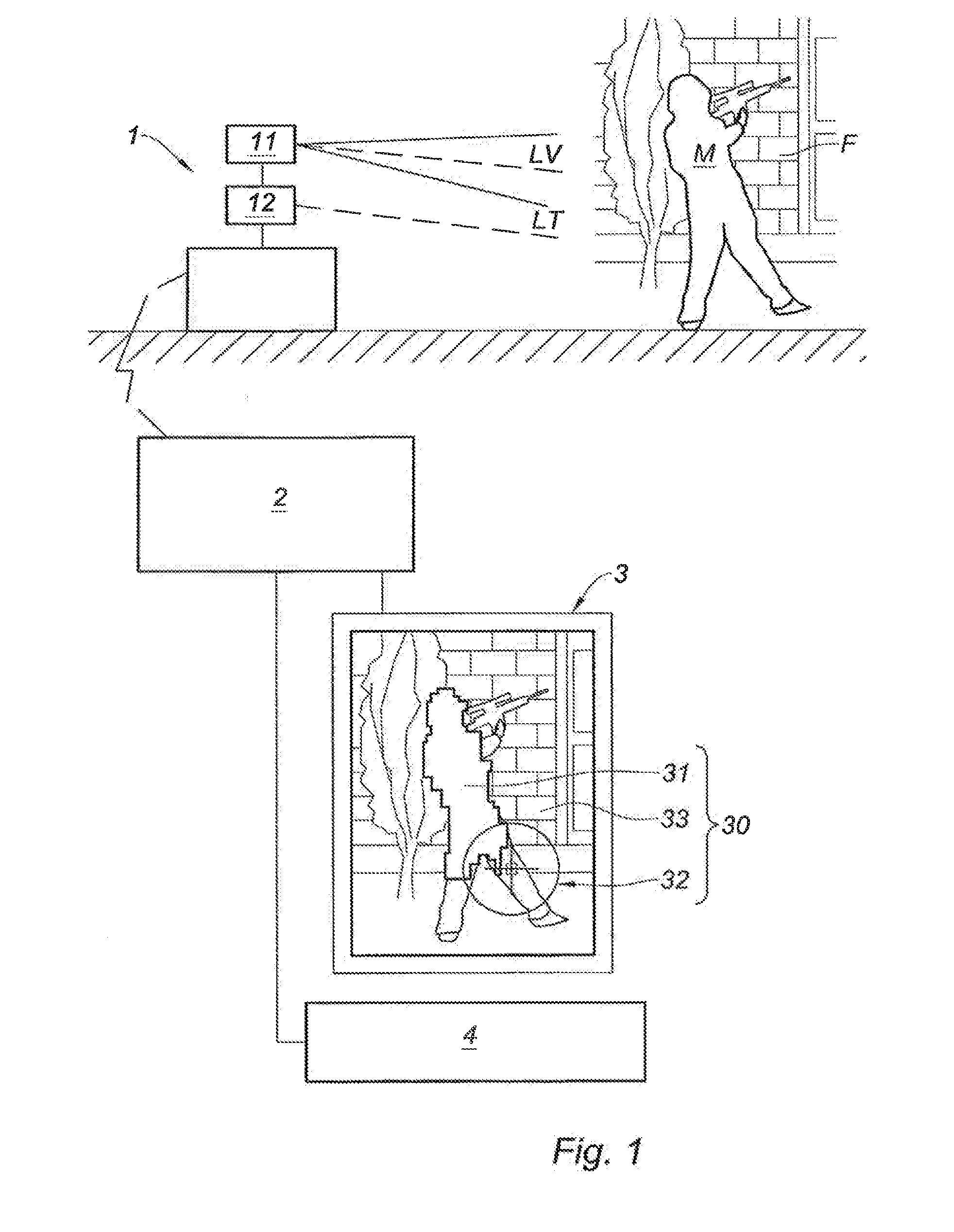

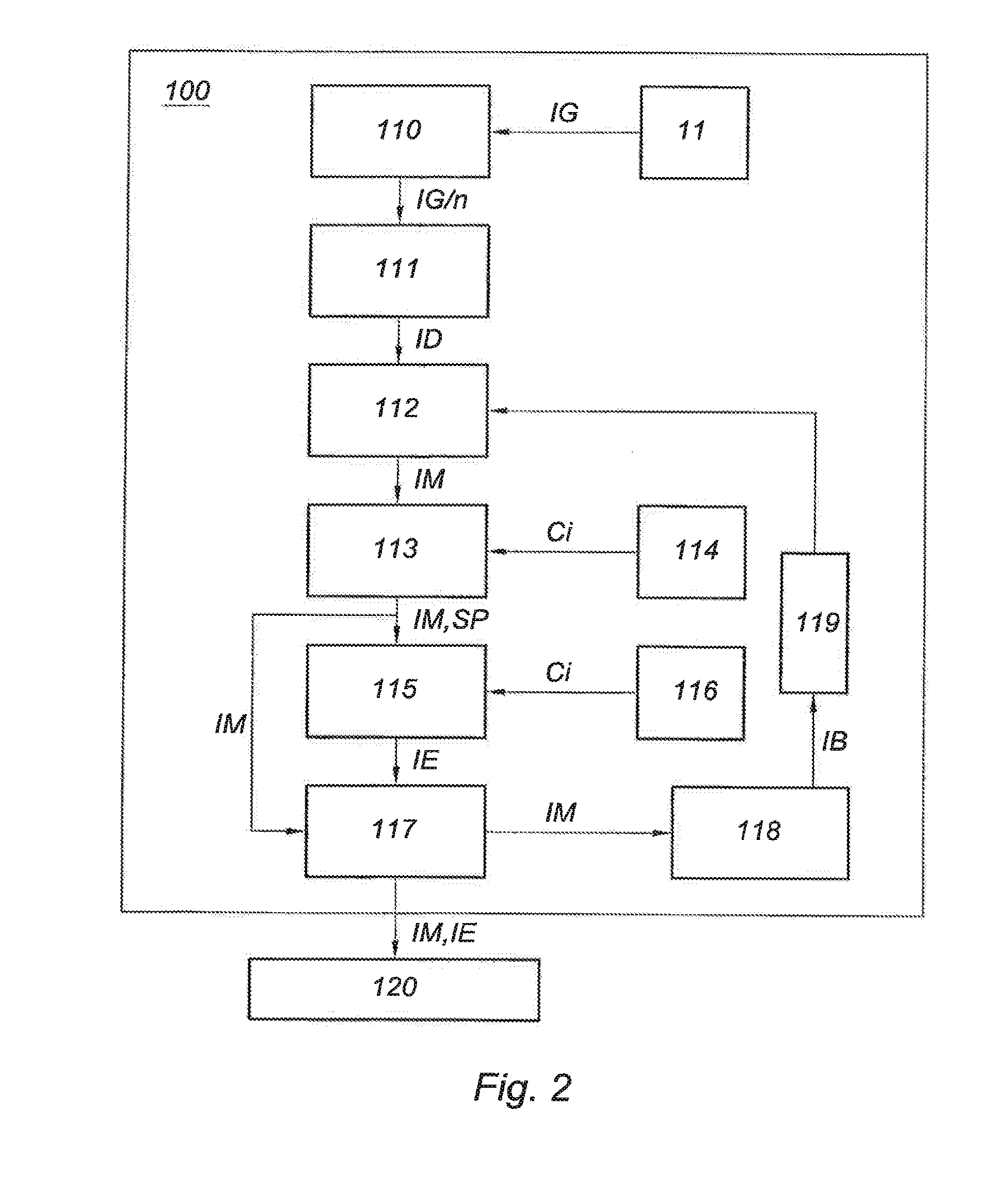

Remote operated selective target treatment system

ActiveUS20160086346A1Low costEfficient managementImage enhancementProgramme-controlled manipulatorComputer graphics (images)Computer vision

A remote operated selective target treatment system including a firing robot having a weapon and an optoelectronic sighting device, a central processing unit and a control screen displaying the prepared image of the target, and a control device. The central processing unit prepares the image intended for display, and includes an input module receiving digital images, an image analyzer receiving the image from the input module and detaching the target image from its environment, a modelling device modelling the contour of the image, a comparator connected to a library of silhouettes receiving the modelled image and checking it against the silhouettes, and an exclusion module receiving an image from the comparator and using a library of masks to apply a mask to the image and transmit the prepared image for display on screen.

Owner:LEVILLY PHILIPPE A

Three-dimensional light-emitting device formed by inverted light-emitting unit array and manufacturing method of three-dimensional light-emitting device

InactiveCN103545337AElimination of process difficultiesImprove production yieldSolid-state devicesSemiconductor devicesConnection designEngineering

Disclosed are a stereo light-emitting device composed of a flip-chip light-emitting unit array and a manufacturing method therefor. By substituting a flip-chip connection of a P-N complementary light-emitting diode (LED) chip for the metal wiring on the LED chip, the stereo light-emitting device realizes a series / parallel connection between individual light-emitting units, so as to completely eliminate the process difficulty of wiring on an LED chip trench, greatly improving the production yield and simultaneously obviating the preparation of a silicon substrate in the conventional flip-chip process. Furthermore, different series connection, parallel connection or series / parallel connection designs can be realized only by changing the layout design of an LED chip, the process is relatively simple and flexible, and the production efficiency can be greatly improved.

