Patents

Literature

303results about How to "Reduce friction noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanomer vibration-reducing noise-reducing self-repairing material and its prepn process

InactiveCN1740290AAutomatically adjust thicknessOptimizing friction pair clearanceBase-materialsMachine partsRepair material

The nanometer vibration-reducing and noise-reducing self repairing material is prepared with nanometer level metal powder and natural ore powder as main material and through adding several kinds of supplementary material and certain technological process, and is added into lubricating oil or ultrasonic medium as high performance repair material. The present invention features that the high performance repair material can create high hardness self-repairing lubricating film fast on the surface of metal friction pairs to regulate the interval of the friction pair, reduce friction coefficient, raise bearing capacity, leveling the friction surface, reduce vibration and noise caused by the unbalance, friction and damage of the moving machine parts, and prolong the service life of the machine parts. The present invention may be used widely in improving performance of mechanical friction parts.

Owner:JIANGSU MOLEDN PETROCHEM

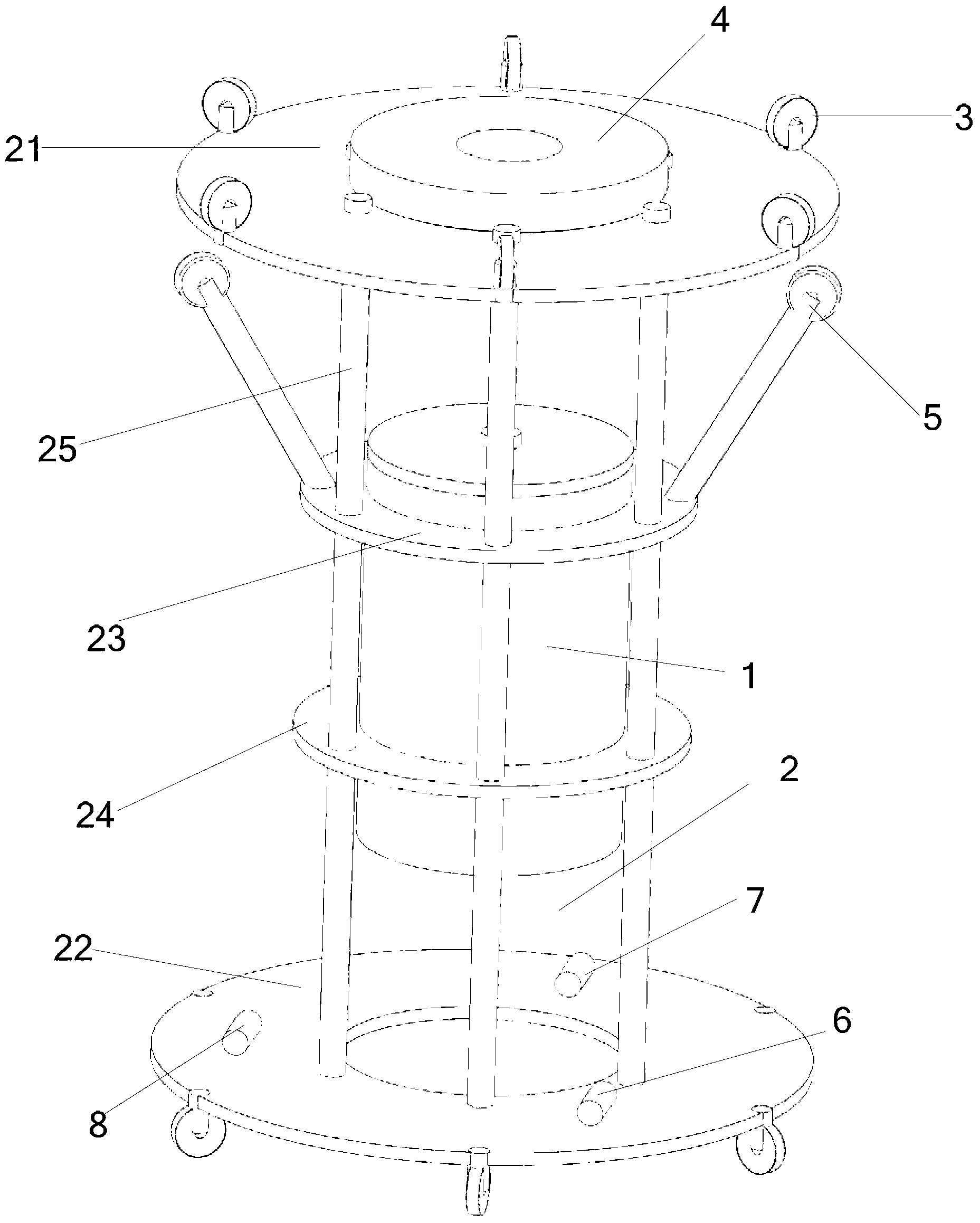

Inner detection system for submarine pipelines and detection method thereof

The invention discloses an inner detection system for submarine pipelines and a detection method thereof. The inner detection system comprises an electronic sealed cabin arranged in a supporting frame. The supporting frame is provided with a supporting roller array, an odometer wheel, a pressure sensor, a temperature sensor and a sound sensor, wherein the supporting roller array, the odometer wheel, the pressure sensor, the temperature sensor and the sound sensor are distributed in an annular mode. The detection method includes: the inner detection system is connected to an upper computer to download signals collected by the sensors, and filtering and noise reduction processing is performed on the signals; traveling mileage of the inner detection system and included angles of the axis of the inner detection system and a local geomagnetic field and local gravitational acceleration are calculated at any time t, and a direction vector of the axis of the inner detection system is obtained through the included angles; the position of the inner detection system at any time is obtained; and whether leakage exists is judged through comparison of processed sound signals, pressure signals and temperature signals, and leakage rate is estimated. The inner detection system for submarine pipelines and the detection method of the inner detection system achieve detection of little leakage, improve detection accuracy, reduce detection difficulty and cost, and shorten detection period.

