Dust removal device for grinding wheel cutting machine

A technology of grinding wheel cutting machine and dust removal device, which is applied in the direction of grinding/polishing safety device, metal processing equipment, grinding/polishing equipment, etc., which can solve the problems affecting the health of the operator, unsatisfactory dust removal effect, and failure of the numerical control system, etc. problems, to achieve the effect of environmental protection and noise reduction, good dust removal and noise reduction effect, and avoid dust pollution intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

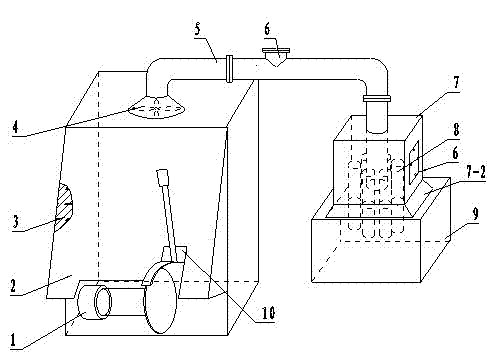

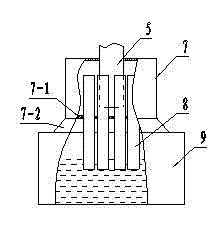

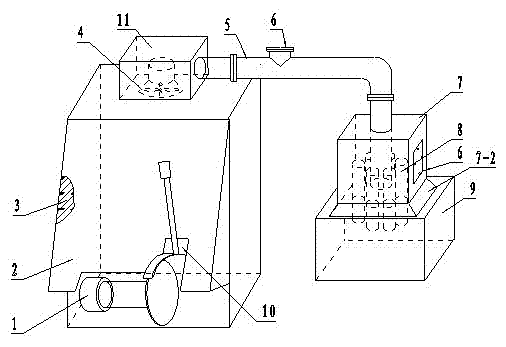

[0016] see figure 1 , image 3 , The present invention includes a protective cover 2 , an ash suction fan 4 , a dust collection pipe 5 , an ash collection cavity 7 and a precipitation ash cleaning tank 9 . The lower part of the protective cover 2 is provided with a grinding wheel cutting machine installation position 10, where the grinding wheel cutting machine is installed, and the dust generated when the grinding wheel cutting machine works enters the protective cover 2. In order to reduce the noise of the grinding wheel cutting machine, the inner wall of the protective cover is provided with There is a sound-absorbing layer 3. There is an ash suction fan 4 connected to the upper part of the protective cover, the ash suction fan is connected with the dust collection pipe 5, and the ash suction fan can be as follows figure 1 Directly connected to the dust collection pipe as shown, or as shown image 3 It is shown that it is communicated with the dust collecting pipe 5 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com