Owner:JIANGSU MICRO WAVE ELECTRONICS TECH

Ultraviolet-cutoff coated glass containing silicon film and preparation method thereof

The invention aims to provide ultraviolet complete-cutoff coated glass prepared by a magnetron sputtering method, and a preparation method thereof, which comprise ultraviolet complete-cutoff sunshine-control coated glass or ultraviolet complete-cutoff sunshine-control low-radiation coated glass and preparation methods thereof. A glass substrate is coated with a silicon or silicon alloy film serving as an ultraviolet absorption film, and the characteristic that the cutoff wavelength of the silicon or silicon alloy film is between 400 and 550 nm is utilized to completely cut off ultraviolet rays. The thickness of the silicon or silicon alloy film is 10 to 200 nm; Ar is used as working gas; and the working pressure is 0.30 to 0.37 Pa. Pure silicon target material is used to sputter and deposit the silicon film, or silicon-alloy target material formed by adding B, P, Al, C and Ge to pure silicon is used to sputter and deposit the silicon alloy film. The coated glass has wide application in automobiles, trains, ships, buildings, glass material for household appliances and illuminating glass lamp industry with broad prospects.

Owner:JIANGSU XIUQIANG GLASSWORK CO LTD

Method for rapidly constructing multilayer cells

InactiveCN102614547ADecreased biological functionRealize 3D constructionProsthesisCell-Extracellular MatrixCulture fluid

The invention discloses a method for rapidly constructing multilayer cells. The method comprises the steps of mixing and suspending seed cells and liquid extracellular matrix gel, putting the liquid suspension on a construction carrier to ensure that the liquid suspension on the carrier is solidified into solid gel and a multilayer cell structure is directly formed, and adding a culture solution to culture the multilayer cells till enough strength. The method disclosed by the invention is capable of rapidly preparing various tissues and organs which contain the multilayer cells and meet the requirements of proliferation activity and mechanical strength, is a breakthrough of tissue engineering construction technology and is reliable in principle, simple and flexible in process, good in product reproducibility and very easy in industrialization at the same time.

Owner:ZHONGSHAN OPHTHALMIC CENT SUN YAT SEN UNIV

Ultrathin carrier cell sheet and preparation method thereof

ActiveCN106924817AHigh mechanical strengthTrait controlCoatingsProsthesisMacromolecular drugUltimate tensile strength

The invention discloses an ultrathin carrier cell sheet and a preparation method thereof. The preparation method comprises the following steps of (1) spreading a gel material solution onto a substrate, and condensing into a solid state; (2) generating an ion polymer layer which has opposite polarity with the gel material on the substrate spread with the gel material, generating an ion polymer layer which has opposite polarity with the upper ion polymer layer, on the upper ion polymer layer, and repeating the operation, so as to form a layered self-assembly film; (3) planting a target cell into the substrate obtained in step (2), and conventionally culturing; (4) in the culture process, enabling the layered self-assembled film loaded with the cell to disengage from the substrate, so as to form the cell sheet. Compared with the traditional preparation method of the cell sheet, the preparation method has the advantages that the character control or decomposing step of a supporter material is not needed, the mechanical strength of the cell sheet is obviously improved, and macromolecular medicines, such as protein, polypeptide, antibody and nucleic acid, can be loaded.

Owner:ZHEJIANG UNIV

Preparation of foam magnesium alloy

The invention discloses a foam magnesium alloy preparing method, belonging to the field of the production of an alloy with open or closed pores. The method is particularly a method for preparing a magnesium alloy by means of foaming a powder entity and comprises the following steps: firstly, mixing 150-270-mesh pure magnesium powder and 250-400-mesh pure aluminum powder according to a mass ratio (pure magnesium powder : pure aluminum powder) ranging from 4:1 to 9:1 so as to obtain a metal powder mixture, uniformly mixing the metal powder mixture with 200-325-mesh TiH2 powder vesicant which accounts for 1.0-2.5 percent of the mass of the metal powder mixture, carrying out cold pressing and hot pressing on the mixture obtained from the previous step, and then obtaining a magnesium alloy foaming precast block; and then, under the protection of argon, preparing the foam magnesium alloy with an average aperture ranging from 1 mm to 5 mm by means of heating the foaming precast block in a mould. The method has the advantages of simple and flexible process, short period, high productive rate and no impurity; and the foam magnesium alloy prepared according to the method has a closed-pore structure and the advantages of high porosity, uniform pore structure distribution, regular pore shapes, wide application scope and good comprehensive performance.

