Patents

Literature

38results about How to "Increase operating speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

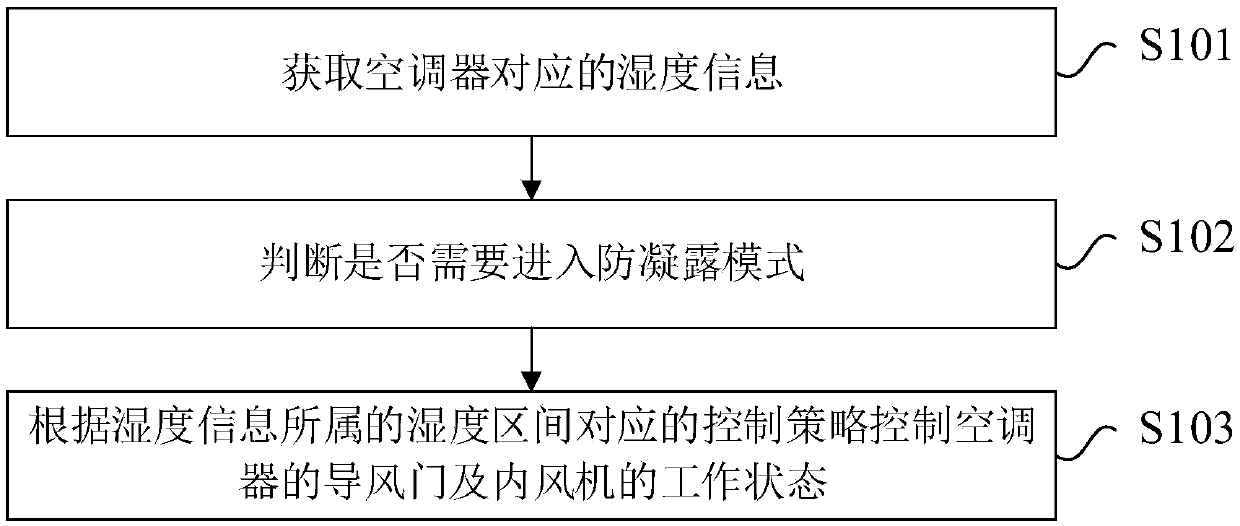

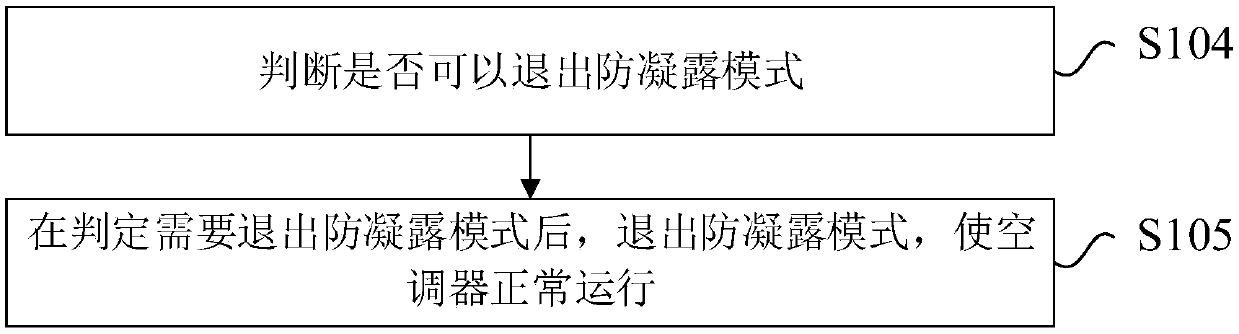

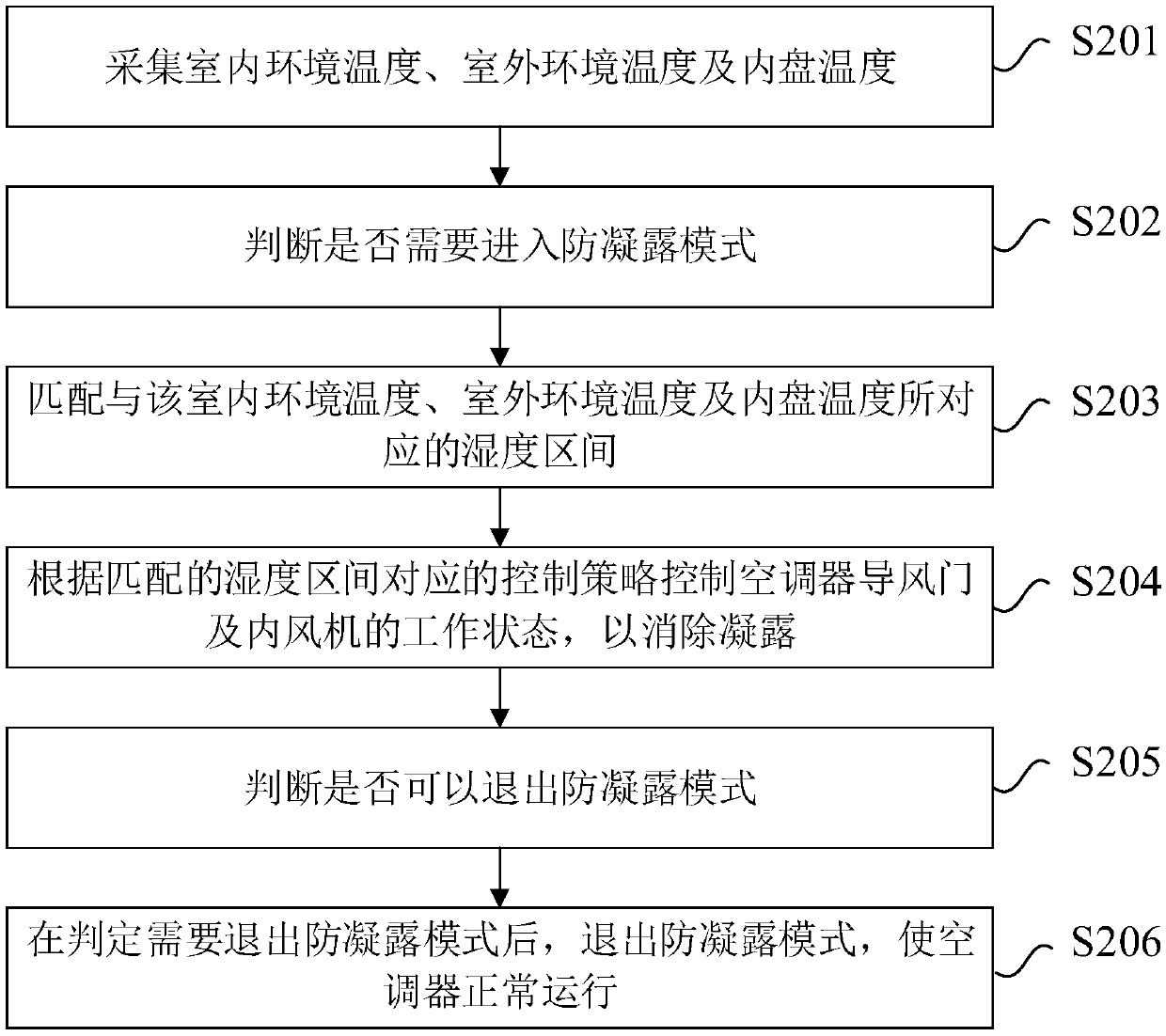

Anti-condensation control method and air conditioner

InactiveCN108679824AImprove anti-condensation effectIncrease operating speedMechanical apparatusCondensate preventionDefrostingComputer engineering

The invention provides an anti-condensation control method and an air conditioner. The anti-condensation control method is applied to the air conditioner, and a plurality of humidity intervals are preset in the air conditioner. The anti-condensation control method includes the steps that humidity information corresponding to the air conditioner is obtained, and whether the air conditioner needs toenter into the anti-condensation mode or not is judged; and when the need for entering into the anti-condensation mode is determined according to the humidity information, the working states of an air guiding door and an inner fan of the air conditioner are controlled according to a control strategy corresponding to the humidity interval to which the humidity information belongs so as to eliminate condensation. In the scheme, after the need for defrosting is judged, the humidity conditions are distinguished, and the corresponding control strategy is selected to adjust the working states of the air guiding door and the inner fan separately, so that a good decondensation effect can be obtained in different humidity environments.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

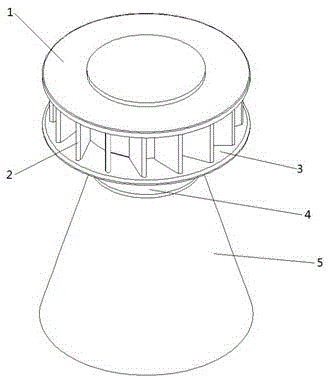

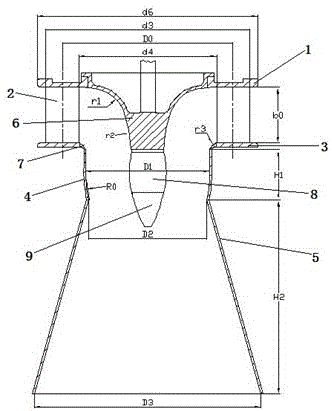

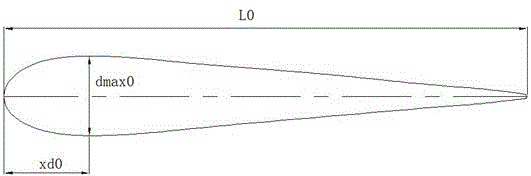

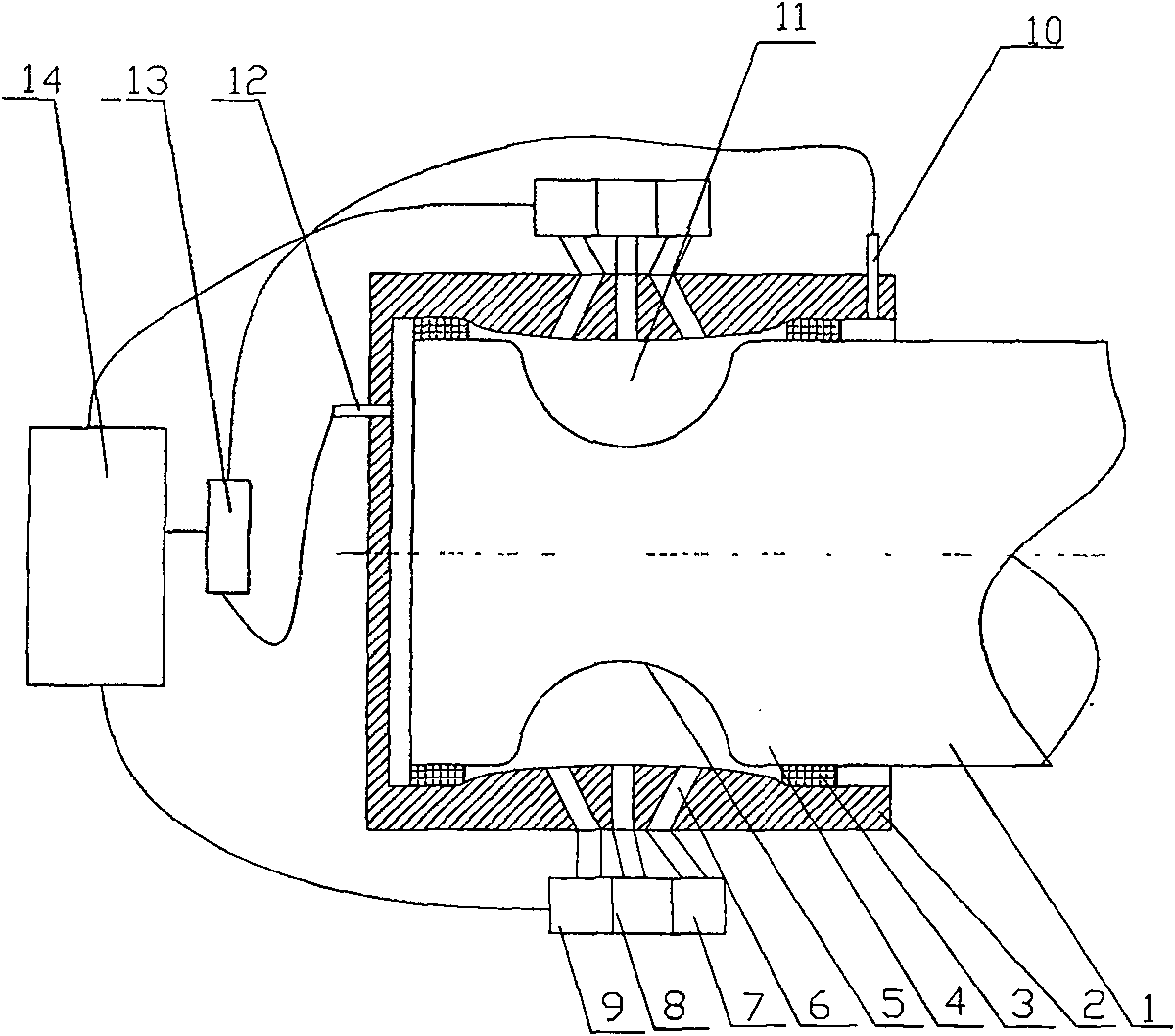

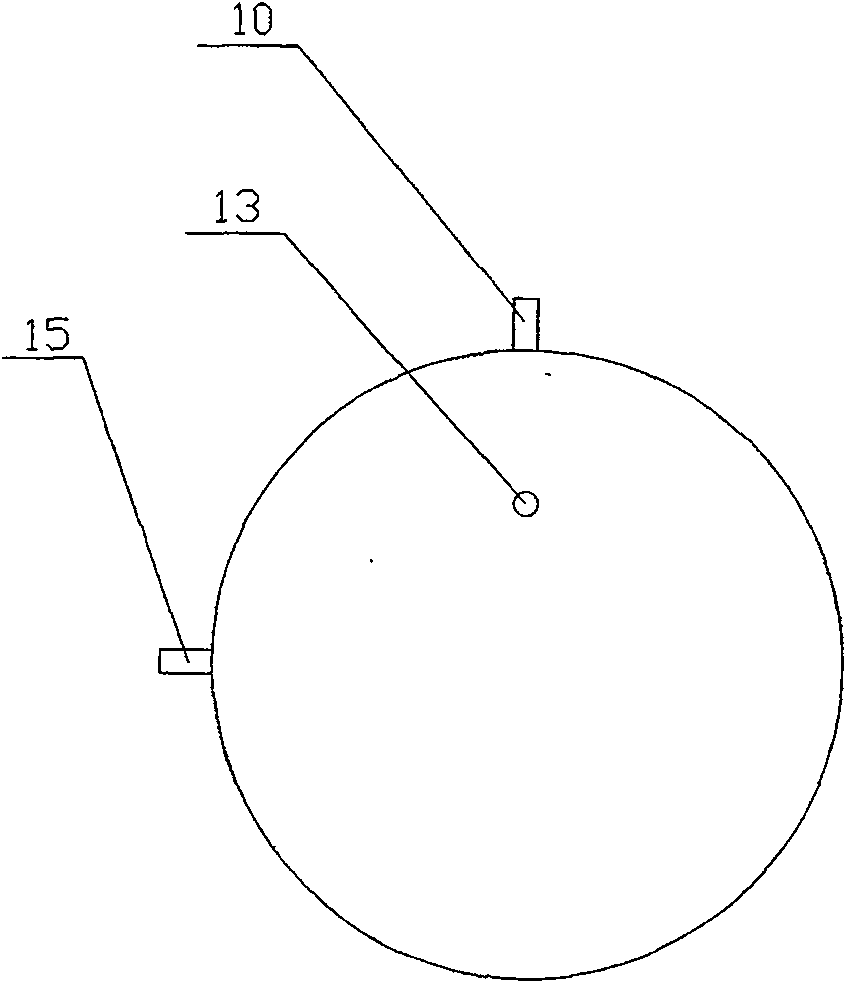

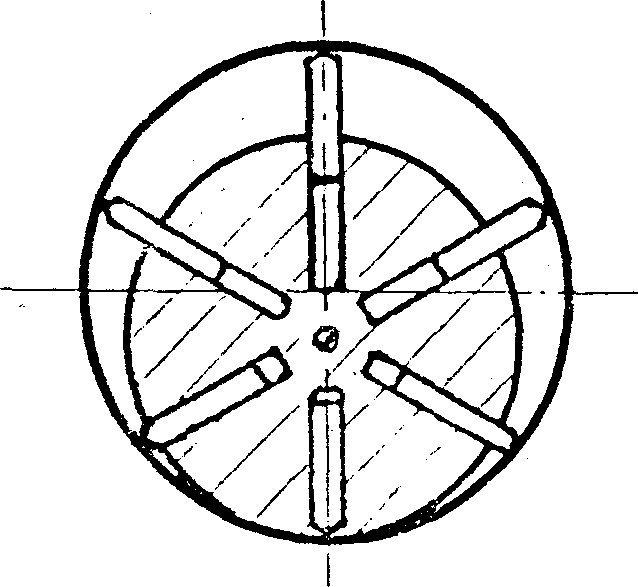

Small-hydropower axial flow turbine device

InactiveCN103912434AReduce flow lossImprove the diversion effectHydro energy generationReaction enginesPower stationWater turbine

The invention discloses a small-hydropower axial flow turbine device. The small-hydropower axial flow turbine device comprises an upper seat ring (1), a lower seat ring (3), sixteen movable guide vanes (2), a support cover (6), a bottom ring (7), a runner chamber (4), a hub (8), a runner cone (9), three blades (10) fixedly mounted on the hub and a straight-cone-shaped draft tube (5), wherein the upper seat ring (1) and the lower seat ring (3) are provided with the guide vanes. The center circle diameter of a water guide mechanism is large, the movable guide vanes and the upper and lower seat rings extend outwards by certain size from a guide vane inlet, the sixteen movable guide vanes which are large in opening are adopted, the runner is high in running speed, inlet and outlet water flow angles of the outer edges of the blades are large, the hub ratio of the runner chamber is low, excess flow is large, the shape contracts at an outlet of the runner and starts to spread again from the straight-cone-shaped draft tube, and numerical simulation shows that efficiency of a turbine can reach 85%. The small-hydropower axial flow turbine device is simple in structure, small in size, convenient to process, low in economic cost and high in efficiency, can be used for low-water-head and high-flow power stations for power generation and can also be used for small-hydropower synergistic expansion modification in the early stage.