Owner:TIANJIN UNIV

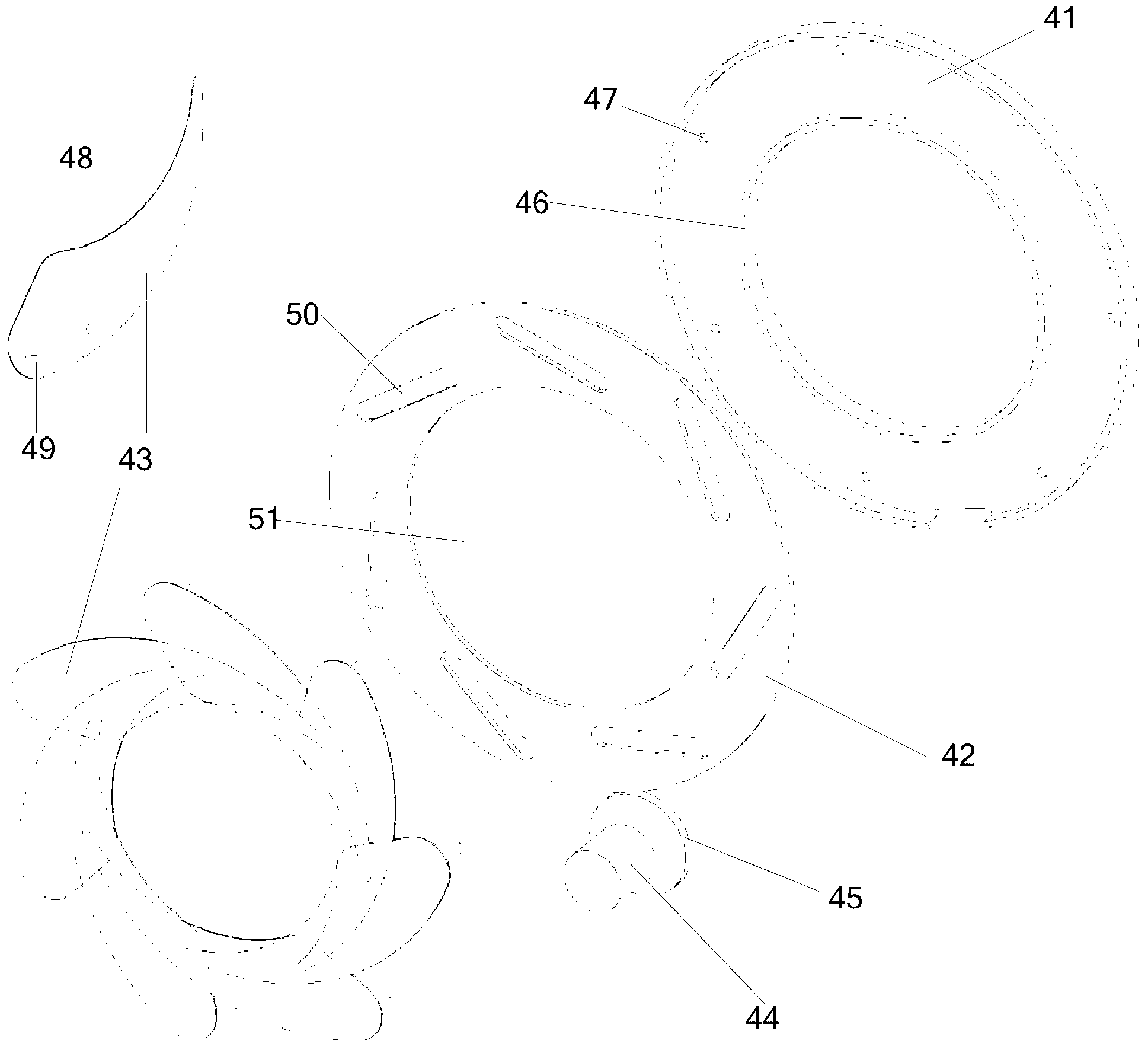

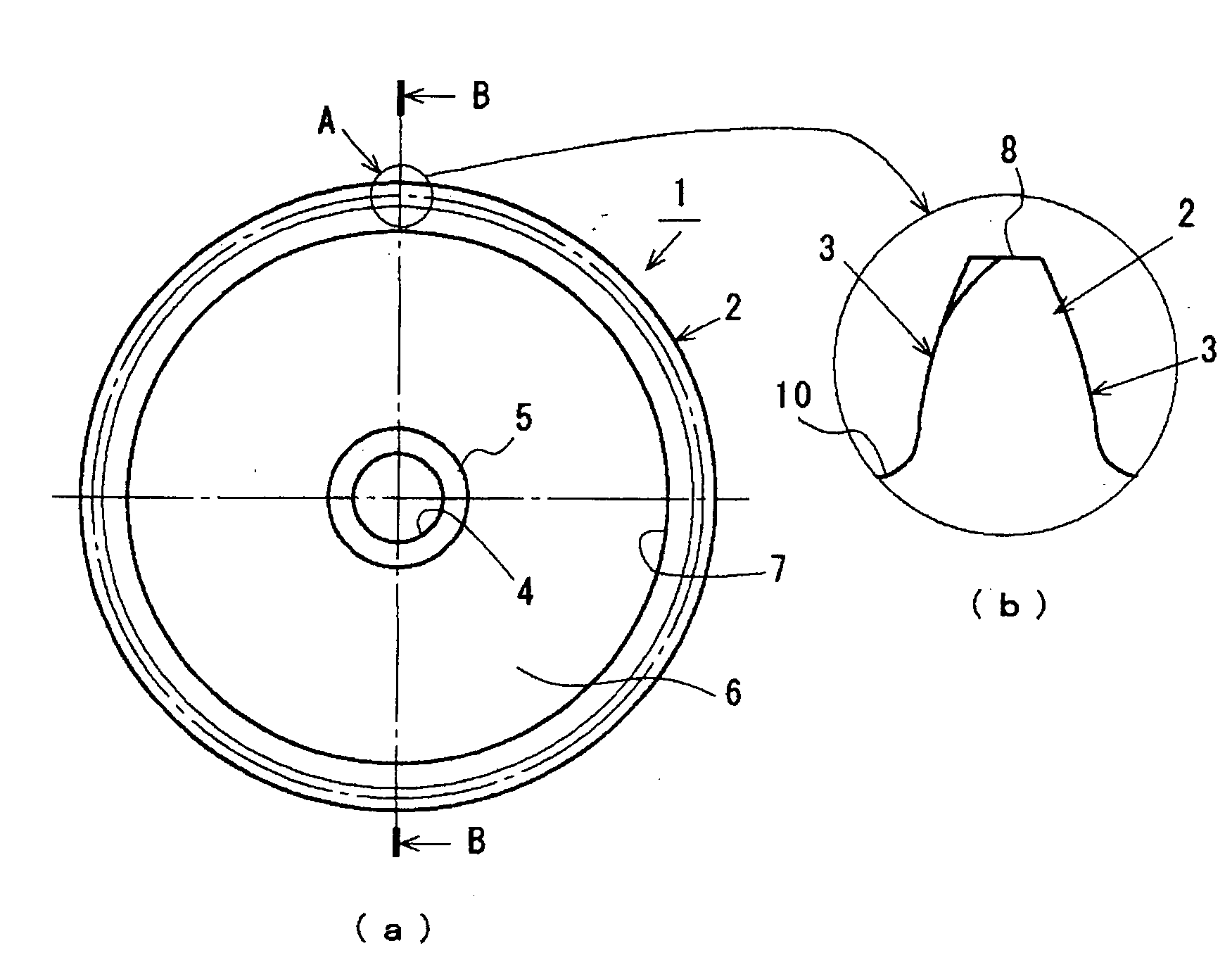

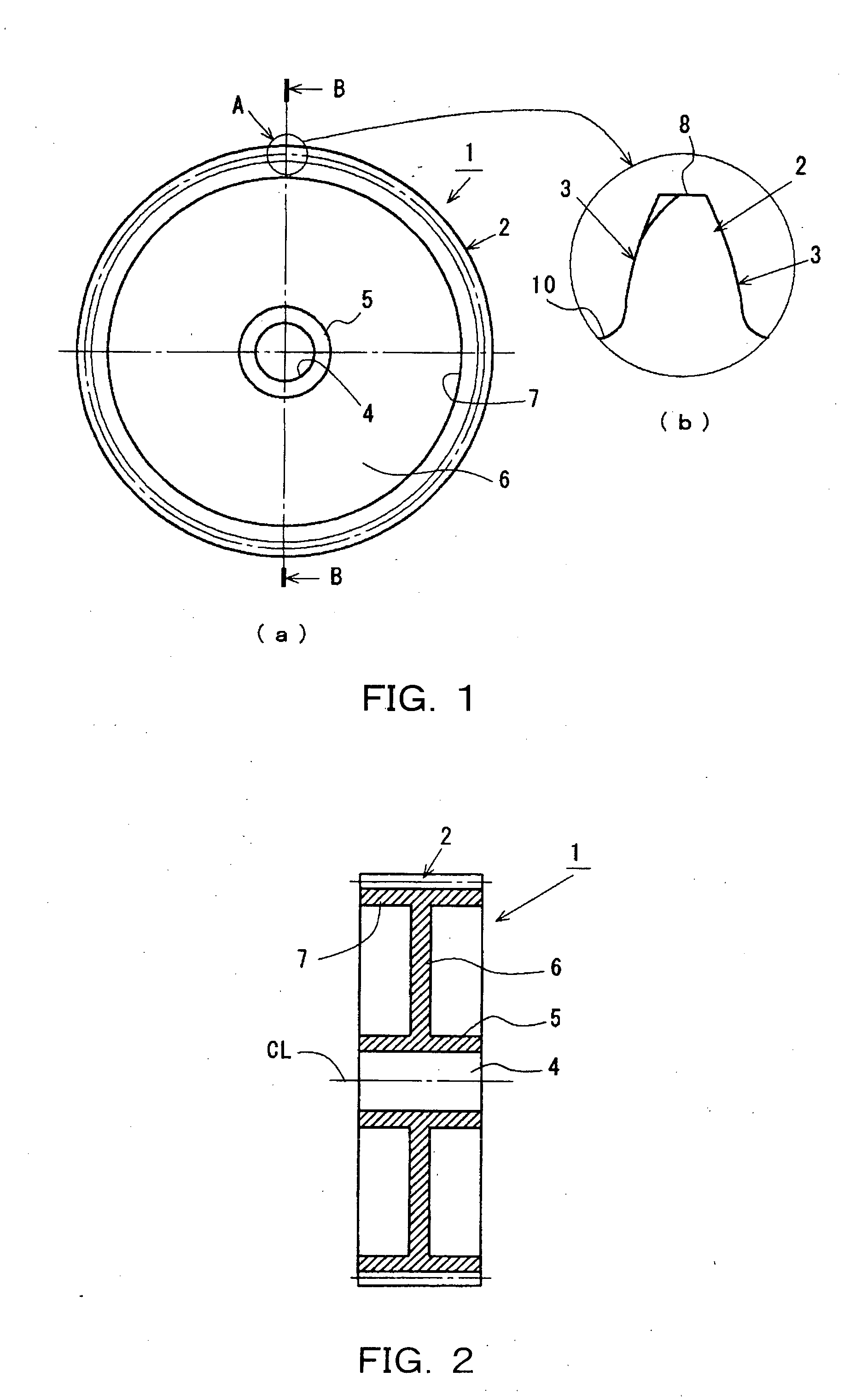

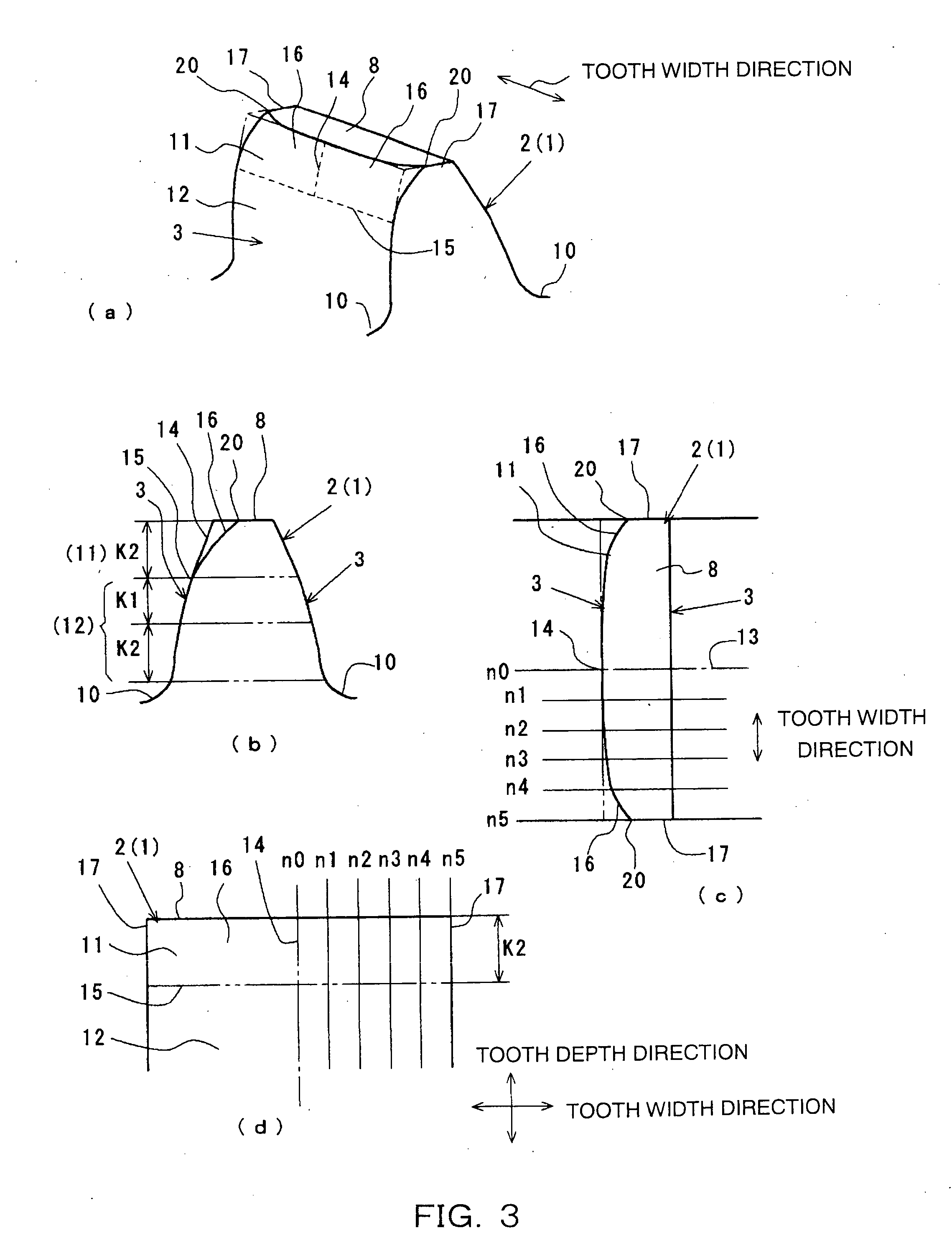

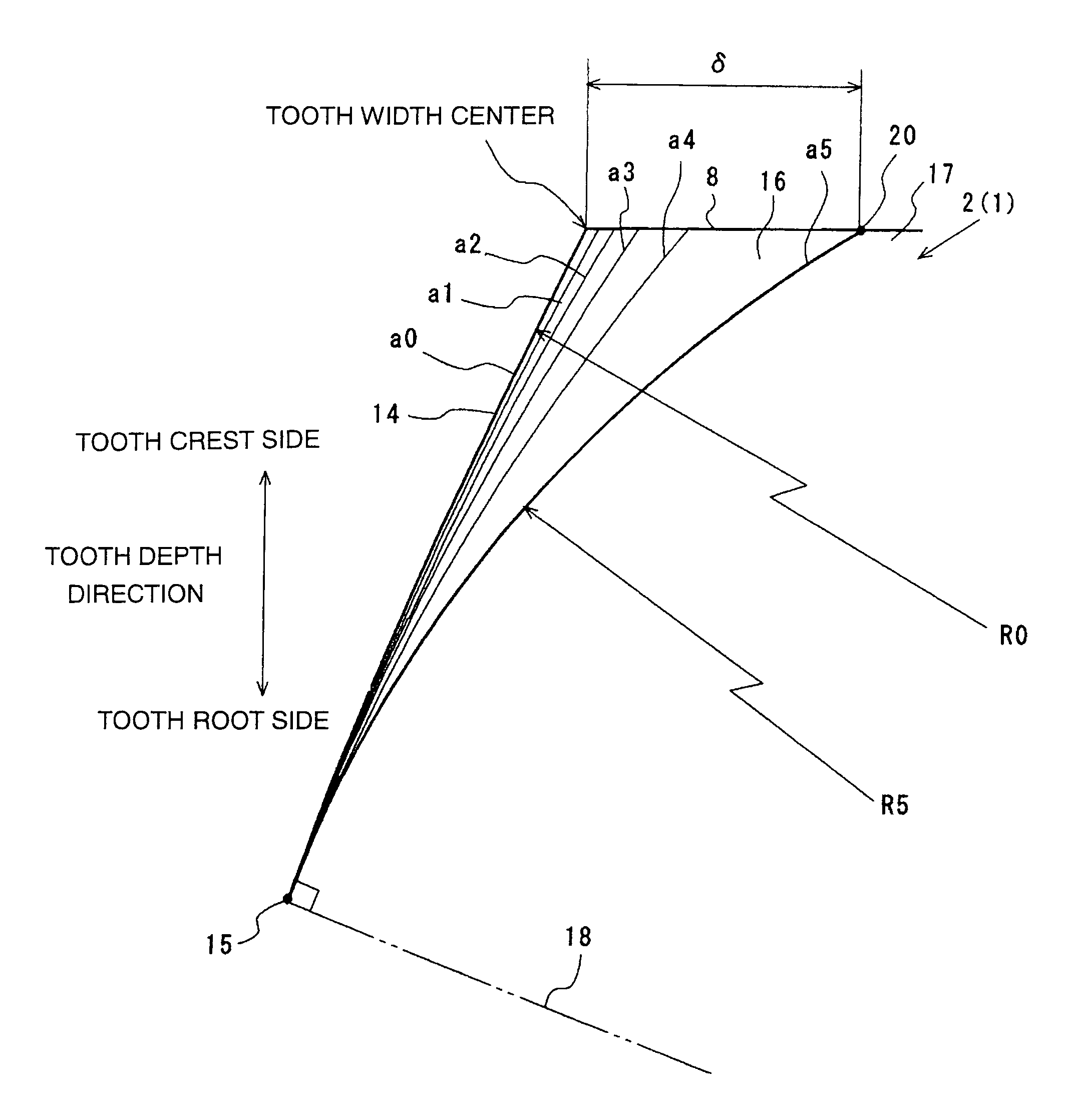

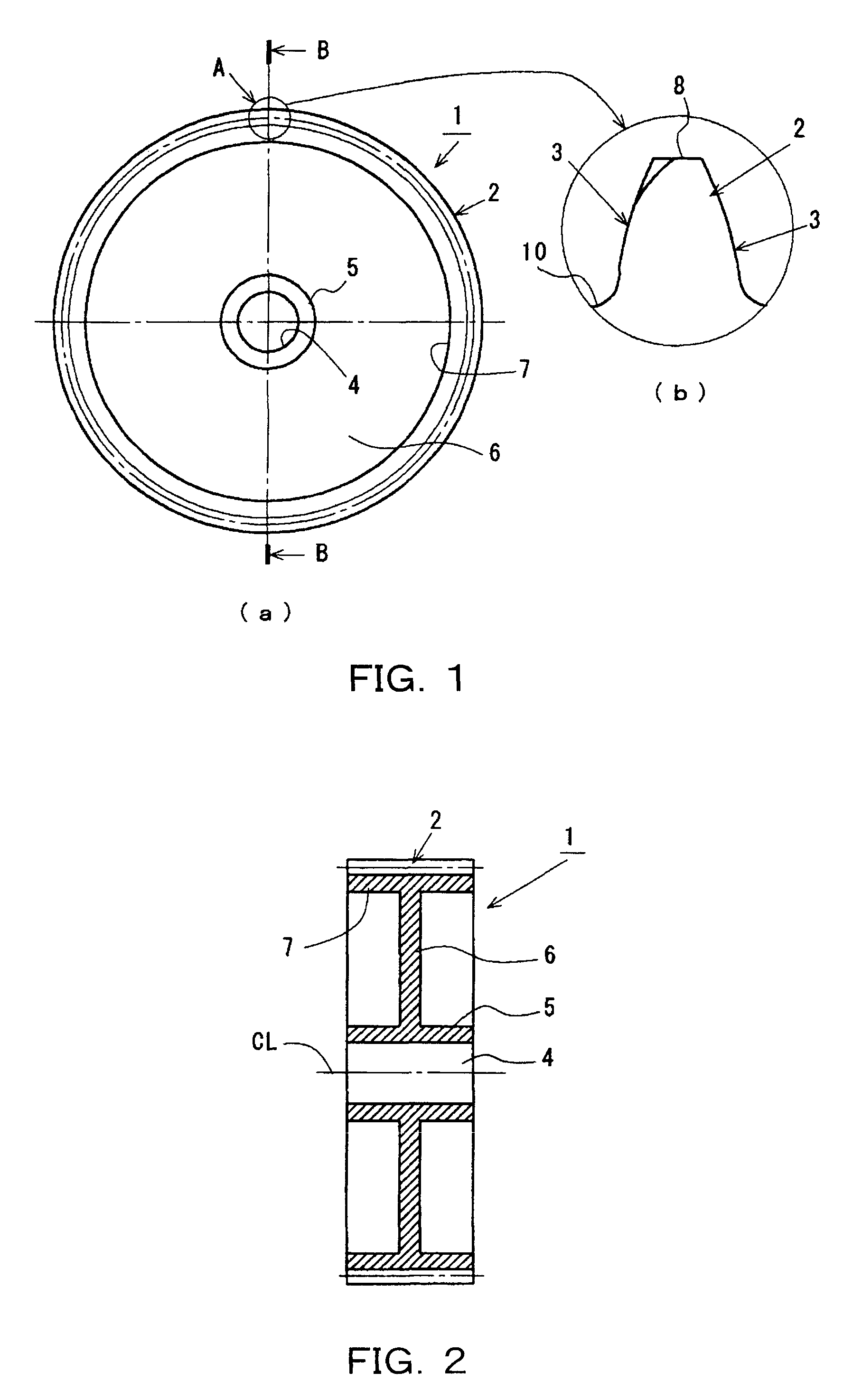

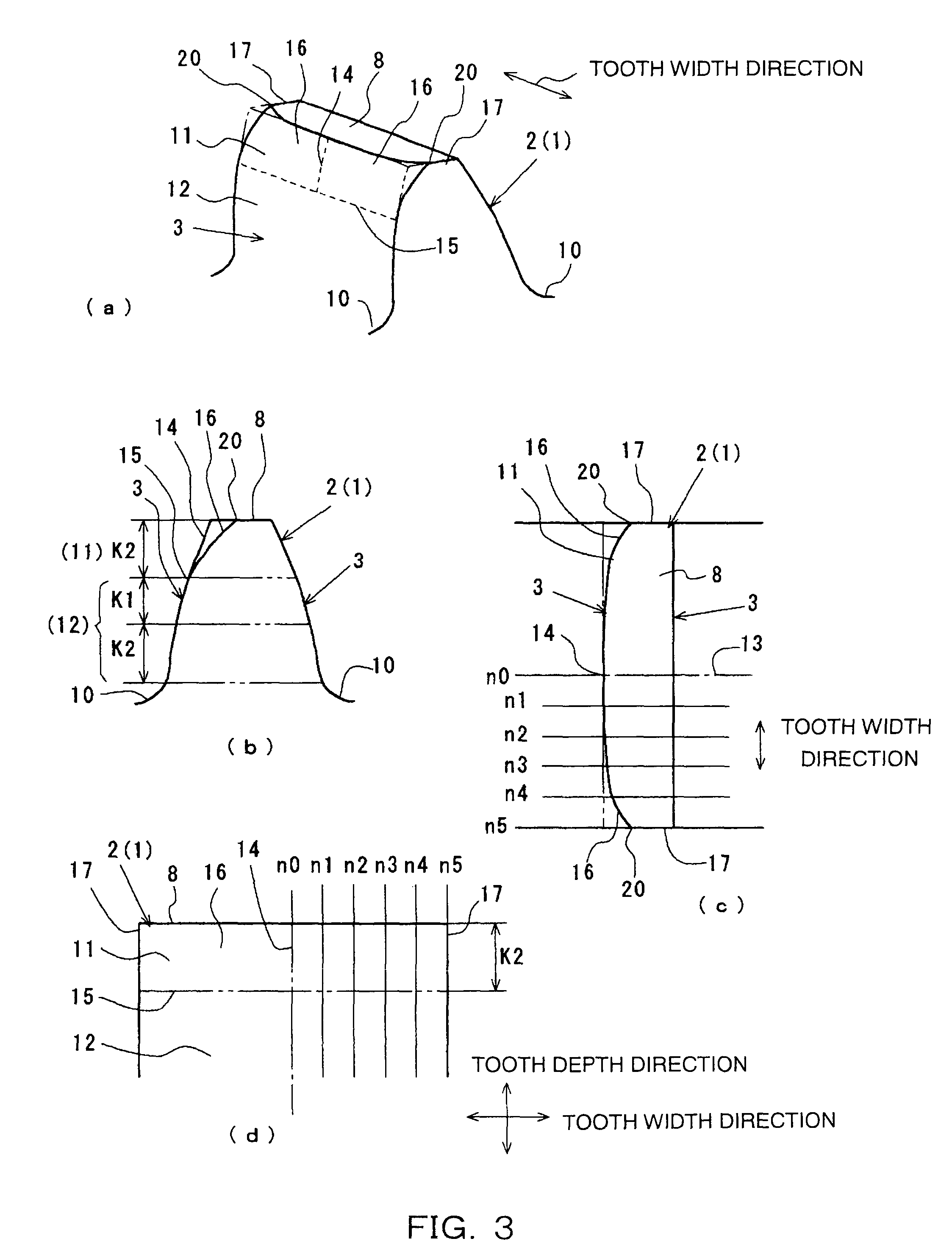

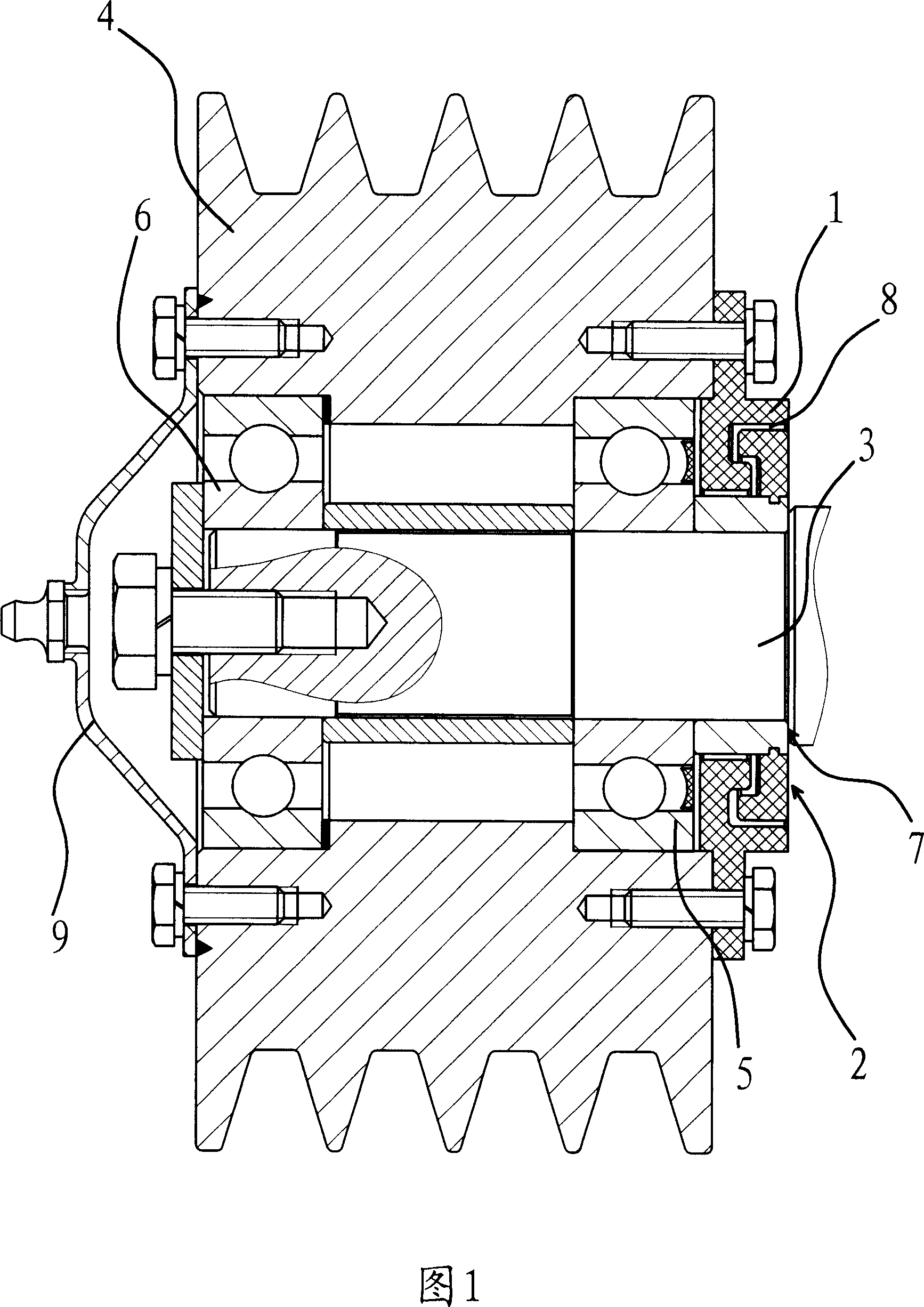

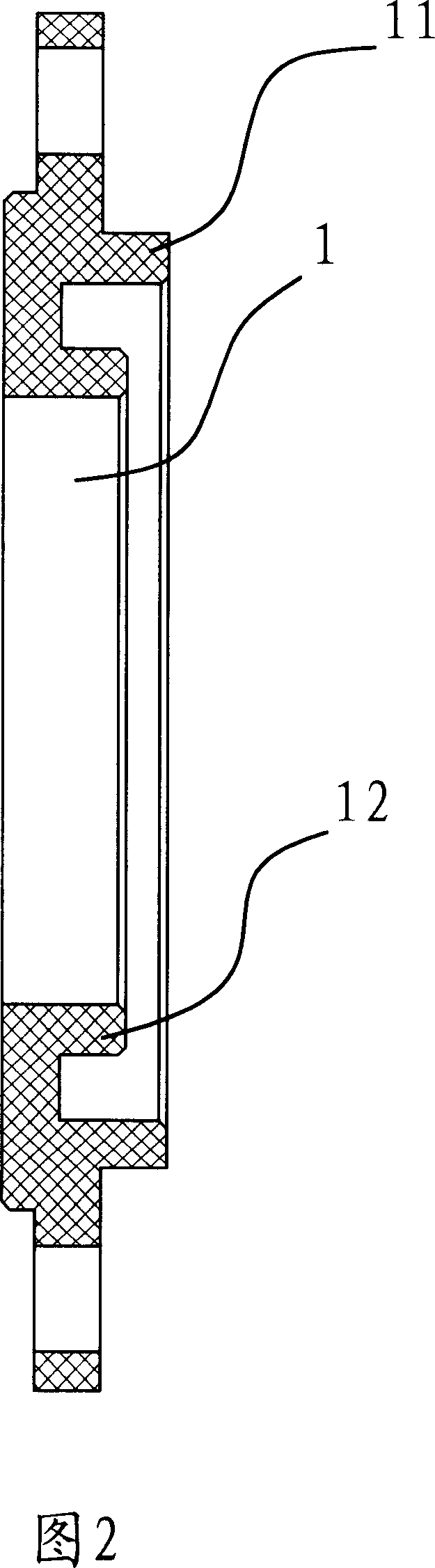

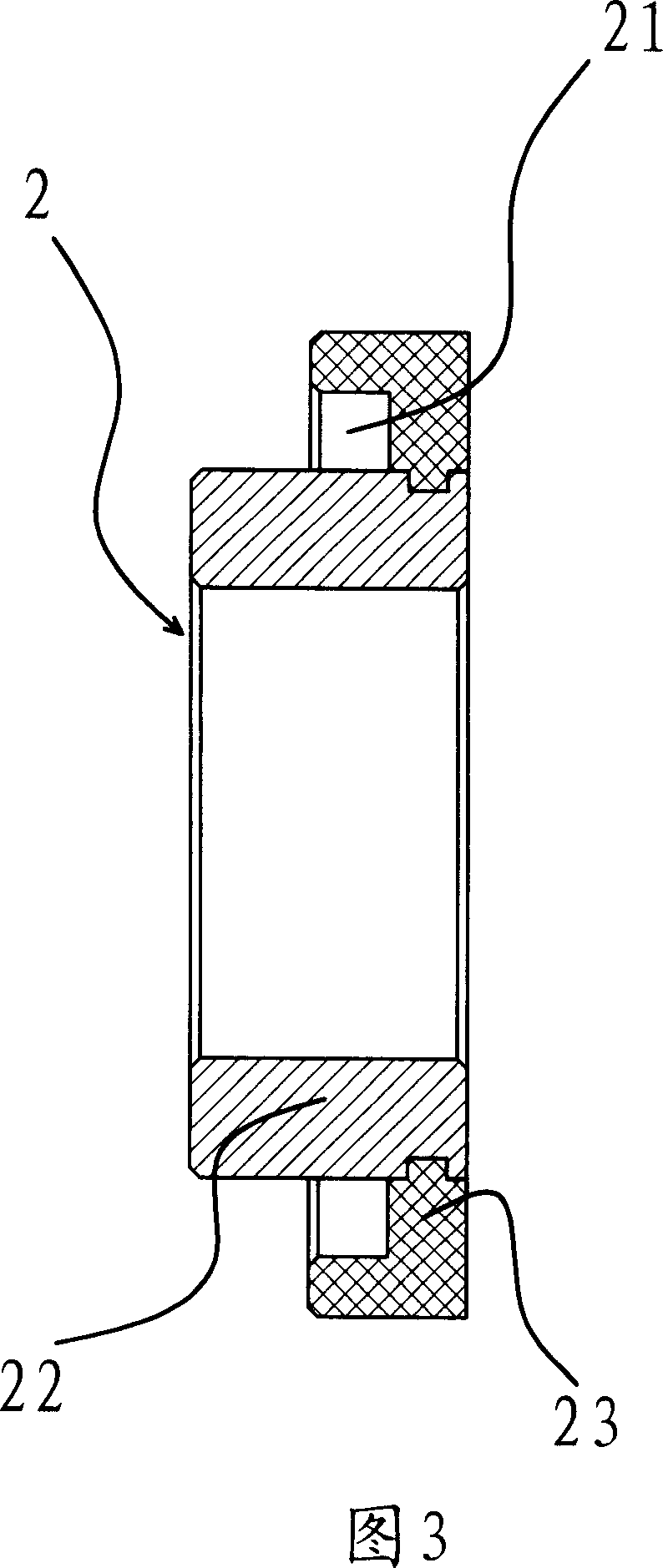

Resin gear

InactiveUS20080236320A1Effective absorptionReduce friction noiseToothed gearingsPortable liftingEngineeringTooth root

Noise can be effectively reduced without rotative power transmission accuracy being compromised.In a tooth 2 of a resin gear 1, a tooth face that is a predetermined area from a tooth crest 8 towards a tooth root 10 side serves as a tooth profile modification area 11. A tooth surface excluding the tooth profile modification area 11 serves as an involute profile area 12. The tooth profile modification area 11 includes a linear standard profile portion 14 formed by an involute curved line from the tooth crest 8 of the tooth towards the tooth root 10 side and a profile modification portion 16 in which a tooth thickness gradually and smoothly decreases from the standard profile portion 14 along a tooth width direction and the tooth thickness gradually and smoothly decreases from a tooth root end side 15 towards the tooth crest 8. In the tooth profile modification area 11, a contacting section becomes elastically deformed as a result of the resin gear coming into contact with a meshing mating gear. A tooth width direction length of the contact surface gradually increases from a minute, point-like width to a full tooth width from the tooth crest 8 side towards the tooth root 10 side.