Owner:HEBEI UNIV OF TECH

Mobile station paging method and mobile call center device

ActiveUS8478293B2Reduce complexitySave air interface resourcesWireless communicationAir interfacePaging

Embodiments of the present invention provide a mobile station paging method and a mobile call center device, The method includes: receiving a service call request, and selecting a corresponding posterior probability table according to an identifier of a target mobile station included in the service call request, where the posterior probability table includes a distribution probability of the target mobile station in each cell of a location area where the target mobile station is located in a service state; and selecting a cell to page the target mobile station according to the distribution probability. The paging is performed based on the distribution probability of a user in the each cell in the service state; the paging process is simple; and the application scenario is wide, thereby saving air interface resources while ensuring a paging efficiency.

Owner:HUAWEI TECH CO LTD

Process for solvent extraction separation purification of rare earth element

ActiveCN101319275BStripping is easyReduce acid and alkali consumptionProcess efficiency improvementRare-earth elementNitrate

Owner:GRIREM ADVANCED MATERIALS CO LTD

Layer-by-layer self-assembly film, preparation method and application thereof

ActiveCN107929810AShorten the timeImprove efficiencyTissue regenerationProsthesisLayer by layer self assemblyInjury wounds

The invention discloses a layer-by-layer self-assembly film, a preparation method and application thereof. The layer-by-layer self-assembly film is formed by laying polymer layers with opposite electrical properties and dropwise adding charged therapeutic drugs; the distribution and rearrangement time of polymer in a mode of sucking unreacted solution through a vacuum extractor to produce flowingliquid phase is reduced, a step of washing with clear water is avoided, formed negative and positive ionic polymer layers are smoothly fitted, and the film can be applied to various wound surfaces through design of dies; a 100 to 20000nm ultrathin film can be formed, materials in contact with organisms are obviously reduced, and foreign body rejection reaction is reduced. The film is wide in material selection and drug selection ranges. Types and dosages of drugs can be selected, the effects of antibacterial property, anti-inflammatory property and promotion of wound healing are achieved; thefilm has flexible and convenient processibility, is suitable for the requirements of repairing of various injury wound surfaces, and is stable in product quality and good in reproducibility.

Owner:ZHEJIANG UNIV

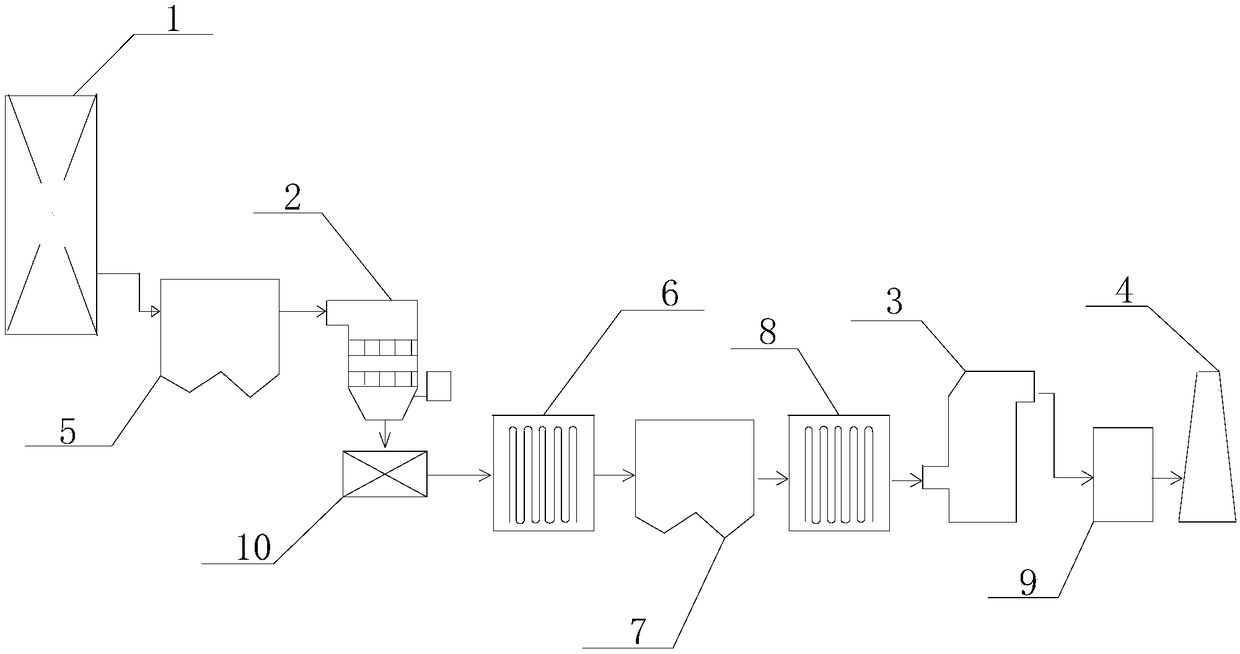

Device with energy conservation and emission reduction effects and simultaneous desulfurization and denitrification effects on flue gas and special coating for device