Owner:HOHAI UNIV

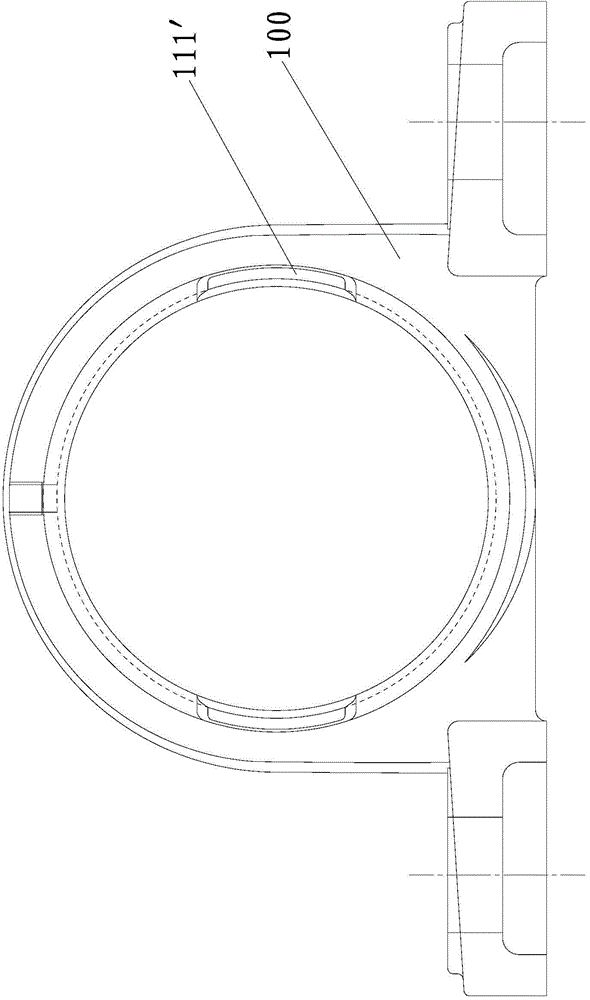

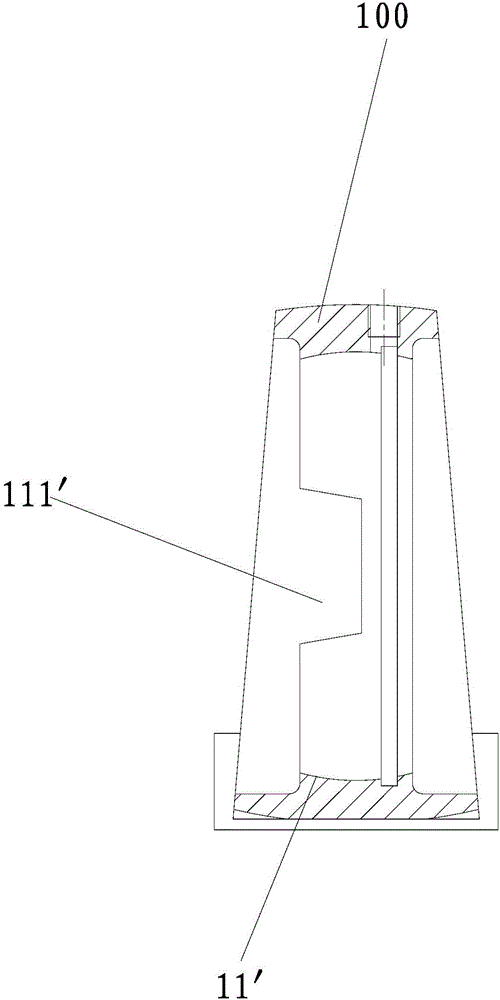

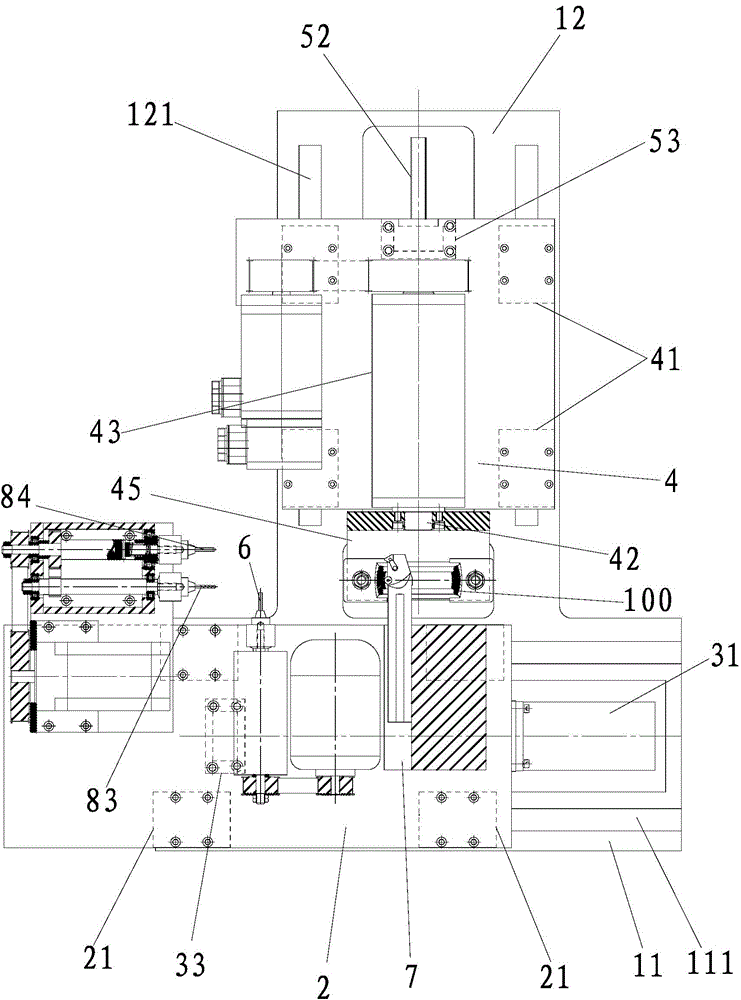

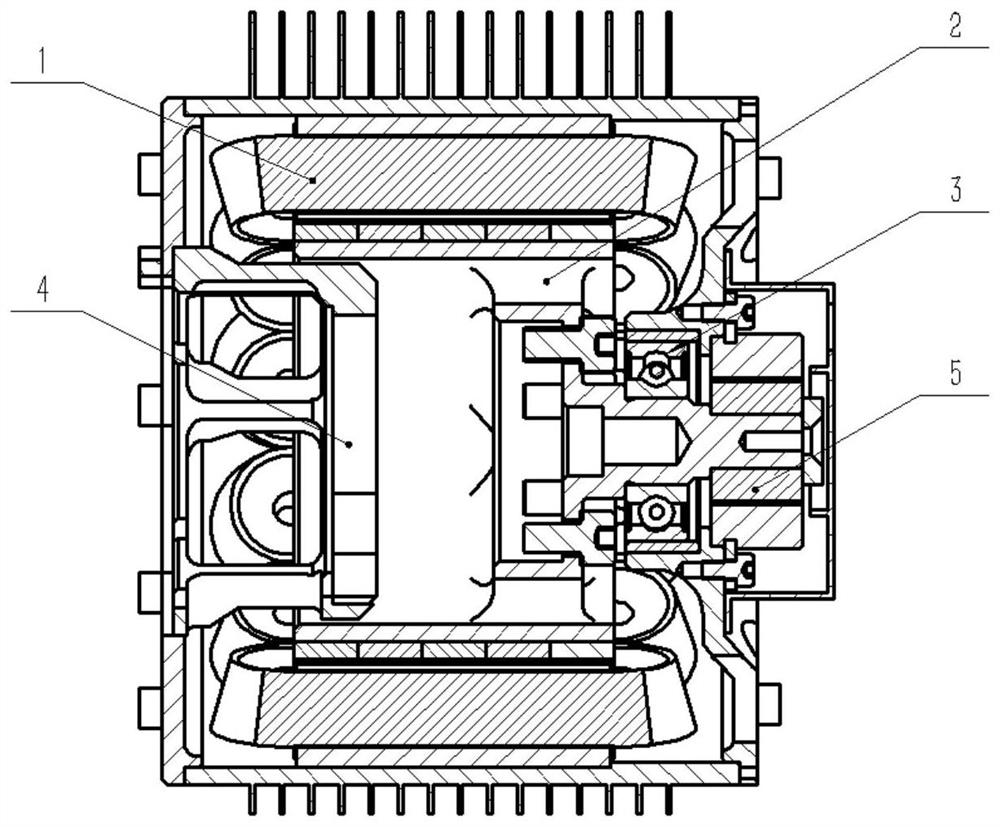

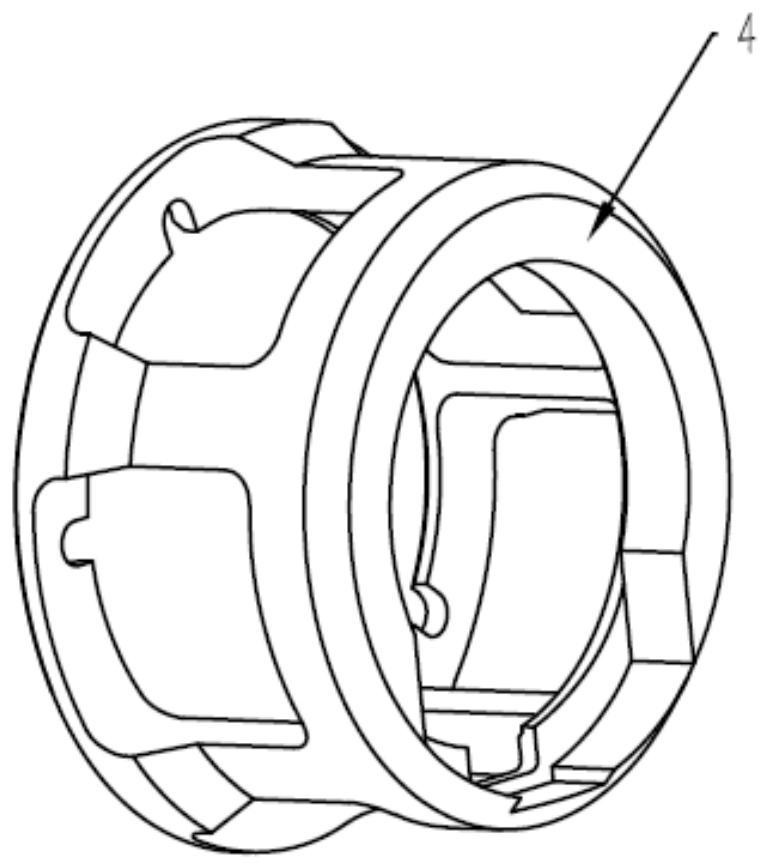

Technology for manufacturing mounted bearing pedestal and numerical control special machine tool thereof

ActiveCN104942547AIncrease operating speedReduce running noiseFeeding apparatusOther manufacturing equipments/toolsNumerical controlEngineering

The invention discloses a technology for manufacturing a mounted bearing pedestal. The method comprises the main following steps that 1, a bearing pedestal workblank with an inner hole and no bearing insertion slot is cast, and an installation reference plane of the bearing workblank is milled; 2, rough turning and half finish turning are performed on the inner spherical surface of the bearing pedestal workblank, and an oil groove is turned; 3, finish turning is performed on the inner spherical surface of the bearing pedestal; 4, two opposite bearing insertion slots are milled through an end mill; 5, an oil injection hole is drilled; 6, oil injection hole threads are tapped, and finally the bearing pedestal is obtained. The technology that finish machining is performed on the inner spherical face and then the bearing insertion slots are milled is the core of the technology for manufacturing the mounted bearing pedestal. The technology has the advantages that no bearing insertion slot exists when the inner spherical face of the bearing pedestal is turned, so that the serious manufacturing quality problem caused when bearing insertion slots exist in the steps of rough turning, half finish turning and finish turning of the inner spherical face of the bearing pedestal is avoided, and the precision and surface quality grade of the bearing pedestal are remarkably improved. In order to improve production efficiency, the invention further discloses a numerical control special machine tool for manufacturing the mounted bearing pedestal.

Owner:庄有土

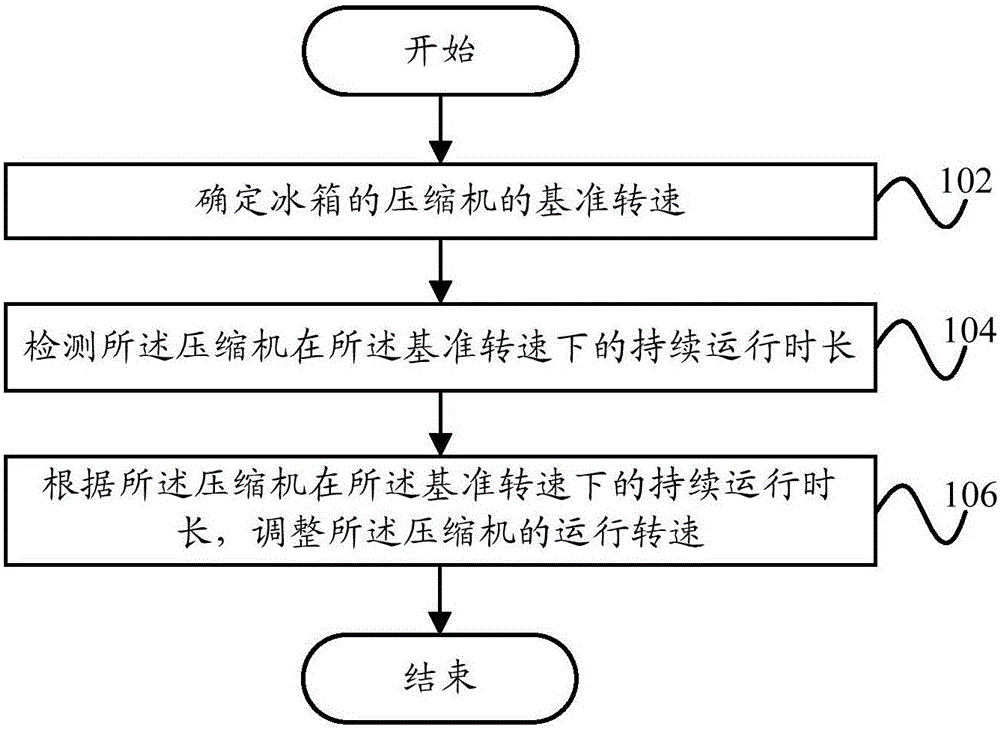

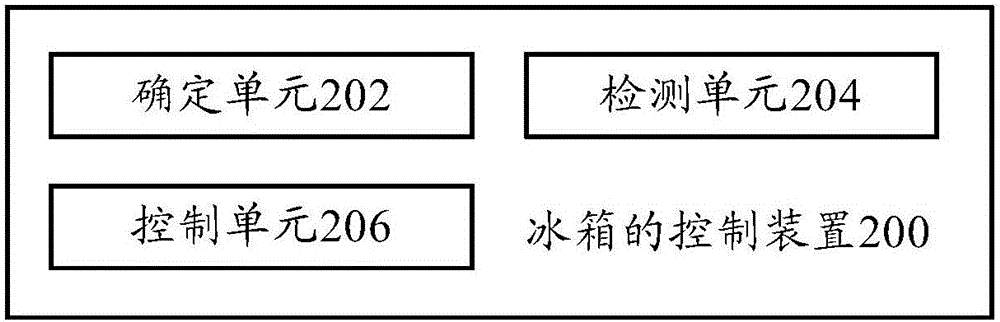

Control method and device for refrigerator and refrigerator

InactiveCN106052290ACooling effectImprove cooling efficiencyLighting and heating apparatusDomestic refrigeratorsControl theoryContinuous operation

The invention provides a control method and device for a refrigerator and the refrigerator. The control method for the refrigerator comprises the steps that the benchmark rotation speed of a compressor of the refrigerator is determined; the continuous operation time of the compressor at the benchmark rotation speed is detected; and the operation speed of the compressor is adjusted according to the continuous operation time of the compressor at the benchmark rotation speed. According to the technical scheme, the condition that the refrigerating effect of the refrigerator is influenced due to the fact that the operation time of the compressor at the same rotation speed is too long is avoided, reasonable cooling is achieved, the refrigerating efficiency of the refrigerator is improved, the operation time of the compressor in the whole refrigerating process is shortened, and the service life of the compressor is prolonged to a certain extent.

Owner:GUANGZHOU MIDEA HUALING REFRIGERATOR

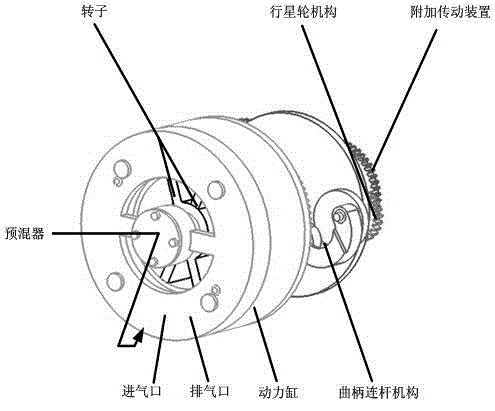

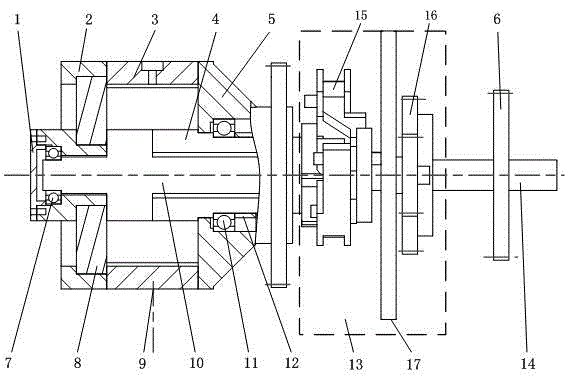

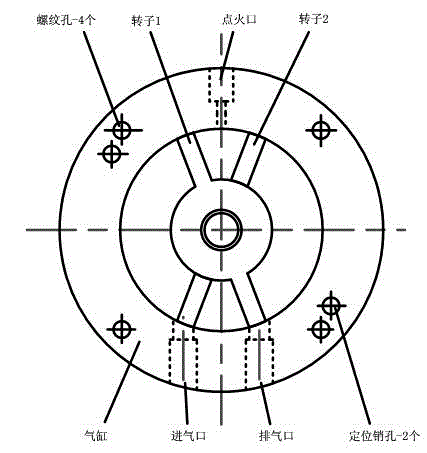

Rotary shell type nonstop rotating pendulum engine

ActiveCN104595023AIncrease the number ofNon-stop operationInternal combustion piston enginesPhase differenceReciprocating motion

The invention provides a rotary shell type nonstop rotating pendulum engine. The rotary shell type nonstop rotating pendulum engine is characterized by comprising an energy conversion assembly and a differential driving assembly of the engine, wherein the energy conversion assembly is composed of a rotary power cylinder block and two rotors; the differential driving assembly is composed of a pair of oppositely-arranged crank and rocker mechanisms and a planetary gear structure, and the phase difference of the differential driving assembly is pi; since the rotational speeds of rotating pendulums of the two rotors in a power cylinder are different, the volume of a chamber in the cylinder is reduced and expanded; consequently, the four-stroke heat engine cyclically does work, and the minimum value of the rotational speed of any rotor is larger than zero, that is, the rotors run without stop; a transmission mechanism connected with an output shaft is arranged; the power cylinder is only provided with an air inlet / outlet and an ignition port, and a valve and other complex components are not needed. The rotary shell type nonstop rotating pendulum engine has the advantages that the structure is simple, the size is compact, and the weight is substantially reduced; since no large-mass component does reciprocating motion, the impact load is low, high-speed operation is facilitated, and the service life is prolonged; the operating rotational speed is high, the rotors run without stop, output power and torque are higher, and the power-to-weight ratio is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