Owner:ENPLAS CORP

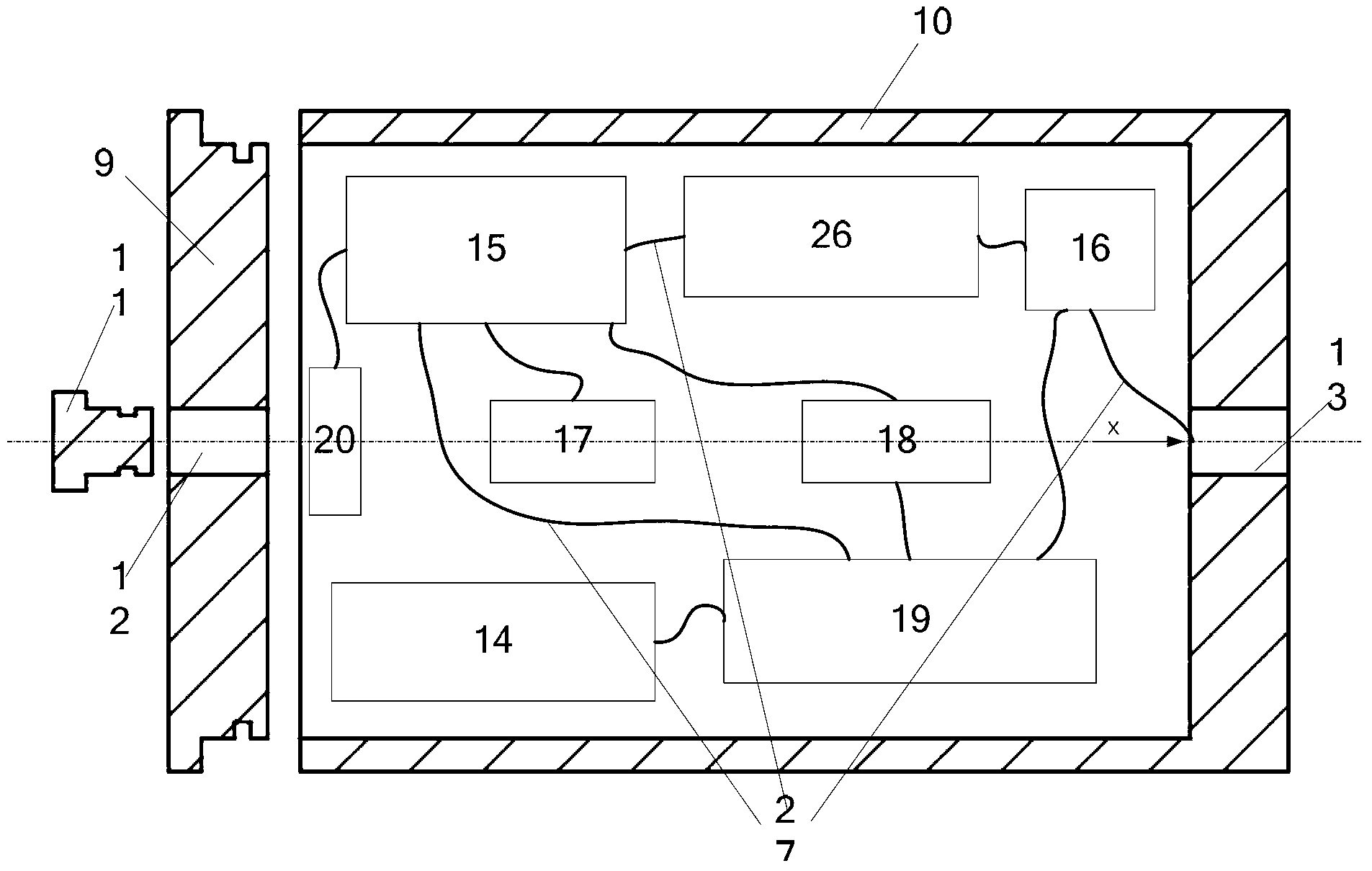

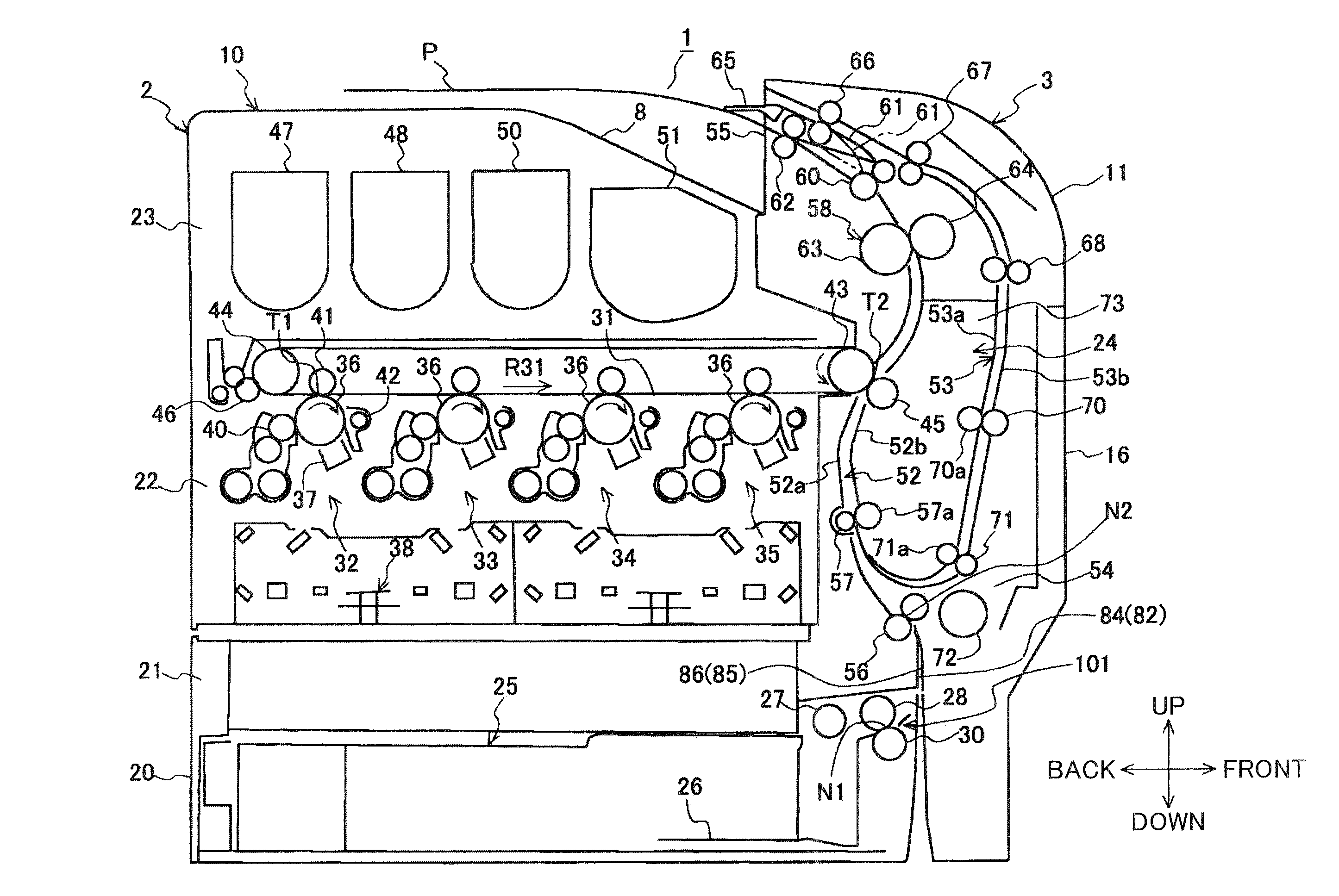

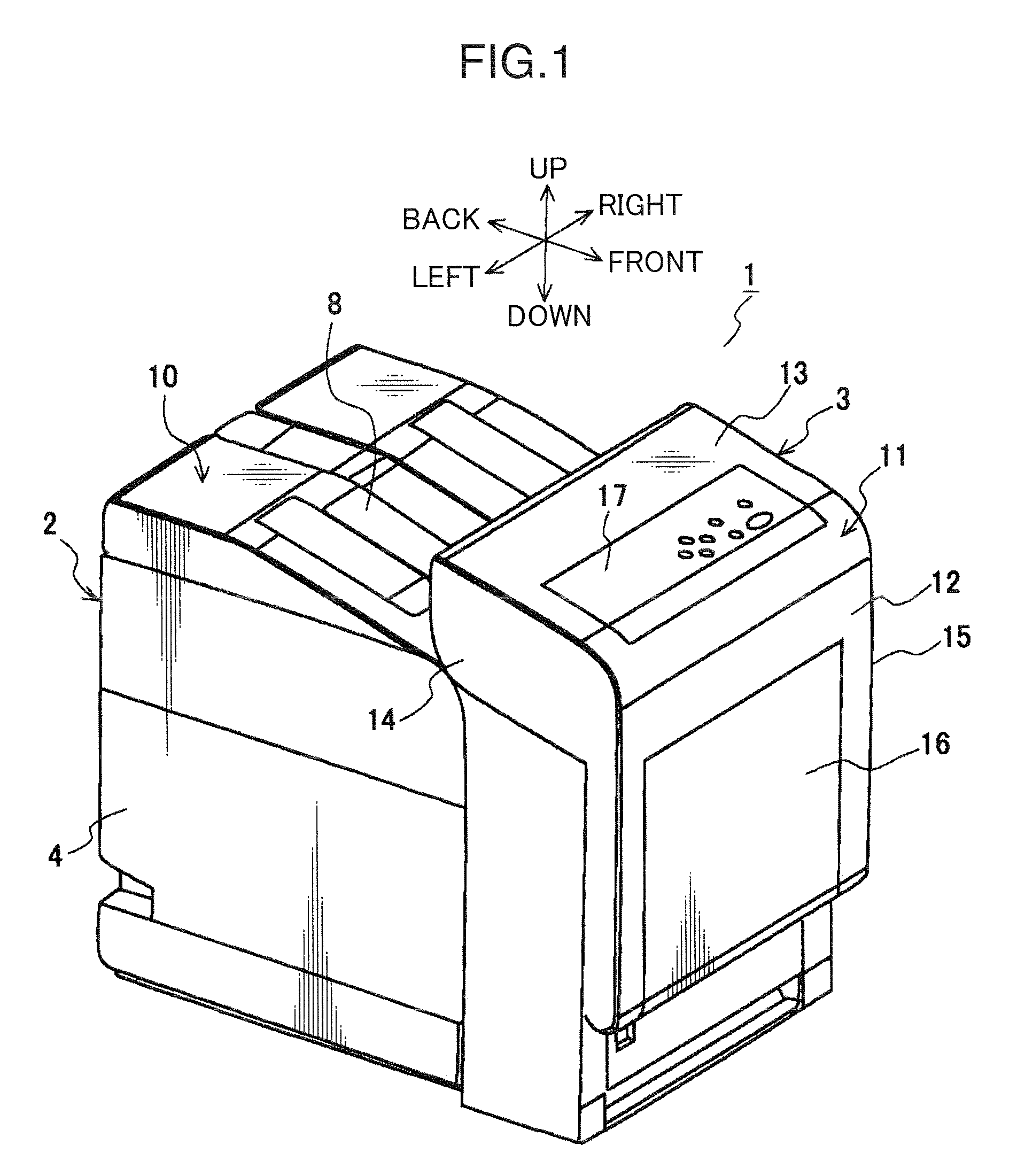

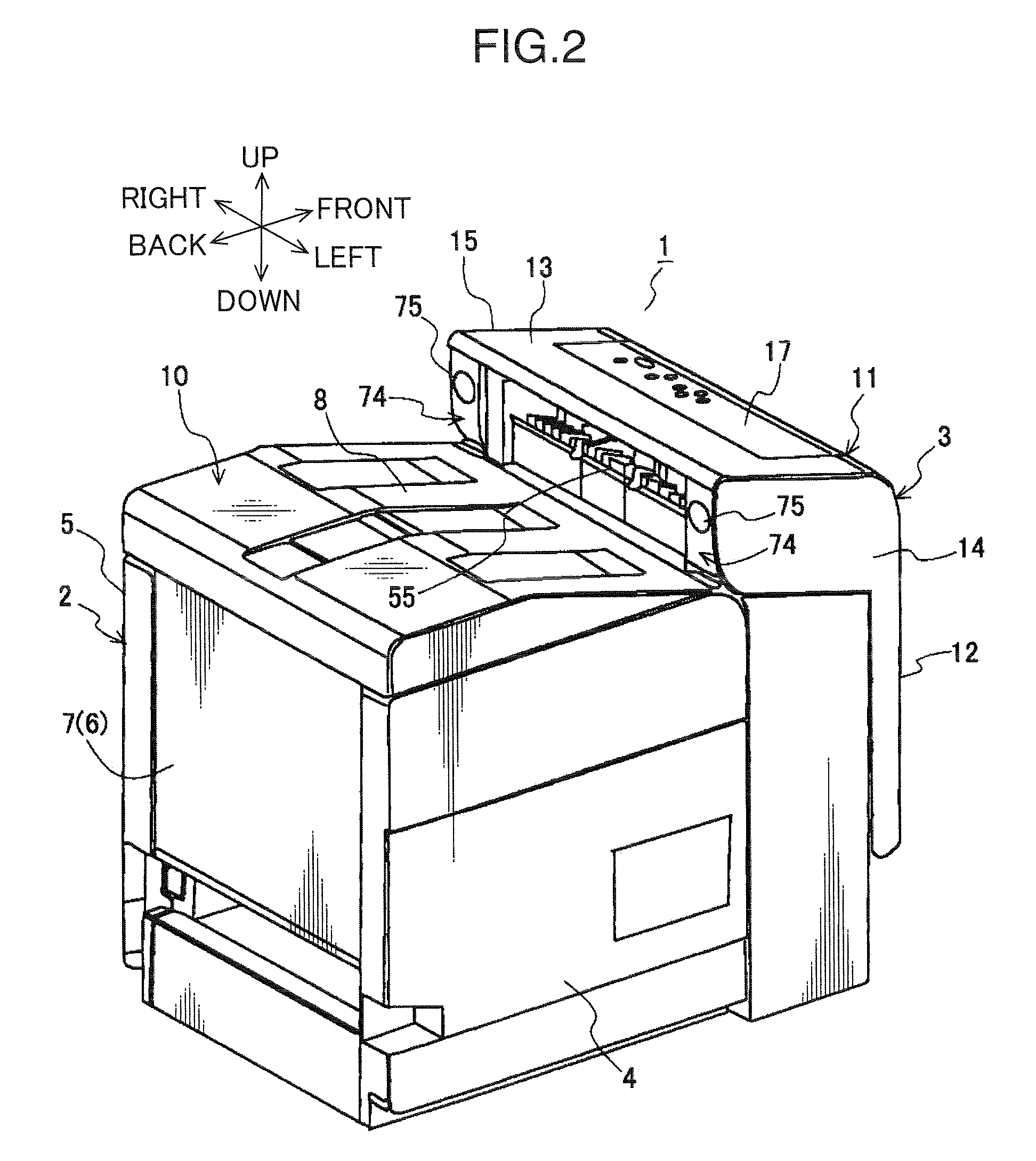

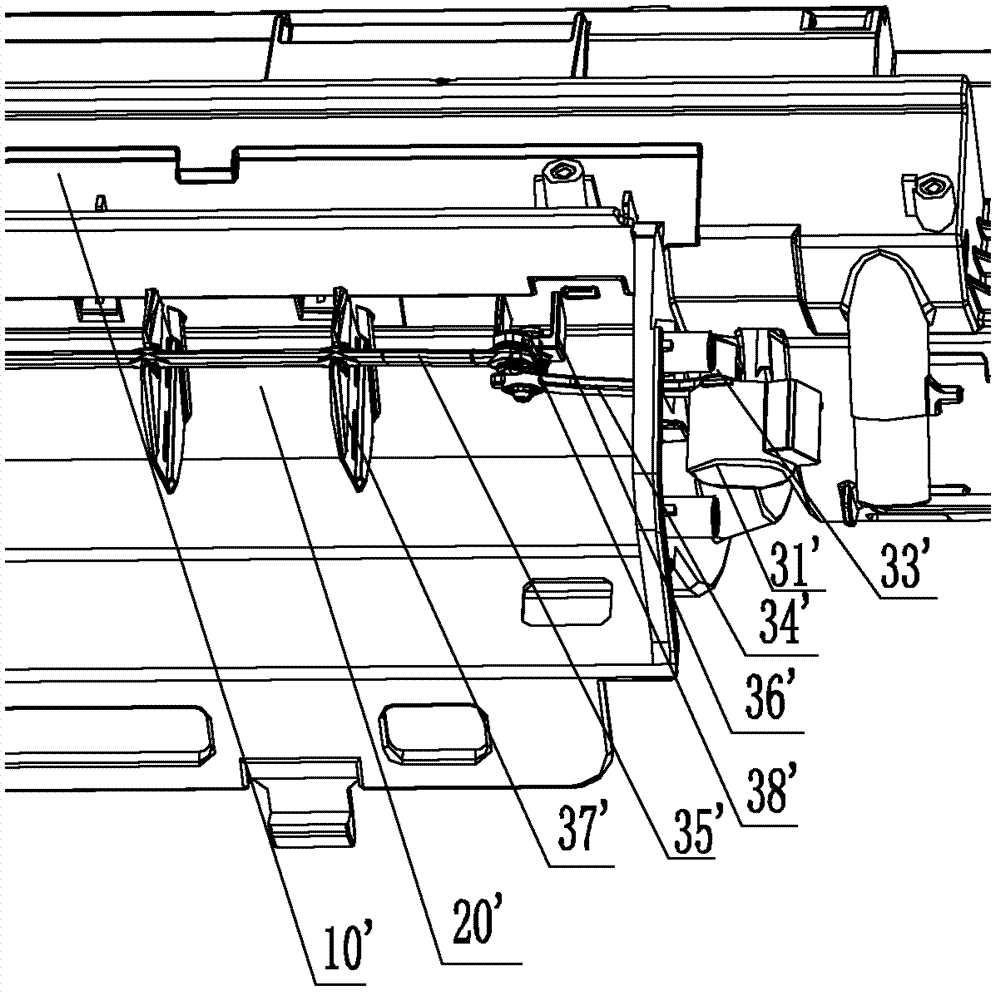

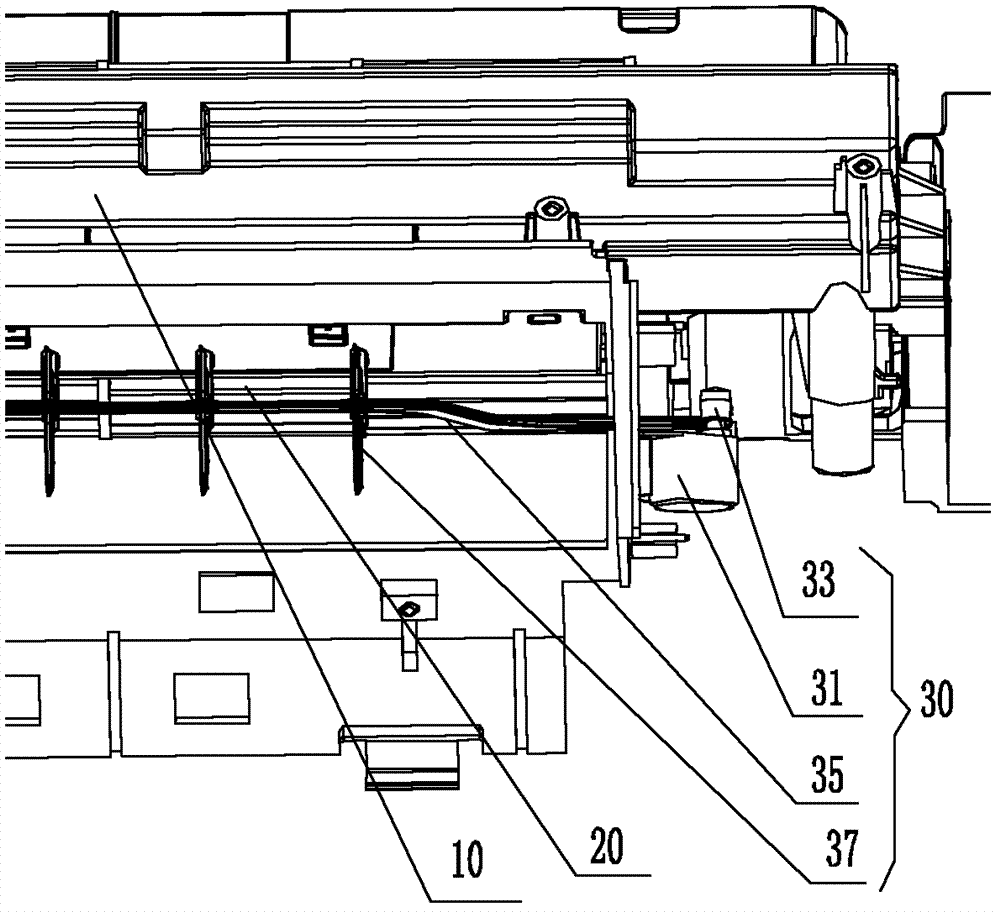

Sheet conveying apparatus and image forming apparatus with the sheet conveying apparatus

ActiveUS20080251991A1Low conveyance friction noiseReduce friction noiseRegistering devicesFunction indicatorsEngineeringMechanical engineering

Owner:KYOCERA DOCUMENT SOLUTIONS INC

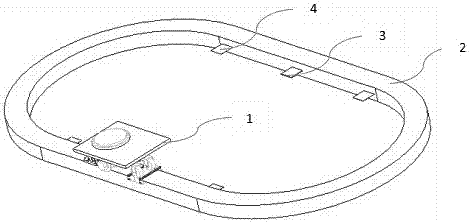

Self-adaption rail car

ActiveCN107128659ASolve the phenomenon of "stuck" and other problemsRealize small radius turnsMechanical conveyorsLow speedEngineering

The invention discloses a self-adaption rail car. The car comprises two front wheels capable of rolling front and back and rotating horizontally and provided with sensors, guide devices connected with the front wheels to facilitate turning of the car, and two rear wheels for self-adaption to the rail deformation; the rear wheels are driven by a power mechanism; and the rear wheels and the power mechanism are mounted on a rotating bearing of a car body. Compared with the prior art, the self-adaption rail car has the following advantages: when the car provided with the sensors, the front wheel guide devices and the car body rotating bearing walks on rails, the rotating bearing can be controlled to drive the rear wheels to rotate by a certain angles according to induction signals of the sensors to a curve limiting switch when the car enters a curve, so that low-speed smooth passing of the car in small-radius curve is realized. When the wheels are suspended and the car is stopped at rail deformation sections, identification signals obtained after detecting the front wheels by the front wheel sensors can be matched with a PLC to start a rear wheel self-adaption device, so that the car passes through the deformation rail sections, and normal walking of the car is realized.

Owner:GUANGDONG OCEAN UNIVERSITY

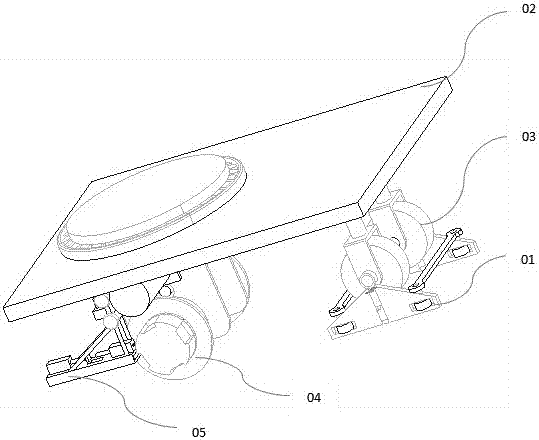

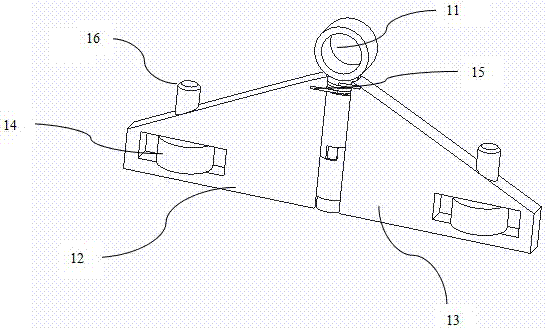

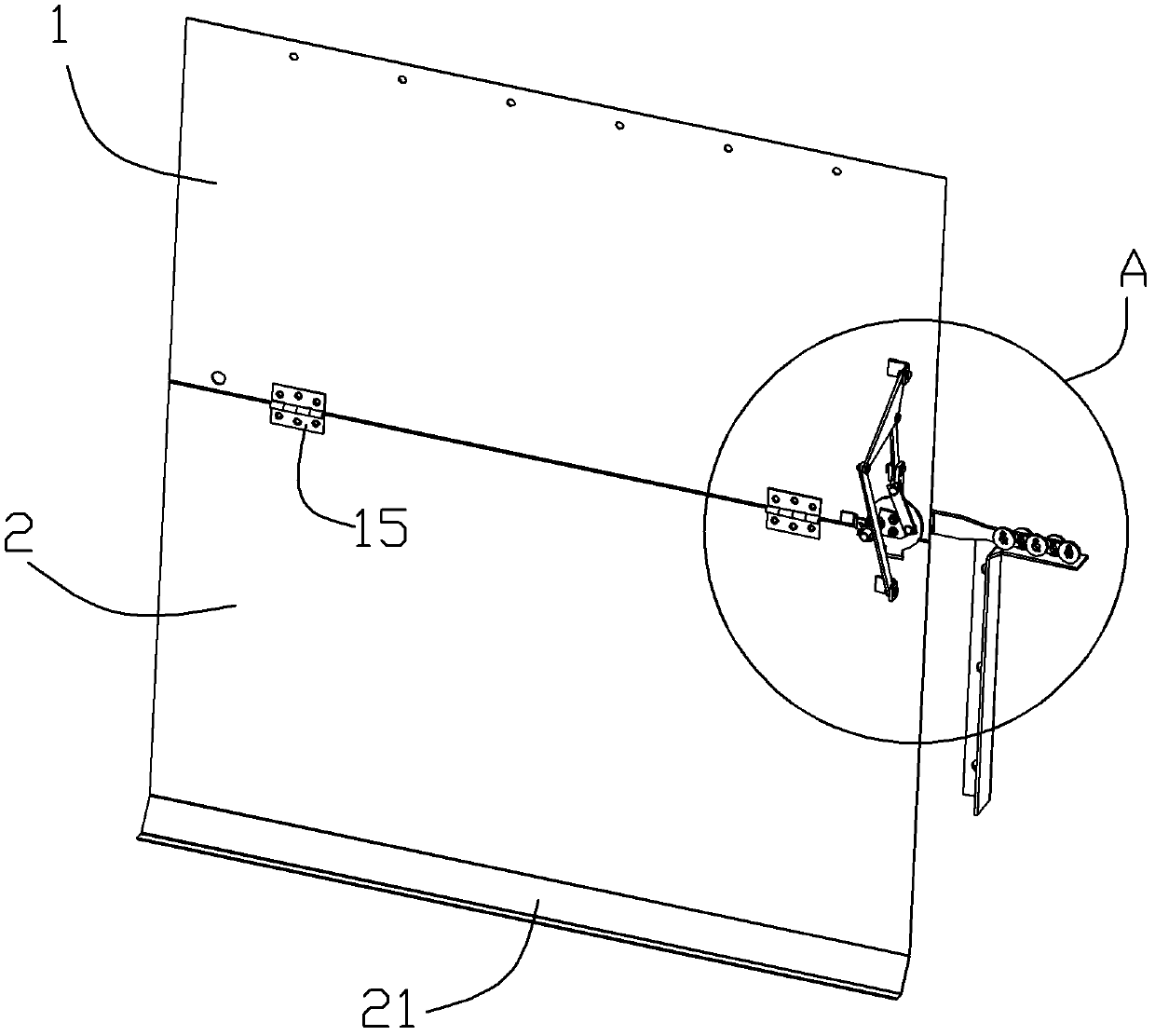

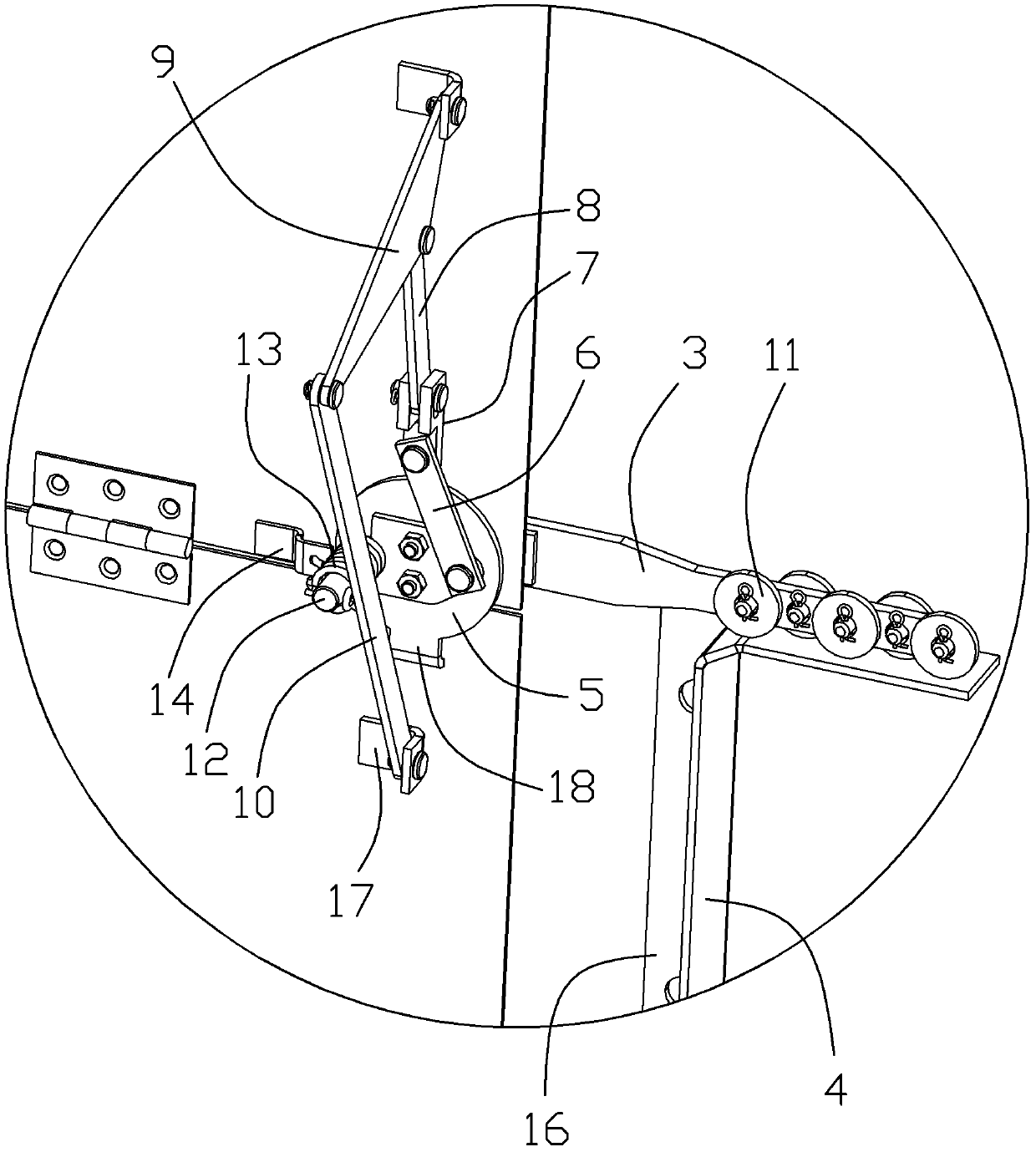

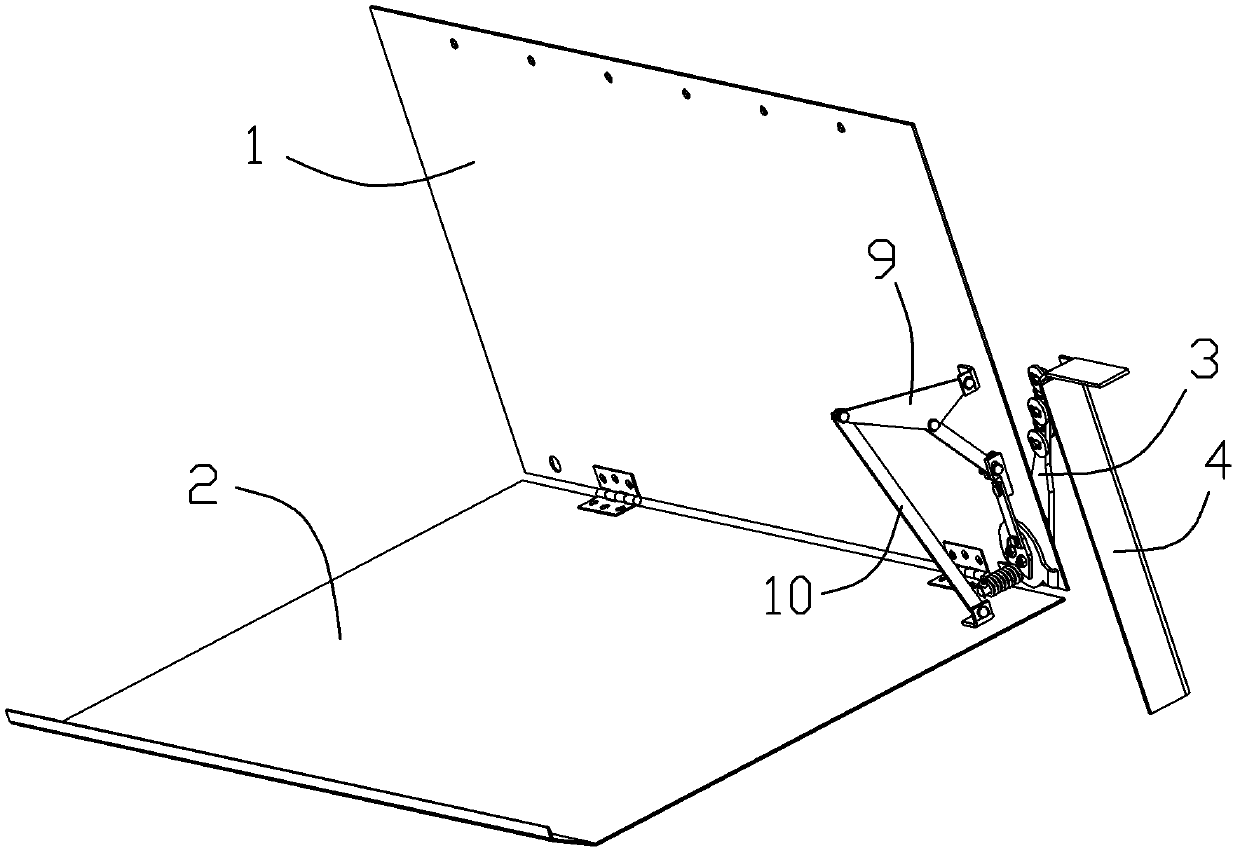

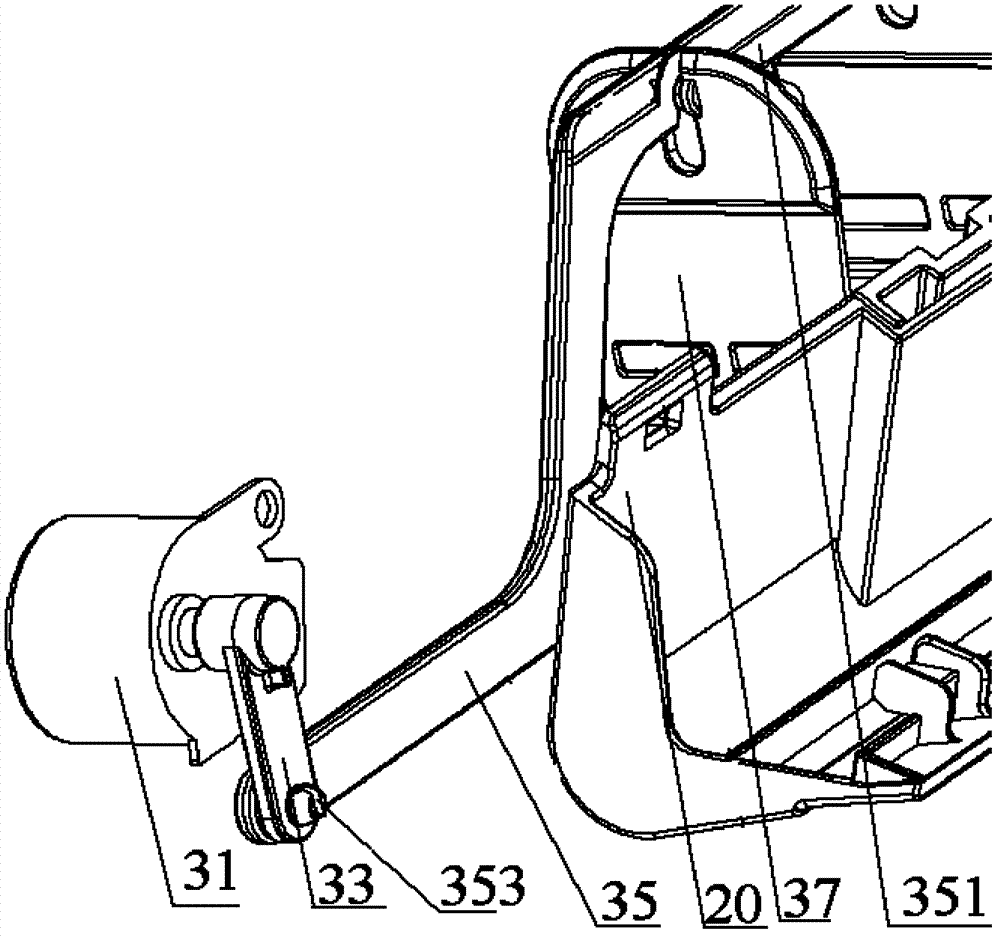

Rotatable lift car toe guard

The invention relates to a rotatable lift car toe guard, solving the problem that the retractable toe guard in the prior art is easy to be damaged upon collision with the ground and possibly cannot be returned in place. The lift car toe guard comprises an upper toe guard piece and a lower toe guard piece articulated to each other, wherein a stop rod mechanism rotating along with the downward movement of the lift is arranged on the upper toe guard piece; a cam coaxially connected with the stop rod mechanism is further arranged on the upper toe guard piece; and a link mechanism capable of pulling the lower toe guard piece for turnover along with the rotation of the cam is arranged on the cam. The design of the stop rod mechanism, the cam and the link mechanism of the toe guard provided by the invention realizes transformation from rotation to linear movement so that the toe guard rotates at a certain angle; in this way, the demand for the depth of the foundation pit is reduced; the toe guard does not need to collide with the ground surface of the foundation pit; and damage on the toe guard and accidental harm on people are avoided.

