Method for fixing biological macro molecule pattern on polymer active surface by micro transfer technology

A technology of biological macromolecules and active surfaces, which is applied in the field of patterning and immobilizing biological macromolecules on polymer active surfaces with micro-transfer technology, can solve problems such as easy desorption and stability, and achieve high contrast, firmness and good application prospects. , the process is simple and flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

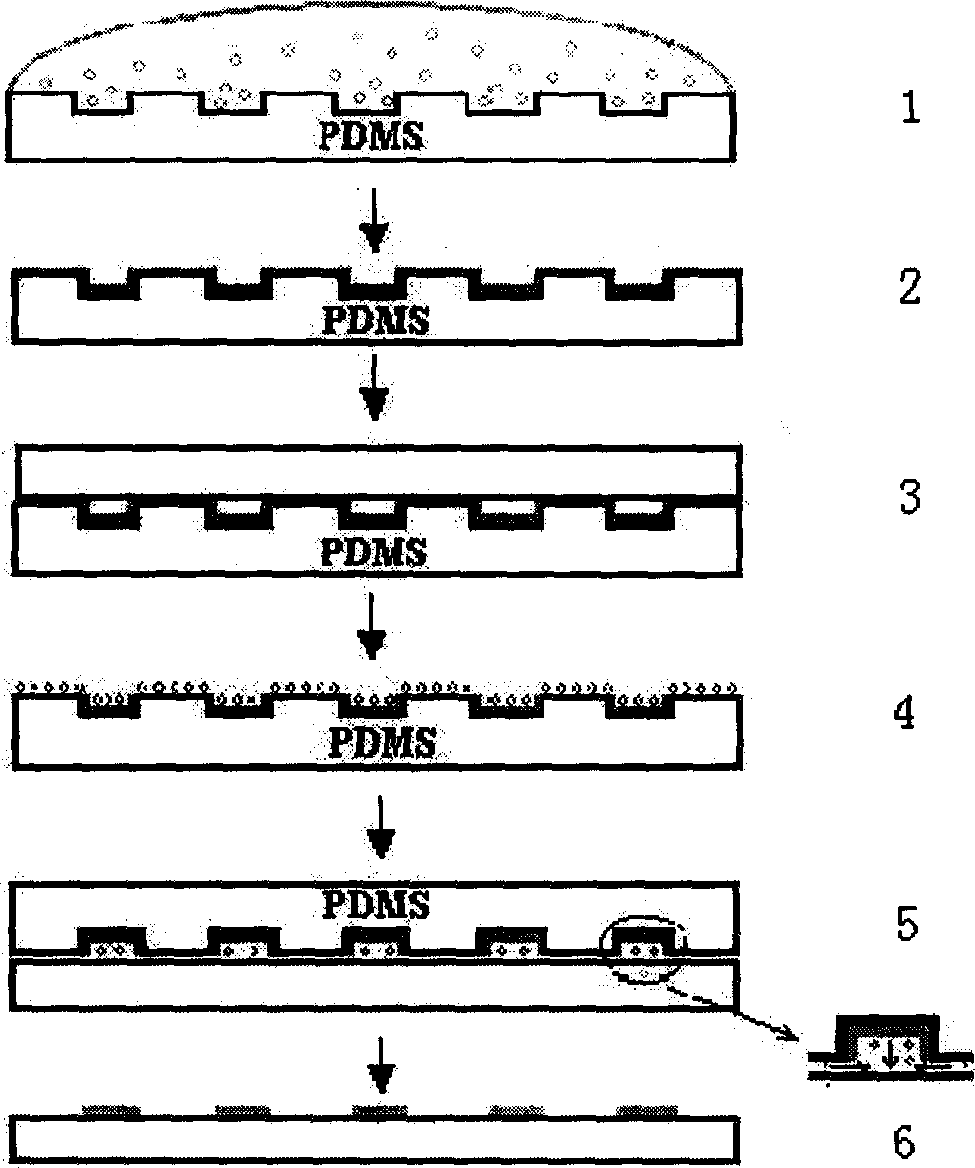

[0026] Example 1 The method for immobilizing biomacromolecules in a patterned polymer active surface with micro-transfer technology of the present invention comprises the following steps:

[0027] 1. Prepare the PCL film with free aldehyde groups on the surface: the PCL film is placed in the isopropanol solution of hexamethylenediamine with a concentration of 10% (wt), and it is aminated for 10 minutes at 37° C. Lots of free amine groups. Then put the PCL membrane rich in amine groups on the surface into 2% glutaraldehyde solution, and conduct a coupling reaction at 37° C. for 30 minutes to prepare the PCL membrane rich in free aldehyde groups on the surface. At this time, the film appears light red or orange red due to the aldylation reaction.