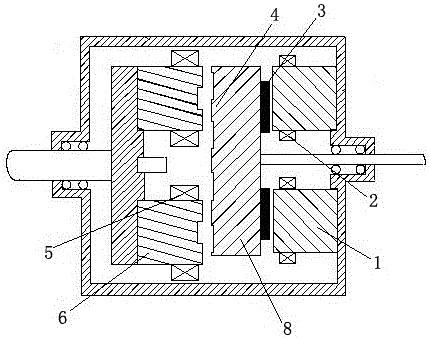

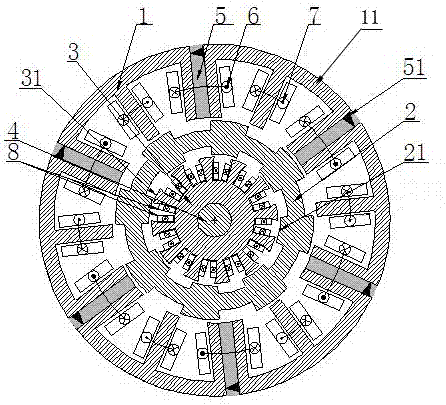

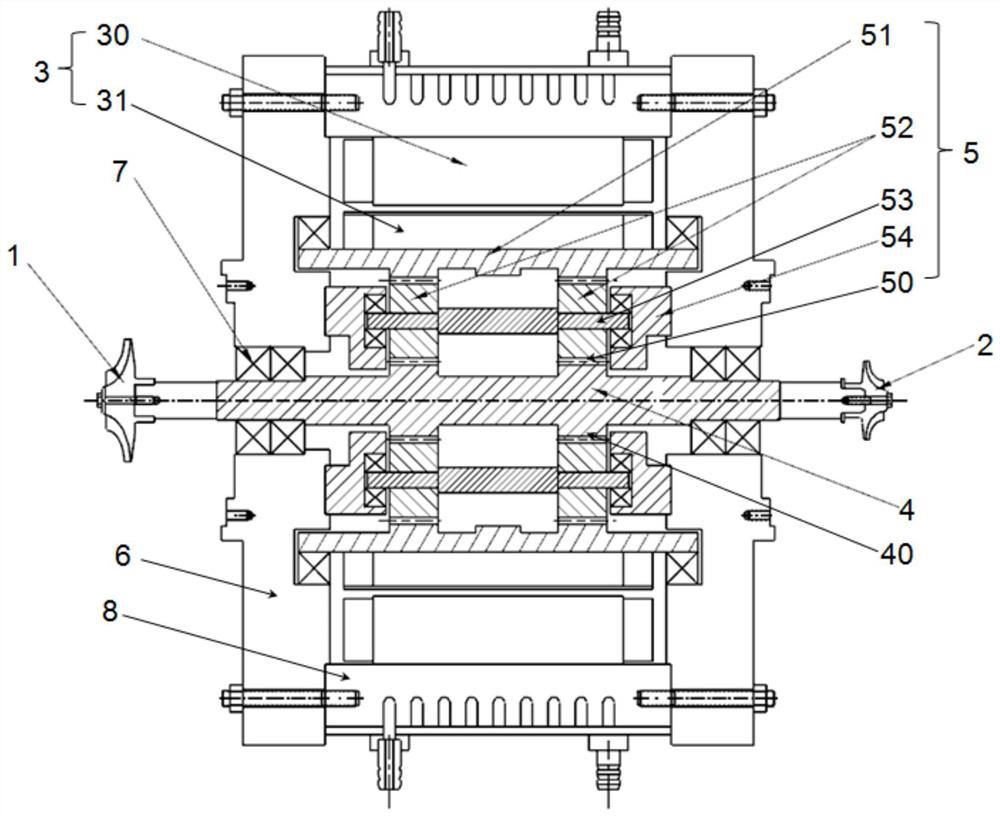

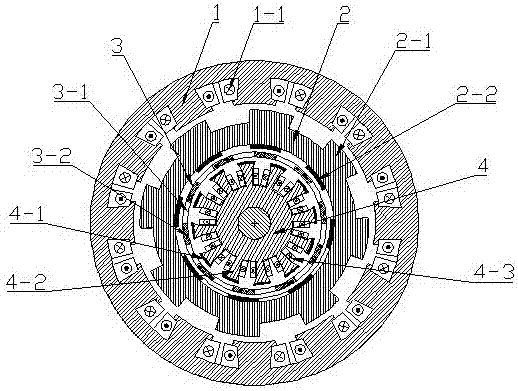

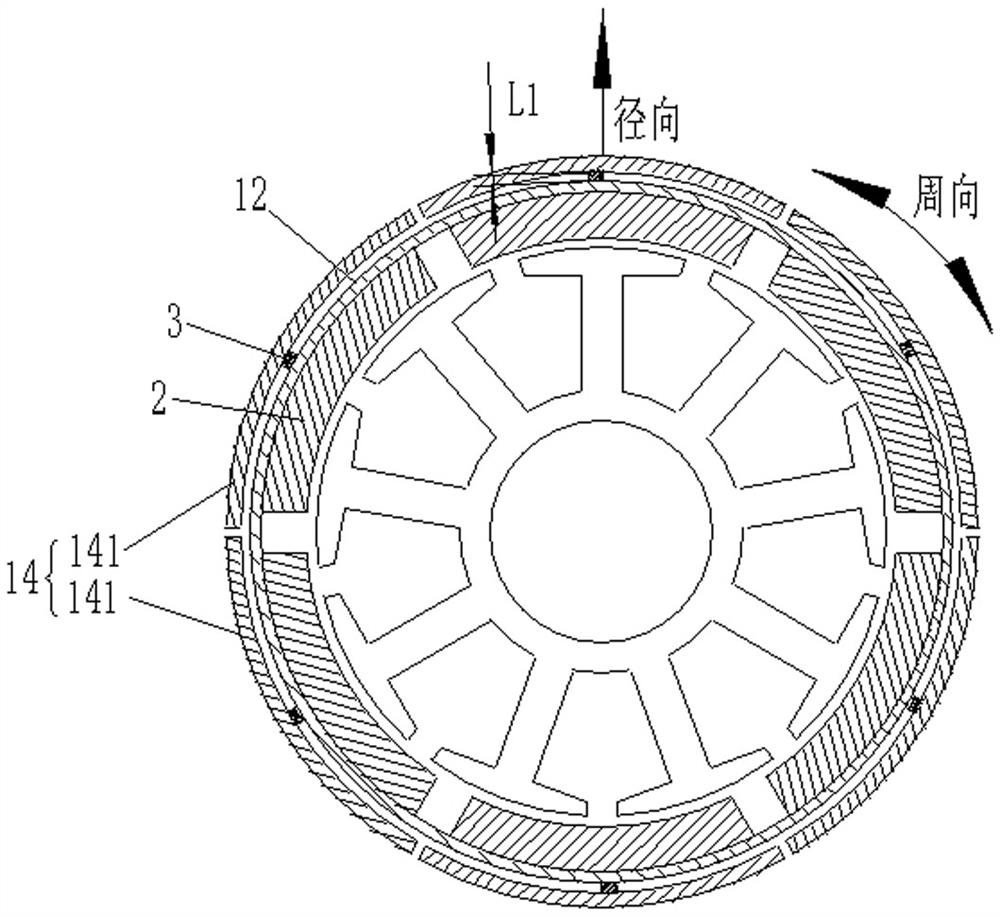

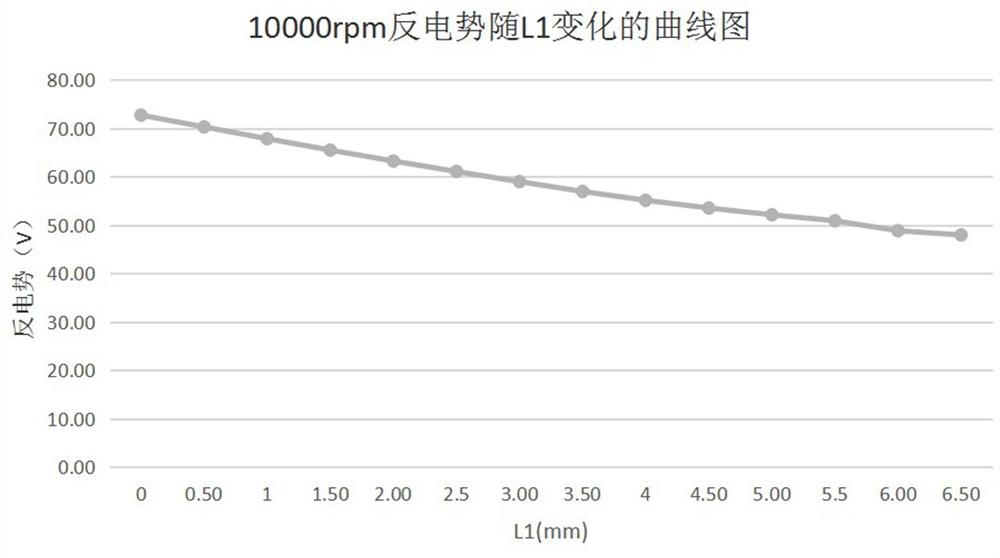

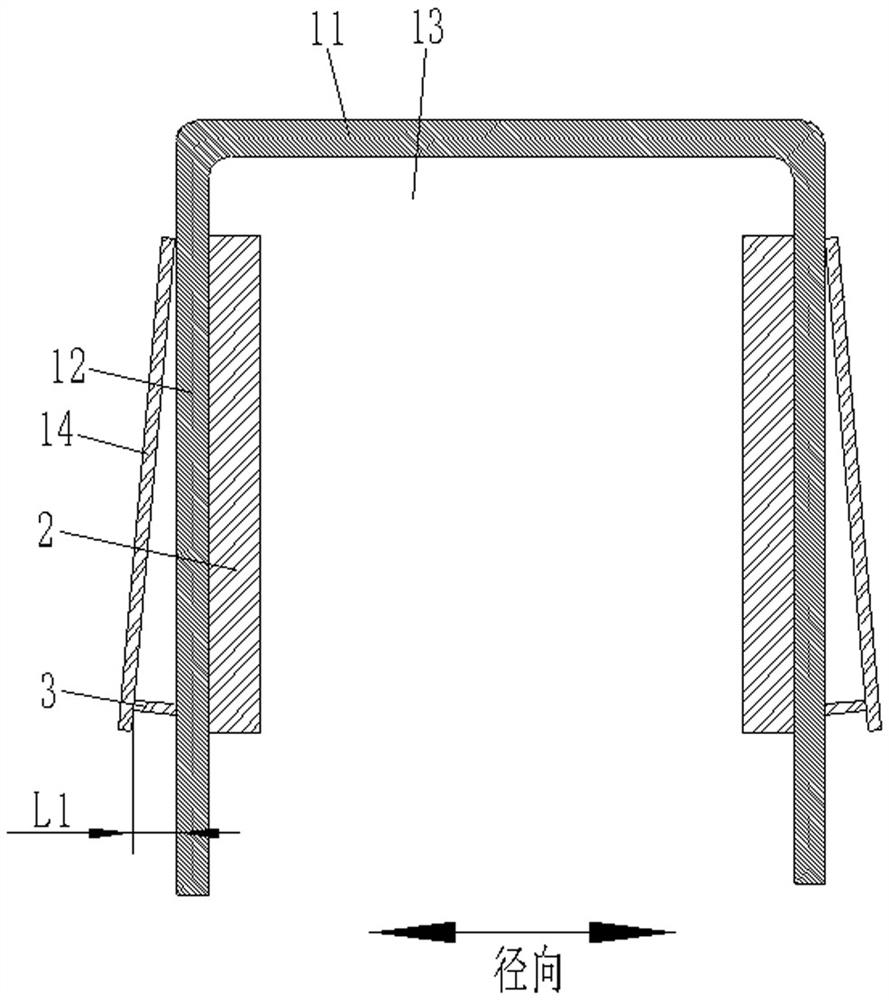

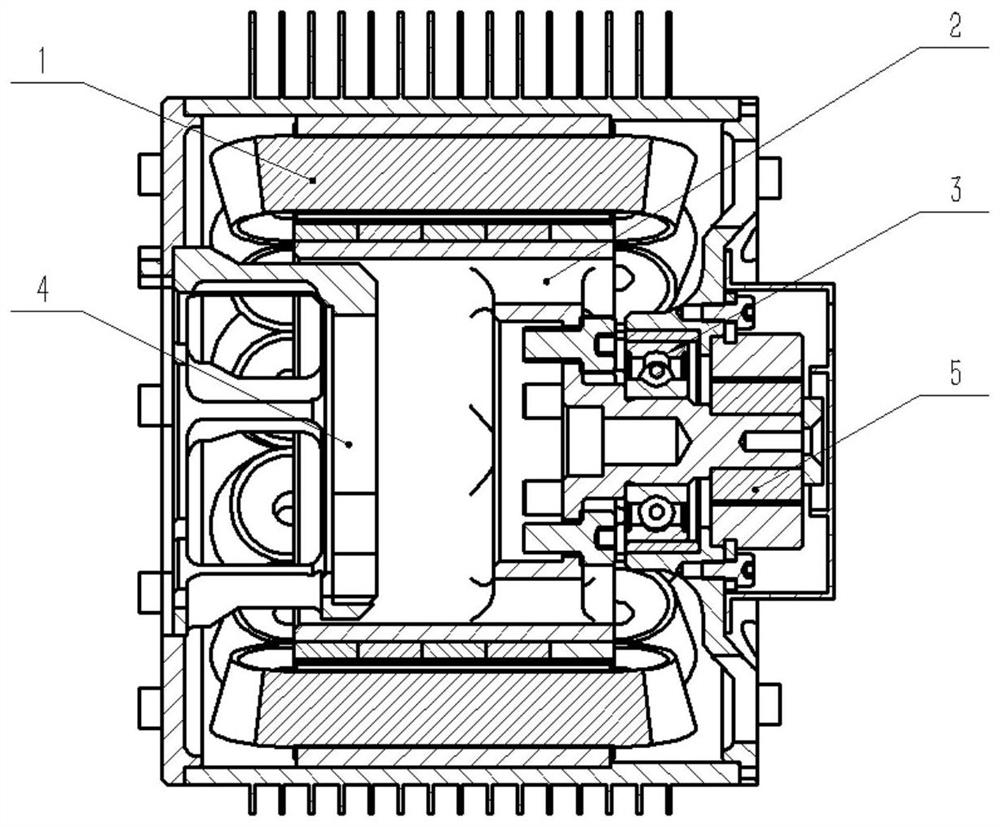

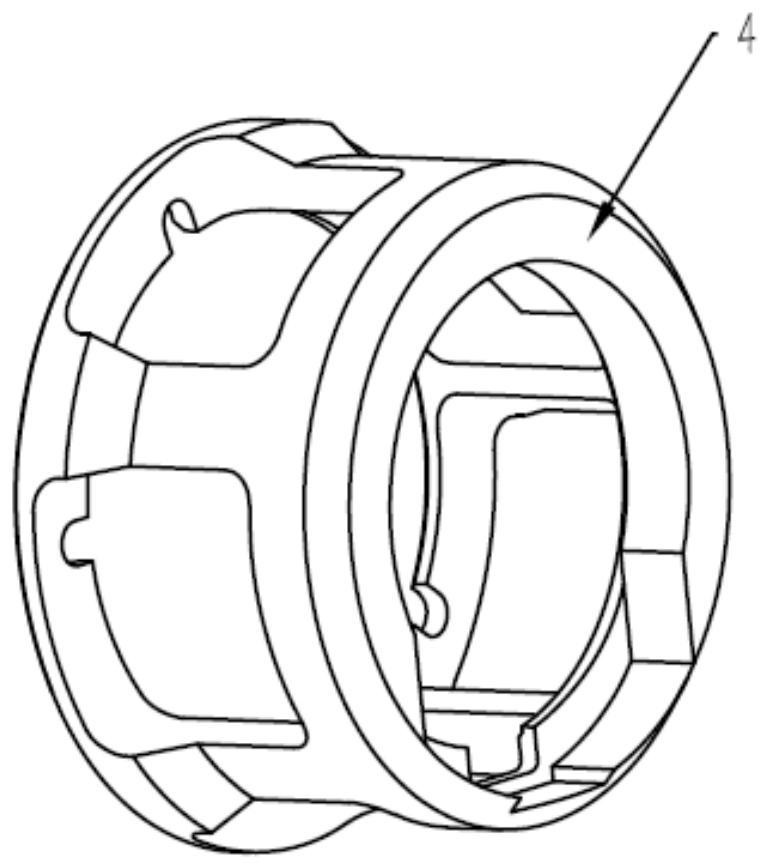

Double-rotor motor with permanent magnet-magnetic resistance axial magnetic flux composite structure

InactiveCN106849571AReduced reluctance differs fromThe air gap gap is reducedMagnetic circuit rotating partsMagnetic circuit stationary partsPower factorConductor Coil

The invention discloses a double-rotor motor with a permanent magnet-magnetic resistance axial magnetic flux composite structure. The double-rotor motor comprises stators (1), a first rotor (8) and a second rotor (6), wherein the stators (1) are arranged in an axial direction; the inner end surface of each stator (1) is a circular surface, grooves are distributed at the inner end surface of each stator in the radial direction, and three-phase distributed type armature windings (2) are arranged in the grooves; permanent magnets (3) are arranged at the end surface, facing the stators, of the first rotor (8), and are uniformly distributed at the circular surface; the end surface, facing the second rotor (6), of the first rotor (8) is provided with convex poles (4) which are distributed along the circumference; grooves are distributed at the inner end surface of the second rotor (6) in the radial direction, and three-phase centralized type windings (5) are arranged in the grooves. The double-rotor motor has the beneficial effects that the toothed groove torque of the system is weakened, and the vibration and electromagnetic noise are decreased; the power density and power factor of the system are improved, and the transfer efficiency is improved; the electromagnetic torque of the system is improved, and the driving force of a hybrid automobile is improved.

Owner:CHONGQING UNIV

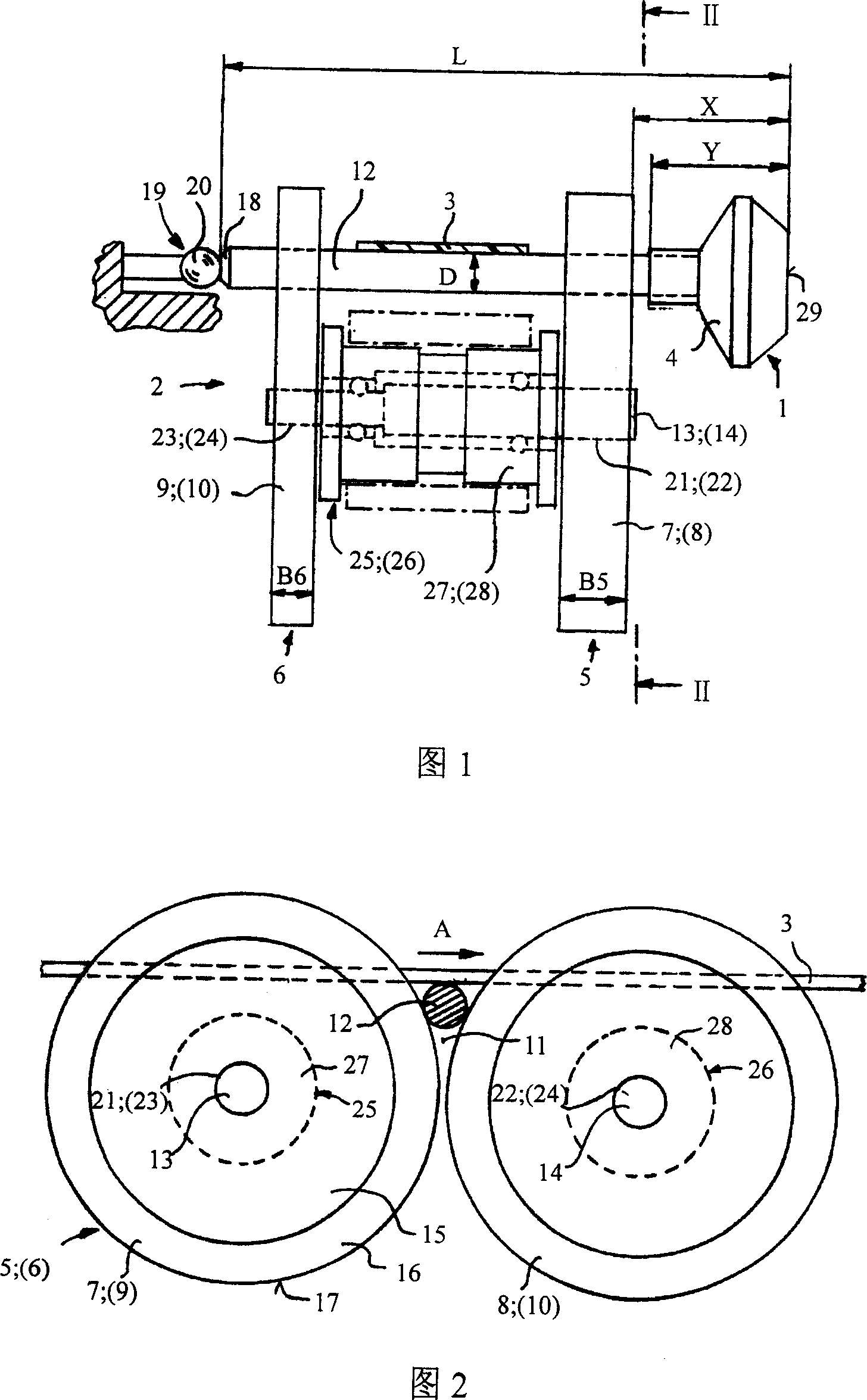

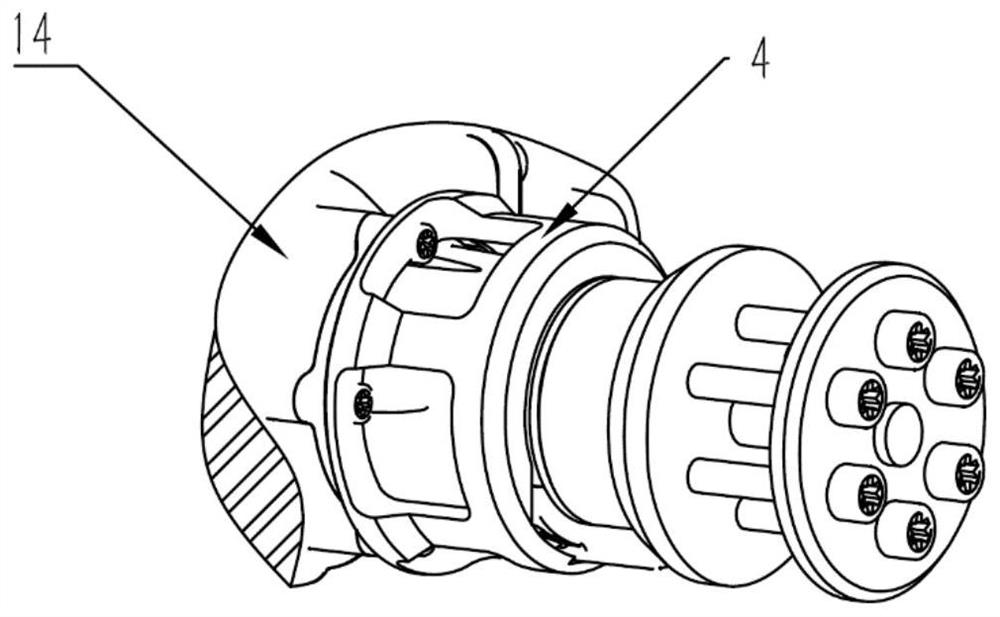

Rotary cup spinning device provided with drivable rotary cup

InactiveCN100999842AShorten the lengthIncrease the critical speedContinuous wound-up machinesOpen-end spinning machinesCircular discTransmission belt

A rotor spinning device includes a drivable rotor-spun having a rotor pan and a rotor shaft. The rotor shaft of the rotor-spun is supported on at least a radial bearing in high rotary speed. An overhanging part is provided on the rotor-spun, which is less than 29 mm measured from an anterior border of the rotor pan to a head of the radial bearing. The rotor-spun can be driven by a tangential transmission belt near the rotor shaft. Product of the overhanging part (mm) and diameter (mm) of the rotor shaft within a range of the tangential transmission belt is less than 250. In addition, it is predefined that the rotor shaft is radially supported on a pair of angular interstices of a pair of supporting discs while the interstices are separated for a certain distance in an axis direction, wherein, width of the supporting disc towards to the pair of supporting discs of the rotor pan is larger than that of the supporting disc opposite to the pair of supporting discs of the rotor pan.

Owner:RIETER INGOLSTADT GMBH

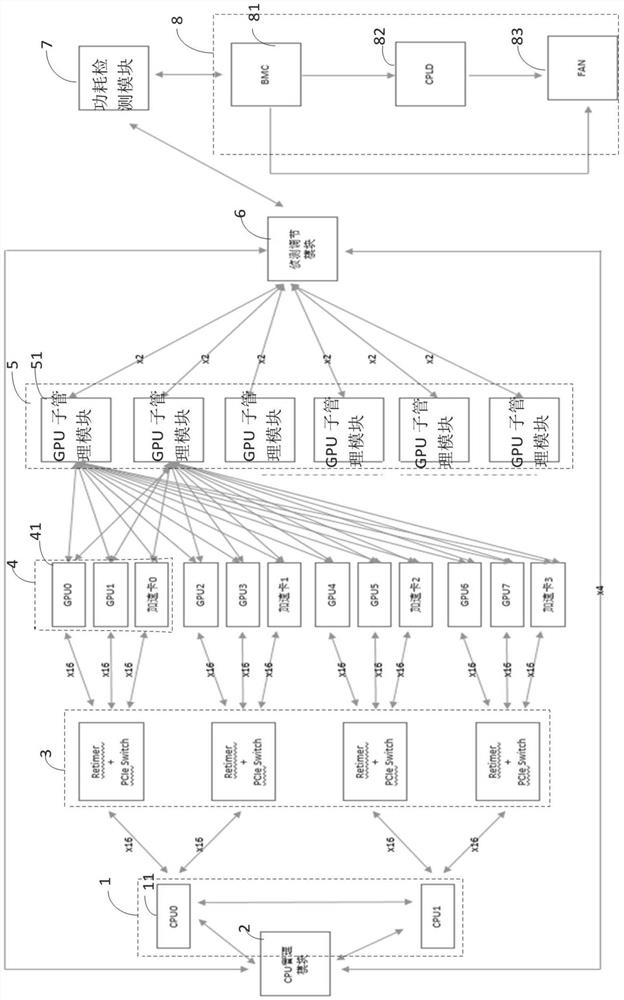

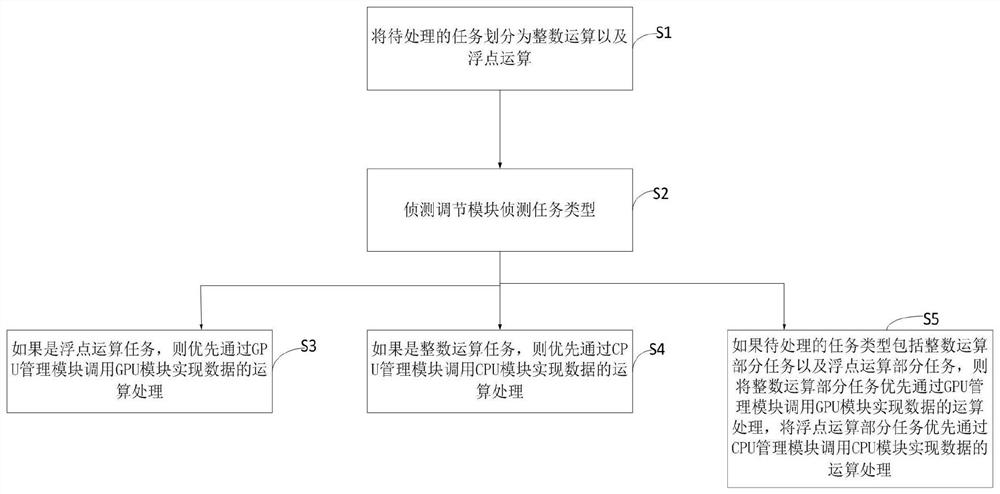

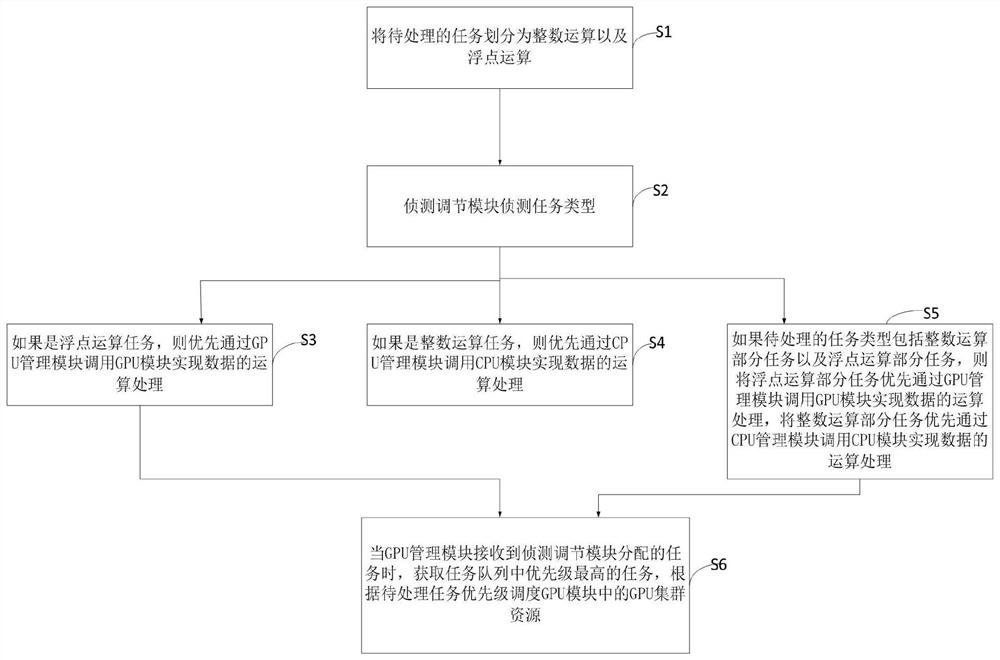

GPU management device and method based on detection adjustment module and GPU server

