Preparation method of biologic morphologies three dimensional network structure Pd system nano-photocatalyst material

A technology of network structure and biological morphology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficult to form multi-level nanocomposite materials, complex process flow, difficult to obtain materials, etc. , to achieve the effect of low preparation cost, simple process and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Select fresh poultry eggs, remove the liquid content, rinse the eggshells with clean water, soak in 1M hydrochloric acid solution for about 10 minutes to peel off the egg film, rinse thoroughly with clean water and deionized water three times, remove and blow at room temperature Dry in the air; weigh 4g of the above-mentioned clean and dry biological material egg membrane, soak it in the prepared 500ml palladium chloride solution with a concentration of 0.001M for 48 hours, take it out and dry it, put it into the induction cooker at 25°C / min Heat up to 400°C at a heating rate and keep at a constant temperature for 1.5 hours, then stop heating, and take it out after the furnace temperature naturally drops to room temperature. The obtained brown flakes are composed of Pd / PdO.

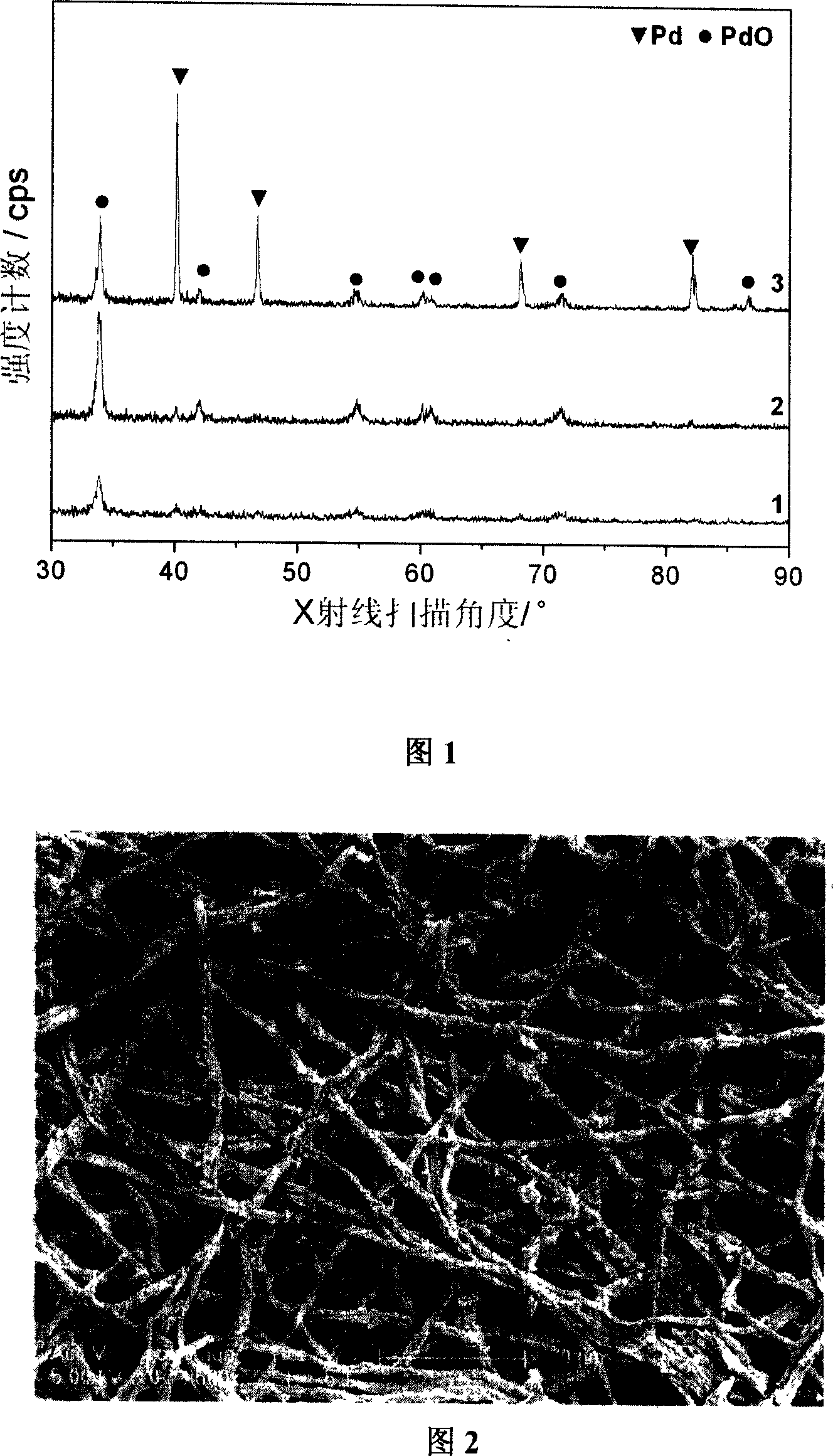

[0028] Curve 1 in Figure 1 shows the XRD pattern of the three-dimensional network structure nano-Pd / PdO photocatalytic composite material prepared at 400°C. The results show that the diffraction pe...

Embodiment 2

[0031] Select fresh poultry eggs, remove the liquid content, rinse the eggshells with clean water, soak in 1M hydrochloric acid solution for about 10 minutes to peel off the egg film, rinse thoroughly with clean water and deionized water three times, remove and blow at room temperature Dry in the air; weigh 4g of the above-mentioned clean and dry biological material egg membrane, immerse it in the prepared 500ml palladium chloride solution with a concentration of 0.002M for 30 hours, take it out and dry it, put it in an induction cooker at a temperature of 25°C / min. Heat up to 500°C at a heating rate and keep at a constant temperature for 1.5 hours, then stop heating, and take it out after the furnace temperature naturally drops to room temperature. The obtained brown flakes are composed of Pd / PdO.

[0032] Curve 2 in Figure 1 shows the XRD pattern of the three-dimensional network structure nano-Pd / PdO photocatalytic composite material prepared at 500 °C. The results show that t...

Embodiment 3

[0037] Select fresh poultry eggs, remove the liquid content, rinse the eggshells with clean water, soak in 1M hydrochloric acid solution for about 10 minutes to peel off the egg film, rinse thoroughly with clean water and deionized water three times, remove and blow at room temperature Dry in the air; weigh 4g of the above-mentioned clean and dry biological material egg film, dip it in the prepared 500ml palladium chloride solution with a concentration of 0.005M for 30 hours, take it out and dry it, put it into the induction cooker at 25°C / min Heat up to 550°C at a heating rate and keep at a constant temperature for 1.5 hours, then stop heating, and take it out after the furnace temperature naturally drops to room temperature. The composition of the resulting brown flakes is Pd / PdO.

[0038] Curve 3 in Figure 1 shows the XRD pattern of the three-dimensional network structure nano-Pd / PdO photocatalytic composite material prepared at 550°C. The results show that while the inten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average width | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com