Dust removal and noise reduction device for grinding of internal surfaces of steel pipes

An inner surface and grinding technology, which is applied in the direction of grinding/polishing safety devices, grinding/polishing equipment, and machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problem of affecting the environment and human health, dust, and noise and other issues to achieve the effect of protecting human health, simplifying the structure, and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

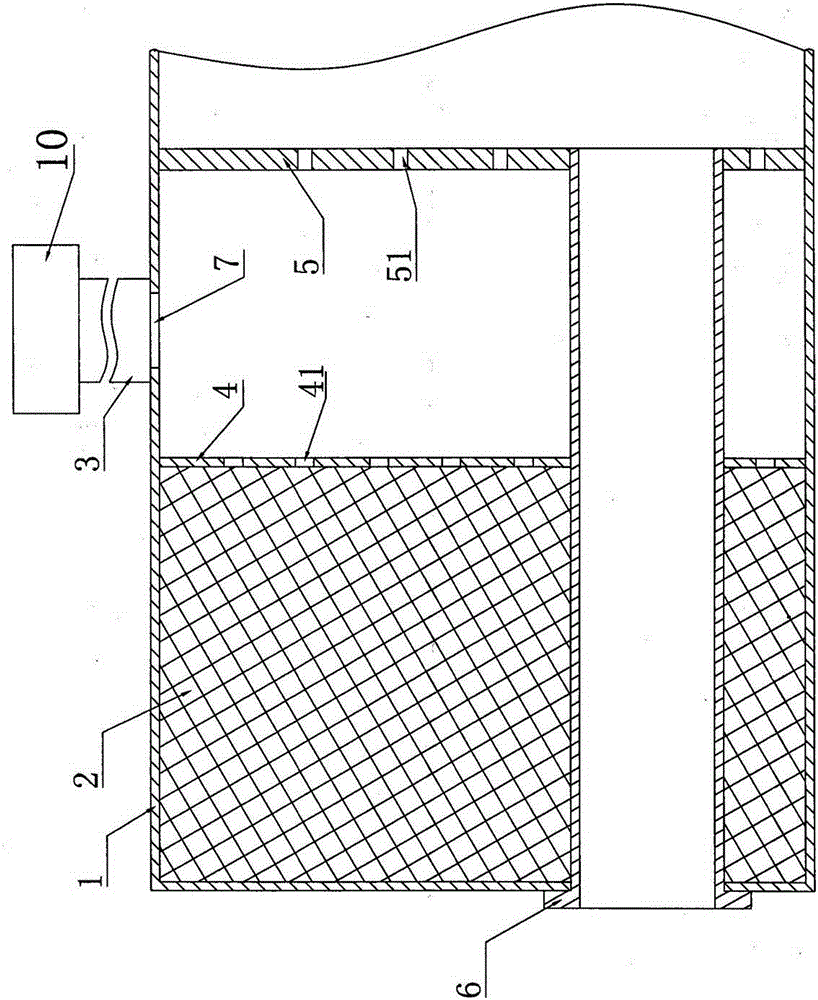

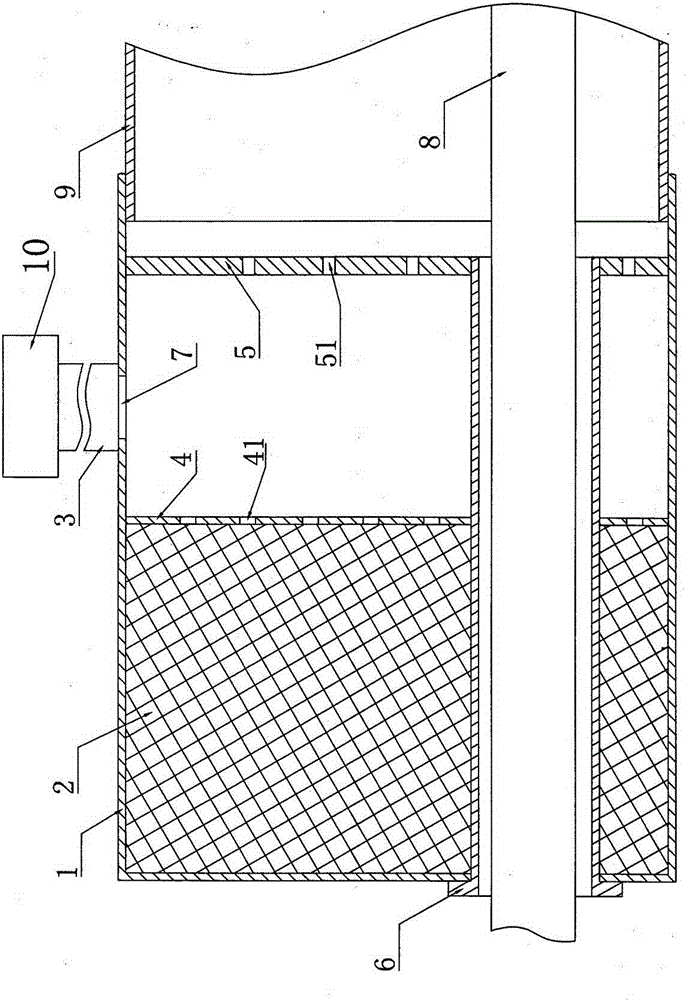

[0015] see figure 1 , steel pipe inner surface grinding dust removal and noise reduction device, including a dust collector, also includes a sound-absorbing dust-absorbing bucket, the sound-absorbing dust-absorbing bucket contains a bucket body 1, the front of the hole in the bucket is connected to a sound-absorbing board 5, and the sound-absorbing board is provided with The suction hole 51, the sound-absorbing plate is a metal plate with sound-absorbing cotton glued on both sides.

[0016] The middle part of staving body hole is connected with dividing plate 4, and dividing plate is provided with sound-absorbing hole 41, and dividing plate is the metal plate that both sides are glued with sound-absorbing cotton.

[0017] A dust discharge hole 7 is provided on the barrel wall between the sound-absorbing board and the dividing plate.

[0018] A sound-absorbing body 2 is placed between the dividing plate and the barrel bottom plate, and the sound-absorbing body is made of sound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com