ActiveCN112000468ASolve the problem of reasonable configurationIncrease profitResource allocationDigital data processing detailsComputer hardwareData class

The invention provides a GPU management device based on a detection adjustment module. The system comprises a CPU module, a CPU management module, a conversion module, a GPU module, a GPU management module and a detection adjustment module. An adjustment control end of the detection adjustment module is in communication connection with control ends of the GPU management module and the CPU management module, and the detection adjustment module is used for detecting a to-be-processed data type and selecting a corresponding GPU module and / or CPU module for processing according to the to-be-processed data type; the GPU management module is in communication connection with the GPU module and is used for realizing management of the GPU module and balanced distribution of to-be-processed tasks; the invention further provides a GPU management method based on the detection adjustment module and a GPU server, and the utilization rate and the task processing efficiency of the CPU and the GPU areeffectively improved.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

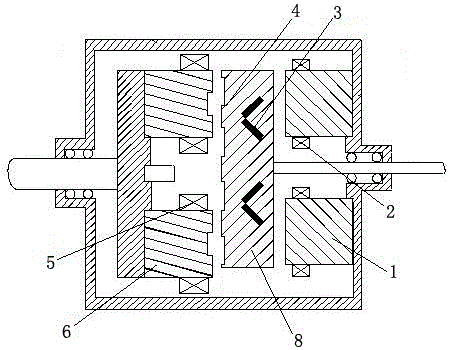

Mixed excitation type composite double-rotor motor

InactiveCN107026544ALow torque densityEnhanced air gap magnetic field adjustment capabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineThree-phase

The invention discloses a hybrid excitation type compound double-rotor motor, which comprises a stator, an outer rotor and an inner rotor assembled from the outside to the inside. The stator is a salient pole structure assembled from six E-shaped arc iron cores. A permanent magnet magnetized in the circumferential direction is clamped between two adjacent E-shaped arc iron cores. The magnetization directions of the two adjacent permanent magnets are opposite. The DC excitation winding is wound on the middle tooth of the E-shaped arc-shaped iron core. Three-phase centralized AC excitation windings are wound on the salient poles formed by two E-shaped arc iron cores and permanent magnets. The DC excitation windings and the three-phase centralized AC excitation windings share a stator slot and are separated from each other. The technical effect of the invention is that the structure is simple, the heat dissipation is easy, the motor performance can be improved, the output force can be increased, the starting torque is large, the speed regulation range is wide, and the motor is suitable for high-speed operation of the motor.

Owner:CHONGQING UNIV

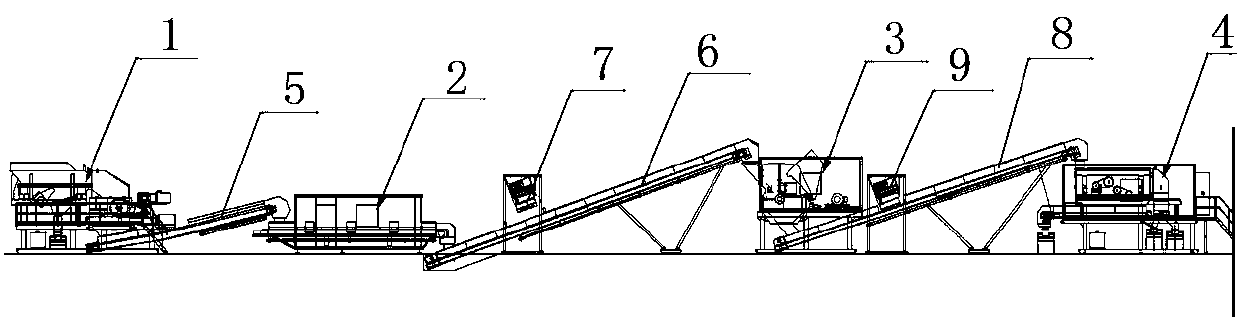

Small-scale modular processing system of building rubbish and disposal method

PendingCN109877134ALow manufacturing costGuaranteed throughputConstruction waste recoverySolid waste disposalNormal positionEngineering

The invention provides a small-scale modular processing system of building rubbish and a disposal method. The small-scale modular processing system of the building rubbish comprises a first crushing module, a manual sorting module, an impact crusher module and a screening module, wherein the first crushing module, the manual sorting module, the impact crusher module and the screening module sequentially process the building rubbish; the first crushing module comprises a vibrating feeder, a first-grade crusher and a first-grade chute; the manual sorting module comprises a material receiving end, a hand sorting belt machine, a manual hand sorting container room, sundries throwing openings on the two sides of the container room, a hand sorting sundries collecting device placed outside the container room and a second-grade chute; the impact crusher module comprises an impact crusher and a third-grade chute; the screening module comprises a vibrating screen classifier and a discharging chute; and the first crushing module, the manual sorting module, the impact crusher module and the screening module are connected with a dust collector. According to the small-scale modular processing system of the building rubbish and the disposal method, the technical problems that in an existing crushing sieve substation, environment-friendly measures are not perfect, impurity sorting capacity is poor, the recycling use ratio is low and site selection and power utilization requirements on a normal position disposal mode are higher are solved.

Owner:BCEG RESOURCES RECYCLING CO LTD

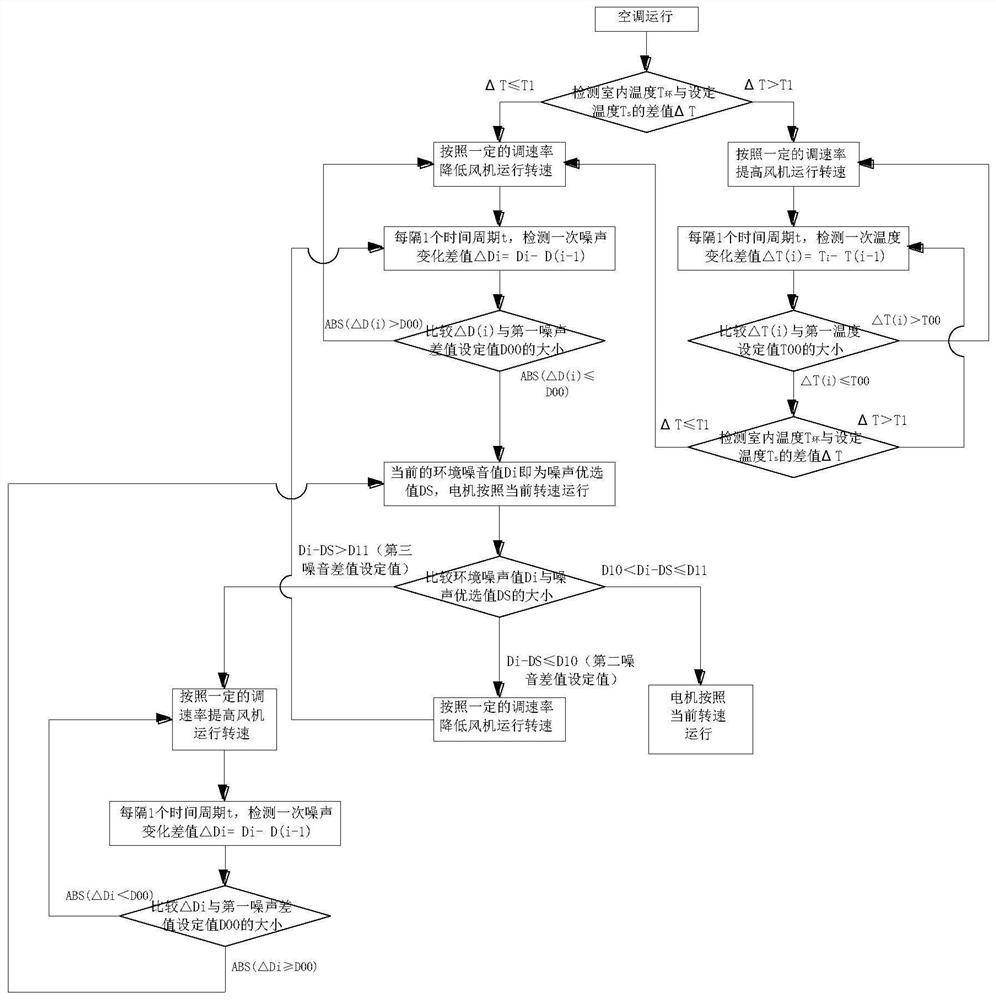

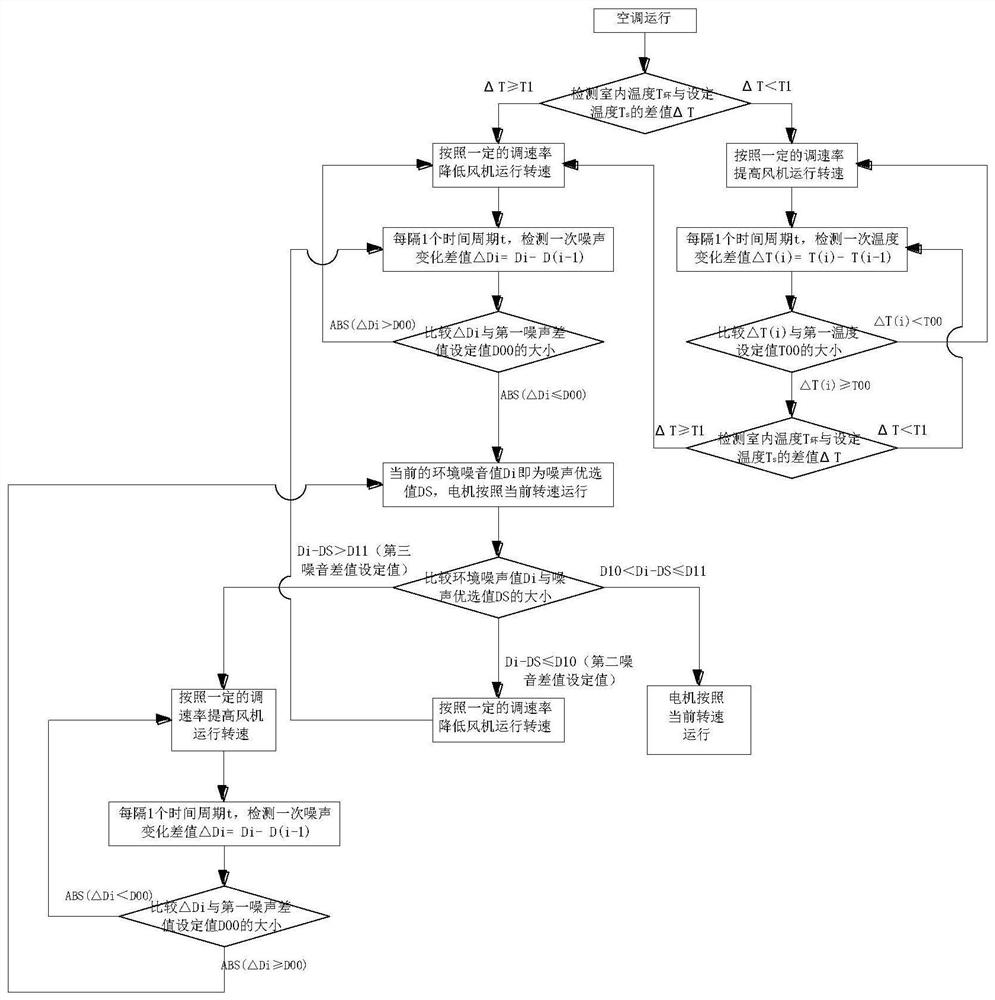

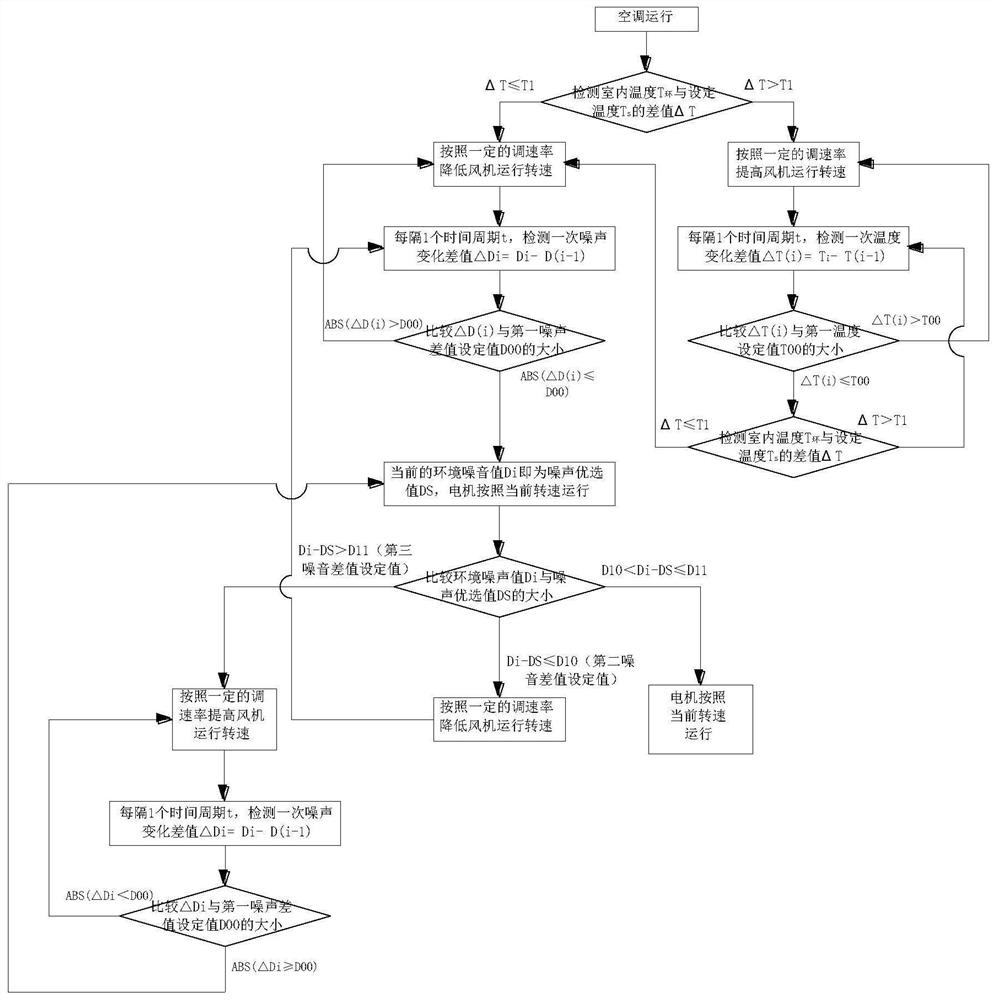

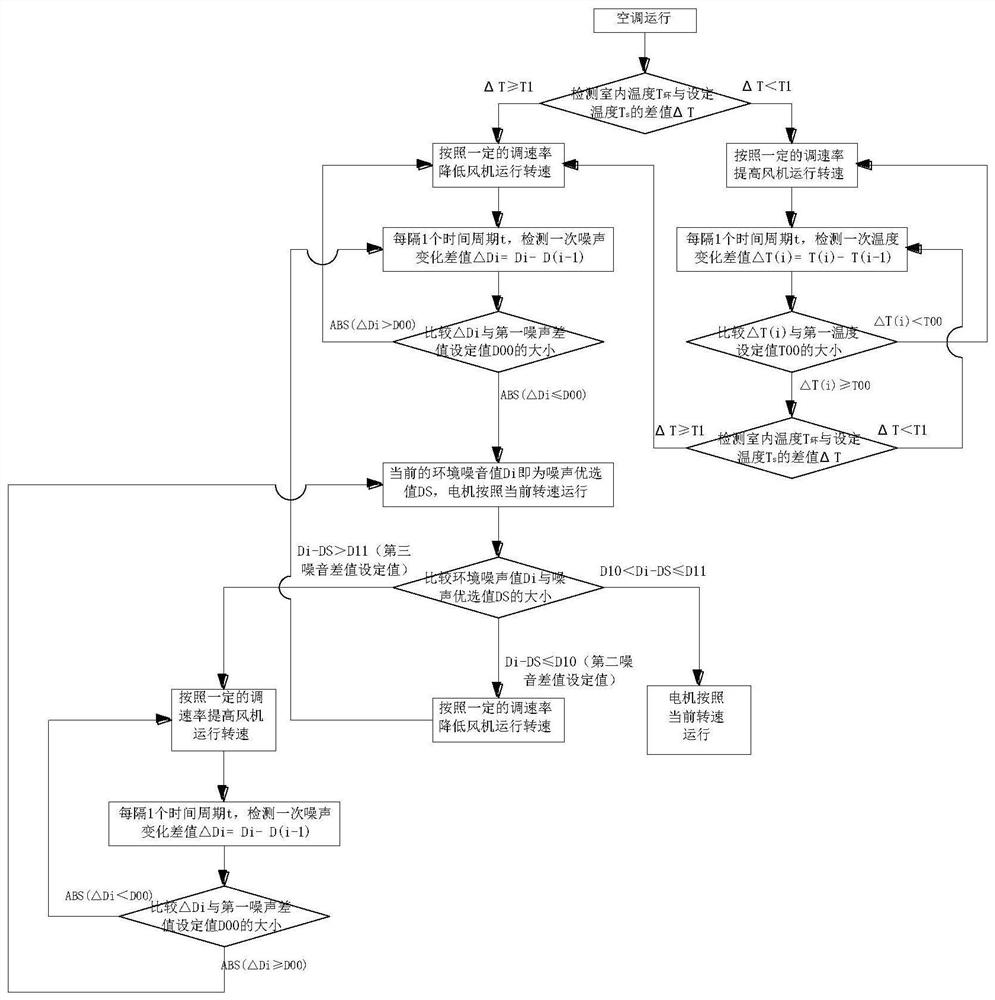

Revolving speed controlling method for draught fan of air-conditioner

ActiveCN111623487AIncrease the wind speed adjustment levelMeet wind speed requirementsMechanical apparatusSpace heating and ventilation safety systemsAir velocityControl engineering

The invention discloses a revolving speed controlling method for a draught fan of an air-conditioner. The method comprises the following steps: in a cooling mode, when [Delta]T is lower than or equalto T<1>, the operation revolving speed of the draught fan is lowered according to a first preset speed regulation rate; environment real-time noises are detected every other time cycle t, and when [Delta]D is less than or equal to D<00>, an environment real-time noise D in the time cycle is defined as an optimal noise value D<s> and the draught fan operates according to current revolving speed; and the difference between the environment real-time noise D and D<s> is compared in real time, so the revolving speed is timely adjusted. According to the revolving speed controlling method for the draught fan of the air-conditioner, the revolving speed of the draught fan of the air-conditioner is controlled based on temperature information and noise information in a certain cycle, and wind speed adjusting levels of the air-conditioner can be added; on the one hand, users' requirements for wind speed of the air-conditioner can be met, and on the other hand, the air-conditioner can operate in a low-noise status; and therefore, an operation status of the air-conditioner can be divided into a plurality of statuses, so the air-conditioner can satisfy multiple types of performance simultaneously.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

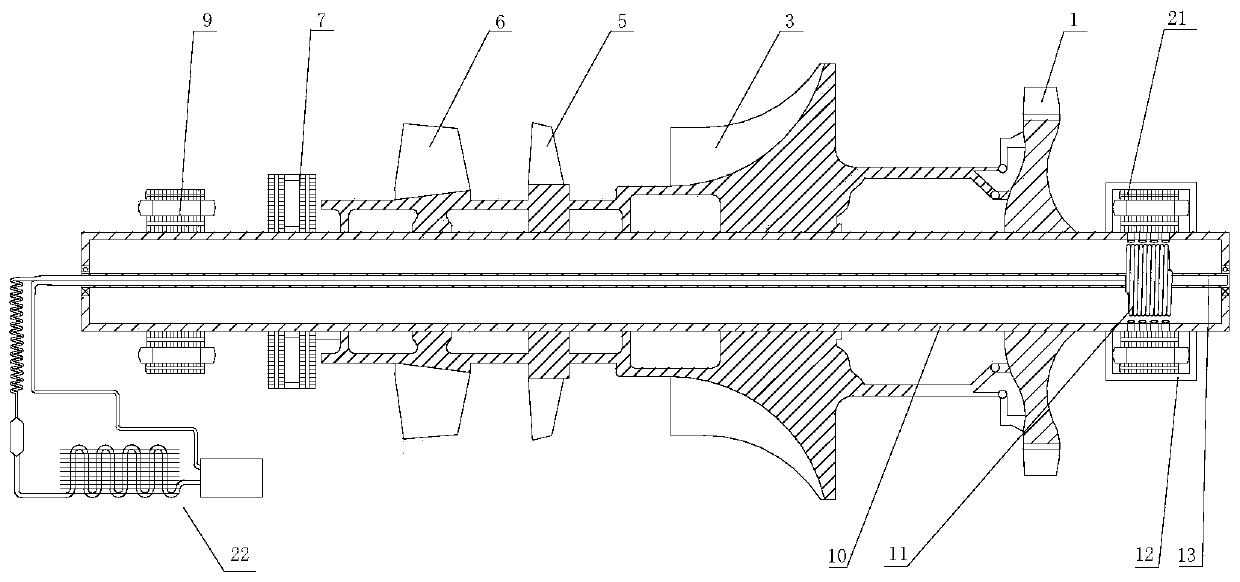

Supercritical carbon dioxide turbine-starting generator-compressor unit

PendingCN112228171APlay a role in speeding upReduce volumeEngine startersSteam engine plantsImpellerElectric machine

The invention discloses a supercritical carbon dioxide turbine-starting generator-compressor unit. A starting generator is provided with an annular motor stator and a motor rotor, and the motor rotoris arranged in an inner cavity of the motor stator rotatably relatively. The unit comprises a high-speed shaft, a plurality of groups of gears and a planetary gear, wherein a turbine impeller and a compressor impeller are mounted at two ends, extending in the axial direction, of the high-speed shaft separately, and the motor stator and the motor rotor are coaxially arranged along the high-speed shaft; the gears are fixedly arranged in the radial direction of the high-speed shaft; and the planetary gear is arranged in an inner cavity of the motor rotor and is provided with an inner gear ring and an outer gear ring, the inner gear ring is engaged with the gear on the high-speed shaft, and the outer gear ring of the planetary gear is connected to the motor rotor as a whole. Synchronous rotation of the motor rotor and the high-speed shaft is achieved through synchronous rotation of the inner gear ring and the outer gear ring. The TAC unit is small in size and compact in structure, the running speed of a turbine-compressor impeller is guaranteed, and meanwhile application of a low-speed high-power motor in the TAC unit is achieved.

