Bolt connecting prefabricated concrete frame structure

A prefabricated concrete and prefabricated concrete slab technology, applied in building components, building structure, earthquake-proof and other directions, can solve the problems of prefabricated component steel bar positioning error and high requirements for grouting equipment, affecting the overall performance of the frame structure, and grouting is not compact, etc. The effect of fast construction, easy hoisting and positioning, and convenient grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

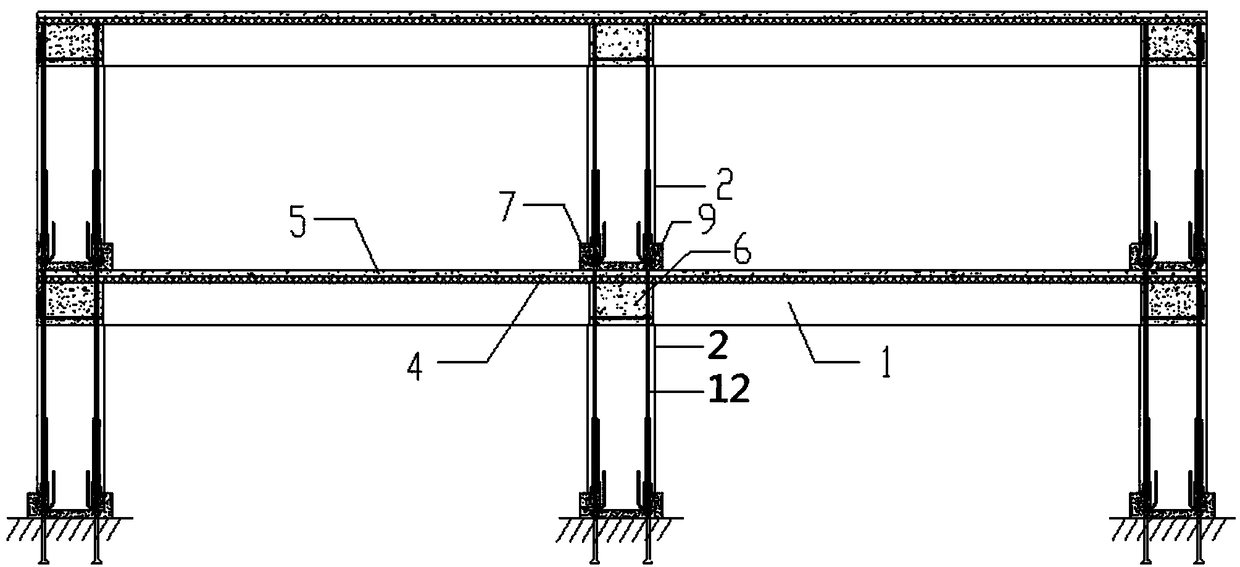

[0030] like figure 1 As shown, the bolt-connected precast concrete frame structure includes a plurality of precast concrete columns 2, a plurality of precast concrete beams 1, a plurality of precast concrete slabs 4, a post-cast concrete laminate layer 5, a plurality of post-cast concrete beam connection node areas 6 and Column foot grouting area 9.

[0031] The plurality of precast concrete columns 2 at the bottom are distributed in a grid shape, and the plurality of precast concrete columns 2 are arranged vertically on the ground in rows, each row is parallel to each other, and the positions of adjacent rows and adjacent precast concrete columns 2 are aligned of.

