Internal control point vertical transmission automatic scribing device and scribing method thereof

An automatic scribing and vertical technology, applied in workshop equipment, manufacturing tools, etc., can solve problems such as inconvenient construction measurement and errors, and achieve the effect of promoting intelligent application, reducing construction measurement errors, and ensuring vertical alignment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

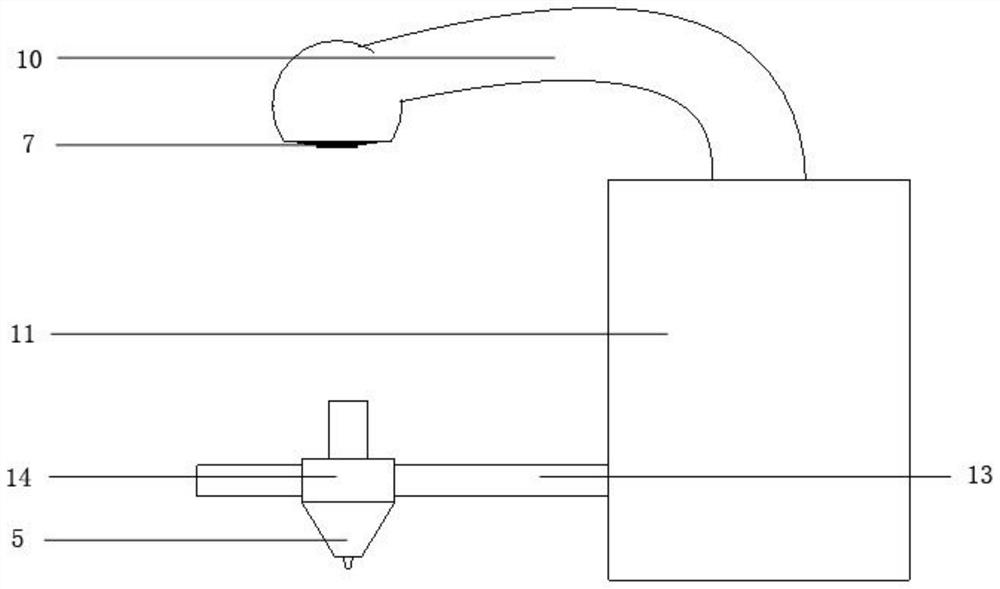

[0062] This embodiment provides a preferred embodiment, an automatic scribing device for vertical transmission of internal control points, such as Figure 1 to Figure 5 As shown, this embodiment includes a laser plumb instrument 1 and an automatic scribing instrument, wherein:

[0063] The above-mentioned laser plumb instrument 1 is erected on the first floor 2 of a multi-storey building, and the laser beam 8 of the laser plumb instrument 1 vertically passes through the reserved square holes 3 of each building layer from bottom to top.