Owner:SHANGHAI MICROPOWERS

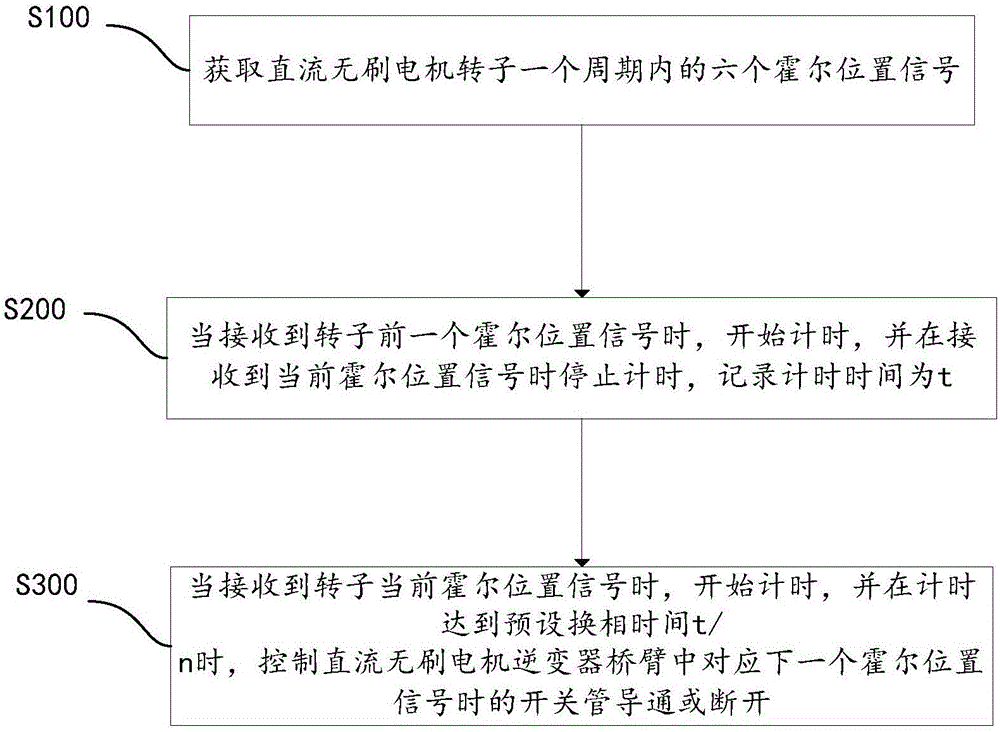

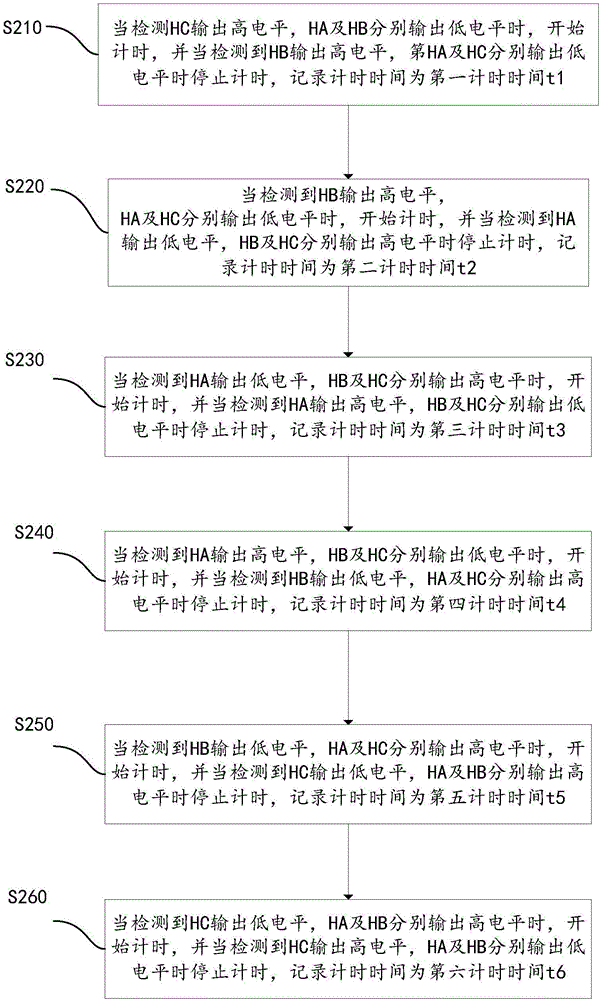

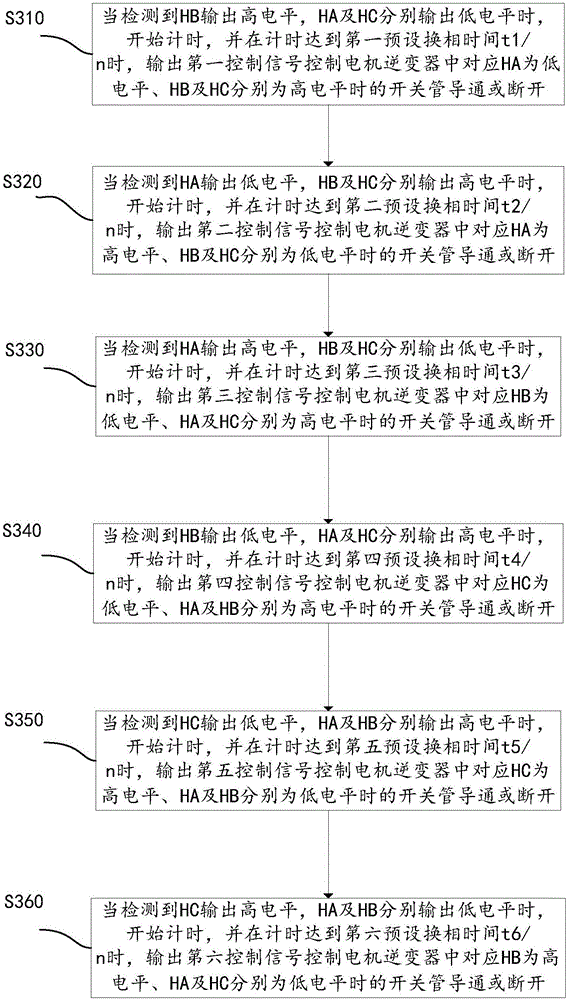

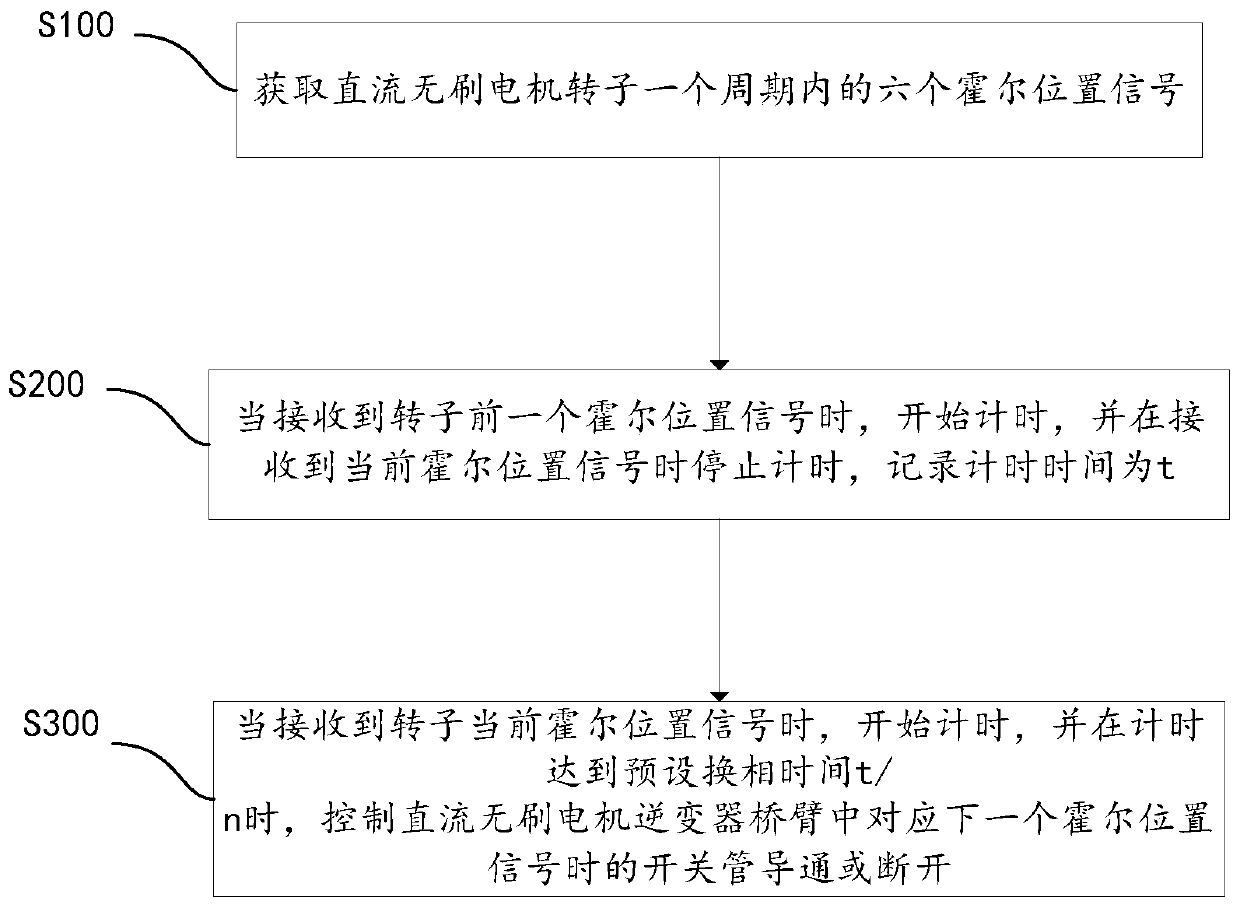

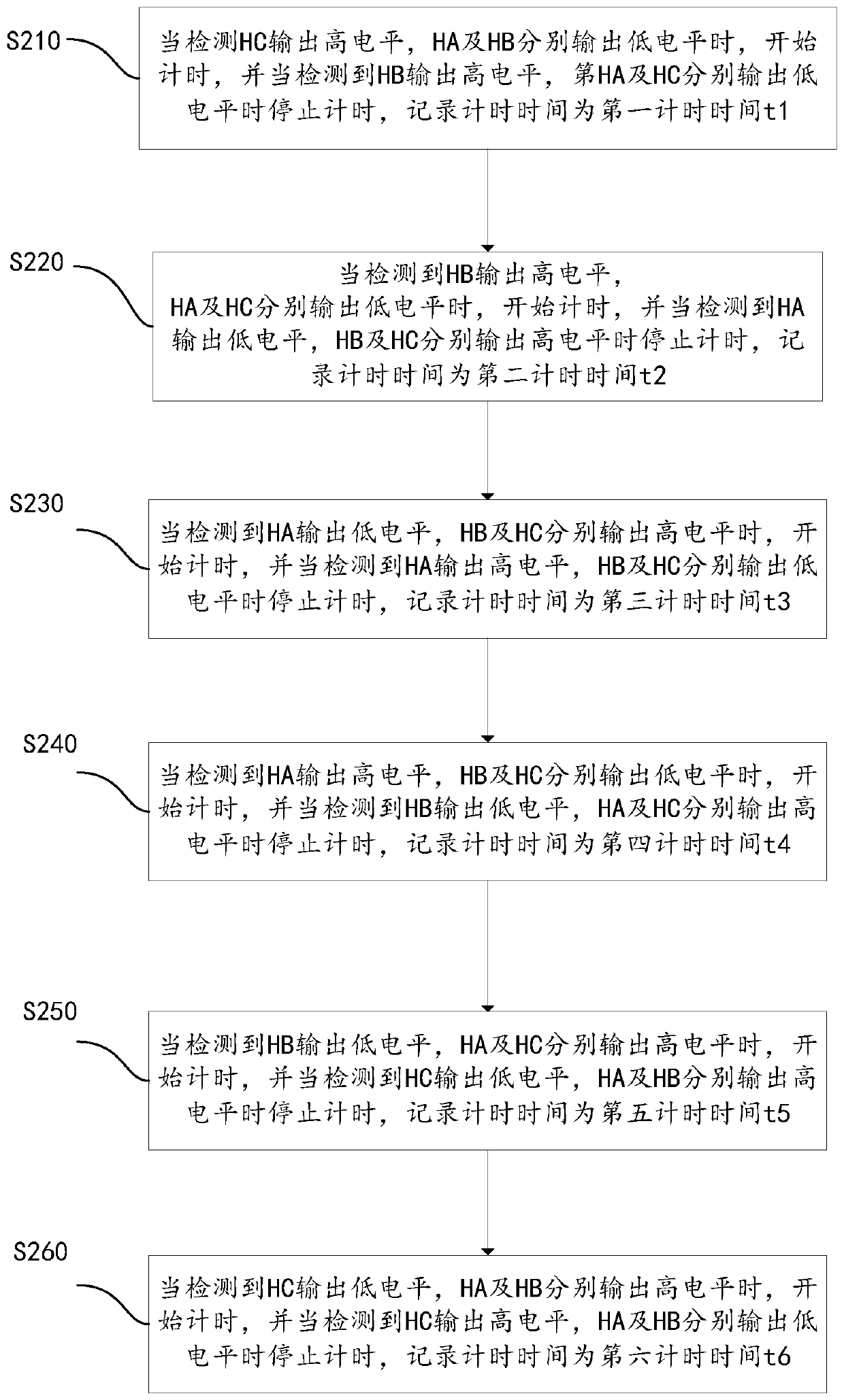

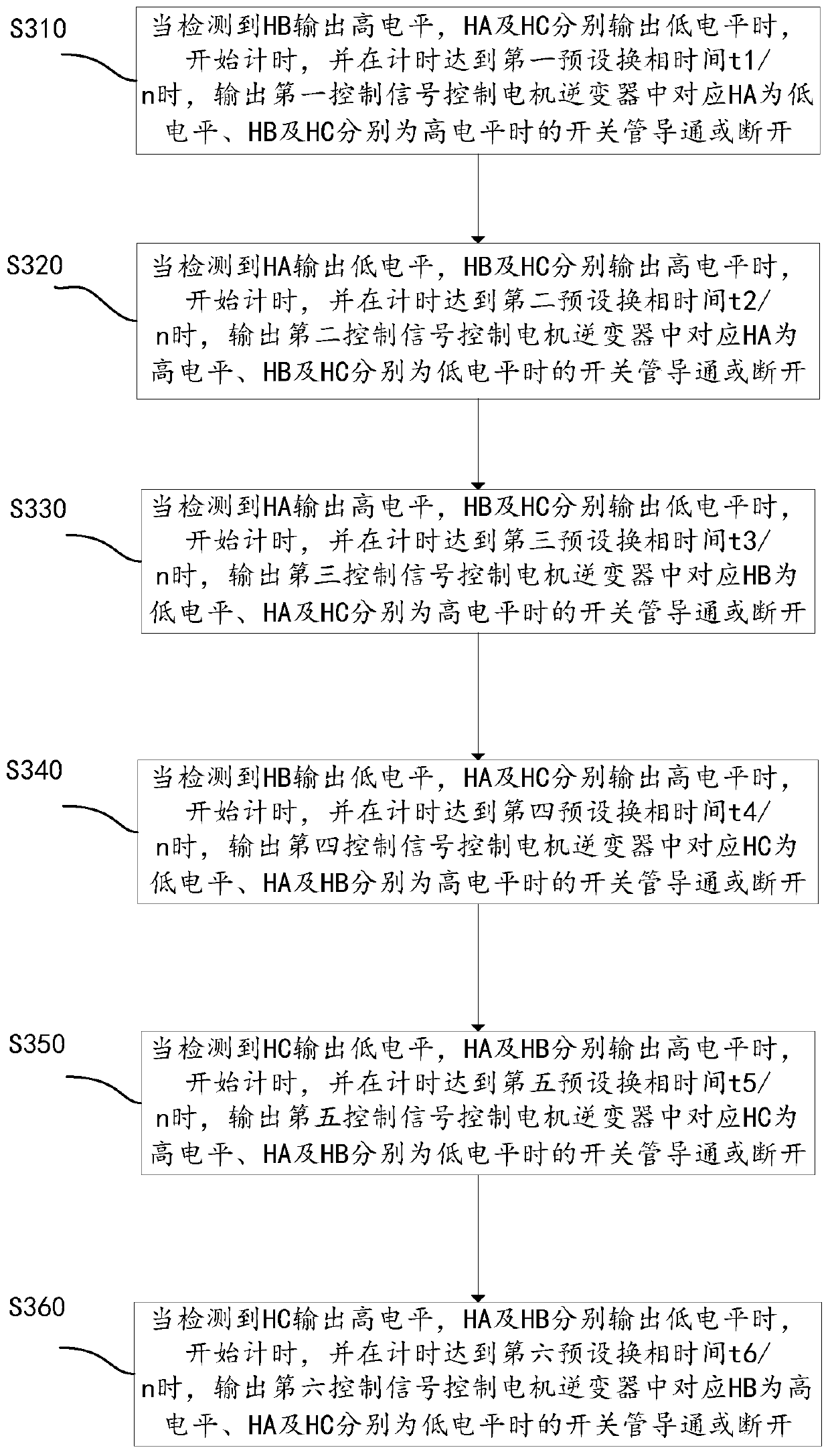

Phase change control method of direct current brushless motor and phase change controller and direct current brushless motor

ActiveCN106452214ASmall excitation currentIncrease operating speedCommutation monitoringSingle motor speed/torque controlBrushless motorsConstant power

The invention is applicable to the technical field of direct current motor control, and relates to a phase change control method of a direct current brushless motor. The method includes the step of obtaining six Holzer position signals of a rotor of the direct current brushless motor within one cycle; when the last Holzer position signal of the rotor is obtained, starting to conducting timekeeping, stopping timekeeping when the current Holzer position signal is received, and recording the timekeeping time as t; when receiving the current Holzer position signal of the rotor, starting to conducting timekeeping, when the timekeeping time reaches the preset phase change time t / n, controlling a switching tube, corresponding to the next Holzer position signal, in an inverter bridge arm of the direct current brushless motor to open or close, wherein when the current Holzer position signal is the first Holzer position signal within the cycle, the last Holzer position signal is the sixth Holzer position signal of the rotor within the last cycle, and 1<n<=2. Under the condition of ensuring the voltage balance of the motor, the method effectively improves the rotation speed of the motor in running under the condition of constant power.

