Small-scale modular processing system of building rubbish and disposal method

A construction waste and treatment system technology, applied in construction waste recycling, solid waste removal, recycling technology, etc., can solve the problems of large investment scale, low resource utilization, long investment return period, etc. The effect of manufacturing cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

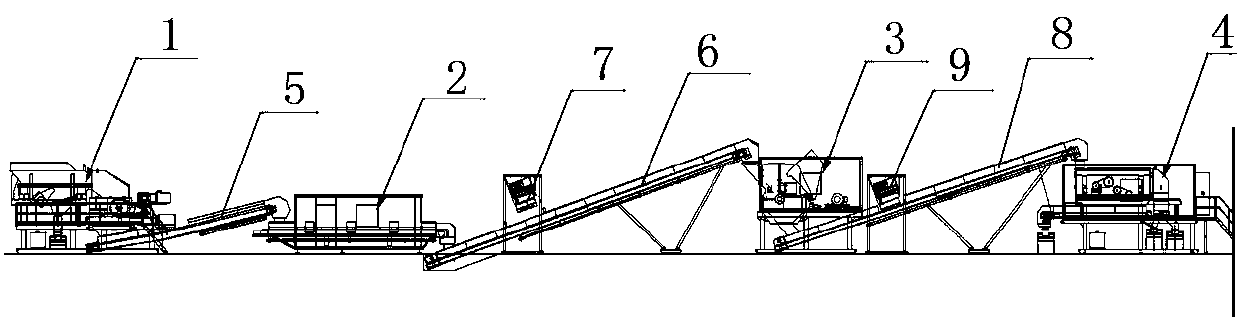

[0034] The technical solution adopted by the present invention is: the vibrating feeder that gives the construction waste to the first crushing module 1, the vibrating feeder evenly transports the construction waste to the primary crusher for crushing operation, and the primary crusher crushes the construction waste to The particle size is 200mm-50mm or less; the construction waste crushed to a particle size of 50mm-200mm is evenly spread on the hand-selected belt conveyor from the receiving end of the manual sorting module 2. After being sorted out, it enters the hand-selected debris collection device through the debris throwing port; the construction waste that has been manually sorted meets the requirements for the content of impurities in the recycled aggregate, and then enters the impact crusher module 3 for secondary crushing. The final material is removed by the iron remover, and then passed through the screening module 4 to obtain recycled aggregate products of differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com