[0028] 2. Preparation of PDMS stamps with arrayed microwells on the surface: first prepare an original bottom mold with conventional "photolithography" technology, that is, on a clean 3×3cm 2 The surface of the glass slide was spin-...

example 2

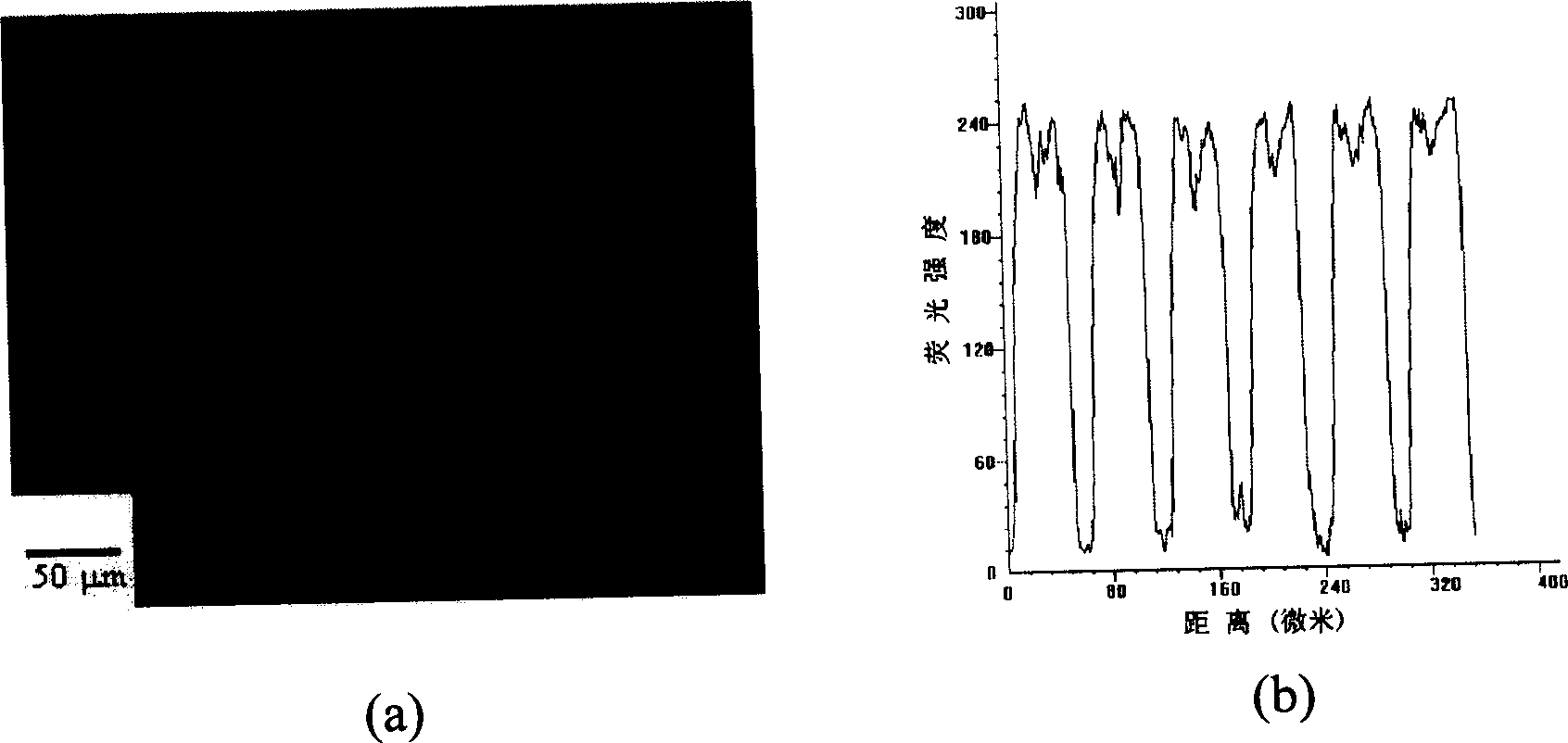

[0035] This example is a comparative example with the present invention. The other steps were the same as in Example 1, but the existing reactive microcontact printing technology was used to pattern and immobilize albumin. That is, dip-coat the PBS buffer solution of FITC-BSA with a concentration of 1.0 mg / ml on the side of the PDMS stamp with microwells, and slowly dry it with nitrogen flow, and quickly transfer it on the aldehyde-formed PCL membrane. Pressure, time, temperature and subsequent flushing are all the same as in Example 1. CLSM observation found that the BSA pattern obtained by this method ( Figure 5 a) It is much darker than the BSA pattern obtained by the present invention, and its corresponding fluorescence intensity analysis shows that the pattern contrast is also much lower ( Figure 5 b). Example 3

example 3

[0036] The other steps are the same as in Example 1, but the PDMS stamp is left standing for 0.1 minute or 3 minutes in an atmospheric environment (25°C) with a relative humidity of 80-90%, and its influence on the pattern quality is observed. It was found that the former formed a ring-shaped pattern due to insufficient condensation water ( Figure 6 a), the latter causing pattern "contamination" due to excess condensation ( Figure 6 b). This shows that when using the microtransfer method to pattern and immobilize biomacromolecules, the amount of condensed water formed on the PDMS surface has a great influence on the quality of the final pattern, and too low or too high will lead to pattern defects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com