Guide rail vibration isolation structure

A kind of guide rail and vibration isolation technology, used in elevators, transportation and packaging, etc., to achieve reliable fixation, reduce friction and vibration noise, and facilitate adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

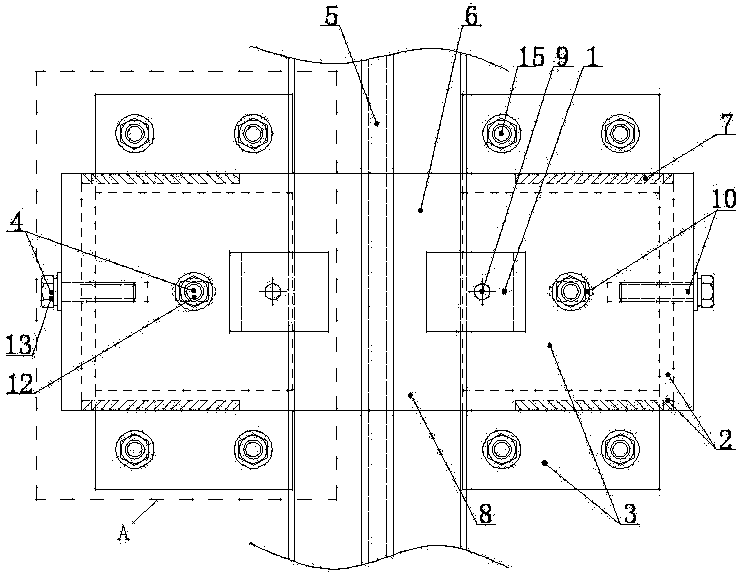

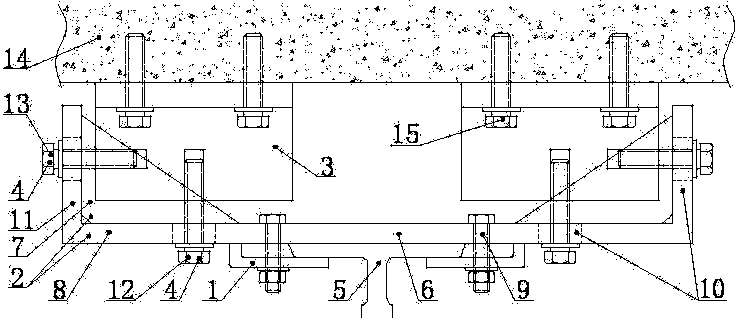

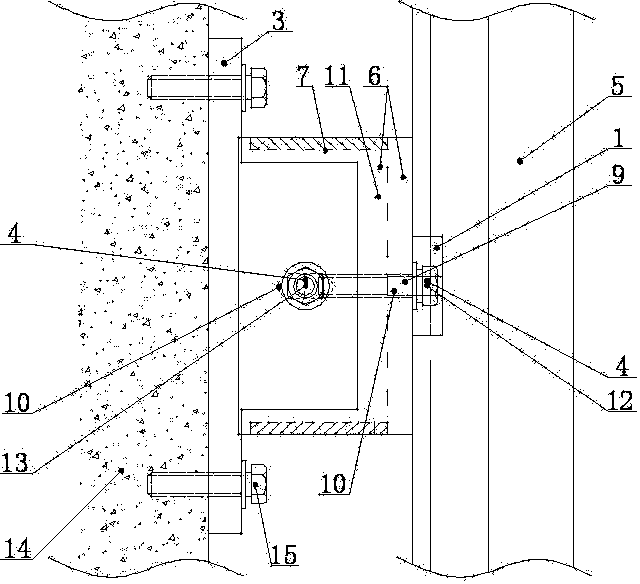

[0014] exist figure 1 , 2 , In the embodiment shown in 3, each guide rail vibration isolation structure consists of two guide rail fixing plates (1), a supporting steel structure (2), two elastic damping parts (3), and 4 adjusting bolts (4) composition. The elevator guide rail (5) is installed on the supporting steel structure (2) through the guide rail fixing plate (1), and the two elastic vibration dampers (3) are respectively connected with the two sides of the supporting steel structure (2) through adjusting bolts (4). The supporting steel structure (2) is composed of U-shaped steel plate structure (6) and stiffeners (7). The front of the U-shaped steel plate structure (8) is provided with two guide rail fixing plates (1) with round holes (9) and two adjustment bolts (4) Install the oblong hole (10). Stiffeners (7) are arranged between the U-shaped steel plate structure front (8) and the U-shaped steel plate structure side (11), and the U-shaped steel plate structure si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com