Owner:SHENZHEN TOPBAND CO LTD

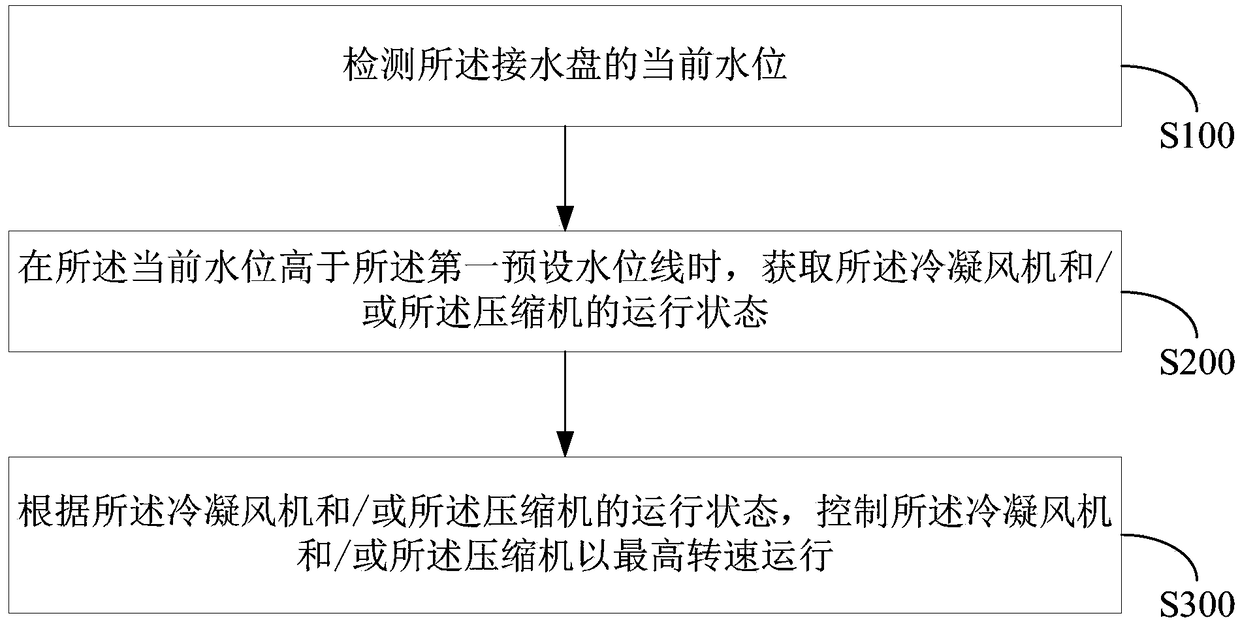

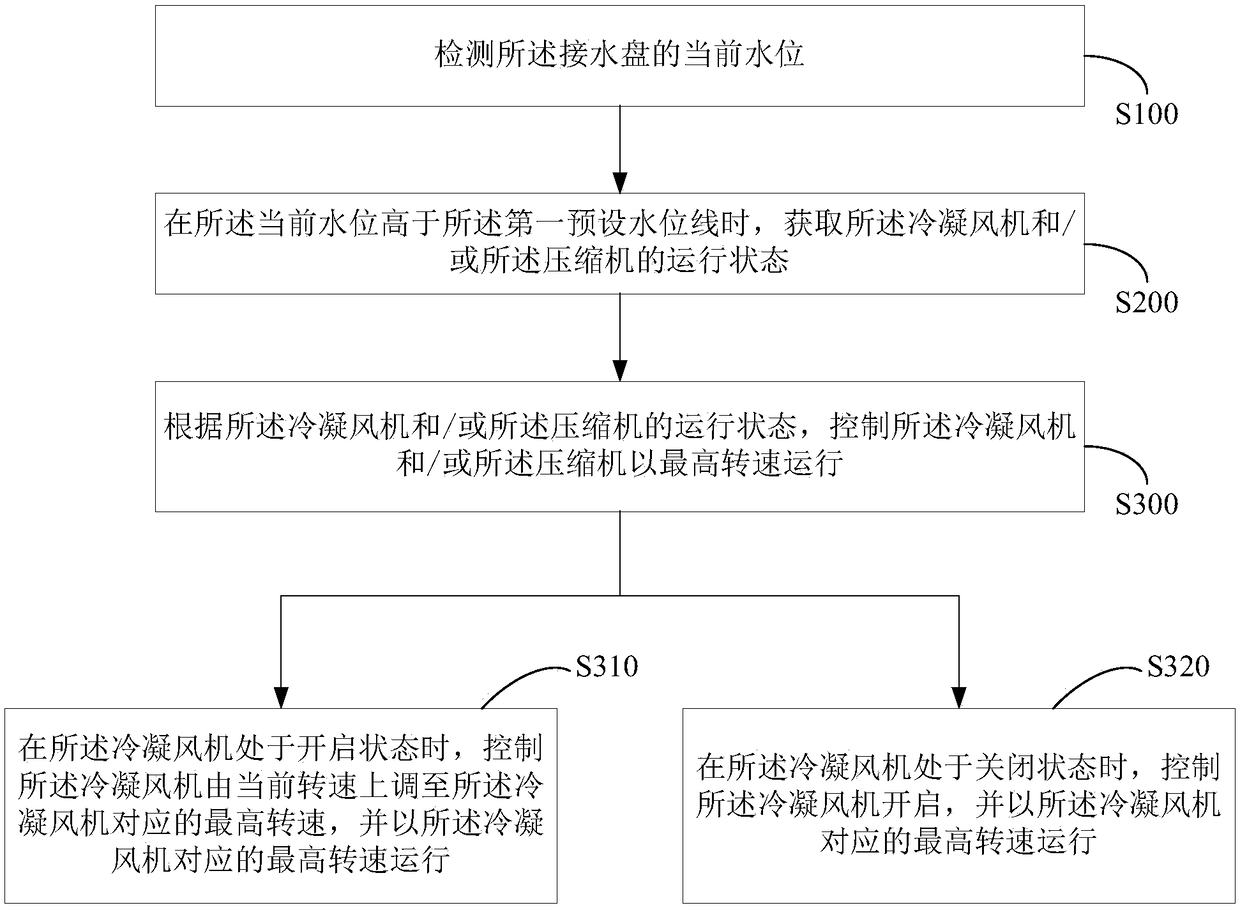

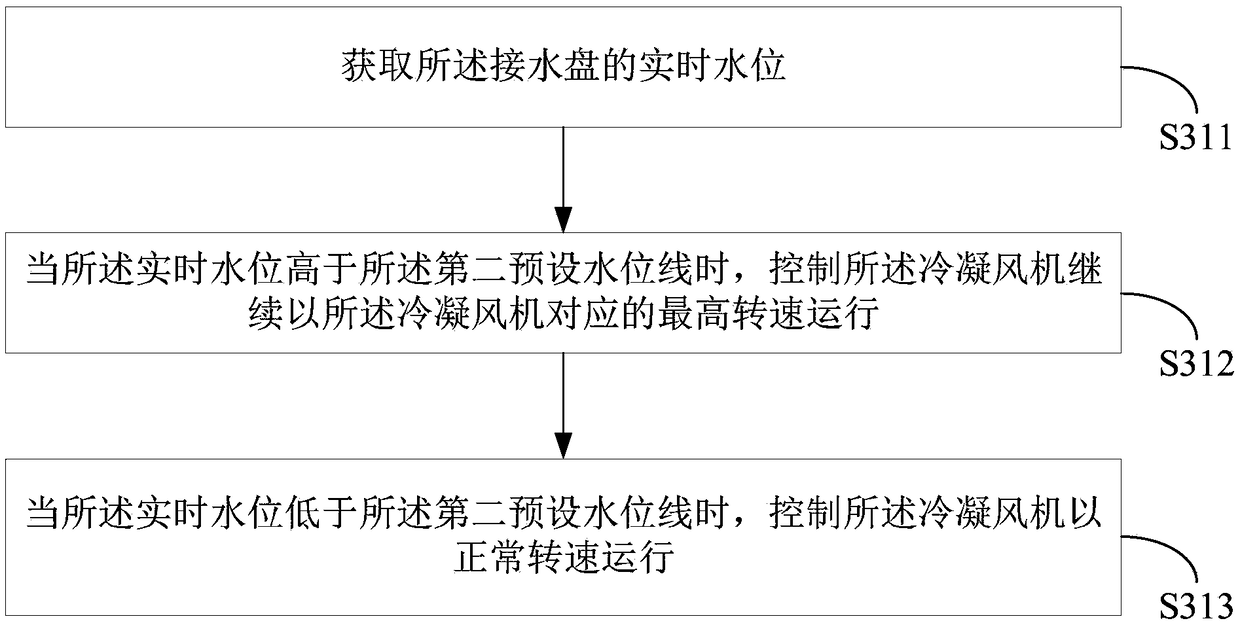

Refrigerator, refrigerator control method and computer readable storage medium

InactiveCN109282561AHigh calorific valueIncrease temperatureLighting and heating apparatusDefrostingEvaporationEngineering

The invention discloses a refrigerator control method. The refrigerator control method comprises the following steps that the current water level of a water receiving disc is detected; when the current water level is higher than a first preset water level line, the running state of a condensation fan and / or a compressor is obtained; according to the running state of the condensation fan and / or thecompressor, the condensation fan and / or the compressor are / is controlled to run at the highest rotating speed. The invention further discloses a refrigerator and a computer readable storage medium. When the current water level in the water receiving disc exceeds the first preset water level, the condensation fan is controlled to run with the highest rotating speed, through improvement of the running rotating speed of the condensation fan, the air flowing in the refrigerator is increased, and evaporation of defrosting water in the water receiving disc is quickened, or the compressor is controlled to run with the highest rotating sped, that is, through increasing of the heating amount of the compressor, the temperature of the defrosting water in the water receiving disc is improved, the evaporation of the defrosting water in the water receiving disc is improved, and the life safety of a user is ensured.

Owner:TCL HOME APPLIANCES (HEFEI) CO LTD

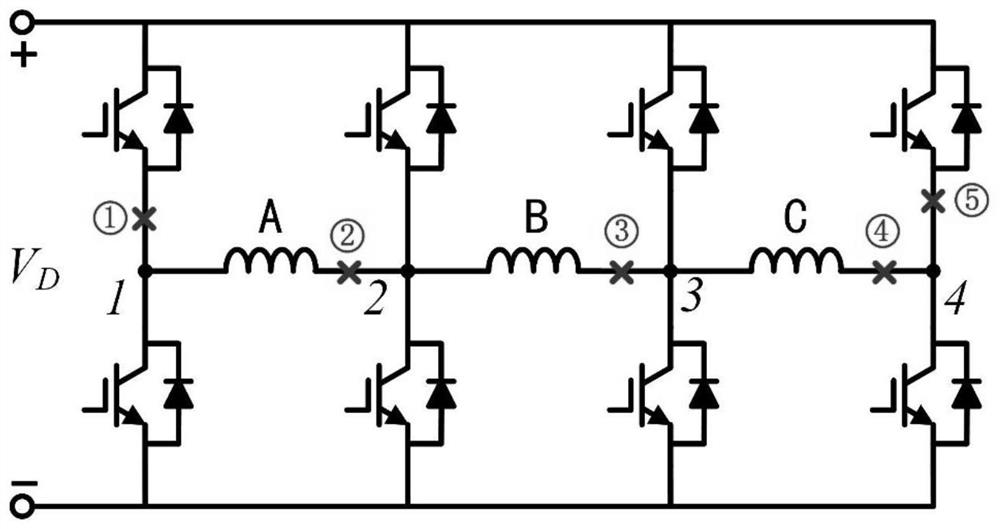

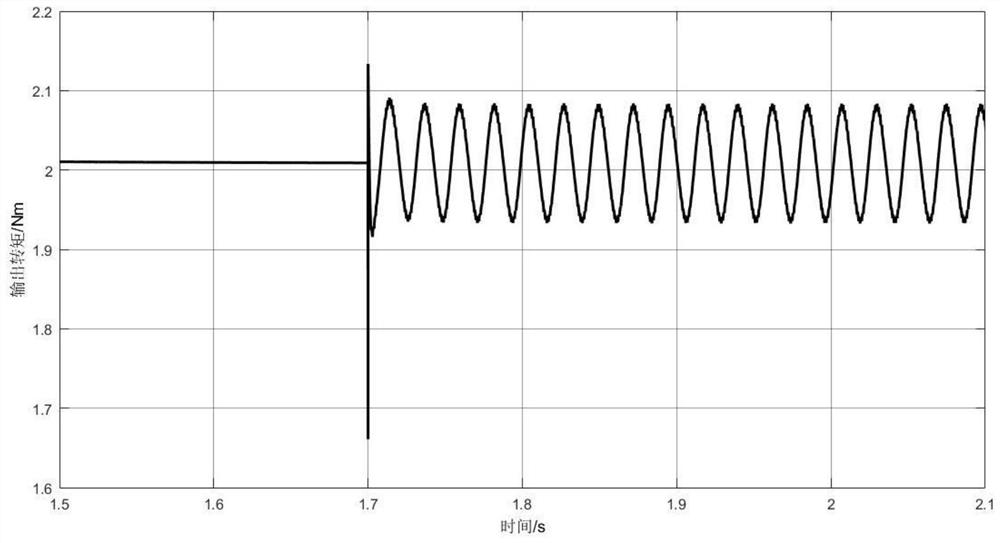

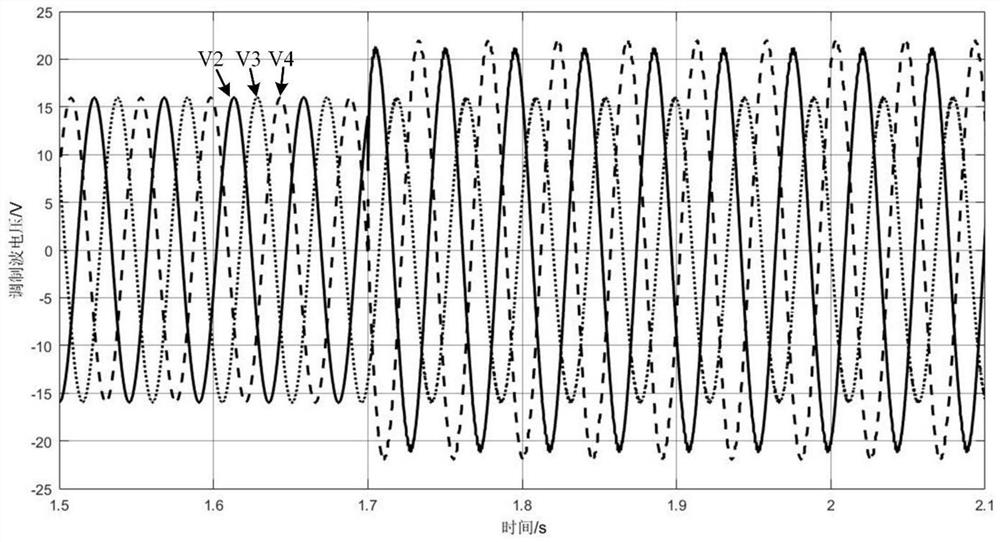

A fault tolerance method for three-phase string winding topology open circuit fault with balanced modulation amplitude

ActiveCN111786613BIncrease operating speedBalance modulation wave amplitudeElectric motor controlPhase currentsA wave amplitude

The invention discloses a three-phase series winding topological open circuit fault fault tolerance method for balanced modulation wave amplitude. When an open circuit fault occurs and any phase of the three-phase current is zero, the negative sequence current component that appears in the system is extracted and suppressed. Fault-tolerant operation of the motor after a fault is realized. After the positive-sequence and negative-sequence modulation wave components required to control the motor are superimposed, they are redistributed with the constraints of equal amplitudes, and finally the new command values of each bridge arm after the open circuit fault occurs are obtained. The invention proposes for the first time a fault-tolerant control method that can ensure the normal operation of the motor after the bridge arm or winding open circuit fault occurs in the three-phase series winding topology, and effectively improve the amplitude imbalance after the modulation wave is superimposed; Simulation verification is carried out on the motor, and the effect of motor fault tolerance and modulation wave equalization control is remarkable.

Owner:HUAZHONG UNIV OF SCI & TECH

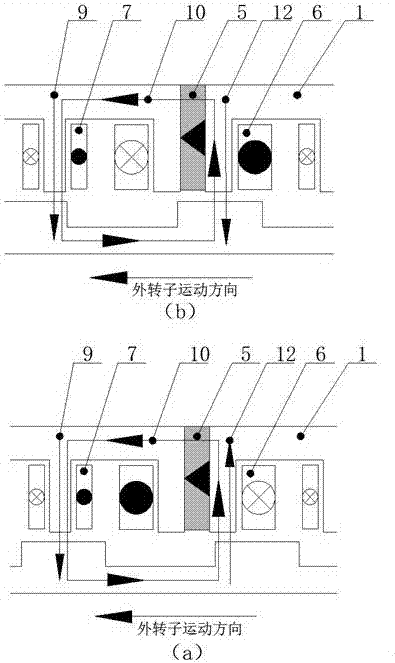

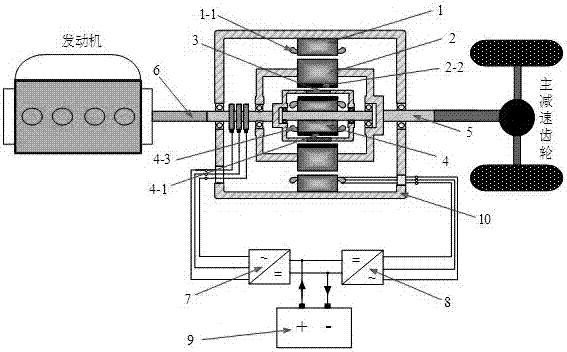

Magnetic field modulation type electromechanical energy converter used for hybrid electric vehicle

InactiveCN107332411AEliminate contact frictionReduce transmission lossMagnetic circuit rotating partsMagnetic circuit stationary partsMechanical wearEngineering

The present invention discloses a magnetic field modulation type electromechanical energy converter used for a hybrid electric vehicle. The magnetic field modulation type electromechanical energy converter comprises a chassis, and a stator, an outer rotor, a modulation ring and an inner rotor are arranged inside the chassis orderly from outside to inside. The inner surface of the stator is equipped with 12 salient poles, a three-phase centralized winding is placed in a cogging of the stator, and a first air gap is arranged between the stator and the outer rotor. The outer surface of the outer rotor is equipped with 8 outer rotor salient poles, 8 outer rotor permanent magnets are placed on the inner surface of the outer rotor uniformly, and a second air gap is arranged between the outer rotor and the modulation ring. The modulation ring is characterized by arranging 10 non conductive magnets and 10 magnetizers alternately to form a cylinder, the inner rotor is equipped with 12 inner rotor salient poles, an inner rotor permanent magnet is pasted on each inner rotor salient pole, and the three-phase centralized winding is embedded in a cogging of the inner rotor. The magnetic field modulation type electromechanical energy converter used for the hybrid electric vehicle of the present invention enables the transmission efficiency to be improved and the mechanical vibration, the mechanical wear and the noise to be reduced, thereby improving the reliability of a device, reducing the maintenance cost, and prolonging the service life of the device.

Owner:CHONGQING UNIV

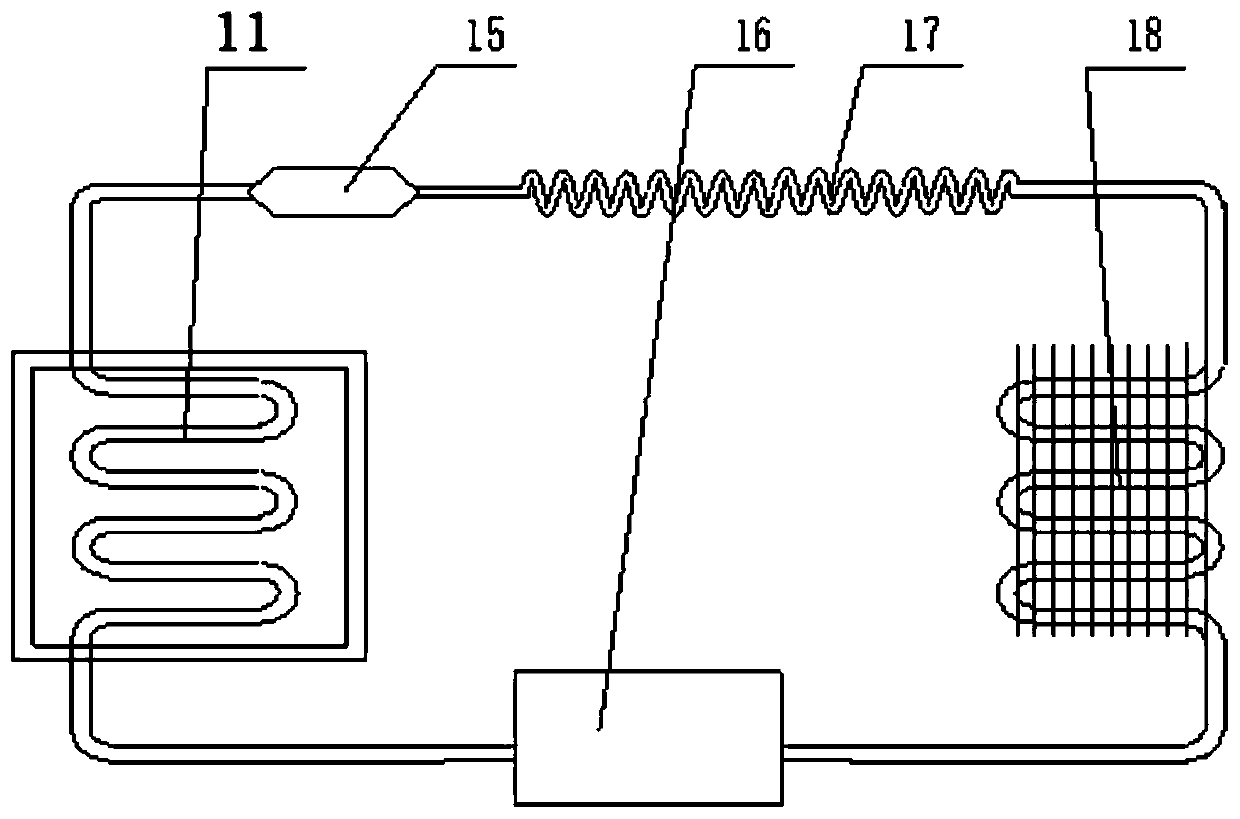

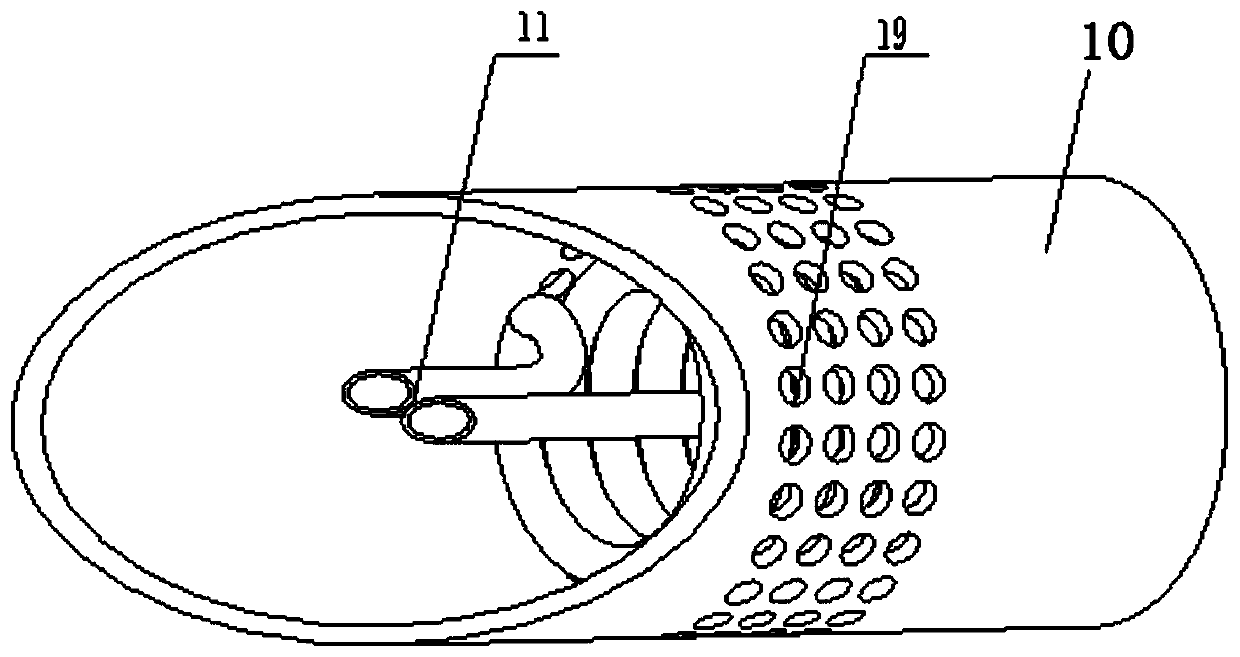

High-temperature magnetic suspension bearing cooling system for gas turbine

PendingCN110966096AReduce axial sizeCompact structureTurbine/propulsion engine coolingTurbine/propulsion lubricationCapillary TubingEngineering

The invention discloses a high-temperature magnetic suspension bearing cooling system for a gas turbine. The system comprises a refrigeration system, a heat shield, a gas turbine rotating shaft, a first radial magnetic suspension bearing, an axial magnetic suspension bearing and a second radial magnetic suspension bearing, wherein the first radial magnetic suspension bearing and the axial magneticsuspension bearing are arranged at one end of the gas turbine rotating shaft, the second radial magnetic suspension bearing is arranged at the other end of the rotating shaft, and the second radial magnetic suspension bearing is close to the rotor side of the gas turbine; the first radial magnetic suspension bearing, the axial magnetic suspension bearing and the second radial magnetic suspensionbearing are all fixed to the outer shell of the gas turbine; the heat shield is arranged outside the second radial magnetic suspension bearing and is fixed to the outer shell of the gas turbine; the refrigerating system comprises a compressor, a heat dissipation condenser, a capillary tube, a drying filter and a refrigerating pipeline which are in circulation connection with each other; the gas turbine rotating shaft is of a hollow structure; a hollow shaft is arranged in the rotating shaft; two ends of the hollow shaft are supported in the rotating shaft through bearings; and the refrigeration pipeline penetrates into the hollow shaft, penetrates out of the hollow shaft and then directly faces the second radial magnetic suspension bearing. The system of the invention has the advantages ofhigh cooling efficiency and reliable operation.