Owner:XIZI OTIS ELEVATOR

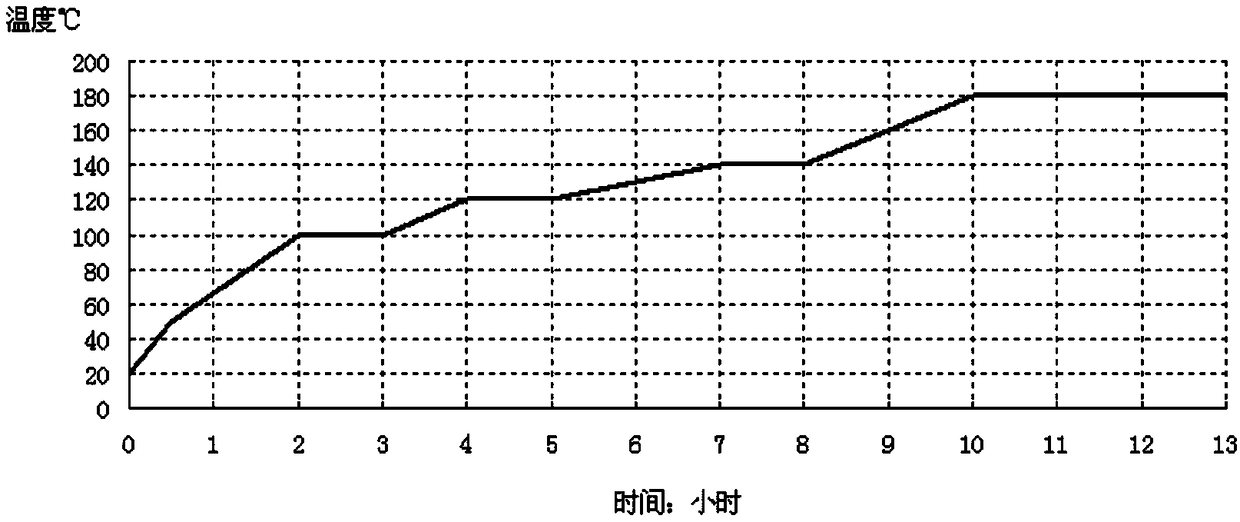

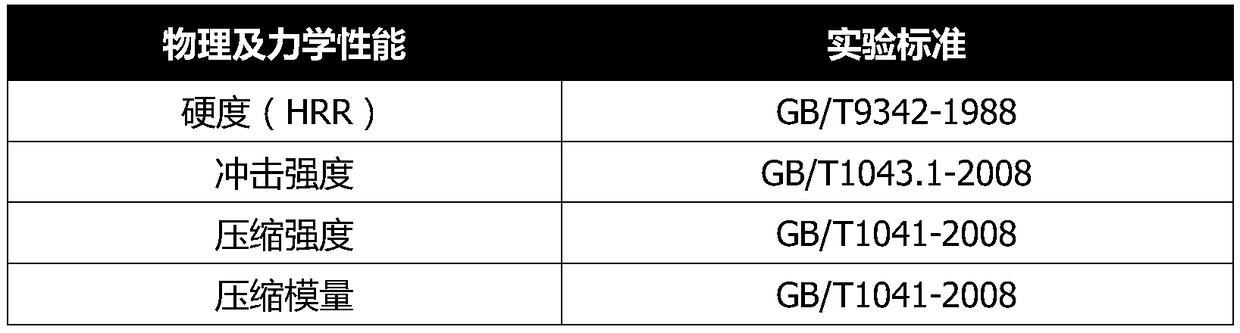

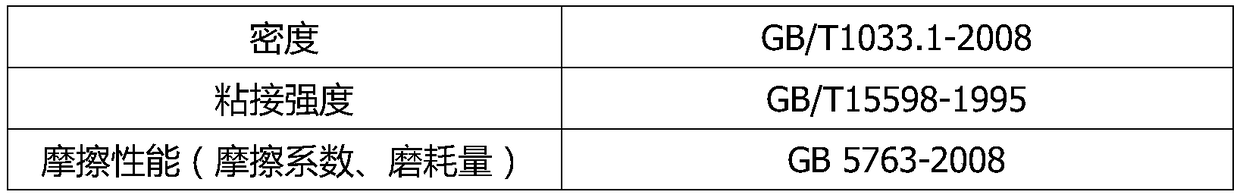

Grinding unit for high speed train and preparation method of grinding unit

ActiveCN108839640AReduce wearReduce friction noiseMetal-working apparatusVehicle cleaningHot pressHigh speed train

The invention provides a grinding unit for a high speed train and a preparation method of the grinding unit. The grinding unit is composed of a friction material and a steel backing, wherein the friction material is composed of phenolic resins having specific physical properties, reinforced fibers, fillers and the like; the components of the friction material need to be pretreated such as mixing and drying; the steel backing needs to be pretreated such as abrasive blasting and resin glue spraying; the pretreated friction material and steel backing are subjected to special hot press molding, heat treatment and other processes, thereby obtaining the grinding unit. According to the grinding unit disclosed by the invention, by improving the thermal stability and enhancing the shock strength, the performance of the grinding unit in aspects such as metal inlaying, crack chipping, wheel shaping, friction noise and the like are improved, damage to the wheel tread is small, the phenomena such as hot cracks and severe wave furrowed abrasion are difficultly caused, and the grinding unit has important application value and wide market prospects in the field of high-speed trains.

Owner:中申(上海)管道工程股份有限公司

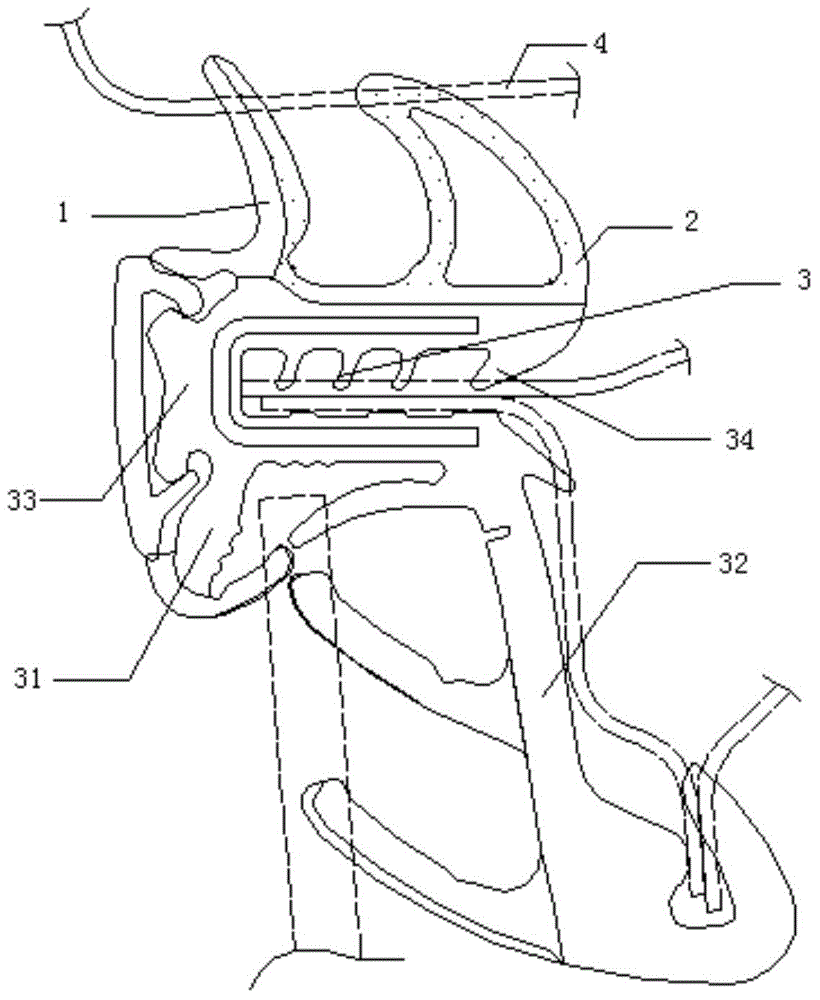

Air conditioner

The invention provides an air conditioner. The air conditioner comprises a machine shell, an air deflector connected with the machine shell, and an automatic air sweeping mechanism connected with the air deflector, wherein the automatic air sweeping mechanism is composed of a motor, a crank, an air sweeping connecting rod and an air sweeping blade set, and the motor, the crank, the air sweeping connecting rod and the air sweeping blade set are linked in sequence. The first end of each air sweeping blade in the air sweeping blade set is connected with the air deflector, and the second end of each air sweeping blade in the air sweeping blade set is a free swinging end and is connected with the air sweeping connecting rod. According to the air conditioner, the air sweeping mechanism composed of the motor, the crank, the air sweeping connecting rod and the air sweeping blade is adopted, and the motor, the crank, the air sweeping connecting rod and the air sweeping blade are linked in sequence, so that the number of the parts forming the air sweeping mechanism is reduced, the production cost is reduced, and meanwhile the friction noise among the parts is reduced. Moreover, the connection mode is simplified and the production efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

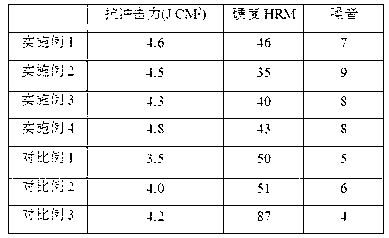

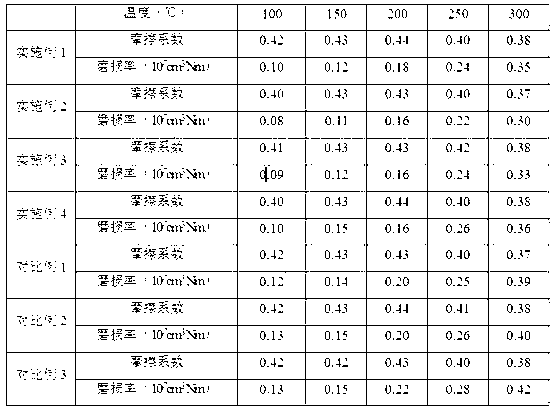

Vibration-damping, denoising and yaw low-speed braking pad and fabrication method thereof

ActiveCN103256325AStable coefficient of frictionGood high temperature friction performanceFriction liningLow speedCarbon fibers

The invention relates to a braking pad, in particular to a vibration-damping, denoising and yaw low-speed braking pad for a yaw braking device of a wind generating set and a fabrication method of the braking pad. The vibration-damping, denoising and yaw low-speed braking pad comprises a steel backing and an abrasive layer attached to the steel backing, wherein the abrasive layer is fabricated by taking PTS (Phenolic Thermospheres) suspension method phenolic resin as a gluing agent, taking graphite, tin sulfide and copper sulfide as a lubricant, taking antimony trisulfide, zirconium silicate, silicon carbide and silicon dioxide as an abradant, taking potassium titanate whiskers, ceramic fibers, aramid fibers, carbon fibers, steel fibers and copper fibers as reinforced fibers, taking calcium carbonate, mica, vermiculite and foam ferrous powder as an inorganic filler, and taking cashew nut shell oil friction powder and rubber powder as an organic filler according to a wet method pressing technology. The braking pad has the advantages that component percentages of a friction material and a processing technology are reasonable; the braking sensitivity is high; the braking vibration is small; the friction noise is low; and the braking pad is provided with a pad abrasion alarm line.

Owner:JIAOZUO LICHUANG BRAKE

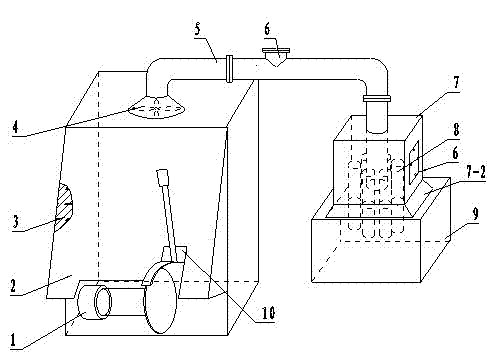

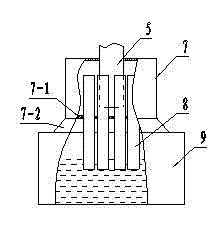

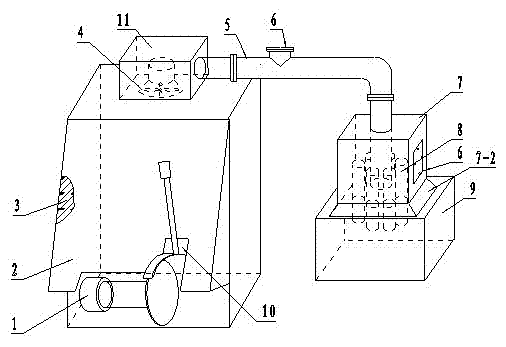

Dust removal device for grinding wheel cutting machine

ActiveCN102785174AGood dust removal and noise reduction effectGood effect of dust removal and noise reductionGrinding/polishing safety devicesEngineeringNoise reduction

The invention relates to a dust removal device for a grinding wheel cutting machine, and is used for solving the problems of dust and noise pollution of the grinding wheel cutting machine. The technical scheme is as follows: the dust removal device for the grinding wheel cutting machine comprises a protective cover, an ash suction fan, a dust collection pipe, an ash collection cavity and a dust cleaning tank, wherein the ash suction fan is positioned at the top of the protective cover and is communicated with the protective cover, and the ash suction fan is communicated with the dust collection pipe; an outlet end of the dust collection pipe reaches the ash collection chamber, and the dust cleaning tank is positioned at the lower part of the dust collection pipe; silencer pipes are arranged in the ash collection chamber and are uniformly distributed around the dust collection pipe, and the upper ends of the silencer pipes are higher than the outlet end of the dust collection pipe; and the lower ends of the silencer pipes penetrate through a bottom plate of the ash collection chamber and reach water in the ash cleaning tank. The dust removal device has the advantages that the dust removal and noise reduction are integrated, the intrusion of dust pollution to operators can be avoided, the production site is purified, and the adverse affect of dust on other equipment in a workshop is prevented, and meanwhile, the friction noise generated by the grinding wheel cutting machine is greatly reduced. The trial shows that the dust removal effect is excellent and the environmental protection and noise reduction effects are obvious.