PendingCN109364668AImprove interchangeabilityReduce weightCombination devicesGas treatmentAir preheaterFlue gas

The invention discloses a device with the energy conservation and emission reduction effects and the simultaneous desulfurization and denitrification effects on flue gas. The device comprises a boiler, a denitrification device body, a desulfurization device body and a chimney, the output end of the boiler is connected to the input end of the denitrification device body through a first dust remover, the output end of the denitrification device body is connected with an air preheater, the output end of the air preheater is connected with a first heat exchanger, the output end of the first heat exchanger is connected to the input end of a second dust remover, the output end of the second dust remover is connected to a second heat exchanger through a fan, the output end of the second heat exchanger is connected with the desulfurization device body, the output end of the desulfurization device is connected with an alkali liquor absorption device, and the output end of the alkali liquor absorption device is connected to the chimney. The device has the advantages of being simple and compact in structure, obvious in effect, good in energy conservation and emission reduction effects and denitrification and desulfurization effects and low in cost. The invention further discloses a coating of the device. The coating of the device is further designed and has good chemical reagent resistance, and the service life of the device is prolonged.

Owner:YIXING HAINA ENVIRONMENTAL ENG

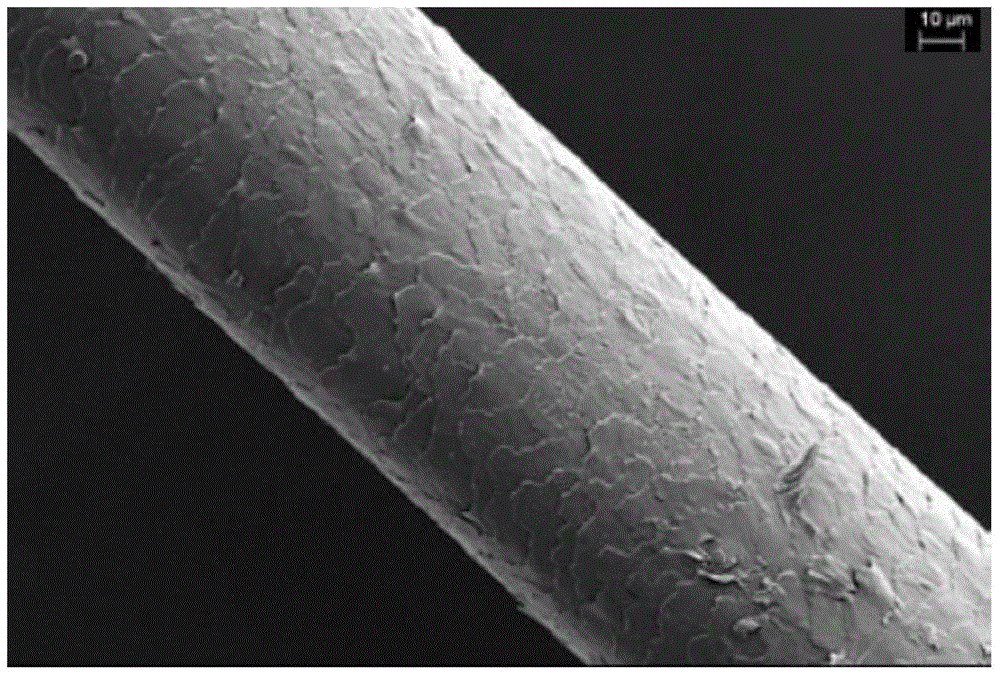

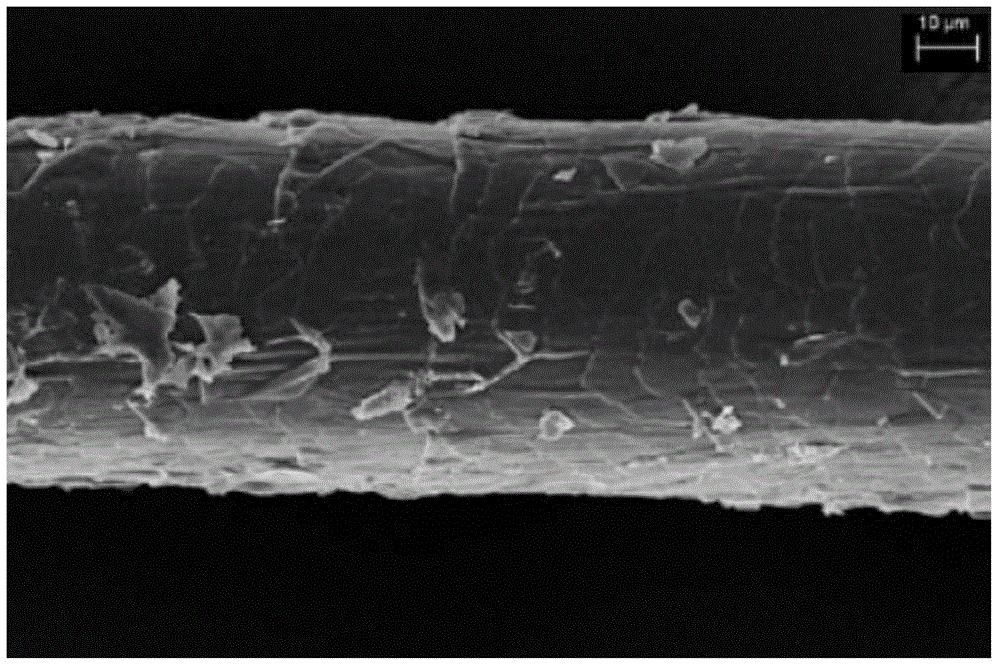

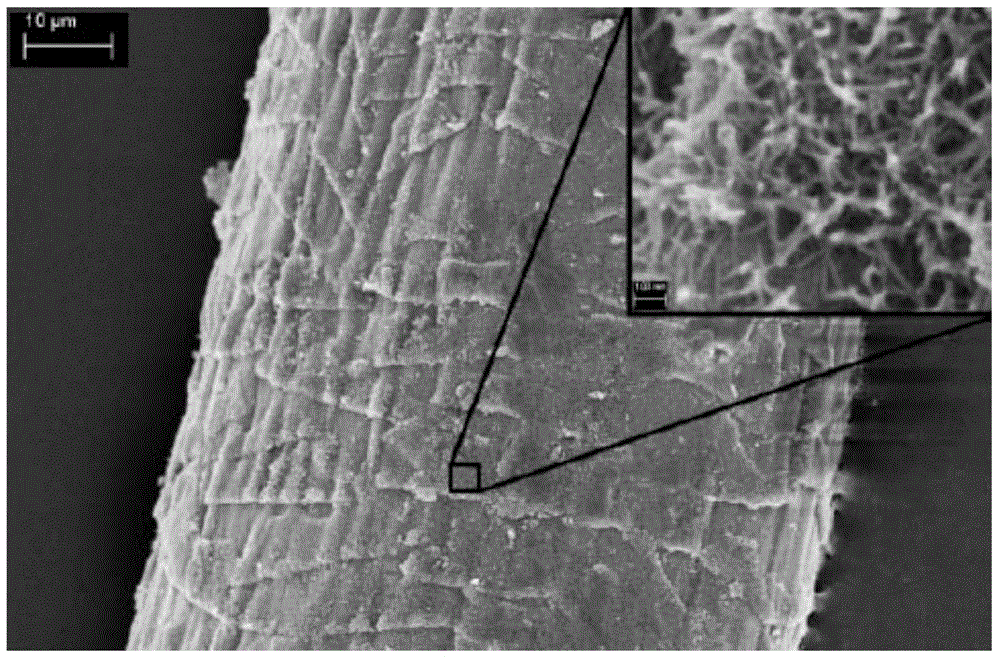

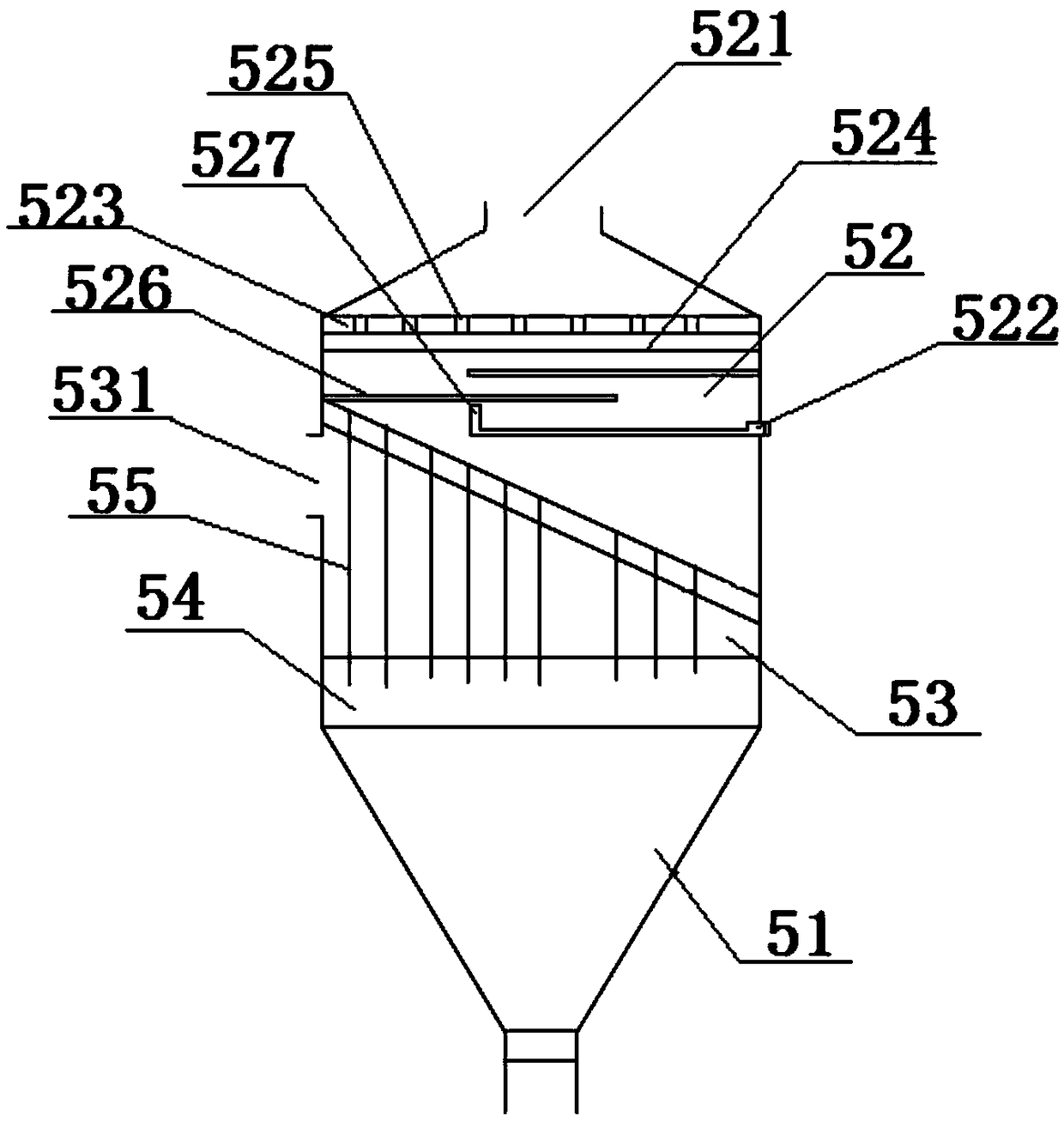

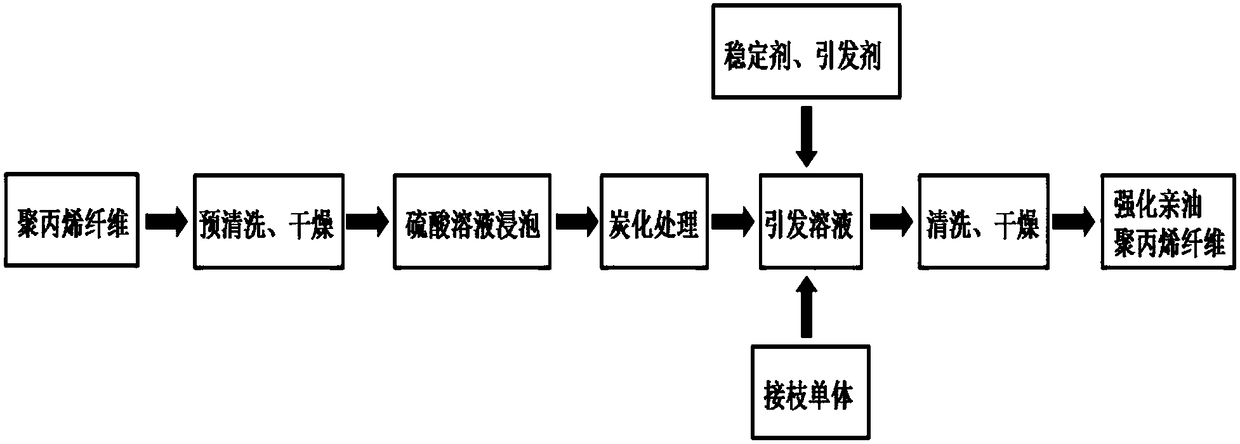

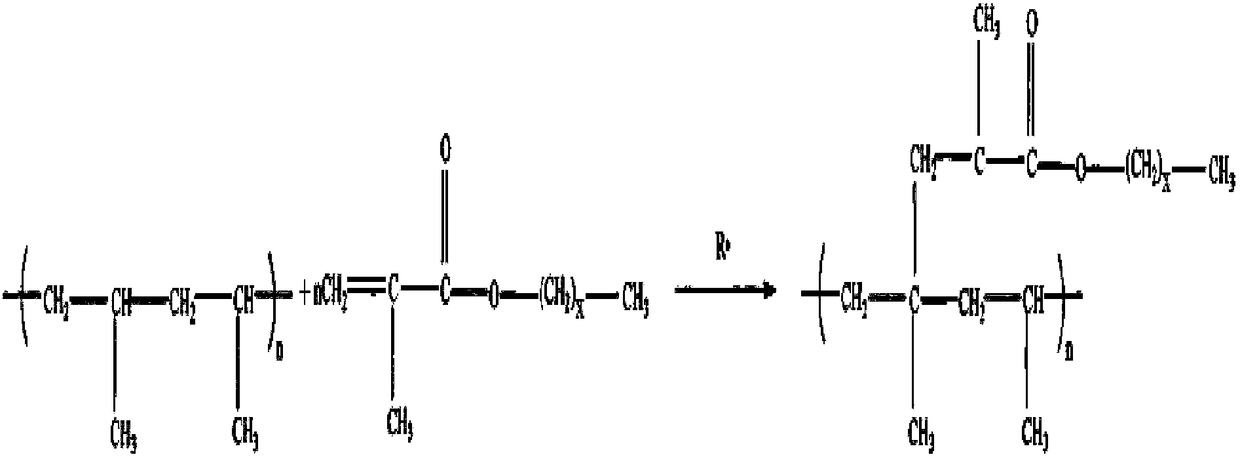

A two-step method for strengthening the lipophilic properties of polypropylene fibers

ActiveCN106012526BExcellent lipophilic adsorption performanceIncrease the areaFibre treatmentFibre chemical featuresOrganic fluidLipophilicity

The invention belongs to the technical field of material modification and particularly relates to a method for enhancing lipophilicity of a PP (polypropylene) fiber in two steps. Firstly, surface pretreatment is performed on the PP fiber with an acid solution, a lot of micropores are distributed in the surface of the fiber, the specific surface area is increased, the oil storage capability of the fiber is