Device with energy conservation and emission reduction effects and simultaneous desulfurization and denitrification effects on flue gas and special coating for device

A technology for desulfurization, denitrification, energy saving and emission reduction. It is used in coatings, combined devices, and greenhouse gas reduction. It can solve problems such as air pollution and large ash content, and achieve the effects of environmental protection, high dust removal efficiency and short dust removal time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

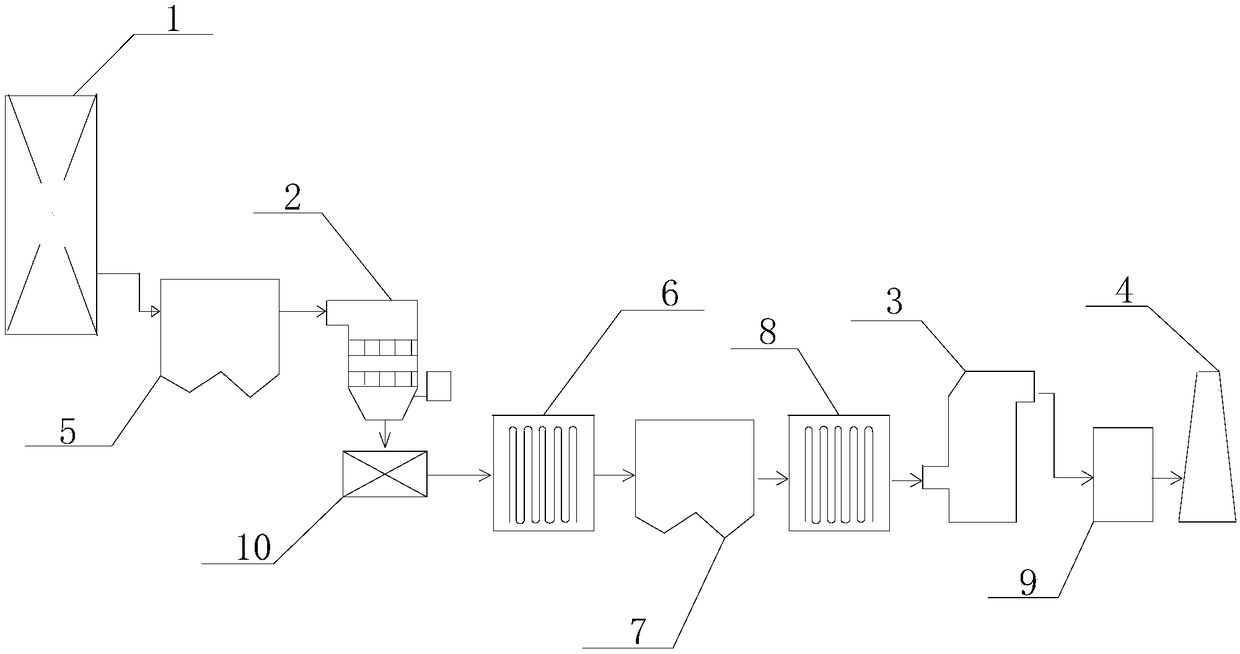

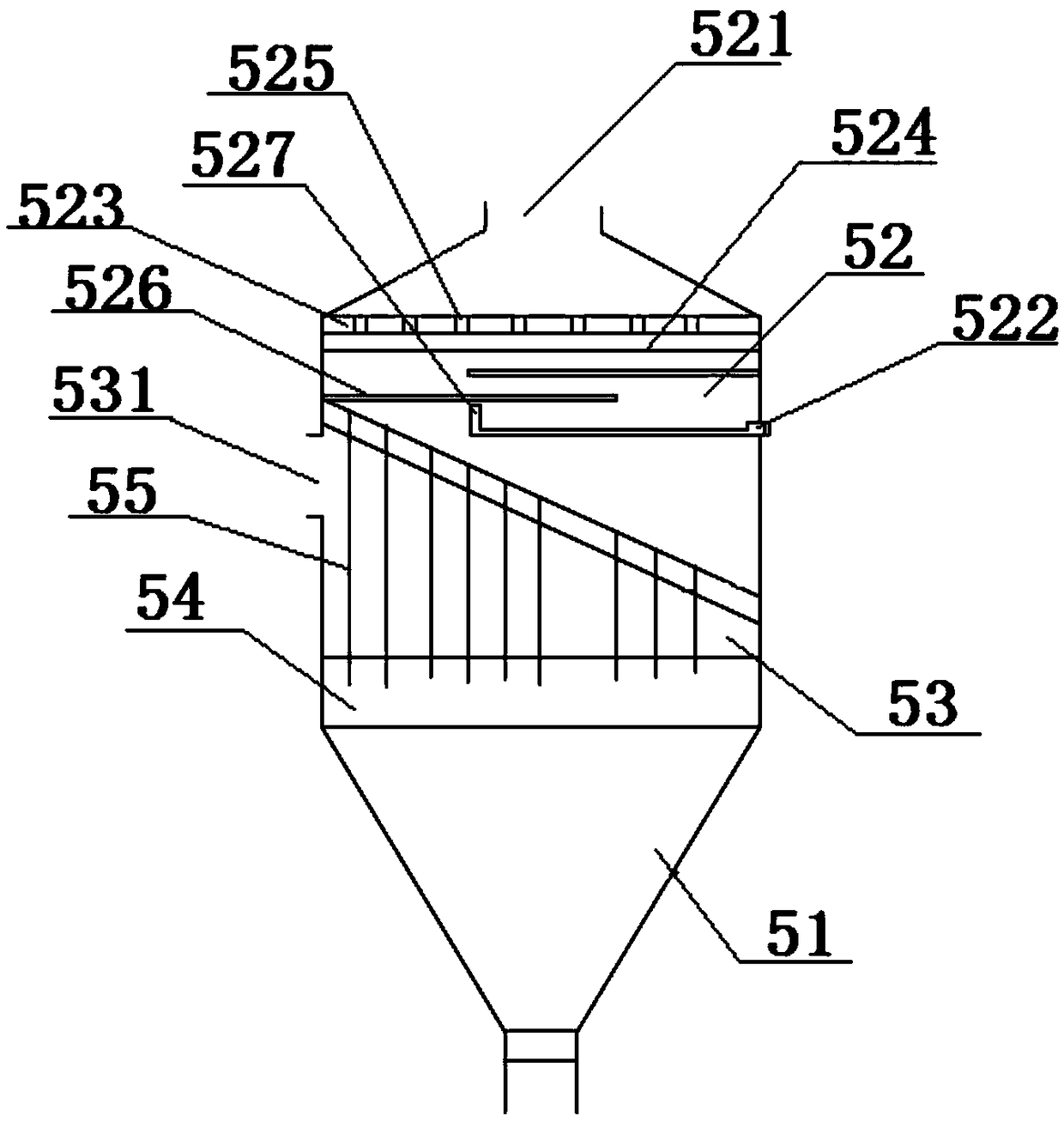

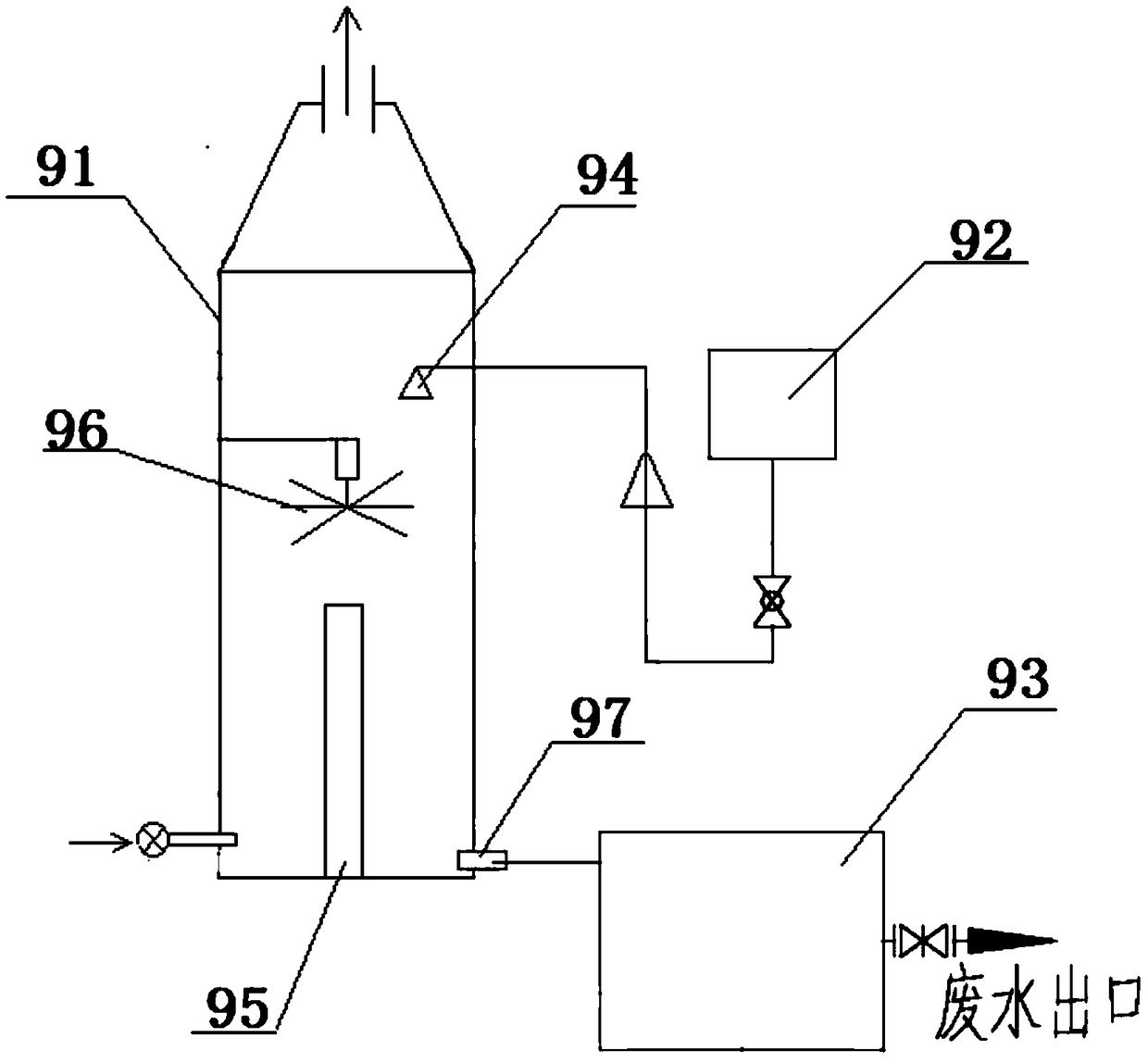

[0047] This embodiment provides an energy-saving and emission-reducing flue gas simultaneous desulfurization and denitrification device, the structure of which is as follows Figure 1-3 As shown, it includes boiler 1, denitrification device 2, desulfurization device 3 and chimney 4, and is characterized in that: the output end of boiler 1 is connected with the input end of denitrification device 2 through the first dust collector 5, and the output end of denitrification device 2 is connected with Air preheater 10, the output end of air preheater 10 is connected