Pressing mold device for hot pressure prepared fuel cell membrane electrode

A fuel cell membrane and pressing mold technology, which is applied to fuel cell parts, battery electrodes, circuits, etc., can solve the problems of not ensuring the reliability of the membrane-electrode bonding, and failing to solve the problem of accurate positioning of each component of the membrane and electrode. Good membrane electrode interface structure, small cooling range and strong interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

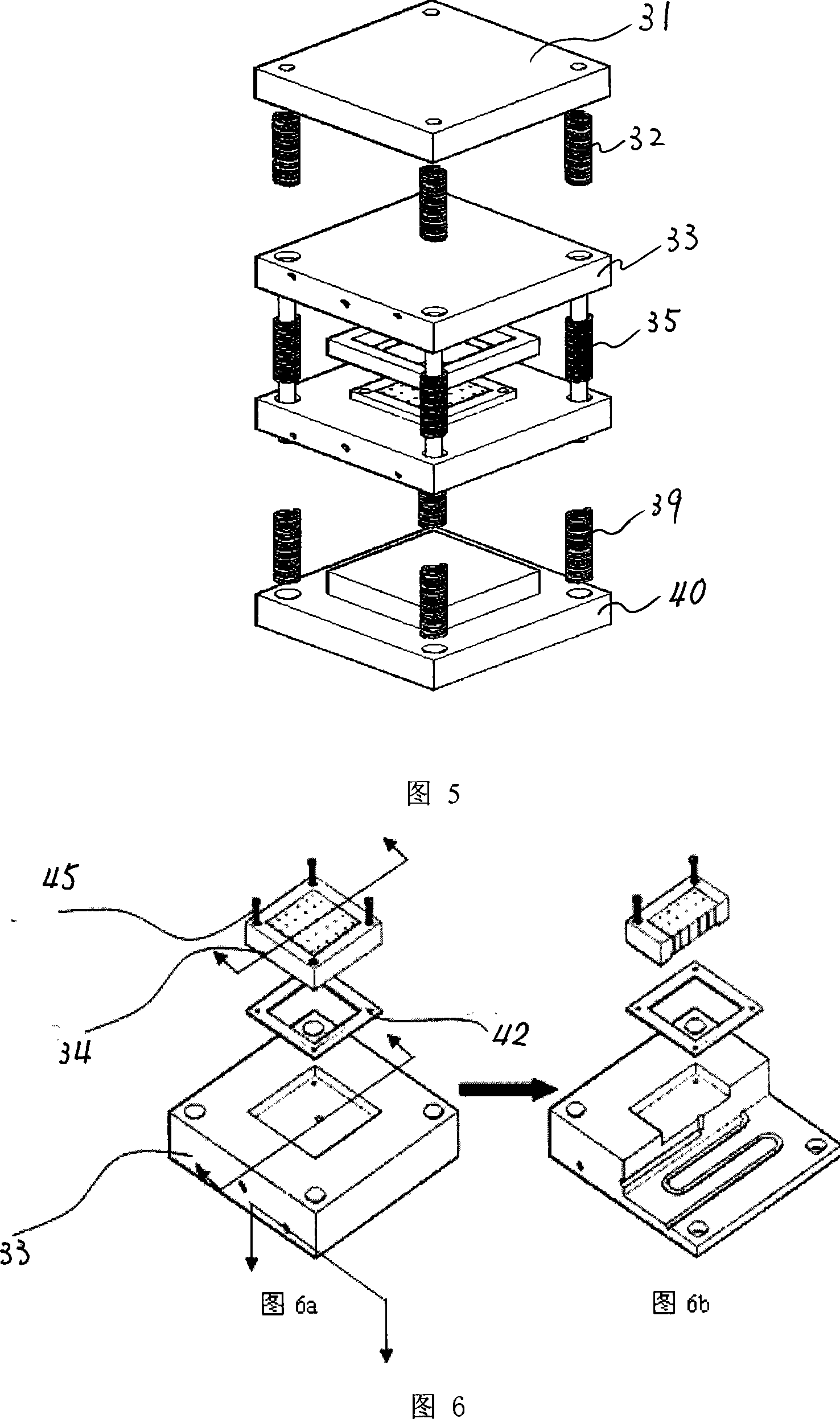

[0027]As shown in Figure 3, the pressing die device for hot pressing of the present invention to prepare fuel cell membrane electrodes includes: an upper pressing plate 31, an upper pressing plate and an upper die module release spring 32, an upper die holder 33, and an upper die head 34 , upper and lower die module disengagement spring 35, positioning frame 36, lower die head 37, lower die base 38, lower pressing plate and lower die module disengaging spring 39, lower pressing plate 40, positioning guide post 41, upper and lower die head and upper , Lower mold base sealing gaskets 42,44. Among the figures 31, 33, 38, 40 are all provided with positioning through-holes that are slidingly fitted with the positioning guide post 41. Grooves are provided at the centers of both sides of the upper and lower die heads 34 and 37, and arrayed small holes 34a and 37a are respectively provided with the two grooves, and the diameter of the holes is between 0.3-0.8mm. The groove between th...

Embodiment 2

[0031] Second embodiment of the present invention Referring to Fig. 7, this set of press-fitting die device for hot-pressing the preparation of fuel cell membrane electrodes and the die device in Embodiment 1 only change the shape of the upper and lower die grooves and the number of divisions. Used to prepare 4 pieces of active area of 20cm on the same ion exchange membrane 2 the membrane electrode. The positioning groove of the die head is evenly divided into 4 areas with an area of 20cm 2 region, the dimensions of each region are consistent with the diffusion layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com