improved, then in combination with the chemical grafting copolymerization technology, one-component or multi-component alkyl (meth) acrylate is used as a monomer and matched with an initiator and a sweller, and grafting modification treatment is performed on the fiber; a lipophilic group is introduced onto the fiber, and the effect of enhancing adsorption separation is realized under the affinity effect of the lipophilic group and an organic liquid, and the lipophilic adsorption performance of the fiber is obviously improved. Meanwhile, the modified PP fiber is endowed with backwashing regeneration performance, and the method has the broad applicability.

Owner:EAST CHINA UNIV OF SCI & TECH

Device and method for integrated synchronous short-range nitrification and anammox combined with short-range denitrification to treat urban domestic sewage with low carbon-to-nitrogen ratio

ActiveCN110054294BReduce consumptionReduce aeration energy consumptionWater treatment parameter controlWater contaminantsNitrationEnvironmental chemistry

An integrated synchronous short-range nitrification anaerobic ammonium oxidation coupled short-range denitrification device and method for treating urban sewage with a low carbon-to-nitrogen ratio belongs to the technical field of sewage biological treatment. The device includes an urban sewage raw water tank, an SBR reactor, a blower aerator, and a water outlet tank. At the beginning of the reaction, the domestic sewage enters the SBR reactor first, and the denitrifying bacteria use the carbon source in the domestic sewage to reduce the remaining NO in the previous cycle. 3 ‑ Short-cut denitrification produces NO 2 ‑ ‑N Sync with NH 4 + ‑N is removed by anaerobic ammonium oxidation, and the remaining organic matter is stored by denitrifying bacteria to synthesize PHA in the body. After the reaction, low-oxygen aeration is performed, and an integrated anaerobic ammonium oxidation reaction is carried out on the biofilm to remove NH 4 + ‑N, generating a small amount of NO 3 ‑ ‑N, and then stirred, the denitrifying bacteria use the stored PHA for endogenous denitrification. The invention achieves NO in the form of short-cut nitrification and short-cut denitrification 2 ‑ Accumulation, efficient removal of N and COD in urban sewage, full use of organic matter in domestic sewage, no need for external carbon sources, saving aeration energy consumption, and achieving deep denitrification.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com