Owner:山海关造船重工有限责任公司

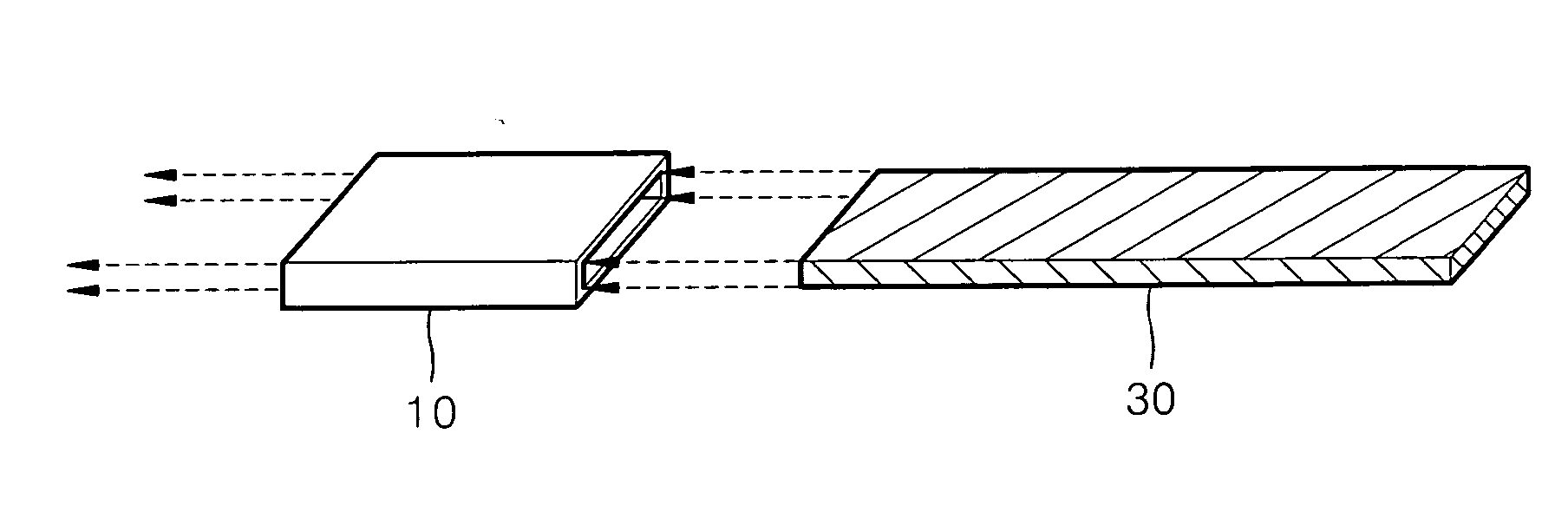

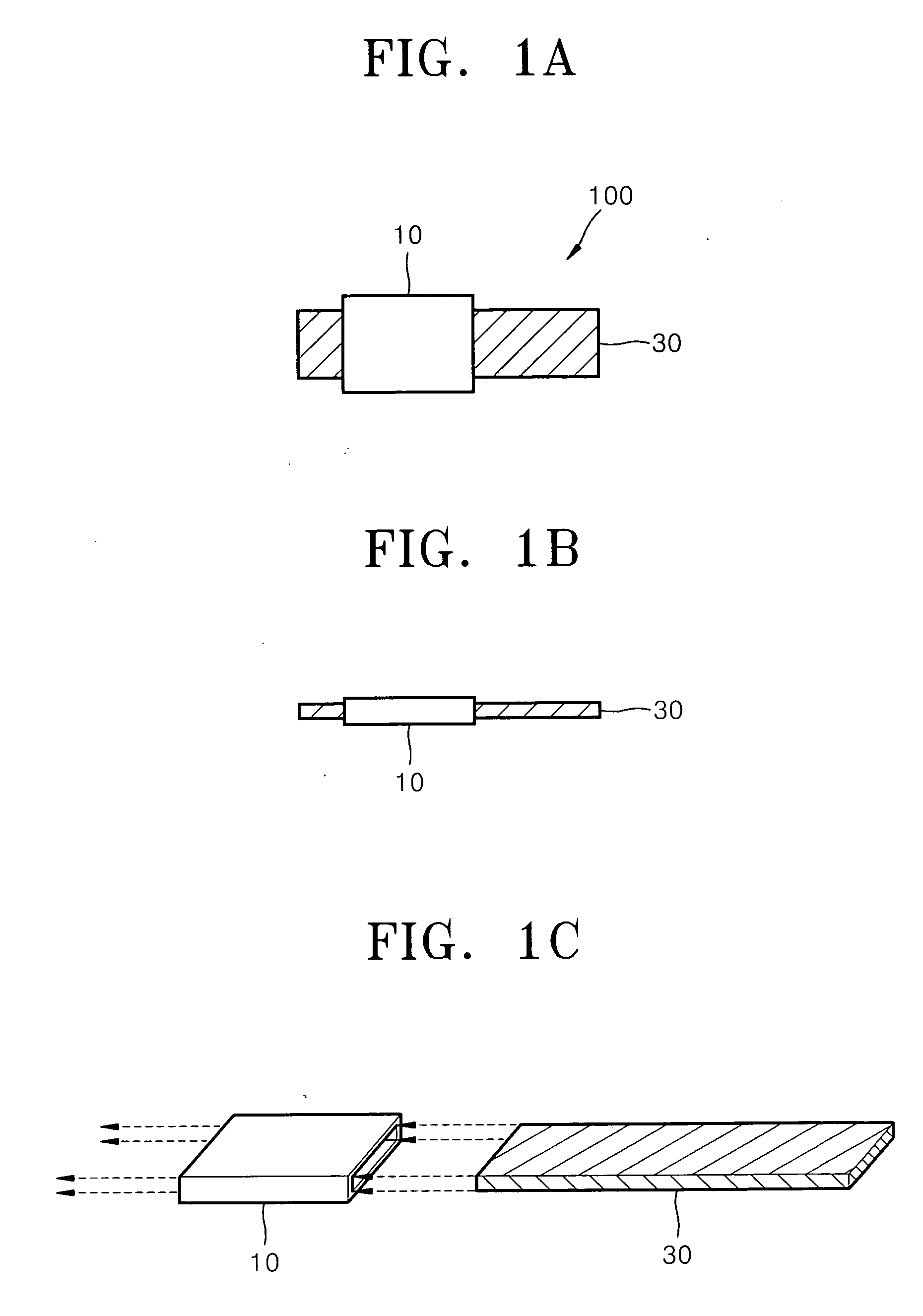

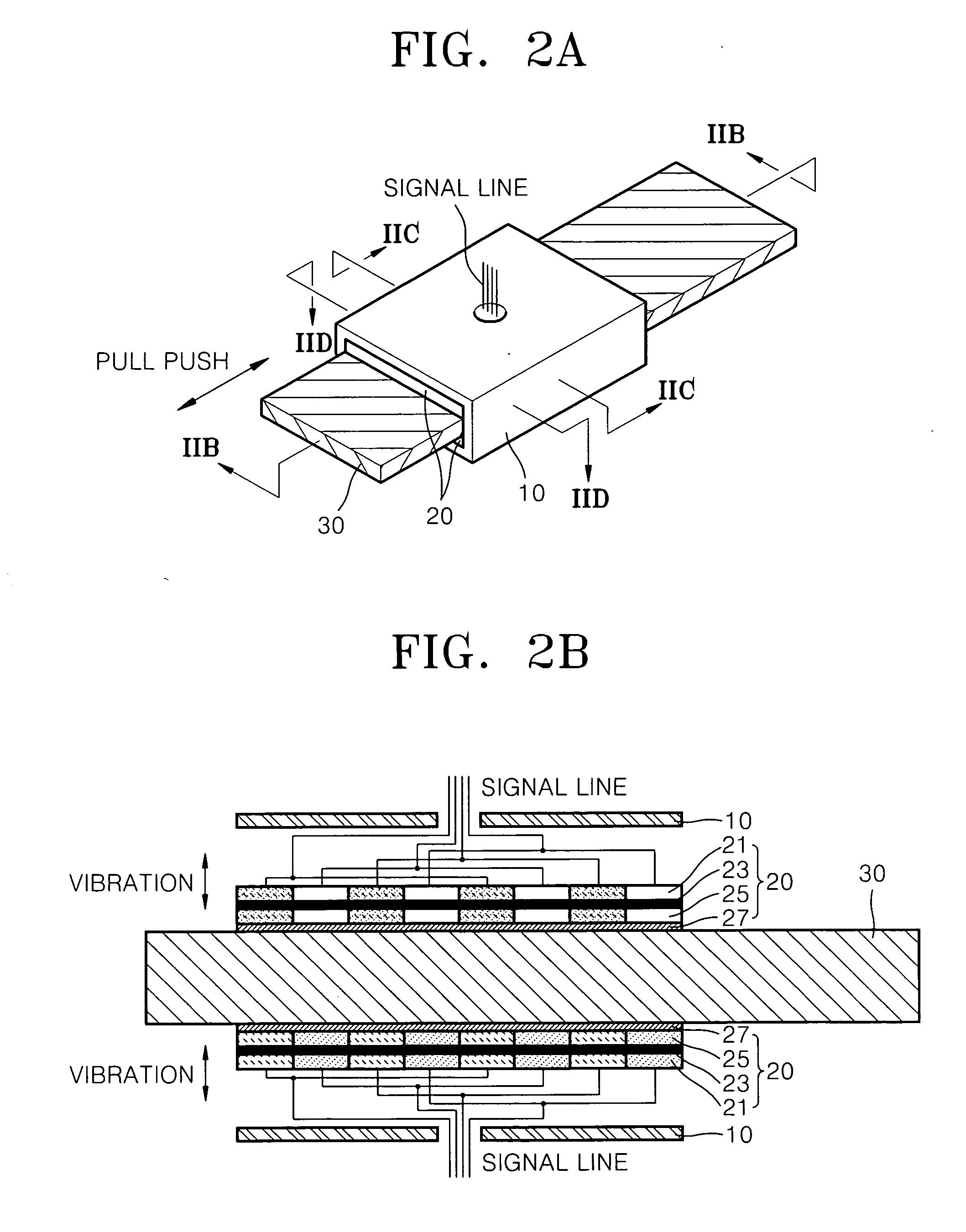

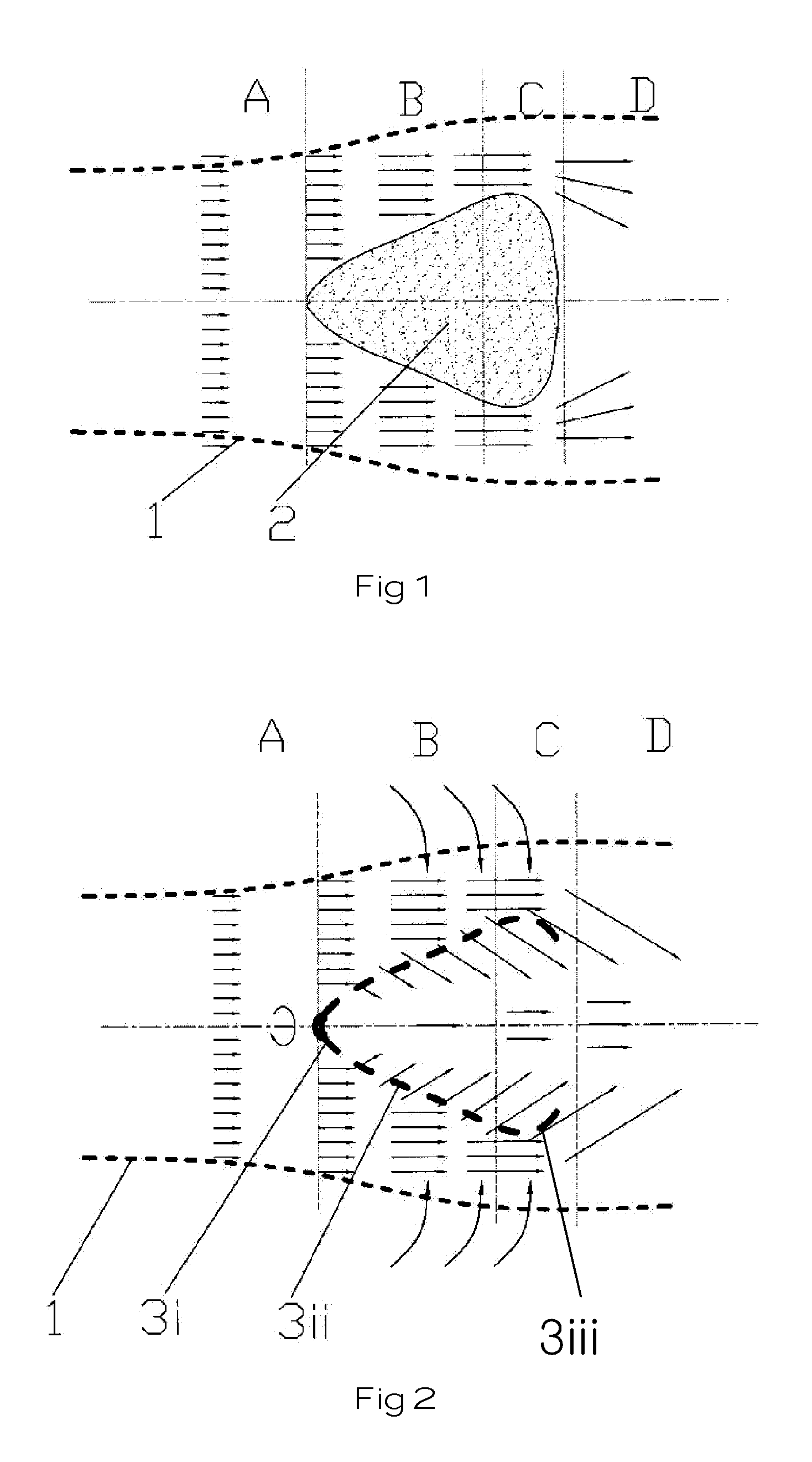

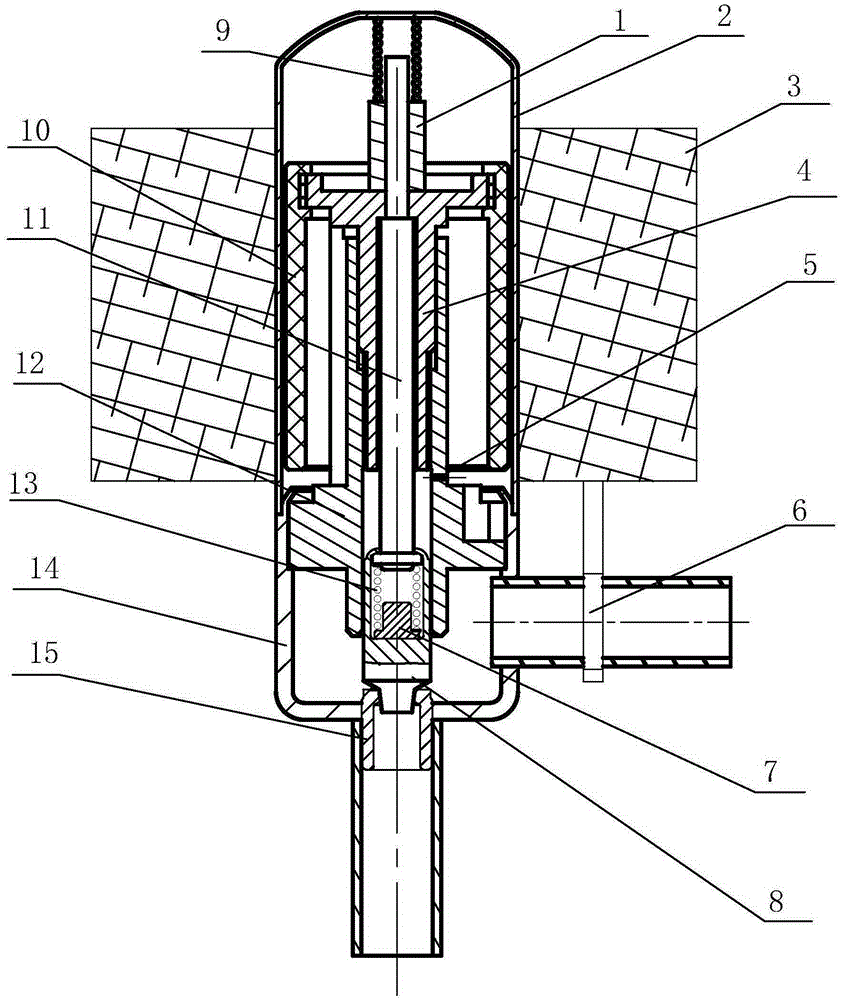

Piezoelectric actuator, and apparatus and method for actuating the same

InactiveUS20070069611A1Reduce frictional noiseReduce friction noisePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesLinear actuatorPiezoelectric actuators

A linear actuator using a metal beam-type piezoelectric material, and an apparatus and a method for actuating the same. The piezoelectric actuator includes: a moving member having a predetermined length and moving in a forward or a backward direction; and a piezoelectric portion contacting the moving member and moving the moving member linearly using a vibration generated when a piezoelectric element contracts or expands in response to an electrical signal.

Owner:SAMSUNG ELECTRONICS CO LTD

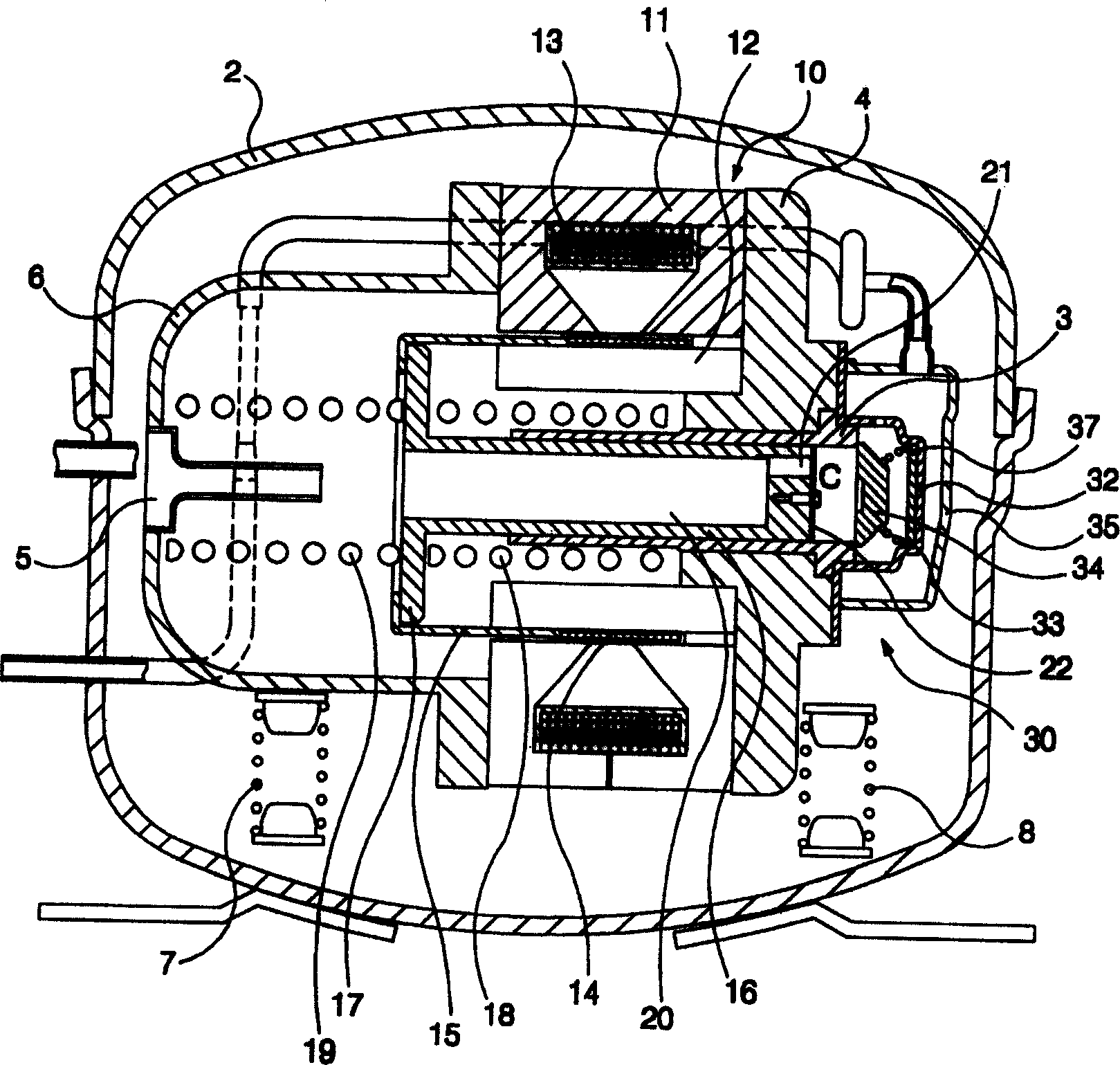

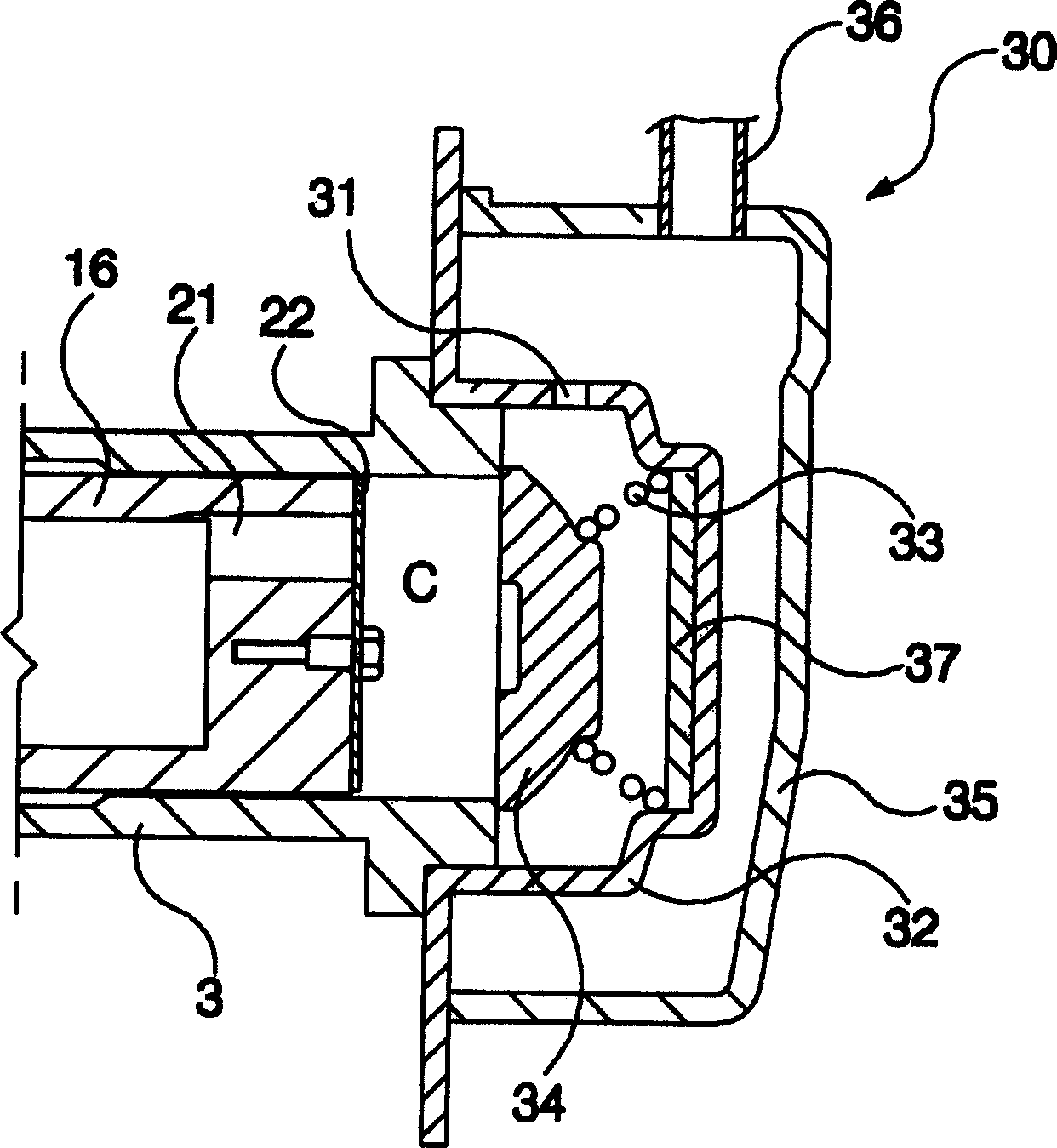

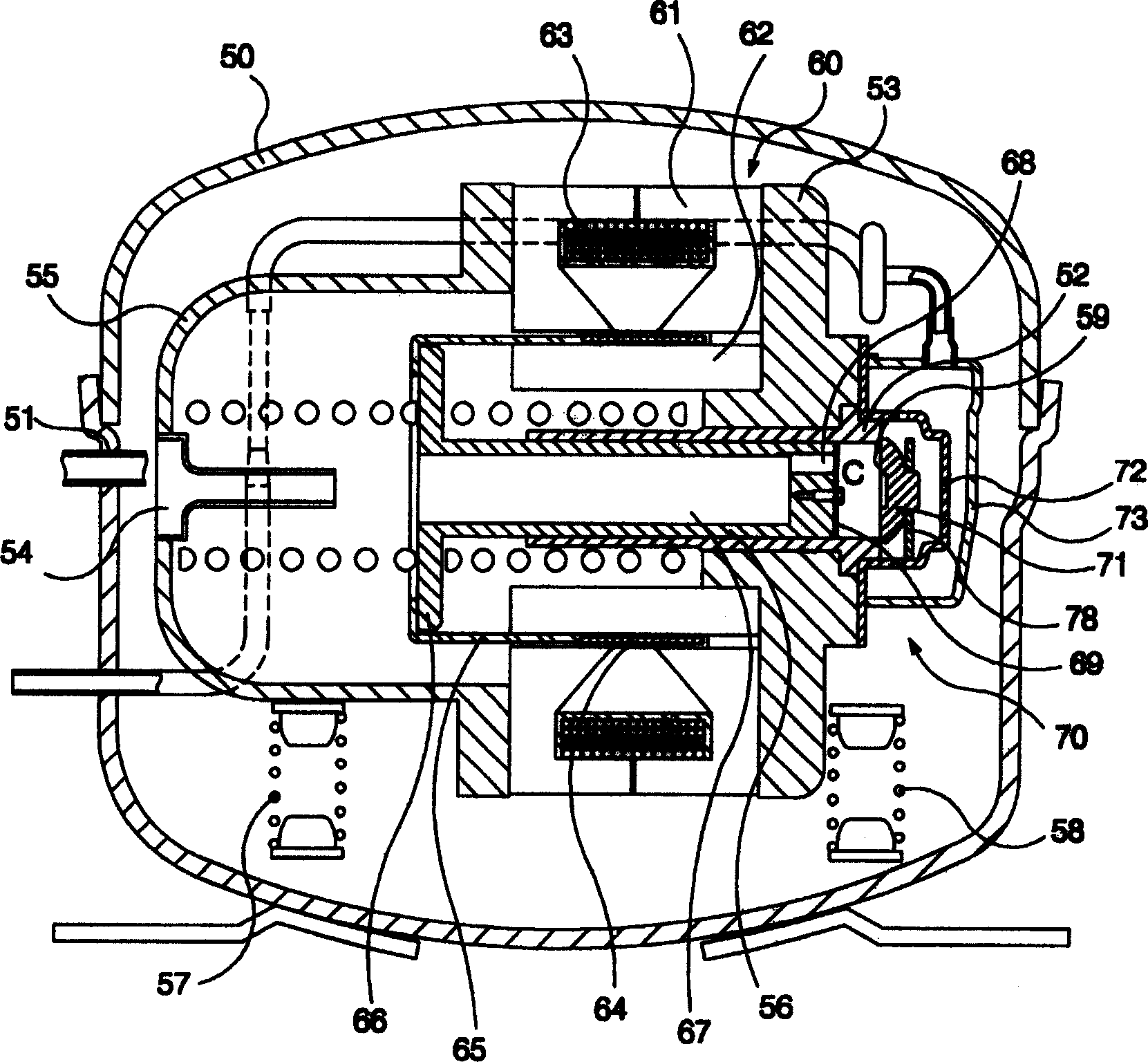

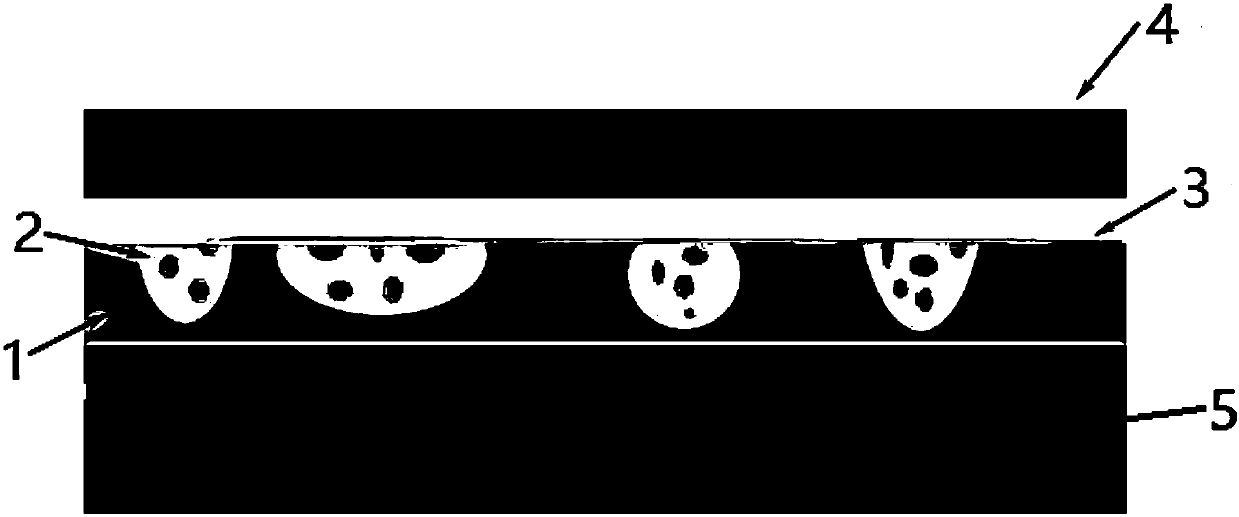

Linear compressor

InactiveCN1757916ACompact structureSmall sizePositive displacement pump componentsLeaf springsLinear compressorLeaf spring

Disclosed herein is a linear compressor. In the present invention, a leaf spring is used for an exhale spring to support an exhale valve. As the leaf spring supports the exhale valve by being bended in a predetermined direction, the exhale valve can be stably opened and closed in the predetermined direction. As a space for the exhale spring becomes reduced in an inner exhale cover, a size of an exhale part is reduced, thus making it possible to produce the compact linear compressor. As the leaf spring is comprised of a plurality of overlapped plates, when the exhale valve is opened and closed, the leaf spring is bended, and friction is generated among the plurality of plates. Therefore, a vibration of the exhale valve is decremented by its friction, thus reducing a friction noise.

Owner:LG ELECTRONICS INC

Composite frictional material and preparation method thereof

The invention provides a preparation method of a composite frictional material. The preparation method comprises the following steps that 1, a ferrous-based powder metallurgical frictional material is prepared; 2, shearing, smashing and screening are performed; 3, material mixing is performed; 4, the composite frictional material is prepared; 5 posttreatment is performed; 6, the composite frictional material is machined. Compared with the prior art, the composite frictional material integrates the characteristics of high temperature resistance and low abrasion resistance of the ferrous-based powder metallurgical frictional material and the characteristics of good toughness and low hardness of a resin-based composite material and has the advantages of high temperature resistance, low abrasion resistance, good toughness and low hardness. The ferrous-based powder metallurgical frictional material is used for preparing an automobile braking accessory, scratching of an automobile brake disc or drum is effectively avoided based on good braking performance, and frictional noise is small.

Owner:CHONGQING AOSHUNTE MACHINERY MFG

Flange friction type shape memory alloy rod self-restoring steel frame beam-edge column joint

ActiveCN107386438ASolve the inconvenience of floor layoutImprove replaceabilityProtective buildings/sheltersShock proofingSteel platesSteel columns

The invention discloses a flange friction type shape memory alloy rod self-restoring steel frame beam-edge column joint. The flange friction type shape memory alloy rod self-restoring steel frame beam-edge column joint comprises a steel column, a steel beam, a shape memory alloy rod, an L-shaped bracket, a shear plate and a friction energy dissipater, wherein the steel beam is located on one side of the steel column, the shape memory alloy rod transversely penetrates through the steel column, the L-shaped bracket is located at the inner side of a steel beam flange, the shear plate is located in the middle position of a steel beam web plate, and the friction energy dissipater is located at the outer side the steel beam flange; the friction energy dissipater comprises a steel plate, an energy-dissipation friction sheet and high-strength bolts, wherein the steel plate is arranged at the outer side of the steel beam flange, the position between the steel plate and the steel beam flange is filled with the energy-dissipation friction sheet, and the high-strength bolts penetrate the steel beam flange to connect the steel plate, the energy-dissipation friction sheet and the L-shaped bracket. According to the flange friction type shape memory alloy rod self-restoring steel frame beam-edge column joint, the stable energy-dissipation capacity of the joint can be improved significantly, and the self-restoring performance of the joint is achieved at the same time by utilizing super elasticity of shape memory alloy; and convenience of floor arrangement of the position of the joint and replaceability of components are improved, and the ability of resisting local buckling deformity of the steel beam flange is strengthened by reasonable designing for the joint structure.

Owner:SOUTHEAST UNIV

Anti-attrition spacer capable of reducing frictional abnormal sound and application of anti-attrition spacer

InactiveCN105782215AReduce friction noiseSqueak and rattle mitigationWashersSolid state diffusion coatingUniversal jointFrictional coefficient

The invention discloses an anti-attrition spacer capable of reducing frictional abnormal sound and an application of the anti-attrition spacer and belongs to the field of mechanical parts. The anti-attrition spacer takes a low-carbon alloy cold-rolled sheet as a base body, and carbonitriding thermal treatment and surface coating treatment of a polyfluorocomplex and / or a nylon 11 coating are successively performed on the low-carbon alloy cold-rolled sheet. The adhesive force between the coating and the base body in the anti-attrition spacer provided by the invention is large, and the coating has excellent anti-attrition effect and wear-resistant effect. The anti-attrition spacer is used between contact surfaces which rub with each other. With prolonging of frictional time, the coating on the anti-attrition spacer does not fall off, so that the durability of the anti-attrition spacer is ensured, the frictional coefficient between the anti-attrition spacer and the contact surfaces is effectively reduced, and the adhesive wear is reduced, and therefore, the frictional abnormal sound is further reduced. In particular, the anti-attrition spacer used in the field of automobiles can effectively relieve the frictional abnormal sound generated between the end face of a universal joint at the fixed end of a driving shaft and a contact surface of a hub bearing of an automobile.