with first heat exchanger 6, the output end of first heat exchanger 6 is connected with the input end of second dust remover 7, the output of second dust remover 7 end is connected with the second heat exchanger 8 through the fan, the output end of the second heat exchanger 8 is connected with the desulfurization device 3, the output end of the desulfurization device 3 is connected with the lye absorption device 9, and t...

Embodiment 2

[0058] This embodiment provides a special coating for the device in Example 1, the coating comprises the following components in parts by mass:

[0059] Silicone modified epoxy resin: 15 parts, polyaryl ether sulfone ketone modified resin: 10 parts, black silicon carbide: 5 parts, leveling agent: 1 part, filler: 1 part, plasticizer: 5 parts, contact Variable agent: 2 parts, precipitated barium sulfate: 5 parts, pigment: 1 part, dispersant: 3 parts, curing agent: 10 parts, compound rare earth: 0.01 part;

[0060] Silicone-modified epoxy resin includes the following components in terms of mass percentage: deionized water: 13%, dibutyltin dilaurate: 10%, methyltriethoxysilane: 10%, and the balance is epoxy resin, above The sum of each component is 100%;

[0061] The plasticizer is dioctyl phthalate; the pigment is titanium dioxide; the dispersant is sodium tripolyphosphate; the curing agent is a modified polyamide curing agent; the thixotropic agent is organic montmorillonite an...

Embodiment 3

[0073] This embodiment provides a special coating for the device in Example 1, the coating comprises the following components in parts by mass:

[0074] Silicone modified epoxy resin: 20 parts, polyarylethersulfone ketone modified resin: 12 parts, black silicon carbide: 7 parts, leveling agent: 2 parts, filler: 3 parts, plasticizer: 5-7 parts , thixotropic agent: 4 parts, precipitated barium sulfate: 7 parts, pigment: 3 parts, dispersant: 5 parts, curing agent: 13 parts, composite rare earth: 0.03 parts;

[0075] Silicone-modified epoxy resin includes the following components in terms of mass percentage: deionized water: 18%, dibutyltin dilaurate: 13%, methyltriethoxysilane: 14%, and the balance is epoxy resin, above The sum of each component is 100%;

[0076] The plasticizer is tricresyl phosphate; the pigment is iron oxide red; the dispersant is sodium tetrapolyphosphate; the curing agent is a modified polyamide curing agent; the thixotropic agent is organic montmorillonite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com