Owner:YANGZHOU UNIV

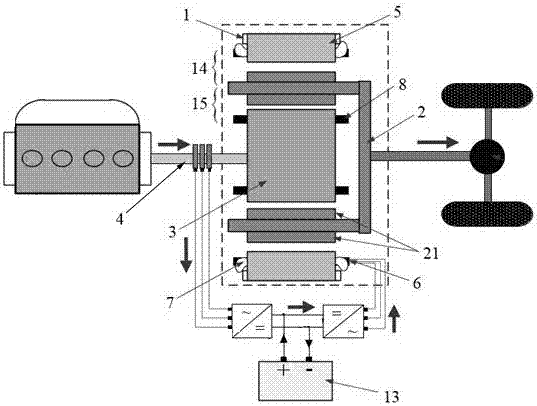

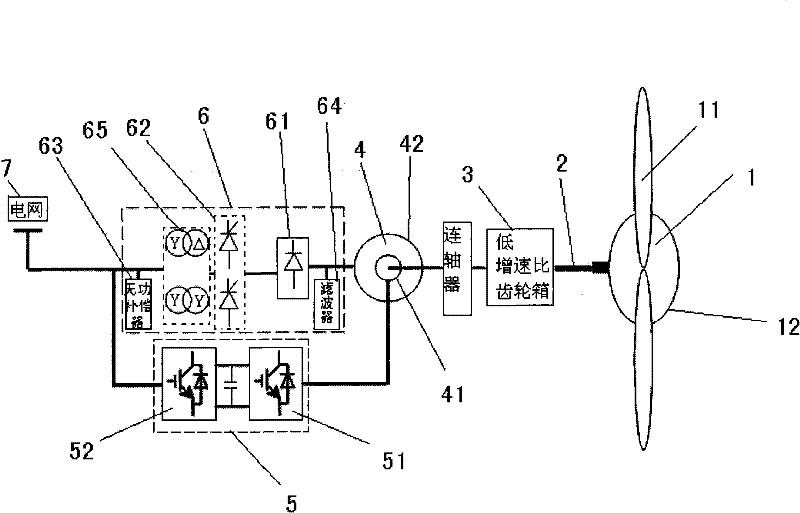

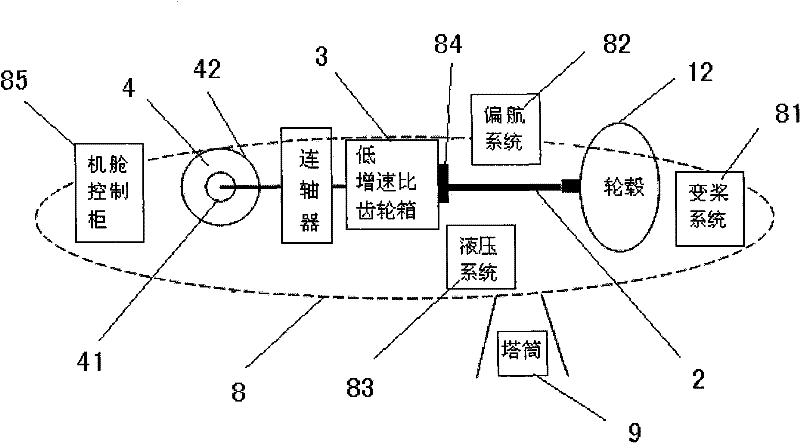

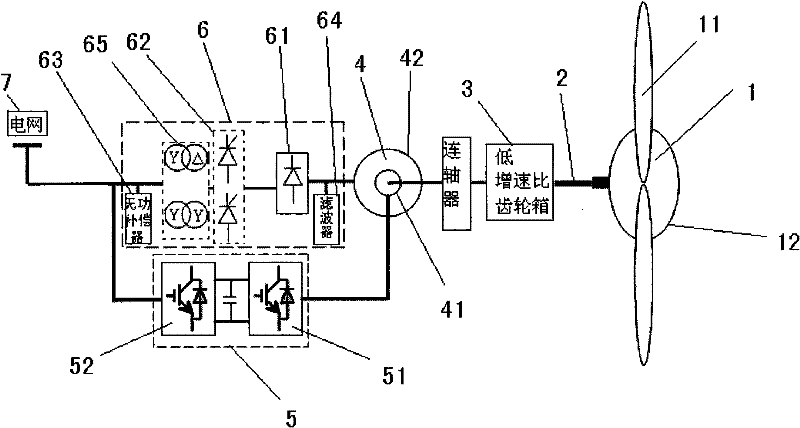

Hybrid wind power generation system

InactiveCN101626163BLow reliabilityAddress reliabilityGearboxesSingle network parallel feeding arrangementsDc ac converterEngineering

Owner:TSINGHUA UNIV

High precision dynamic gas rotation device for fluting machine

InactiveCN100553962CExtended service lifeSimple structureMechanical working/deformationProgramme control in sequence/logic controllersData acquisitionEngineering

Owner:李新桥

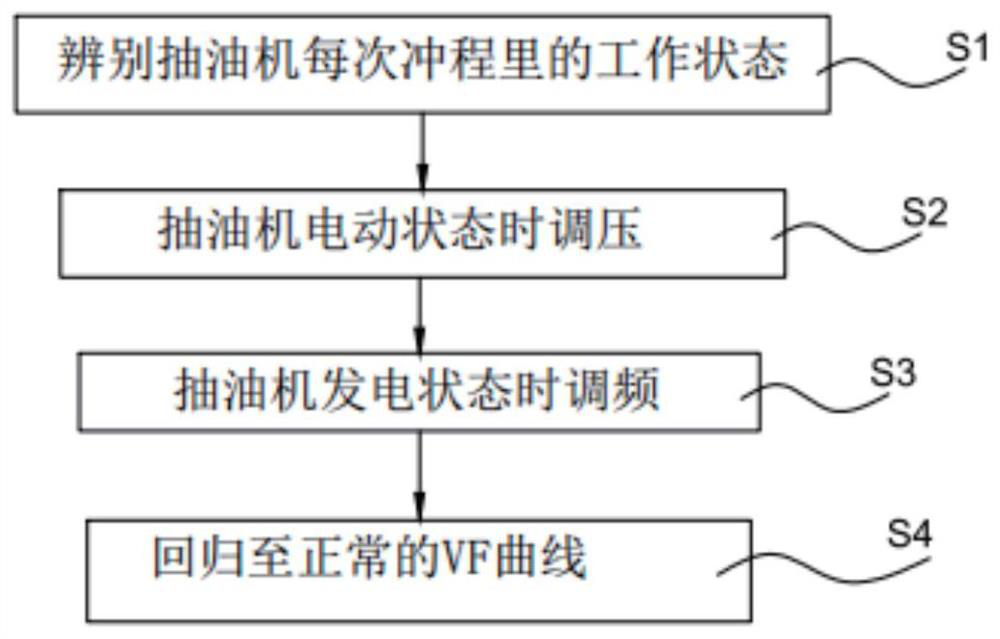

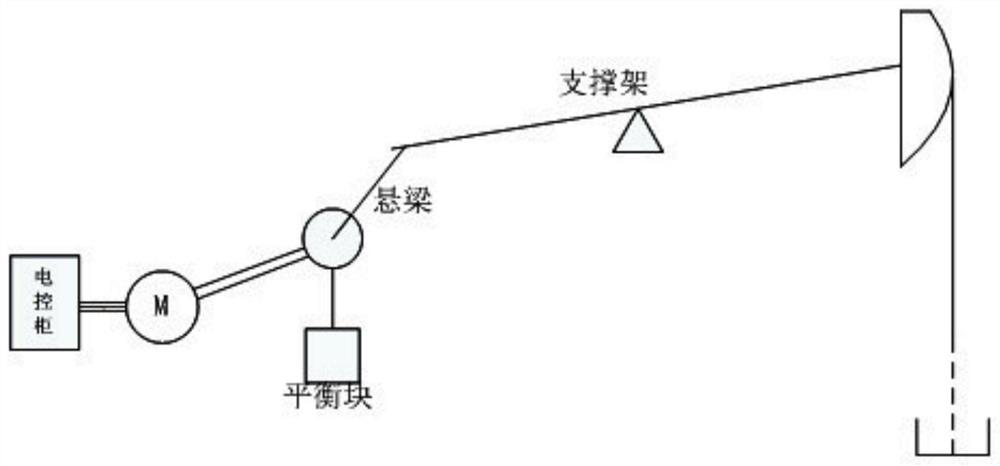

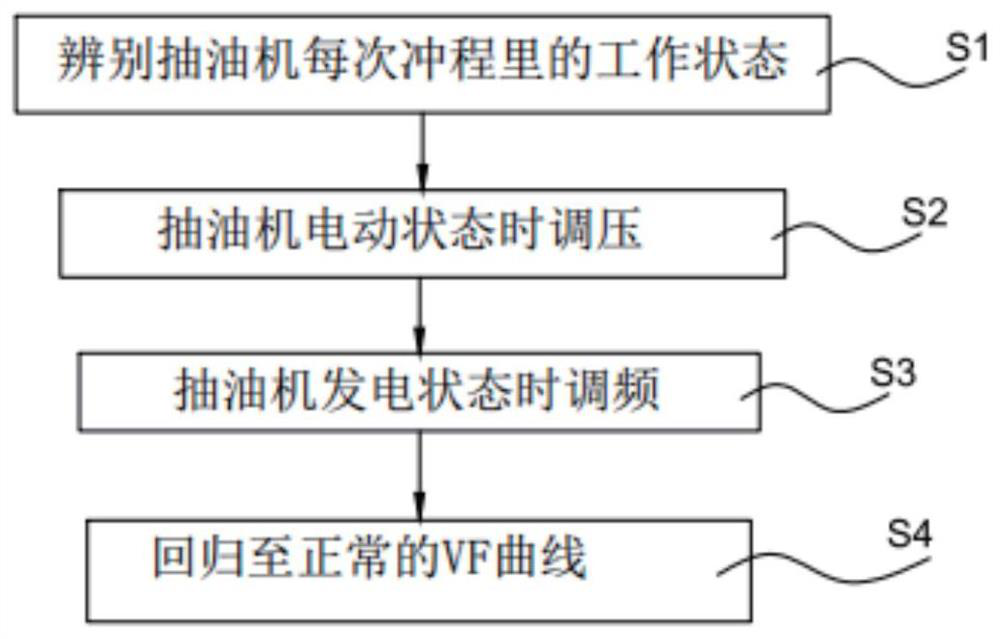

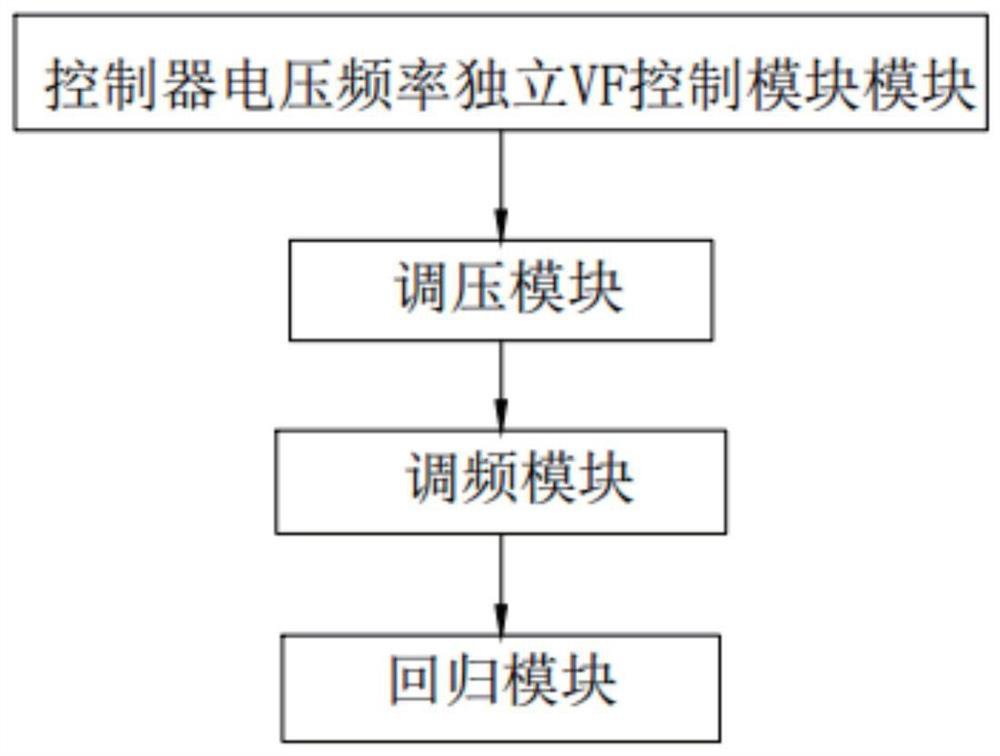

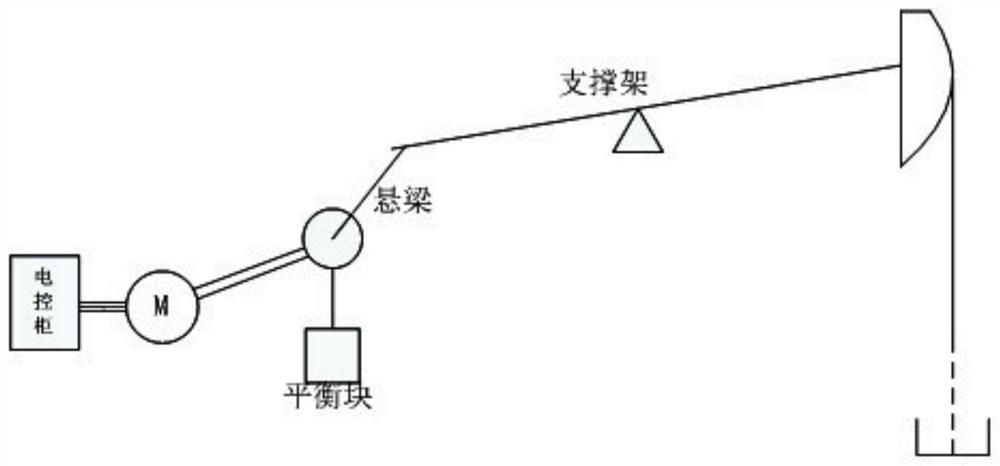

Self-adaptive intelligent energy-saving control method and system for oil field pumping unit

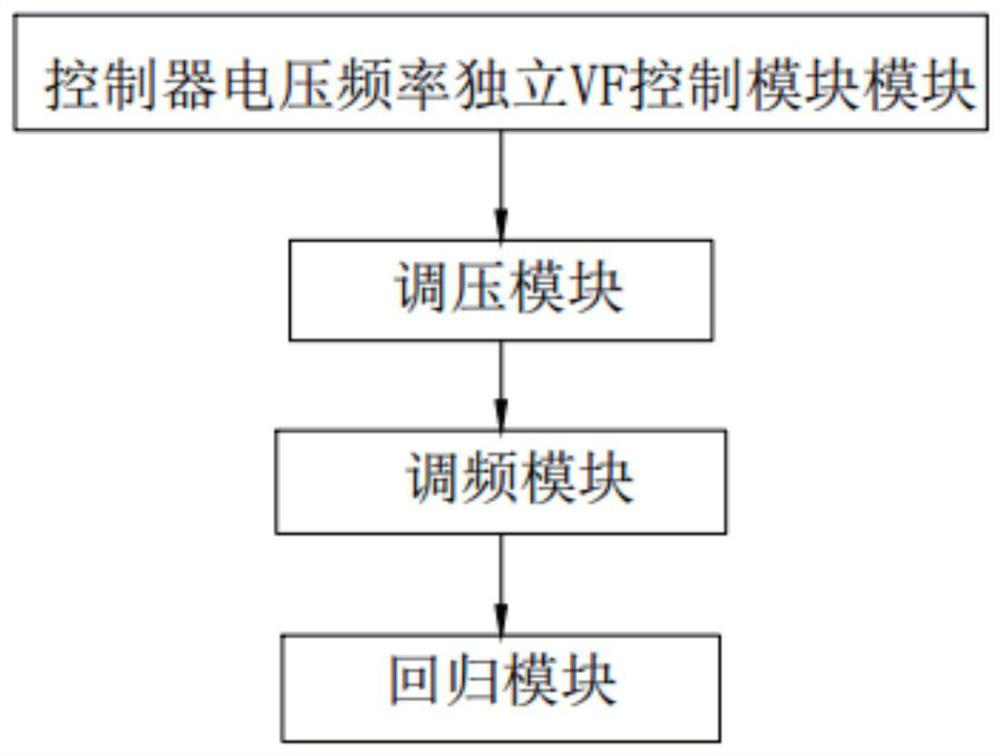

ActiveCN112422016AImprove energy savingNo additional costFluid removalElectric generator controlFrequency modulationElectric power

The invention provides a self-adaptive intelligent energy-saving control method for an oil field pumping unit, and the method comprises the steps: distinguishing the working state of the pumping unitin each stroke, regulating the pressure of the pumping unit in an electric state, regulating the frequency of the pumping unit in a power generation state, returning to a normal VF curve and the like.The self-adaptive intelligent energy-saving control system of the oil field pumping unit comprises a controller voltage frequency independent VF control module, a voltage regulation module, a frequency modulation module, a regression module and the like, self-adaptive intelligent energy-saving control of the pumping unit can be achieved, and the purpose that the operation rotating speed of a motor is increased when the pumping unit works in a power generation state is achieved. When the VF independent control method works in an electric state, the VF independent control method recovers to a normal operation rotating speed, so that the stroke frequency is not lower than the normal stroke frequency within the same time, and the oil pumping amount in unit time and unit energy is only increased and cannot be reduced. The unique VF independent control method can automatically reduce the output voltage and the output current in a no-load state and automatically store energy under the powergeneration condition; therefore, the energy-saving device can be widely applied to oil field pumping units, centrifugal machines, machine tools and other application occasions with two working modes of electric power generation and power generation.

Owner:SHENZHEN SINE ELECTRIC

A direct-drive inner rotor starter-generator system for an aero-engine

ActiveCN113612349BIncrease operating speedHigh output powerManufacturing stator/rotor bodiesMechanical energy handlingStarter generatorControl theory

An aero-engine direct-drive internal rotor starter-generator system, which is applied in the field of unmanned aerial vehicle hybrid electric power, installs and fixes the starter-generator outer stator assembly on the aero-engine through a stator bracket, so that the starter-generator system has a compact structure and Short length, high integration, and high power-to-weight ratio; the coaxiality between the starter generator stator and the engine is ensured through the support of the stator bracket, and the starter generator inner rotor assembly is directly installed on the aeroengine shaft, so that the starter generator system There is no need for bearing support near the engine side, and a single bearing support is used on the far engine side, which reduces the heat generation of the bearing and improves the reliability of the bearing; there is also a resolver at the end of the rotor assembly in the starter generator far away from the aeroengine, which can accurately Detect the position of the rotor, so that the starter generator system can output high-power direct current by means of controllable rectification, and the power generation efficiency is high.