Owner:CHERY AUTOMOBILE CO LTD

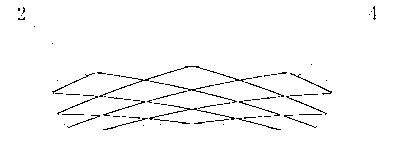

Resin gear

InactiveUS7921745B2Effective absorptionReduce friction noisePortable liftingGearing elementsInvoluteEngineering

Noise can be effectively reduced without rotative power transmission accuracy being compromised.In a tooth 2 of a resin gear 1, a tooth face that is a predetermined area from a tooth crest 8 towards a tooth root 10 side serves as a tooth profile modification area 11. A tooth surface excluding the tooth profile modification area 11 serves as an involute profile area 12. The tooth profile modification area 11 includes a linear standard profile portion 14 formed by an involute curved line from the tooth crest 8 of the tooth towards the tooth root 10 side and a profile modification portion 16 in which a tooth thickness gradually and smoothly decreases from the standard profile portion 14 along a tooth width direction and the tooth thickness gradually and smoothly decreases from a tooth root end side 15 towards the tooth crest 8. In the tooth profile modification area 11, a contacting section becomes elastically deformed as a result of the resin gear coming into contact with a meshing mating gear. A tooth width direction length of the contact surface gradually increases from a minute, point-like width to a full tooth width from the tooth crest 8 side towards the tooth root 10 side.

Owner:ENPLAS CORP

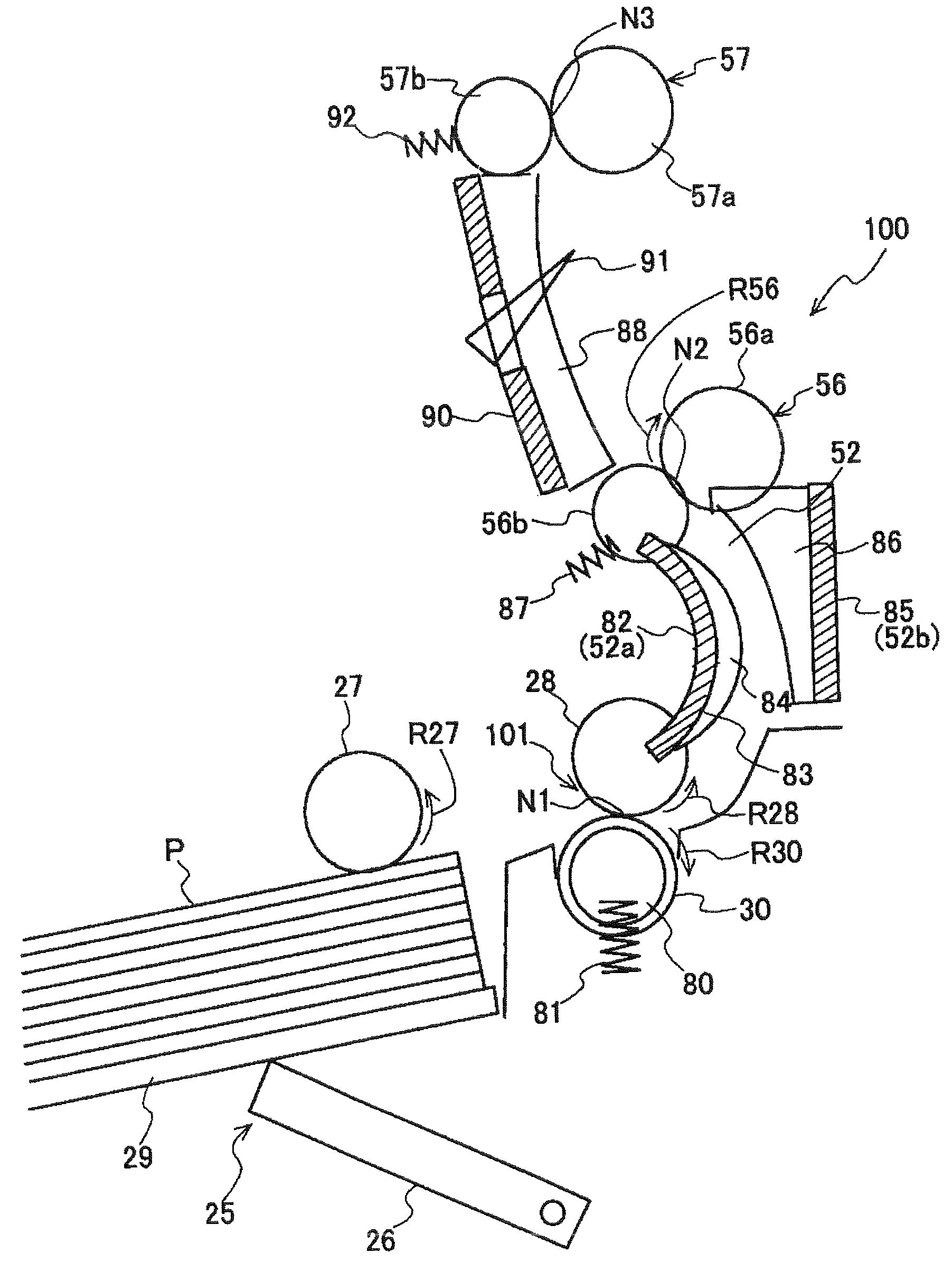

Sheet conveying apparatus and image forming apparatus with the sheet conveying apparatus

ActiveUS7661673B2Reduce friction noiseRegistering devicesFunction indicatorsEngineeringMechanical engineering

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Hard framework guide slot top strip

InactiveCN104924999AReduce friction noiseReduce wind noiseEngine sealsVehicle sealing arrangementsSemi solidEngineering

The invention relates to a hard framework guide slot top strip. The hard framework guide slot top strip comprises a hard framework guide slot top strip body with an opening in the lateral direction, a first upper clamping part and a second upper clamping part. The first upper clamping part and the second upper clamping part are located on the top face of the hard framework guide slot top strip body and are parallel to the axial direction of the hard framework guide slot top strip body. The first upper clamping part is located on the sealed side of the hard framework guide slot top strip body and is a semi-solid-rubber semi-sponge-rubber lip. The part, facing the open side, of the lip is made of solid rubber, and the part, opposite to the open side, of the lip is made of sponge rubber. The second upper clamping part is located on the open side of the hard framework guide slot top strip body and is a fin-shaped hollow sponge foam pipe parallel to the axial direction of the hard framework guide slot top strip body. Due to the design, abnormal friction sounds generated by connection of the top strip structure and a vehicle body in the vehicle running process are reduced, air noise is lowered, and the sealing performance of a system without a first sealing strip is achieved.

Owner:SAIC METZELER SEALING SYST

Preparation method for alloy sample surface wear-resisting protective layer

InactiveCN108018589AEffective lubricationGood self-lubricating performanceAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention relates to a preparation method for an alloy sample surface wear-resisting protective layer. Firstly, an alloy sample is subject to micro-arc oxidation treatment, and a multi-hole micro-arc oxidation layer is obtained on the alloy sample surface; and secondly, a sealant is applied to the alloy sample surface. According to the preparation method, through the technologies of micro-arcoxidation, sealant applying and the like, an even micro-arc oxidation layer and lubrication particle composite self-lubricating wear-resistant coating is prepared on the alloy sample surface, the characteristic that micropores and lubrication particles are organically bonded is effectively used, and the antiseptic, wear-resisting and lubricating properties are greatly improved.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

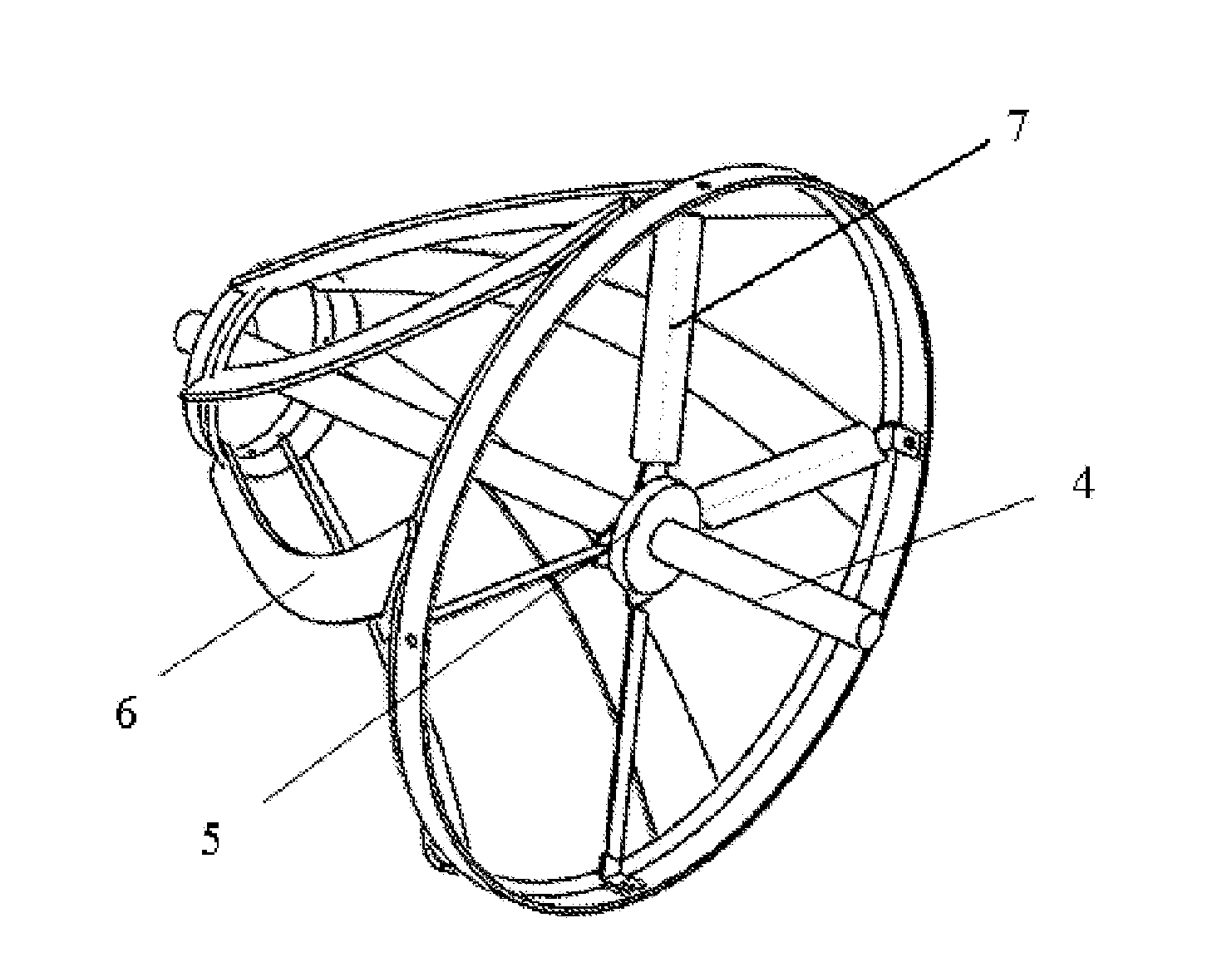

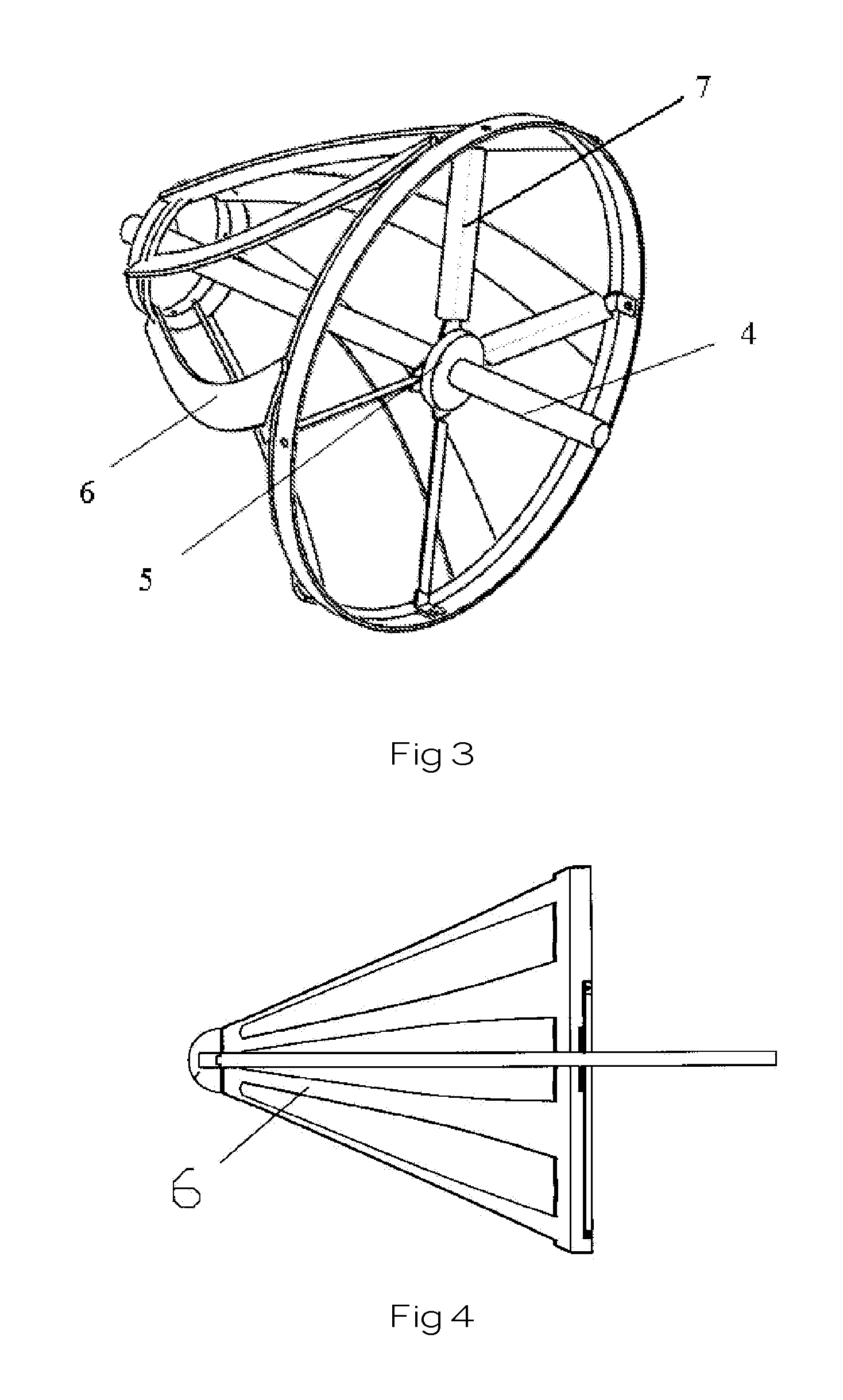

Wind turbine rotor with venturi tube effect

InactiveUS20110176920A1Simple and efficientImprove wind energy utilization efficiencyPropellersPump componentsEnergy transferWind energy conversion

The present invention discloses a rotor of wind energy conversion system (WECS) with the Venturi-tube effect. All the blades mounted on the blade-mounting seat envelop together to form a revolving-body cage turbine, which can be divided from structure into a head portion at the windward end, a tail portion at the wind exhaust end, and an airstream compression portion between the head portion and the tail portion and constituted by the enveloping blades. The revolution diameter of the airstream compression portion is gradually substantially increased from the head portion to the tail portion. The cage turbine forms a dynamic Venturi tube during the revolving process, with which the blade revolves to constitute its outline tube wall with the air permeability. The airstream passes through a window between the blades, and the incoming wind does work towards the blade during the process of permeating from the external space to the internal space of this outline tube wall, thus realizing the energy transfer.

Owner:SHANGHAI FOREVOO NEW ENERGY SYST +1

Friction particle, friction material and friction goods

ActiveCN103059811AHigh strengthImprove impact resistanceOther chemical processesNitrile rubberMixed materials

The invention provides a friction particle which can be prepared by the following methods of: 1) preparing the following materials in percent by mass: 55-73% of grinding dust, 1-3% of phenolic resin, 15-20% of liquid butyronitrile rubber and 7-22% of a first tribological property conditioning agent; and (2) uniformly mixing the materials in proportion, feeding the mixed materials into an internal mixer to be refined for 5-8 minutes, wherein the refining temperature is 80-100 DEG C, and cooling the refined material blocks and crushing so as to obtain the friction particle. The invention further provides a friction material and friction goods with the friction particle. The friction material and friction goods prepared from the friction particle have the advantages of low corrosion loss, high strength, low hardness, low noise and the like.

Owner:HUBEI FEILONG FRICTION & SEALING MATERIALS

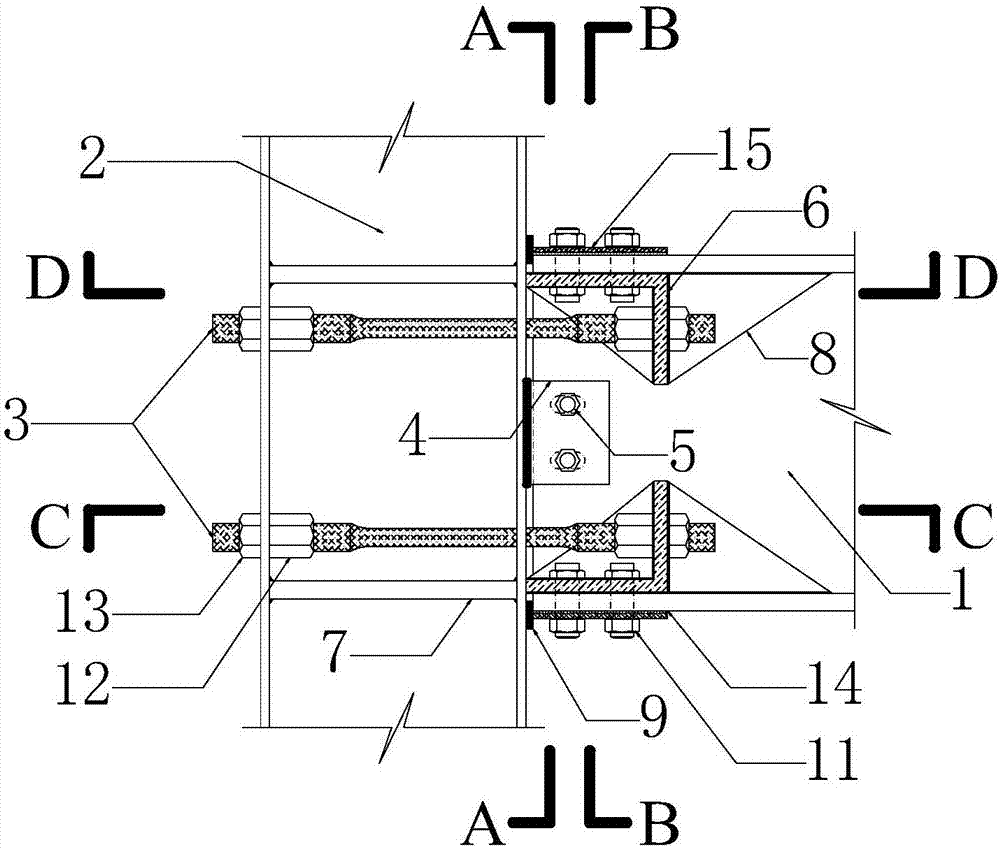

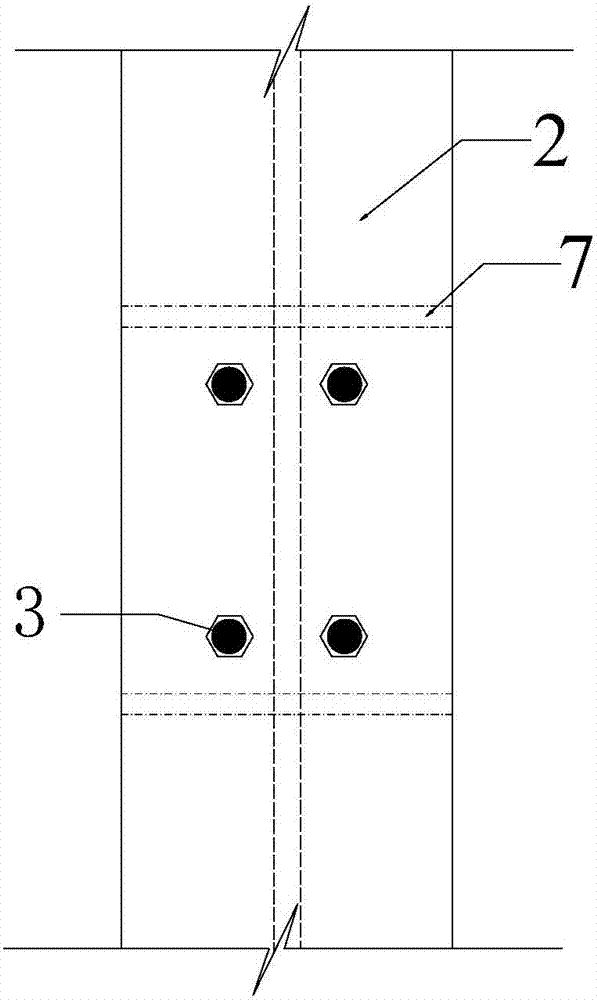

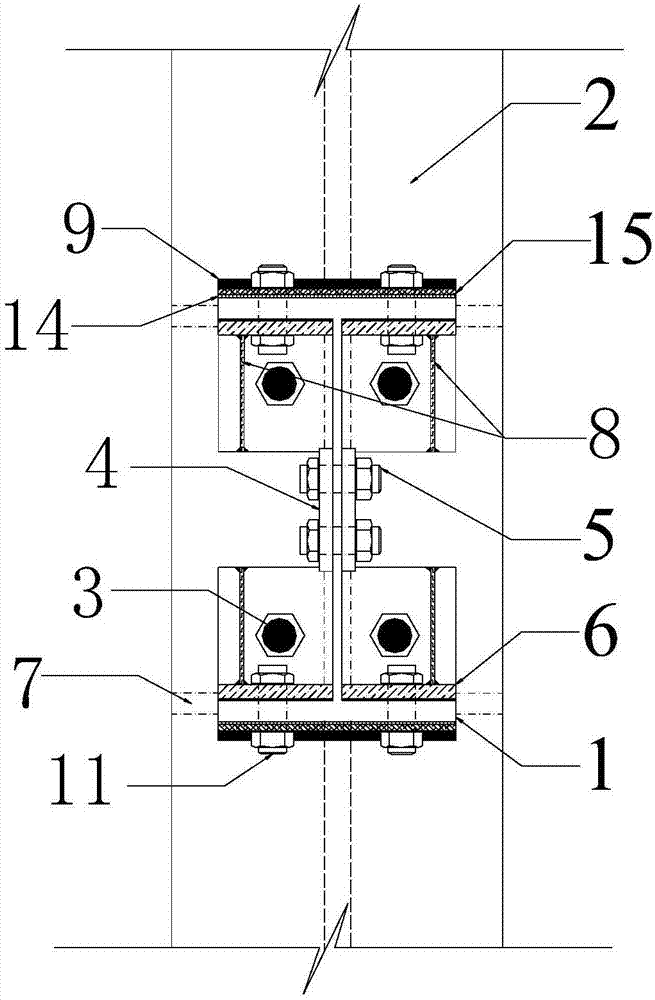

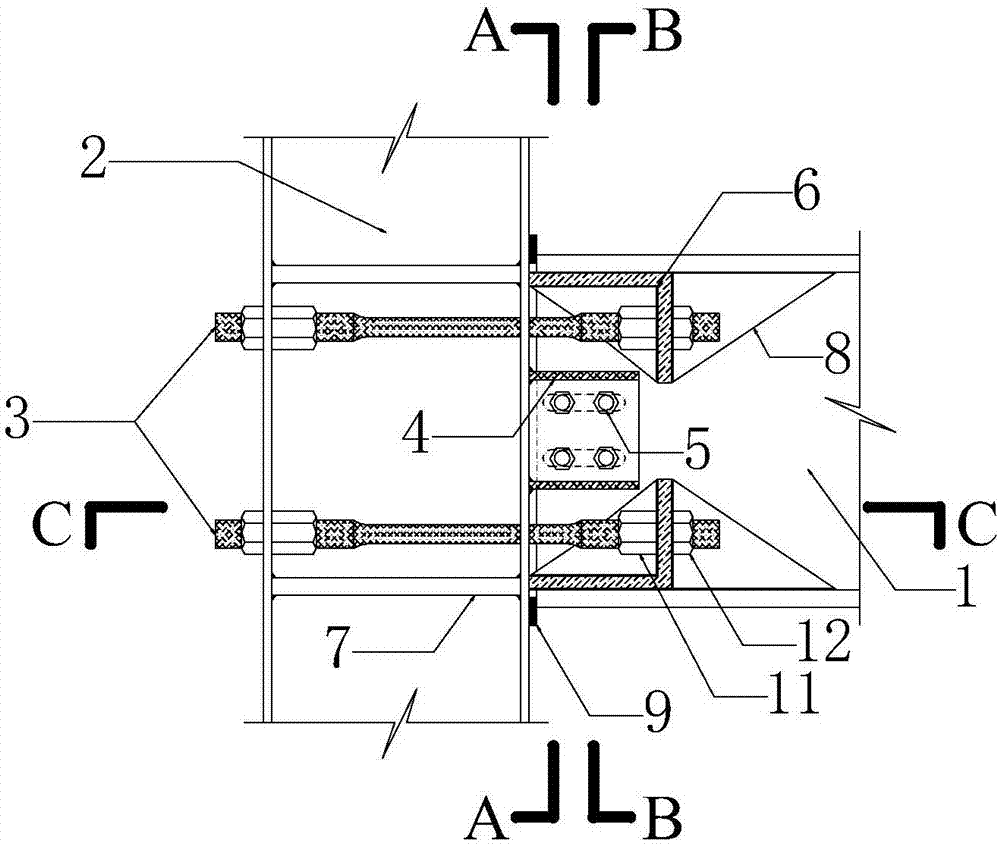

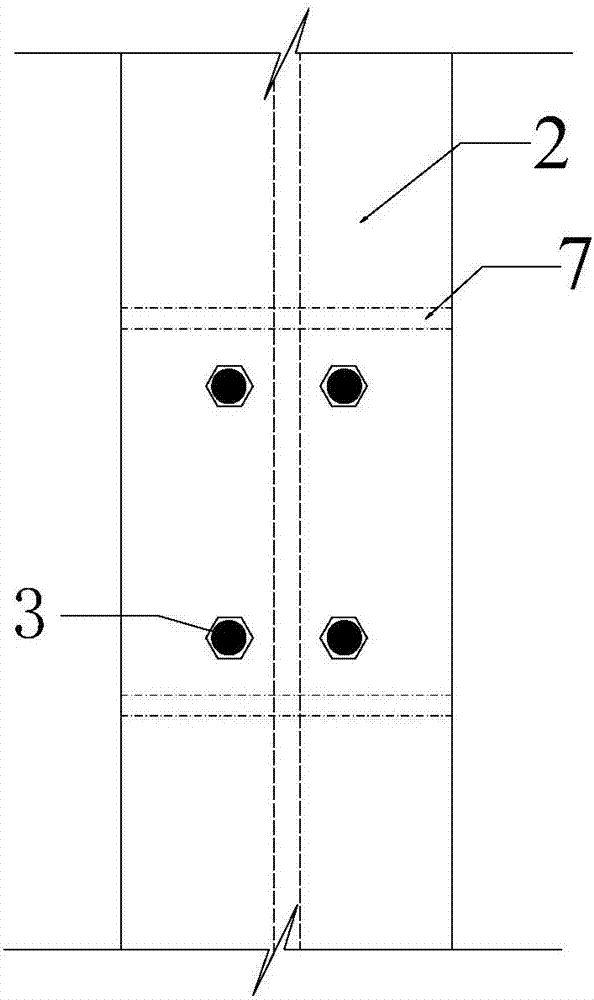

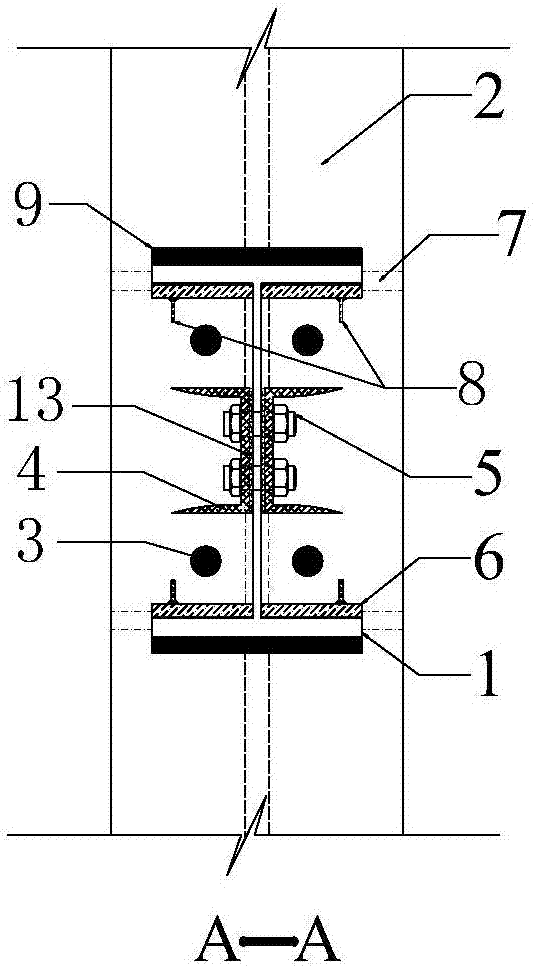

Web friction-type shape-memory alloy rod self-resetting steel frame beam-edge column joint