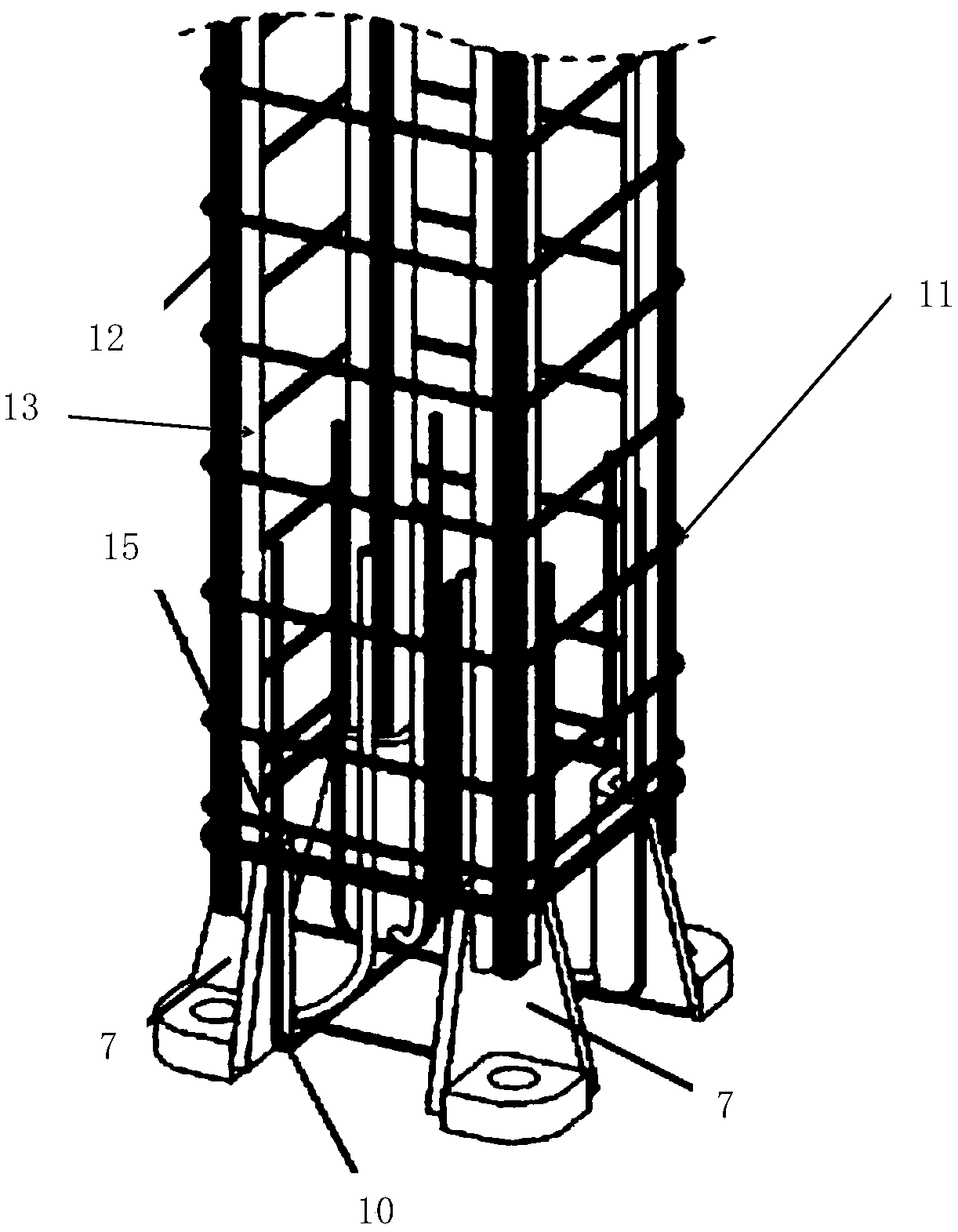

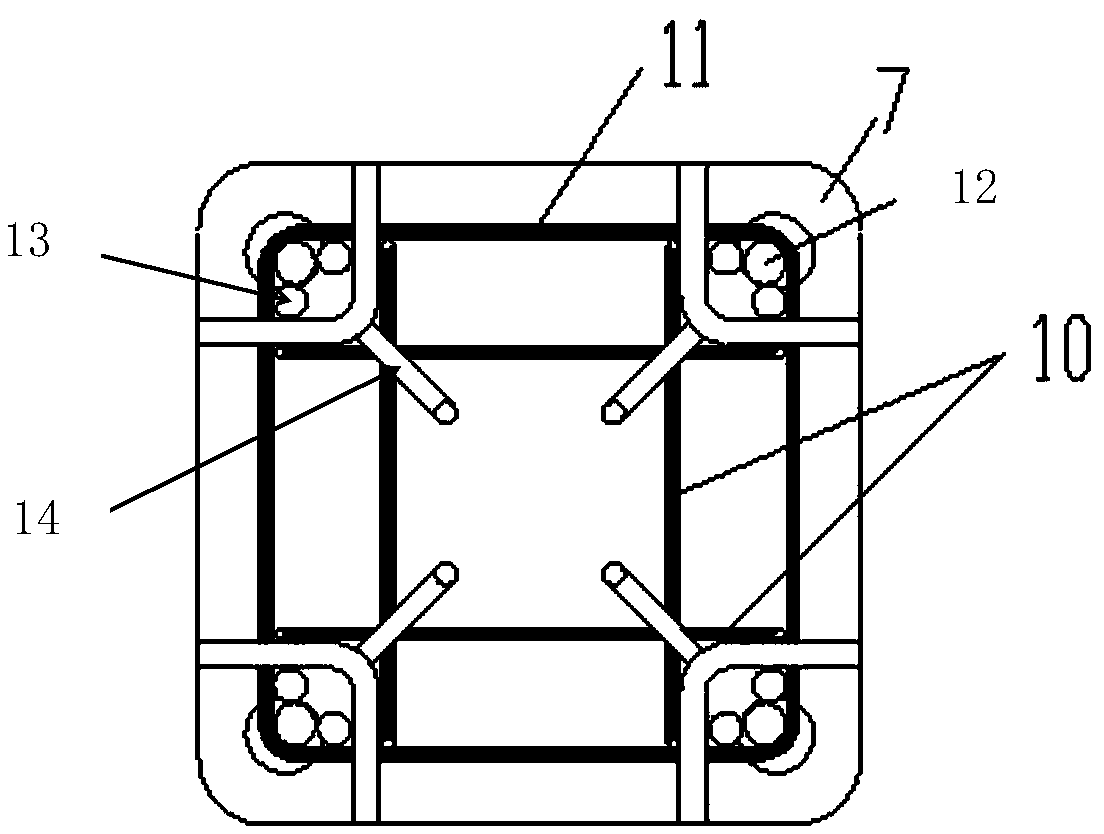

[0032] like figure 2 , 3 As shown, the prefabricated concrete column 2 includes 4 connectors 7, 4 U-shaped stirrups 10, multiple transverse stirrups 11, 4 longitudinal reinforcements 12, 8 lapping reinforcements 13, 4 positioning reinforcements 14, 2 Additional stirrups 15.

[0033] In the embodiment, the pr...

Embodiment 2

[0052] The present embodiment is the same as the other structure of the first embodiment, except that the ends of the four longitudinal steel bars 12 exposed to the concrete in the first embodiment are replaced by pre-embedded high-strength screw rods.

[0053] The top area of the high-strength screw is provided with external threads.

[0054] Function and effect of embodiment

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com