Construction technology of recyclable steel pipe pile without grouting

A construction technology and steel pipe pile technology, which is applied in sheet pile walls, foundation structure engineering, excavation, etc., can solve the problems of underground pollution, waste of building materials, etc., and achieve saving of steel and cement, saving of construction costs, and large support depth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

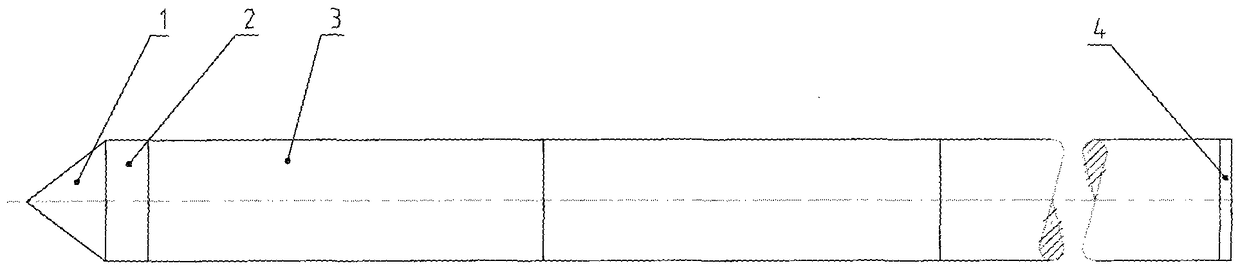

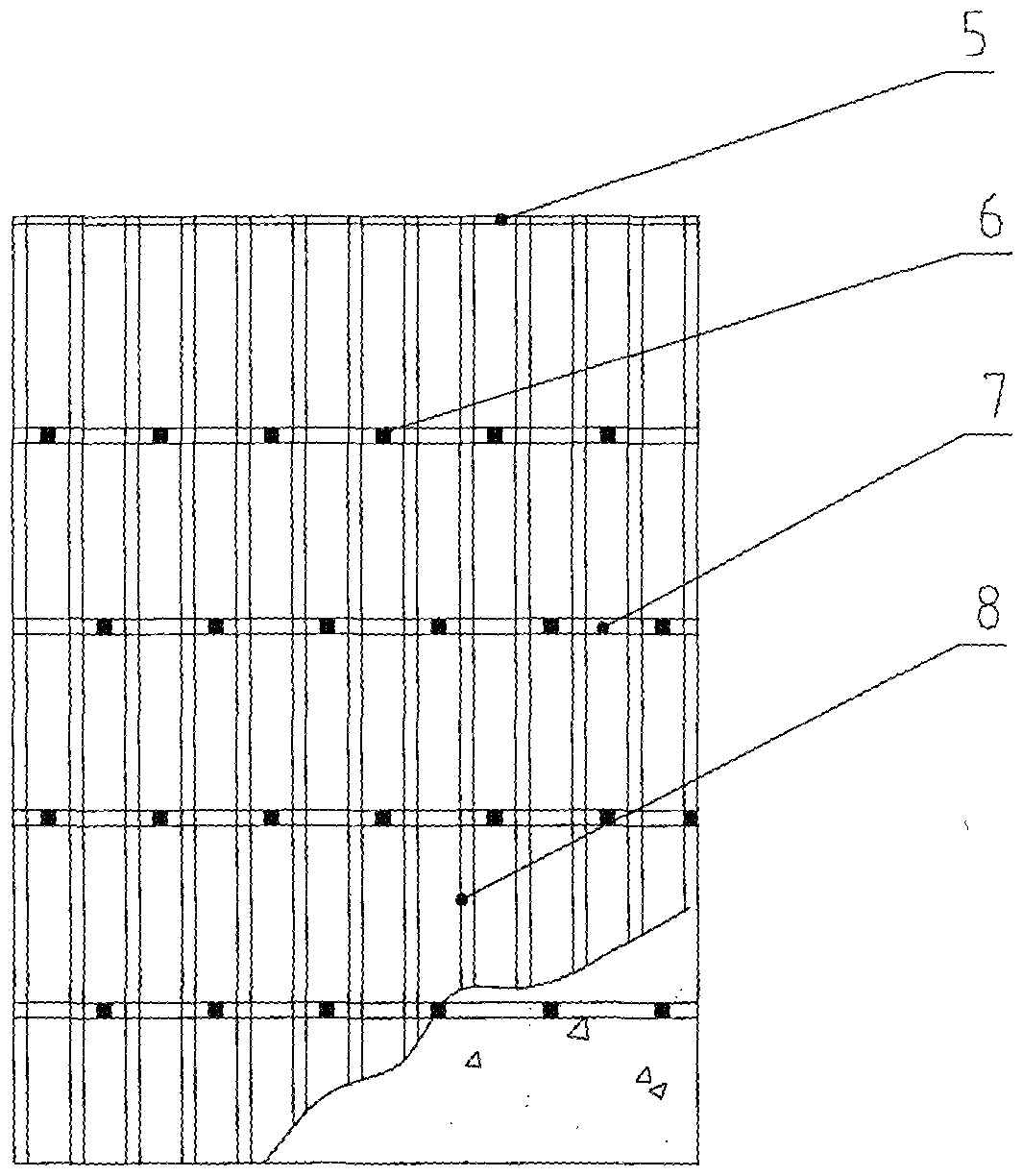

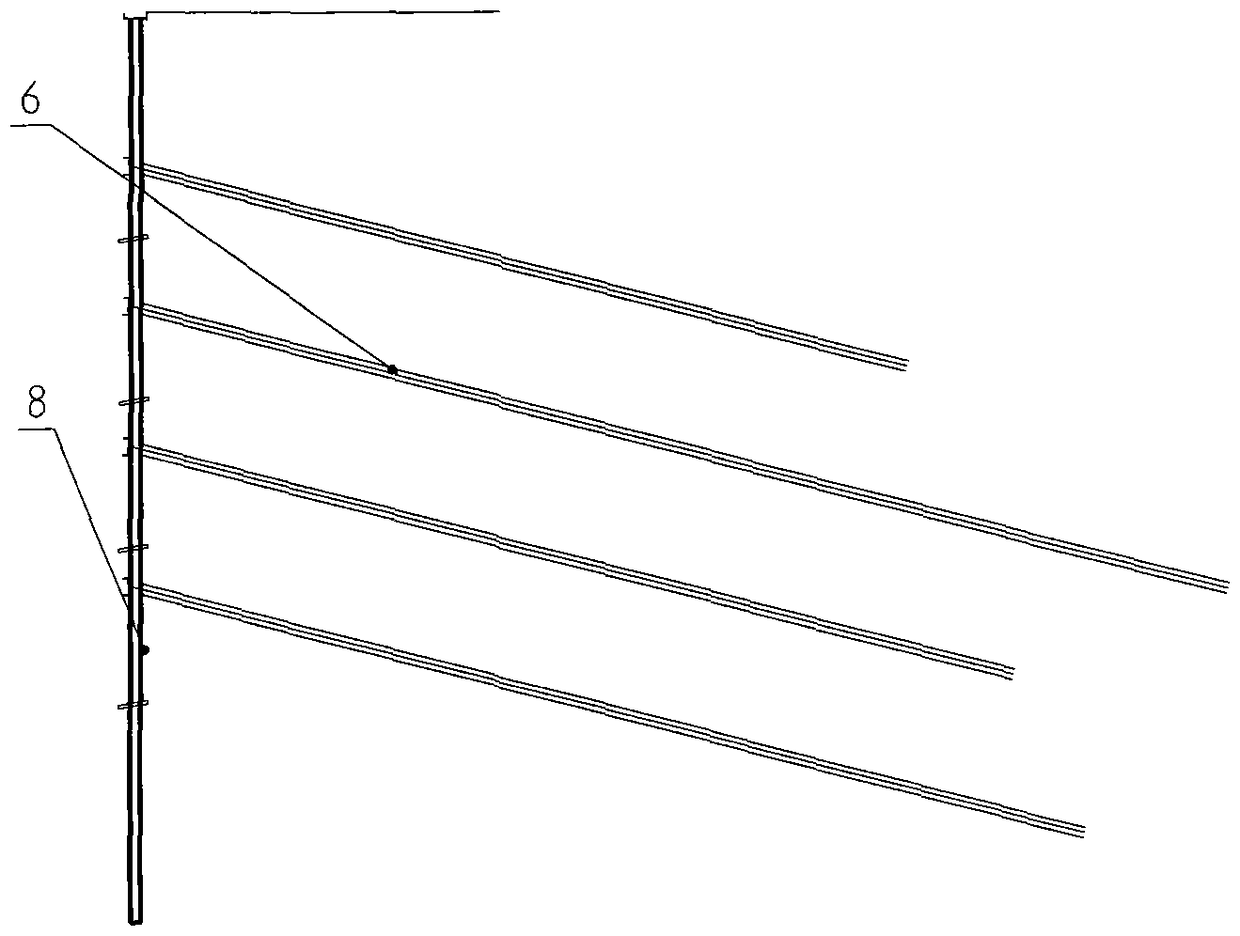

[0024] Refer to attached figure 1 To attach image 3 , in the figure: bottom pointed cover 1, wire plug 2, thick-walled steel pipe 3, top flat cover 4, recyclable crown beam 5, anchor cable 6, waist beam 7, recyclable steel pipe pile 8 without grouting.

[0025] In this embodiment, there are two ways to manufacture steel pipe piles: threaded connection and welded connection.

[0026] Production of threaded steel pipe piles: both ends of the thick-walled steel pipe 3 are welded with internal and external threaded joints through the seam to form a steel pipe pile (completed in the processing workshop); A section of steel pipe piles is connected by threads; the steel pipe pile with the bottom tip cap 1 is the starting end, and each section of steel pipe piles is connected two by two through internal and external threaded joints, and the top of the steel pipe pile is the top Flat cover 4, see attached figure 1 .

[0027] Fabrication of welded steel pipe piles: At the support s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com