ActiveCN107355000ASolve the problem of inconvenient arrangementHigh replaceabilityProtective buildings/sheltersShock proofingFloor slabShape-memory alloy

The invention discloses a web friction-type shape-memory alloy rod self-resetting steel frame beam-edge column joint comprising steel columns, steel beams, shape-memory alloy rods, L-shaped supports and friction energy dissipaters. The steel beams are located on one sides of the steel columns; the shape-memory alloy rods transversely penetrate through the steel columns; the L-shaped supports are located on the inner sides of flanges of the steel beams; and the friction energy dissipaters are located in the middles of webs of the steel beams and comprise channel steel, energy dissipation friction pieces and high-strength bolts, wherein the channel steel is connected with flanges of the steel columns and the webs of the steel beams, the energy dissipation friction pieces are arranged between the channel steel and the webs of the steel beams in a filling mode, and the high-strength bolts penetrate through the webs of the steel beams and enable the channel steel, the energy dissipation friction pieces and the webs of the steel beams to be connected together. Arranging convenience of a floor at the joint can be improved; the anchoring effect of the shape-memory alloy rods and the steel beam ends is strengthened while the local deformation resistant capability of the flanges of the steel beams is reinforced; and the replaceability of members is improved while the self-resetting performance and hysteretic energy dissipation of the joint are effectively improved.

Owner:SOUTHEAST UNIV

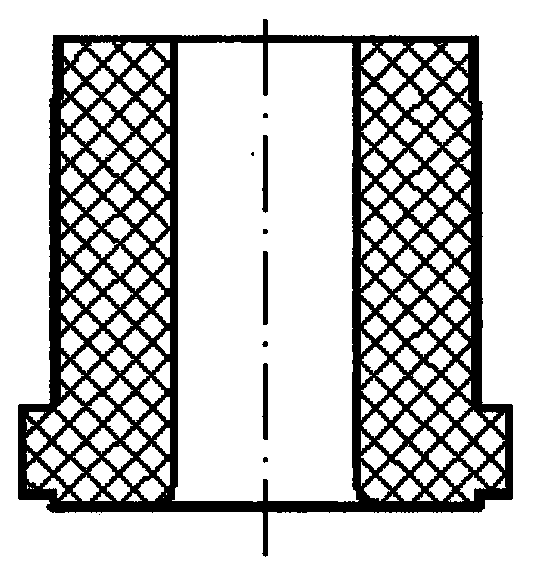

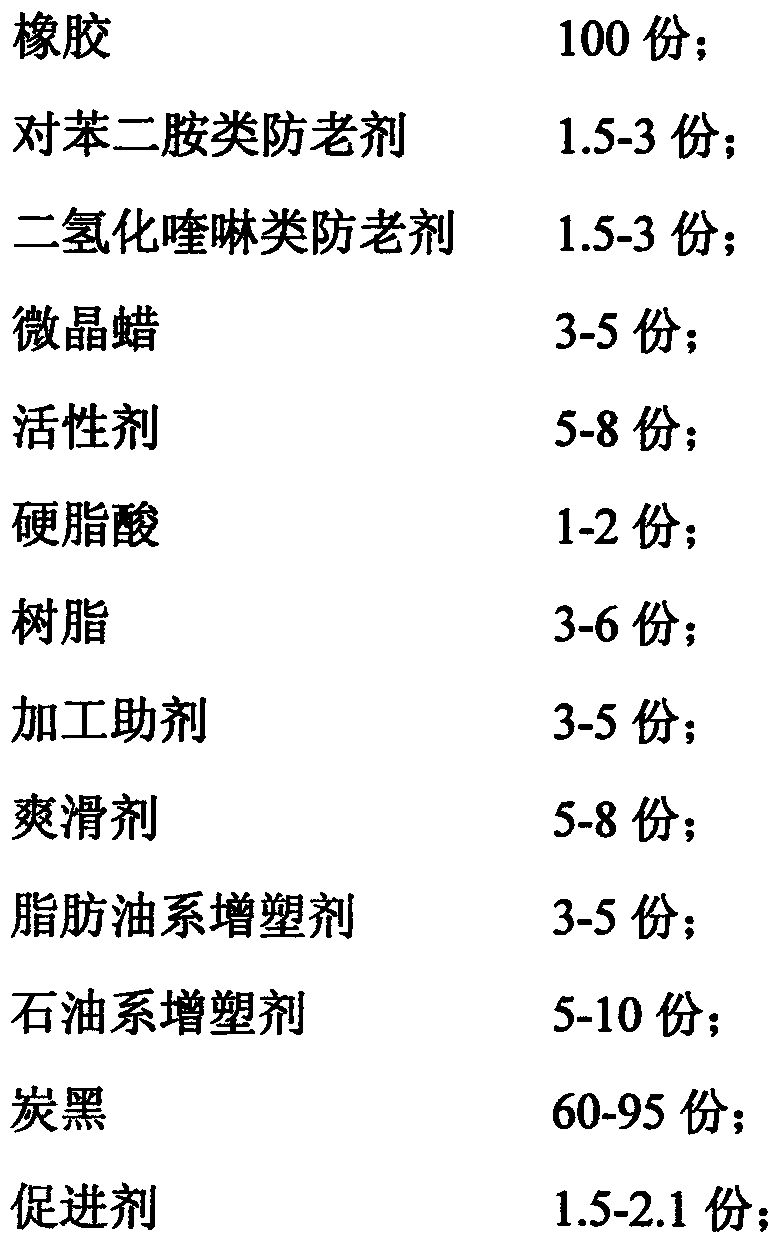

Rubber composition for leaf spring lug bushing for automobile

The invention discloses a rubber composition for a leaf spring lug bushing for an automobile. The rubber composition is characterized by comprising the following components in parts by weight: 100 parts of rubber, 1.5-3 parts of a p-phenylenediamine type anti deteriorant, 1.5-3 parts of a hydrogenated quinoline type anti deteriorant, 3-5 parts of microcrystalline wax, 5-8 parts of an active agent, 1-2 parts of stearic acid, 3-6 parts of resin, 3-5 parts of a processing addition agent, 5-8 parts of a slipping agent, 3-5 parts of a fatty oil plastifier, 5-10 parts of a petroleum plastifier, 60-95 parts of carbon black, 1.5-2.1 parts of an accelerant, and 1.5-1.8 parts of a vulcanizing agent. Through the adoption of the rubber composition disclosed by the invention, the lubricating property between the lug bushing and a bearing is improved, the friction noise is reduced, and the abrasion resistance is improved, so that the lug bushing is not invalid under the long-term use state, under the circumstance that the cost is not increased, the fabrication process is simple, and the lug bushing is convenient to use and mount.

Owner:SHANGHAI ZHONGLI AUTO PARTS

Rubber noise-reduction wear-resistant road brick and preparation method thereof

The invention relates to a rubber noise-reduction wear-resistant road brick and a preparation method thereof, belonging to the technical field of building materials. The invention provides a rubber noise-reduction wear-resistant road brick and a preparation method thereof, wherein the method comprises the steps of: evenly mixing 10wt%-15wt% cement, 5.0wt%-10.0wt% of pulverized fuel ash, 50wt%-70wt% of broken stones and 0.12wt%-0.8wt% of rubber powder and a proper amount of water, so as to obtain a mixture in a semi-dry state for die-filling; then evenly mixing 3.0wt%-5.0wt% of white cement, 7.0wt%-12wt% of quartz sand, 0.08wt%-0.4wt% of rubber powder, more than or equal to 0.4wt% of pigment and a proper amount of water, so as to obtain a mixture in a semi-dry state for die-filling; and washing the rubber powder in advance by adopting water and alkali solution, shaping in a jolt-squeeze manner and carrying out maintenance to obtain the rubber noise-reduction wear-resistant road brick. The method is simple, the road brick has the advantages of good compressive strength, wear resistance property, impact resistance property and noise reduction effect.

Owner:ZHEJIANG FANGYUAN BUILDING MATERIALS TECH

Thread transmission type electronic expansion valve

InactiveCN106766418AIncrease the support surfaceImprove installation firmnessOperating means/releasing devices for valvesEfficient regulation technologiesCavity wallButt joint

The invention relates to a thread transmission type electronic expansion valve, and belongs to valves. An existing electronic expansion valve is large in running noise, and abrasion or clamping of a magnetic steel sleeve is prone to occurrence; the thread transmission type electronic expansion valve is characterized in that a backward step end face leaning shoulder is arranged on the outer circle face of a front base sleeve, the opening end of a back base sleeve is in butt joint with the step end face leaning shoulder in a fixedly welding manner to form a straight-cylinder-shaped shell with two ends closed, a front section of a nut sleeve is inserted into an inner cavity wall of the front base sleeve, and an end face leaning shoulder on the inner cavity wall and an inward turning edge of the opening end of the front base sleeve are used for limiting and fixing; a valve is installed in a hollow inner cavity of a valve rod sleeve fixed to the magnetic steel sleeve in a penetrating manner, the back end of the valve extends out of the back end of the magnetic steel sleeve, and a spacer bush and a spring arranged outside the valve rod in a sleeving manner are used for back stroke limiting; and the valve rod sleeve is matched with inner threads in an axial through hole of the nut sleeve through outer threads to drive the valve rod to move, a buffer connecting piece connected with the front end of the valve rod is arranged on the front section of the axial through hole of the nut sleeve to conduct guide supporting on the valve rod, circumferential limiting protrusions and limiting leaning shoulders which are matched with each other are arranged for front stroke limiting, and the collision noise and friction are reduced.

Owner:新昌县儒岙镇锦云机械厂

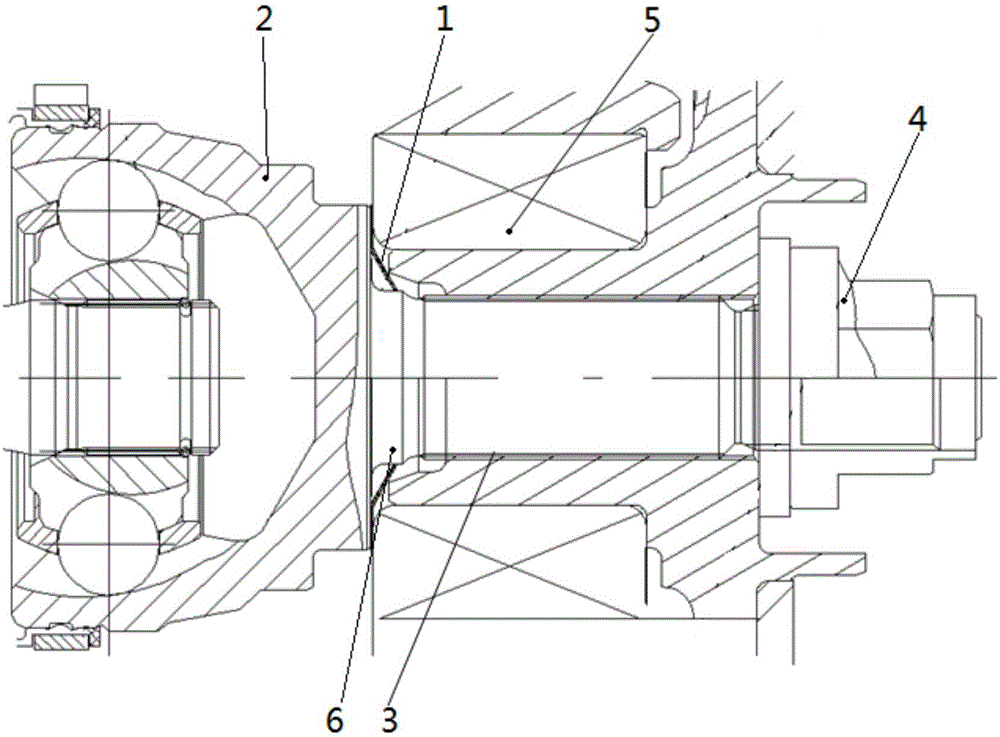

Sealing structure in automobile cooling transmission device

InactiveCN1967021AEasy to prevent dustImprove waterproof performanceEngine sealsBall bearingsFriction reductionEngineering

It solves the complex structure and difficult processing of the existing seal device for the bearings of cooling drive device for vehicles. With major shaft and belt wheels on the cooling drive device, this seal device is set at the end face of the belt wheel, comprises a seal washer embedded outside the seal cover on the major shaft, said seal cover fixed with the inner ring of the bearing and the major shaft, seal washer fastening with the belt wheel, seal cover and seal washer locking with each other with the gaps forming into a labyrinth seal. It has fine anti dust and water proof performance with reduced friction noise and heat. It is convenient for loading and unloading with low cost.

Owner:ZHEJIANG NESSRAL MACHINERY

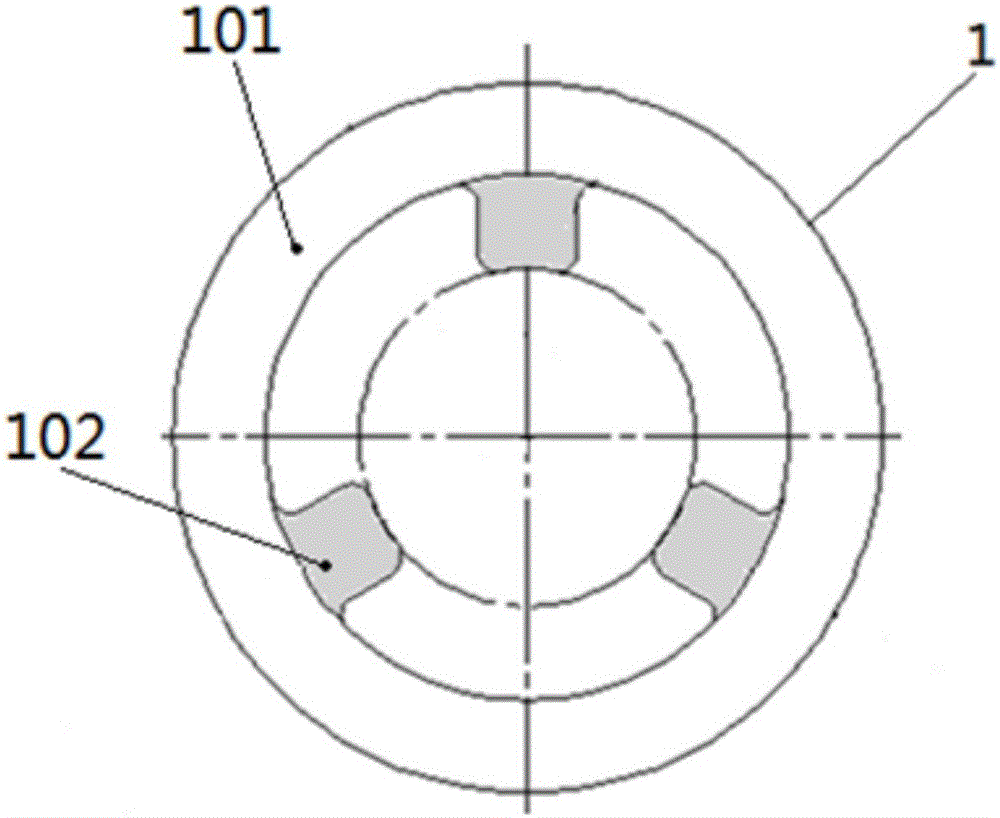

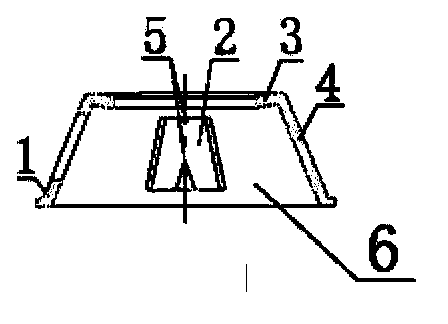

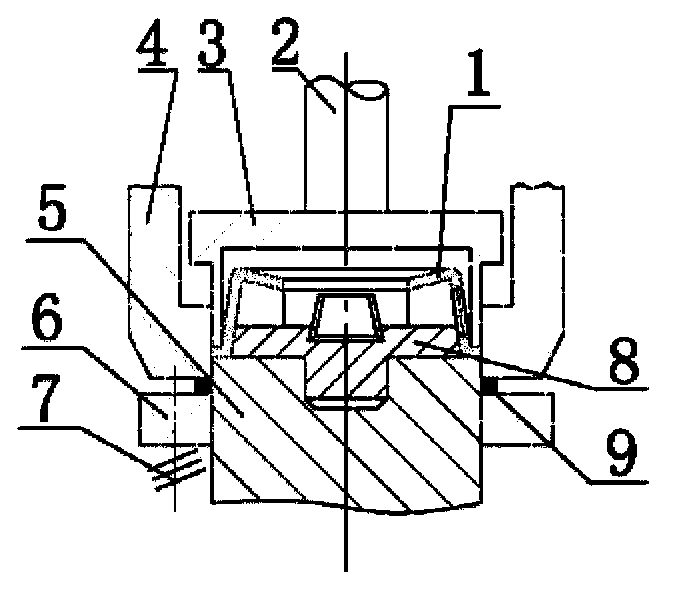

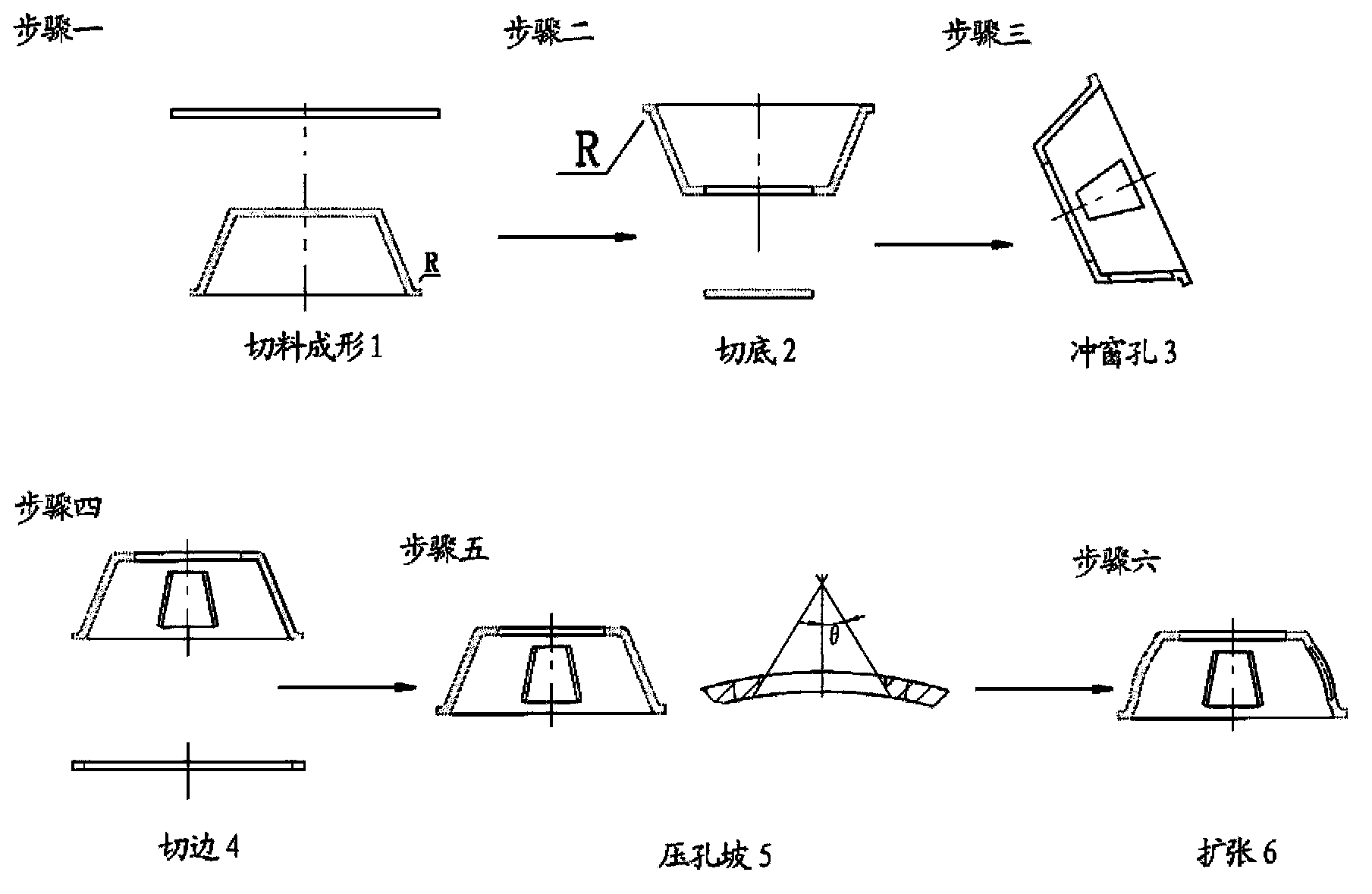

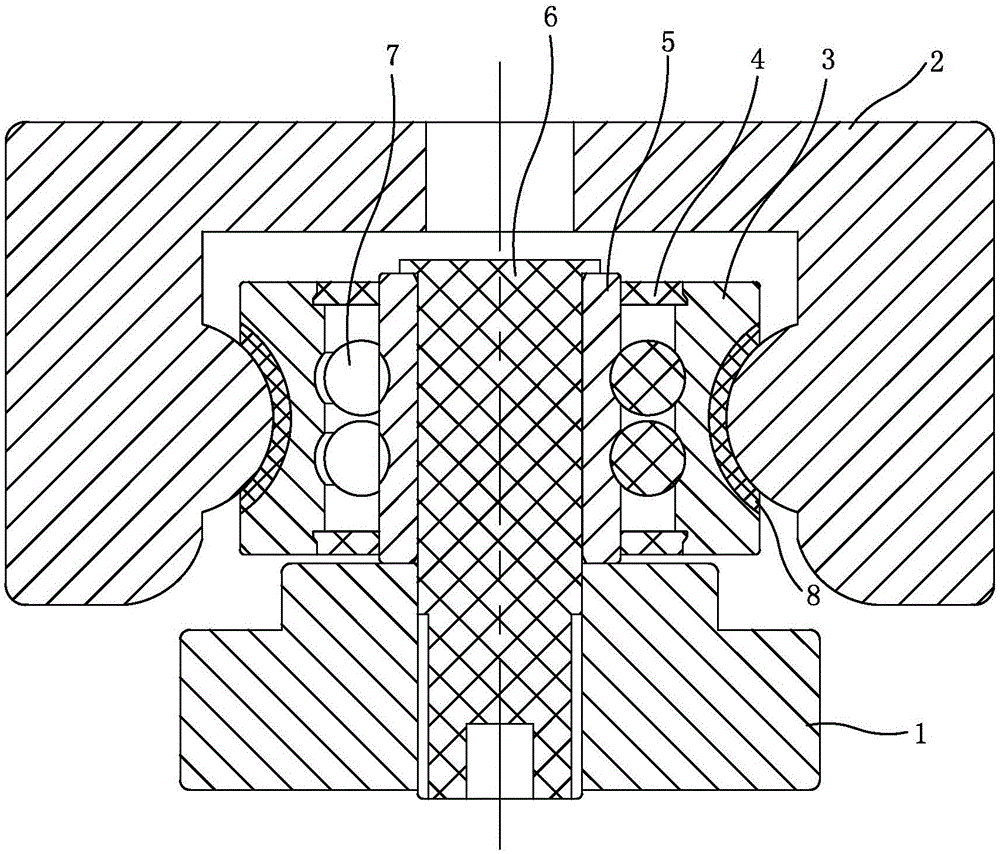

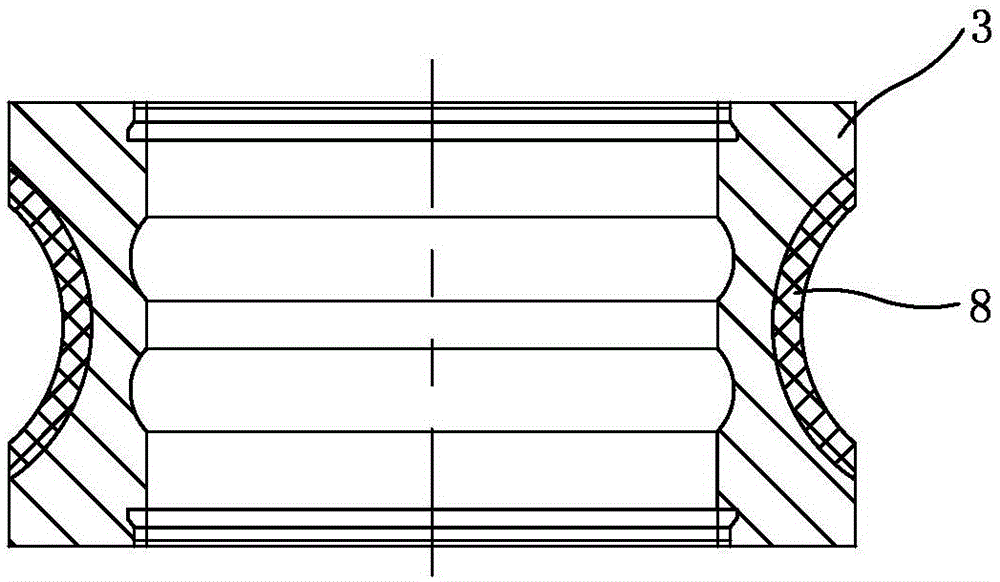

Whole-stamping retainer structure for tapered roller bearings

The invention relates to a whole-stamping retainer structure for tapered roller bearings, which comprises a retainer annular main body formed by a cellular beam and an inner hole, a flange, window holes, a bottom, and arc-shaped bumps; a plurality of window holes are uniformly distributed on the retainer annular main body in a circumferential direction; the annular flange is disposed at the large end and extends outwards in a direction of the central axis of the inner hole away from the retainer annular main body; the arc-shaped bumps are disposed respectively at two ends of each window hole in the axial direction of the retainer annular main body. A trimming die device of the whole-stamping retainer for tapered roller bearings comprises a retainer, a push rod, a discharging ring, a female die, a male die, a lower discharging plate, a spring, a positioning plate, and residual materials; the lower discharging plate is disposed at the outer side of the male die; the upper part of the male die is sleeved with the positioning plate and the retainer; the discharging ring is connected with the push rod, and the inner side of the female die is sleeved with the discharging ring; the purposes of the invention are to innovate the retainer structure, to reduce the plate thickness, and to realize the manufacturing of the retainer by a whole-stamping method.