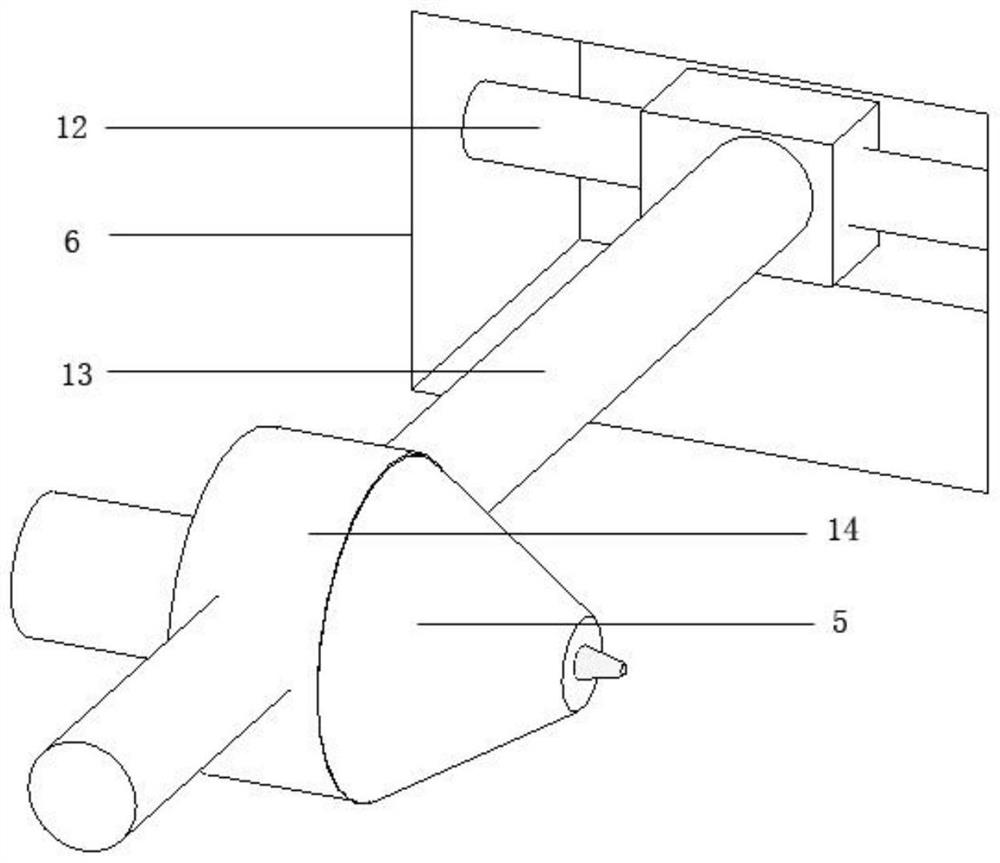

[0064] The above-mentioned automatic scriber is arranged on the superstructure layer 4 near the reserved square hole 3, and the automatic scriber includes a laser receiving mechanism, a nozzle 5 and a three-dimensional moving mechanism of the nozzle.

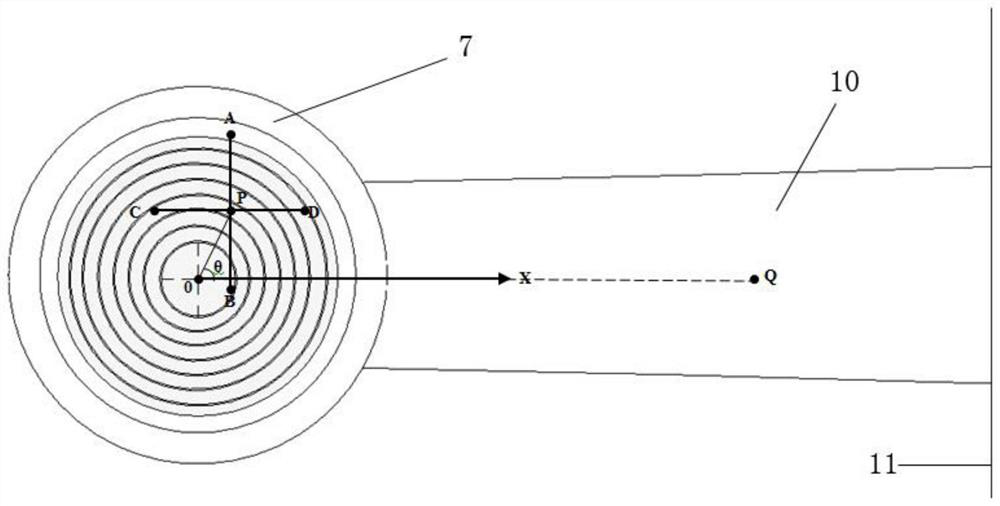

[0065] Further, the above-mentioned laser receiving mechanism includes a laser receiving end 7, a camera and a laser intelligent receiving and processing system, and the specific structure is as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com