Owner:LUOYANG YISONG PRECISION BEARING TECH DEV

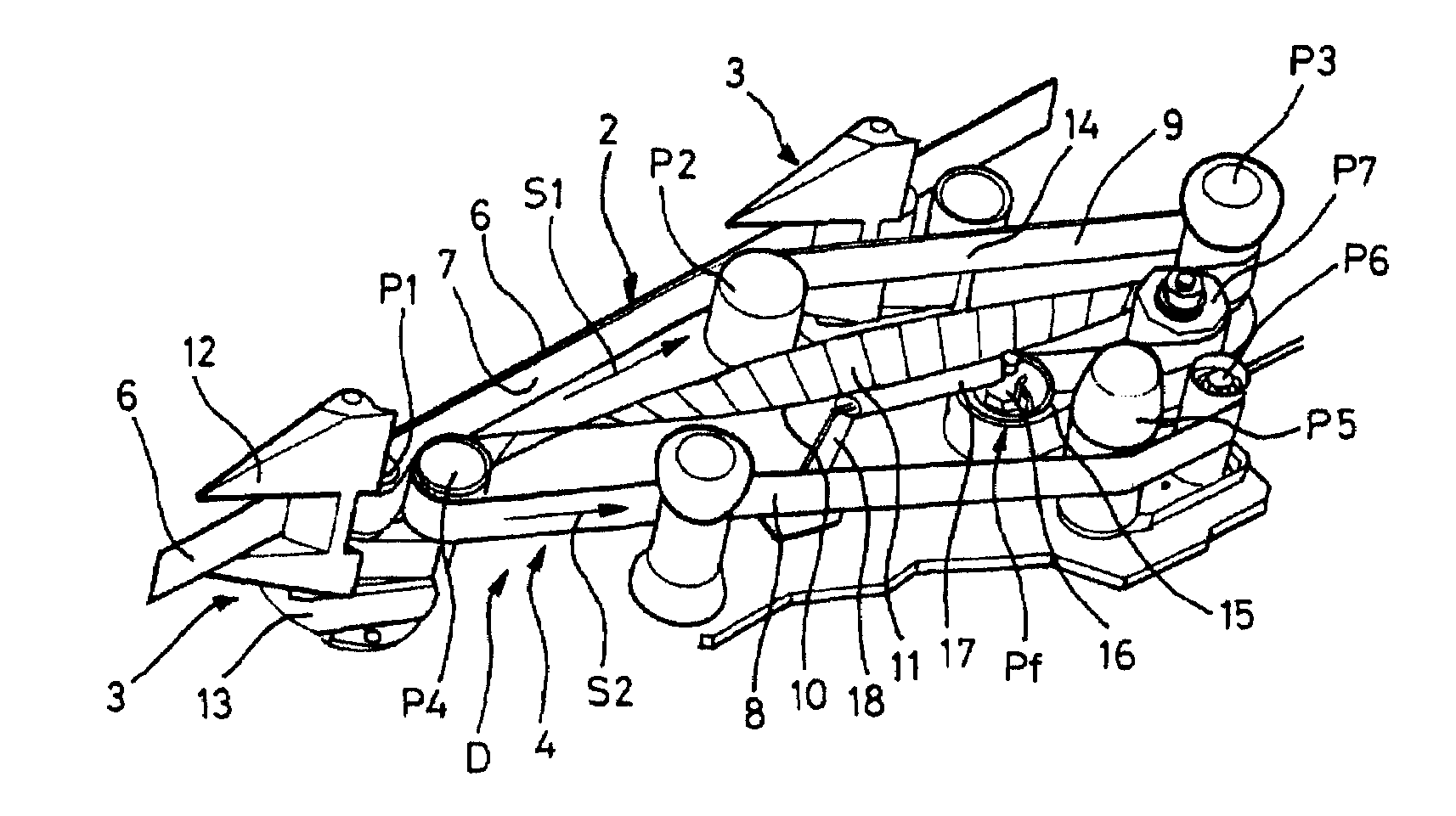

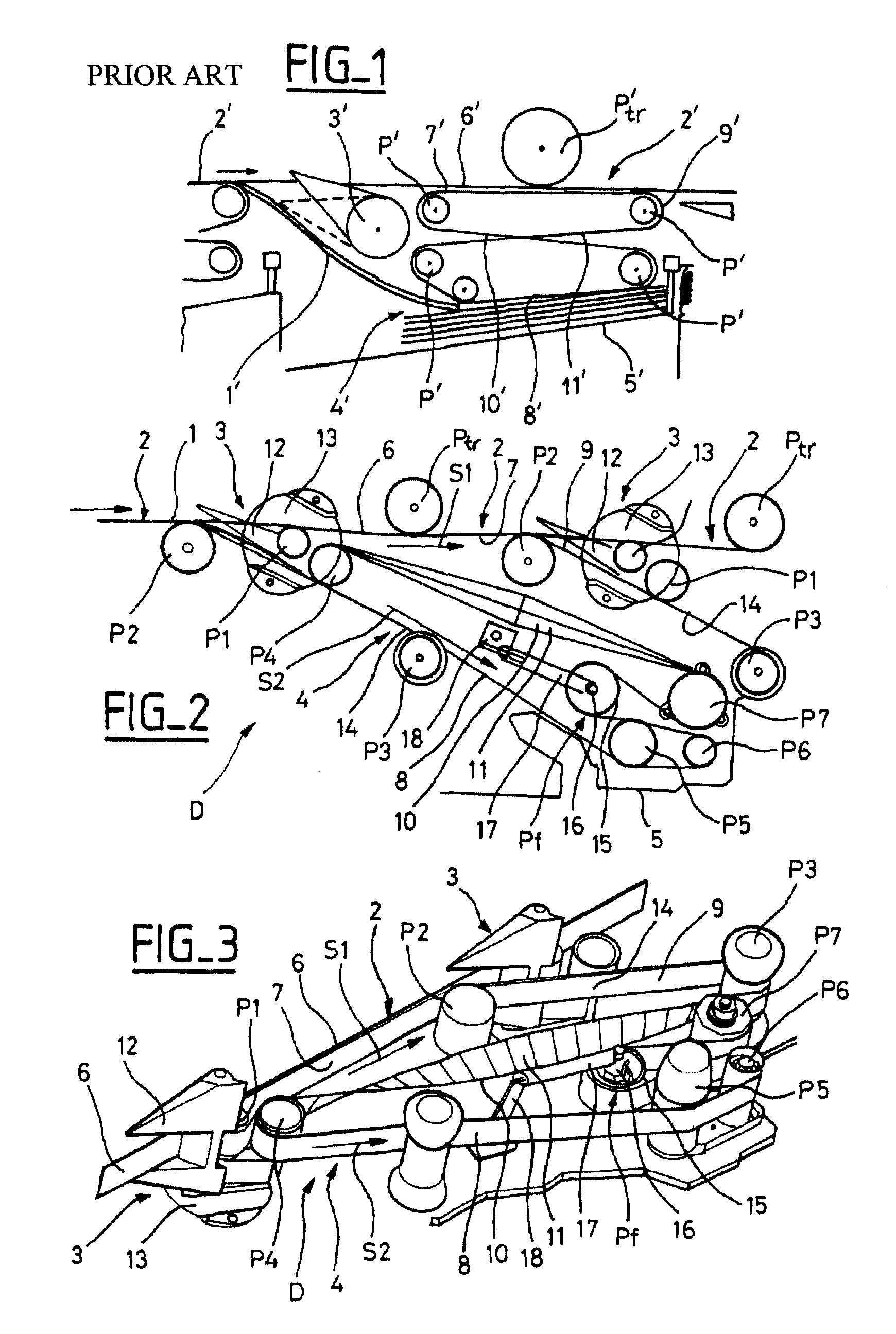

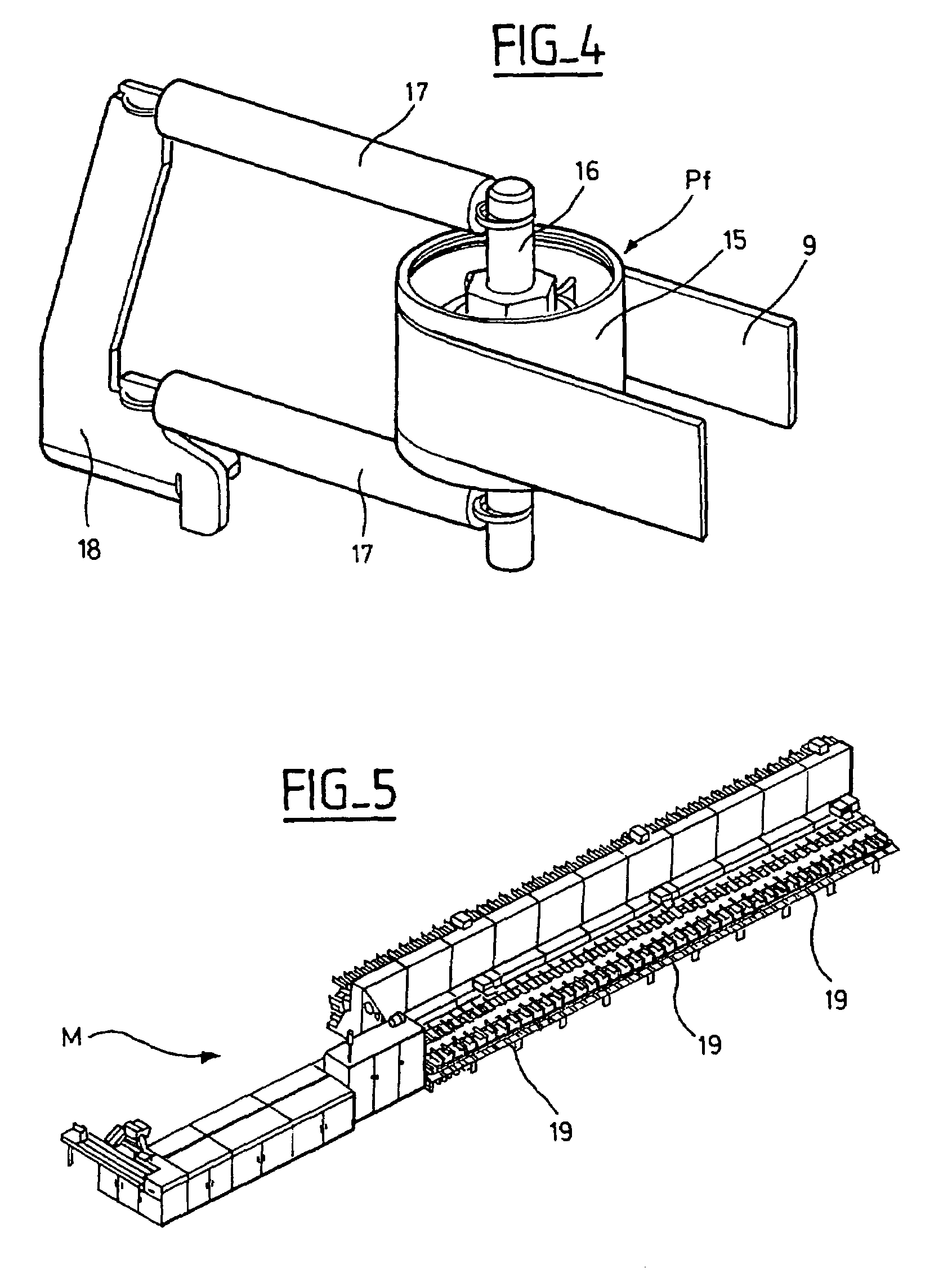

Conveyor apparatus having a twice-twisted belt and a floating-tension pulley

A conveyor apparatus including a main conveyor by which mail items are routed by being nipped between a transport belt and a main belt, and a secondary conveyor towards which the mail items are routed, after switching, along a secondary belt. The main and secondary belts performing the main conveying and the secondary conveying functions are constituted by a single, common belt that is twisted twice. The twice-twisted belt is engaged over a tensioner pulley that is a floating pulley.

Owner:SOLYSTIC

Guide rail sliding block device and machining technology thereof

ActiveCN105020269AReasonable structural designEasy to installLinear bearingsBearing componentsSand blastingEngineering

The invention relates to a guide rail sliding block device and a machining technology thereof. The guide rail sliding block device and the machining technology thereof are designed aiming at solving the technical problems that the structural design of bearings and guide rails in existing guide rail sliding block devices of the same kind is poor, the noise is large, and the stability is poor. The guide rail sliding block device comprises a sliding block, a guide rail and a sliding block bearing. The guide rail sliding block device is characterized in that a sliding groove of the outer ring of the sliding block bearing is provided with a gluing layer, a polyurethane material is adopted in the glue layer, and the glue layer is integrally formed with the outer ring; the machining technology of the outer ring comprises the steps that the sliding groove is formed in the manufactured molded outer ring, heat treatment is conducted, and sand blasting, groove milling, molding, injection molding, groove lathing and groove grinding are conducted on the sliding groove of the outer ring to obtain the finished product outer ring; a reserved pre-polymer is adopted in the injection molded gluing layer, and the reserved pre-polymer is machined through heating and stirring chain-extending of the pre-polymer and MOCA. Meanwhile, the guide rail is integrally molded by aluminum alloy; and the guide rail sliding block device is good in stability, long in service life, low in friction noise, feasible in machining method, and suitable for sewing machine equipment like an embroidery machine and a quilting machine and sliding rails with the same kind application requirements.

Owner:宁波博时培林机械有限公司

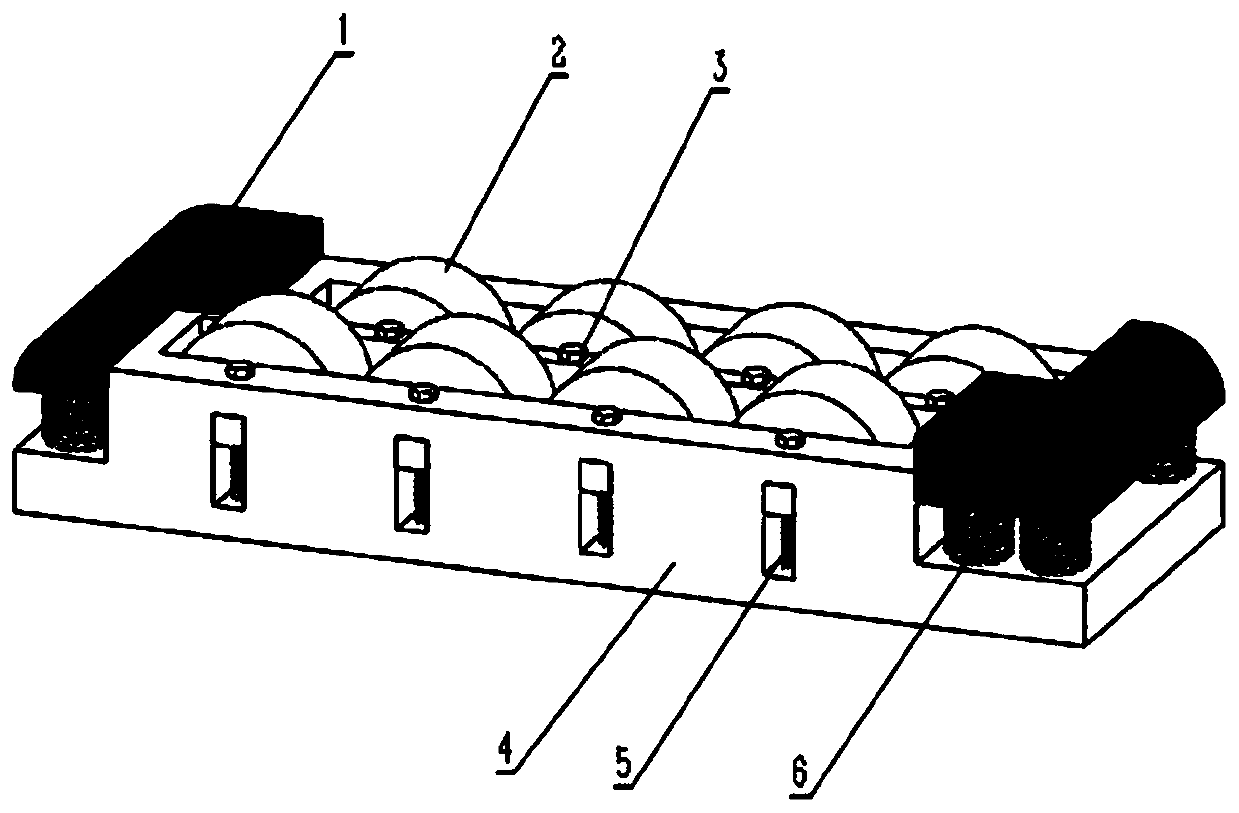

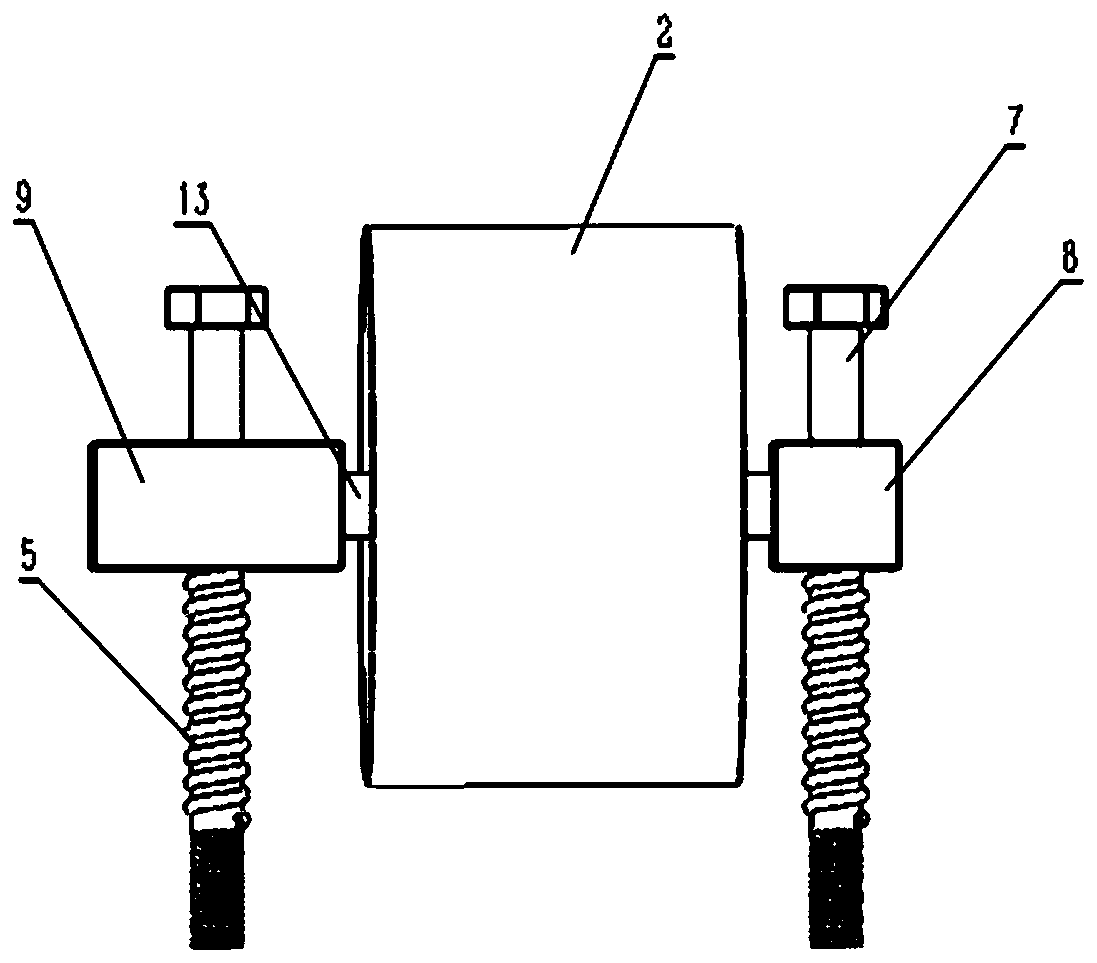

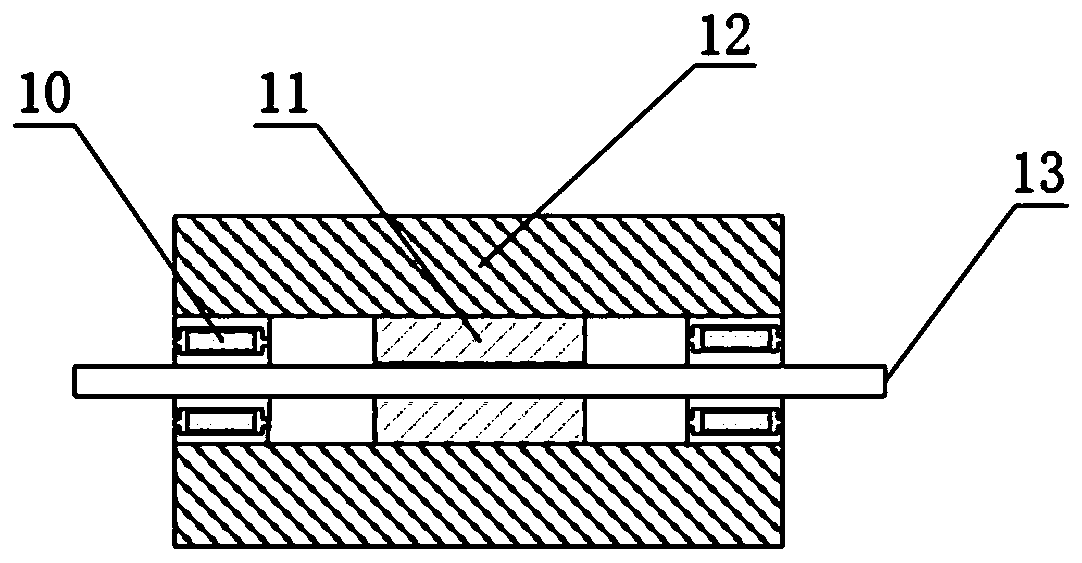

Double-row multi-roller type modular current-receiving device for electric locomotive

PendingCN110370936AReduce wearReduced service lifeRotary current collectorPower current collectorsModularitySlide plate

Disclosed is a double-row multi-roller type modular current-receiving device for an electric locomotive. According to the double-row multi-roller type modular current-receiving device for the electriclocomotive, two rows of metal rollers are annularly arranged on an insulating base; each rolling wheel is arranged in the manner that two insulating stand columns are fixed to the insulating base, compression springs sleeve the two insulating stand columns correspondingly, insulating blocks sleeve the insulating stand columns and are located above the compression springs, metal shells of the rollers are installed on metal shafts through two insulating bearings, the metal shafts are fixed to the two insulating blocks, the outer surface of an annular current receiving electric brush makes contact with the roller metal shells to receive current, the inner surface of the annular current receiving electric brush is fixed to the metal shafts, all the metal shafts are connected through cables and are then used for supplying power to vehicle-mounted power consuming equipment, and two pure carbon sliding plates are fixed to the insulating base through more than four springs. The friction forceand the friction noise of the current-receiving device and a rigid contact rail can be effectively reduced, and the double-row multi-roller type modular current-receiving device can adapt to the changes of locomotive traction power requirements and has good buffering performance, heat dissipation performance and rail attaching performance.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com