Owner:BEIHANG UNIV

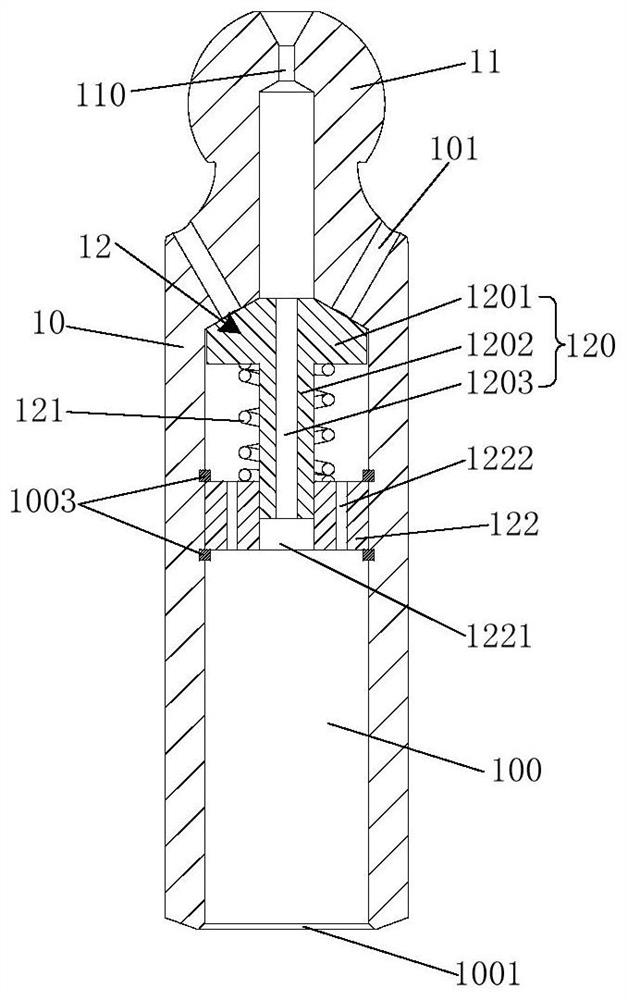

Compressor and heat pump equipment

PendingCN112360746AReduce opening depthGuaranteed structural strengthHeat pumpsRotary/oscillating piston pump componentsEngineeringInjection air

The invention provides a compressor and heat pump equipment. The compressor comprises at least one air cylinder assembly, a supporting piece, an air injection channel and the one-way valve, each air cylinder assembly is provided with an exhaust cavity, and a first mounting groove is formed in the end face of each air cylinder assembly; the supporting piece is arranged on one side of one air cylinder assembly in the at least one air cylinder assembly, a second mounting groove is formed in the end face of the supporting piece, the second mounting groove and the first mounting groove are oppositely formed, and the first mounting groove and / or the second mounting groove communicate / communicates with the exhaust cavity; the air injection channel is arranged on the at least one air cylinder assembly and / or the supporting piece, and the air injection channel can communicate with the first mounting groove and the second mounting groove; and the one-way valve is arranged in the first mounting groove and / or the second mounting groove. An air supplementing cavity is partially formed in the air cylinder assembly and partially formed in the supporting piece, the forming depth of the first mounting groove and the forming depth of the second mounting groove cannot be too large, the structural strength of the air cylinder assembly and the supporting piece are guaranteed, the stability is high,and use is safe and reliable.

Owner:ANHUI MEIZHI PRECISION MFG

Air conditioner fan speed control method

ActiveCN111623487BIncrease operating speedMechanical apparatusSpace heating and ventilation safety systemsLow noiseAir velocity

The invention discloses a fan speed control method of an air conditioner, which comprises the following steps: in cooling mode, when ΔT≤T 1 When ΔD i ≤D 00 When , set the optimal noise value of the real-time noise of the environment in this time period to D s , the fan runs at the current speed; compare the real-time noise of the environment in real time D i with D s The difference in order to adjust the speed in time. According to the fan speed control method of the present invention, according to the temperature information and noise information within a certain period, the rotation speed of the fan of the air conditioner is controlled, and the wind speed adjustment level of the air conditioner can be increased. On the one hand, it can meet the user's wind speed requirements for the air conditioner. On the other hand, the air conditioner can also be operated in a low-noise state, so that the operating state of the air conditioner can be subdivided into multiple states, so that the air conditioner can satisfy multiple performances at the same time.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

Commutation control method of DC brushless motor, commutation controller and DC brushless motor

ActiveCN106452214BSmall excitation currentIncrease operating speedCommutation monitoringSingle motor speed/torque controlBrushless motorsConstant power

The invention is applicable to the technical field of direct current motor control, and relates to a phase change control method of a direct current brushless motor. The method includes the step of obtaining six Holzer position signals of a rotor of the direct current brushless motor within one cycle; when the last Holzer position signal of the rotor is obtained, starting to conducting timekeeping, stopping timekeeping when the current Holzer position signal is received, and recording the timekeeping time as t; when receiving the current Holzer position signal of the rotor, starting to conducting timekeeping, when the timekeeping time reaches the preset phase change time t / n, controlling a switching tube, corresponding to the next Holzer position signal, in an inverter bridge arm of the direct current brushless motor to open or close, wherein when the current Holzer position signal is the first Holzer position signal within the cycle, the last Holzer position signal is the sixth Holzer position signal of the rotor within the last cycle, and 1<n<=2. Under the condition of ensuring the voltage balance of the motor, the method effectively improves the rotation speed of the motor in running under the condition of constant power.

Owner:SHENZHEN TOPBAND CO LTD

Coaxial multi-slip-sheet wave-ring rotor machine

InactiveCN1096570CEliminate channelingReduce leakageRotary piston pumpsRotary piston liquid enginesFriction lossSlide plate

A piston machine able to generate variable volume directly by rotation is composed of annular wave rotor, cylindrical stator, three sets of slide pates arranged coaxially and convertged in space, andtwo end covers, and features that the rotor with cross-section of annular sine curve is matched with the slide plate sets of stator to realize new working mechanism. Its advantages include less friction loss, high volume efficiency and rotational speed, and low vibration and noise. It is suitable for compression, pumping and extraction of fluid.

Owner:徐浩冠

A self-adaptive intelligent energy-saving control method and control system for oilfield pumping units

ActiveCN112422016BImprove energy savingNo additional costFluid removalElectric generator controlStored energyControl system

The invention provides an adaptive intelligent energy-saving control method for pumping units in an oil field, which includes identifying the working state of each stroke of the pumping unit, adjusting the voltage when the pumping unit is in the electric state, adjusting the frequency when the pumping unit is in the power generation state, and returning to normal Several steps such as VF curve, oilfield pumping unit self-adaptive intelligent energy-saving control system includes several modules such as controller voltage and frequency independent VF control module, voltage regulation module, frequency modulation module and return module, the present invention can realize the automatic control of pumping unit Adapt to intelligent energy-saving control, increase the running speed of the motor when the pumping unit is working in the power generation state, and return to the normal running speed when working in the electric state, so as to realize that the number of strokes is not lower than the normal number of strokes in the same time, and the unit time, The oil pumping rate per unit energy will only increase and not decrease. The original VF independent control method of the present invention can automatically reduce the output voltage and output current when no-load, and automatically store energy under power generation, so as to achieve the purpose of energy saving and can be widely used It is used in oil field pumping units, centrifuges, machine tools and other applications with two working modes of electric and power generation.

Owner:SHENZHEN SINE ELECTRIC

Rotor structure of external rotor motor and external rotor motor

ActiveCN114499010AReduced risk of demagnetizationReduce lossMagnetic circuitSupports/enclosures/casingsMagnetic currentElectric machine

The rotor structure comprises a rotor shell and a plurality of permanent magnets, the rotor shell comprises an end plate and a sleeve shell extending from the edge of the end plate, a cavity is defined by the end plate and the sleeve shell, and the permanent magnets are installed on the inner wall face of the sleeve shell at intervals in the circumferential direction. The permanent magnet motor is characterized in that a movable shell is installed on the outer surface of the sleeve shell, the movable shell is movably installed on the outer wall face of the sleeve shell, the movable shell is arranged on the radial outer side of the permanent magnet, and when the rotation speed of the rotor exceeds a certain rotating speed, the movable shell moves in the radial direction or the axial direction to achieve the purpose of increasing the running rotating speed through flux weakening; d-axis weak magnetic current does not need to be increased, the coil winding loss is reduced, the motor efficiency is improved, and the demagnetization risk of the permanent magnet can be reduced.

Owner:ZHONGSHAN BROAD OCEAN

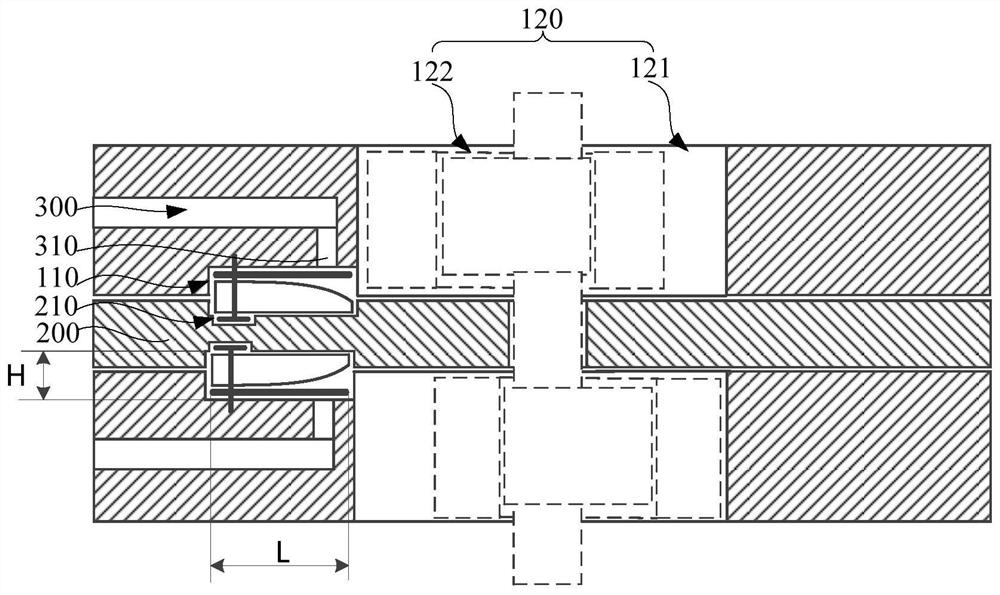

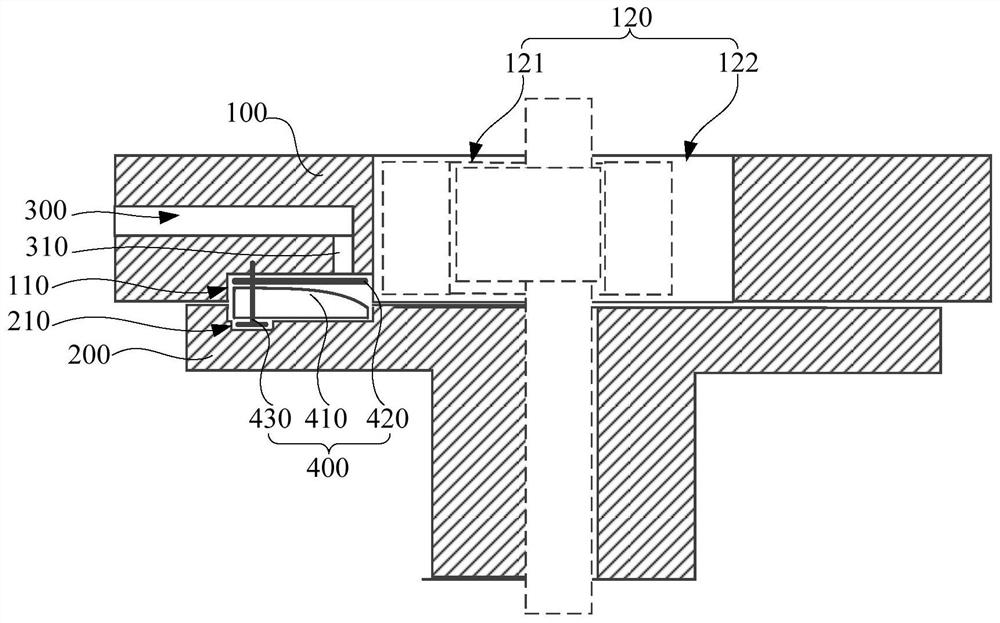

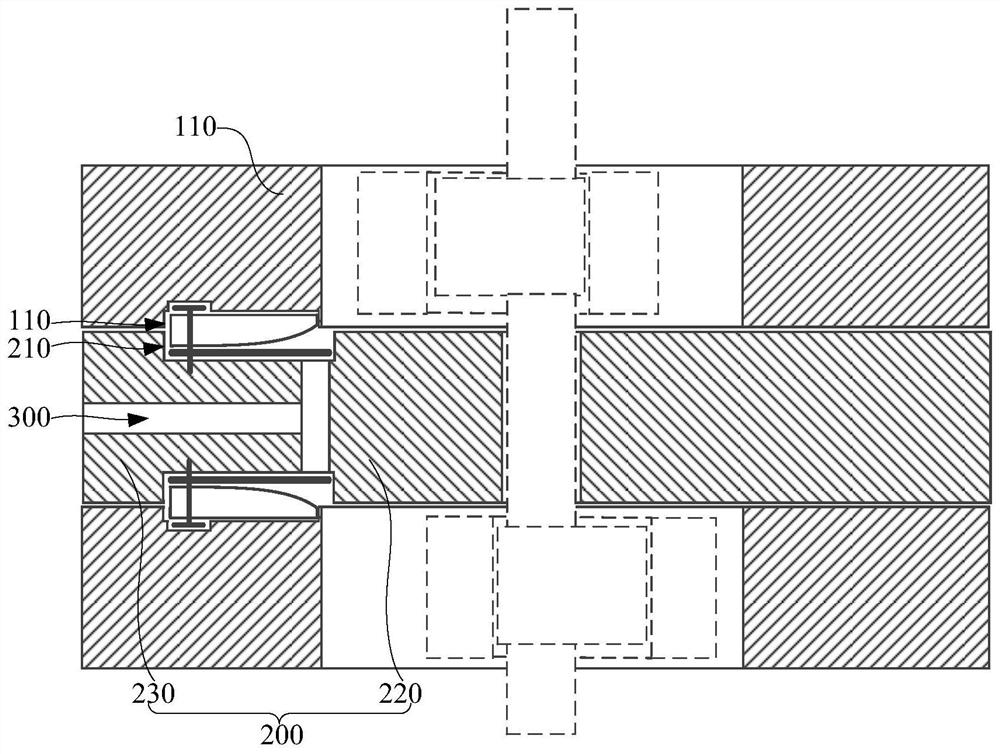

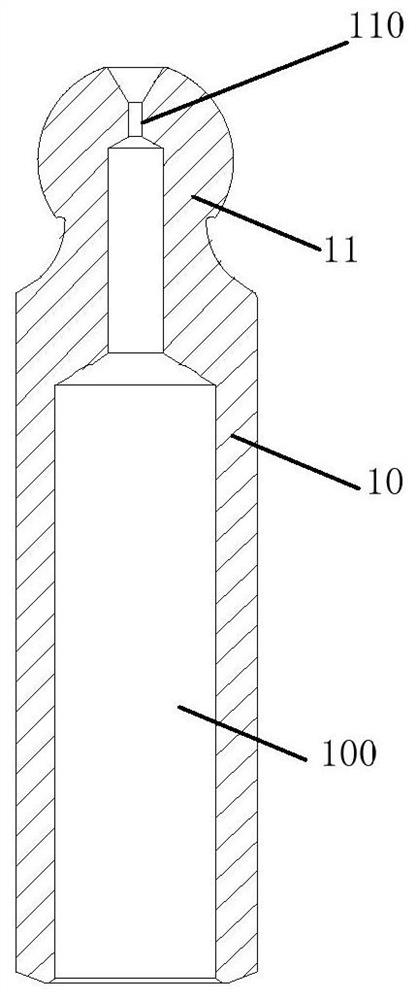

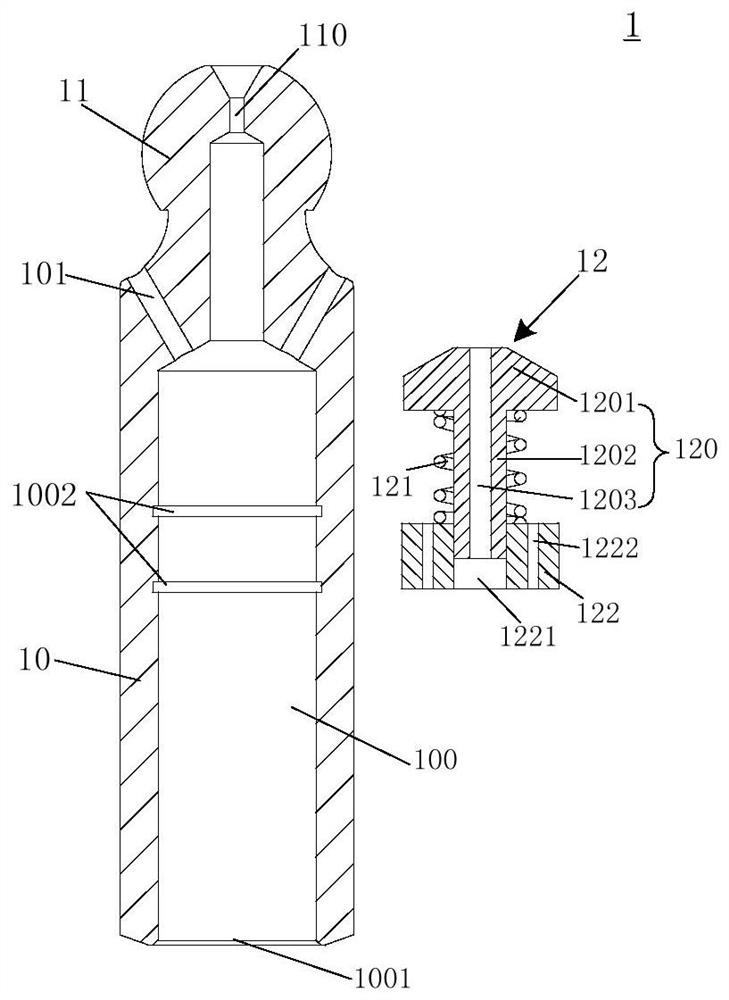

Plunger structure of plunger type hydraulic pump and plunger type hydraulic pump comprising plunger structure

PendingCN113738635AFairly technologically advancedQuite practicalPositive displacement pump componentsLiquid fuel engine componentsHydraulic pumpStructural engineering

The invention relates to a plunger structure of a plunger type hydraulic pump and the plunger type hydraulic pump comprising the plunger structure. The plunger structure of the plunger type hydraulic pump comprises a plunger body, a plunger ball head and a one-way throttle valve, wherein the plunger ball head is connected to one end of the plunger body, the plunger body is provided with a hollow cavity, one end of the hollow cavity is of an opening structure, at least one first hole channel is formed in the plunger body and communicates with the hollow cavity and the exterior of the plunger body, and the one-way throttle valve is arranged in the hollow cavity and is used for opening and closing the at least one first hole channel. According to the plunger structure of the plunger type hydraulic pump and the plunger type hydraulic pump comprising the plunger structure, by means of the manner that the at least one first hole channel is formed in the plunger body, when the plunger structure absorbs insufficient oil, the oil can be supplemented and absorbed through the at least one first hole channel, the phenomenon that the plunger structure absorbs the insufficient oil is avoided, especially the problem that cavitation occurs due to the fact that the oil is completely absorbed when the operation speed of the hydraulic pump is increased at a top speed is solved.

Owner:BEIJING HUADE HYDRAULIC INDAL GROUP

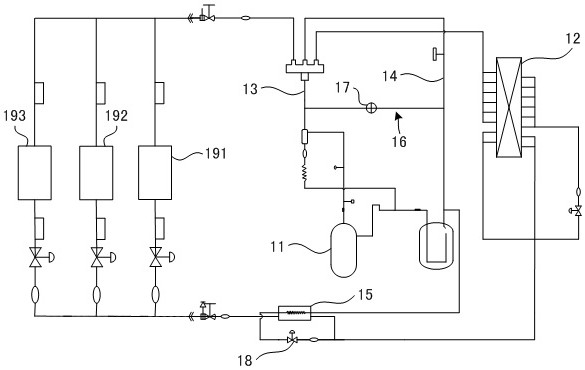

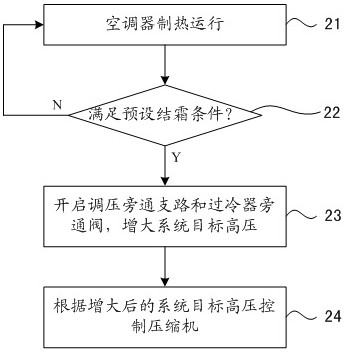

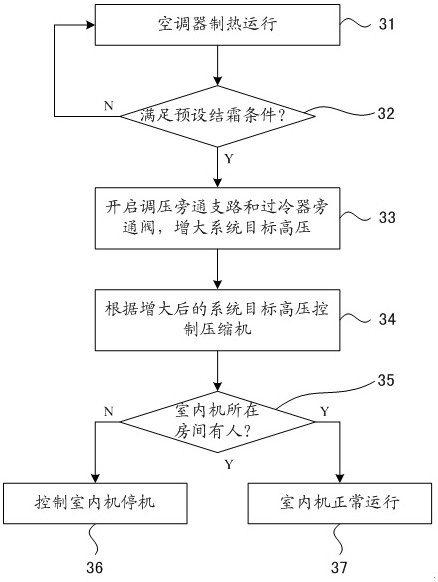

Air conditioner control method, control device and air conditioner

PendingCN113883659AIncrease heatIncrease operating speedMechanical apparatusSpace heating and ventilation safety systemsThermodynamicsEngineering

The invention discloses an air conditioner control method, a control device and an air conditioner. The method comprises the steps of: in the heating operation process of the air conditioner, at least when the air conditioner meets a preset frosting condition, starting up a pressure regulating bypass branch; and when the pressure regulating bypass branch is started up, opening a subcooler bypass valve in a refrigerant circulating system, increasing a target high pressure of the system, and controlling a compressor according to the increased target high pressure of the system. The control device comprises corresponding structural units for implementing the control method; and the air conditioner comprises a memory, a processor and a computer program stored in the memory, and the processor executes the computer program to implement the air conditioner control method. By the adoption of the air conditioner control method, the control device and the air conditioner, frosting of an outdoor unit heat exchanger is reduced or eliminated when the heating operation is not stopped, and the operation performance of the air conditioner is improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

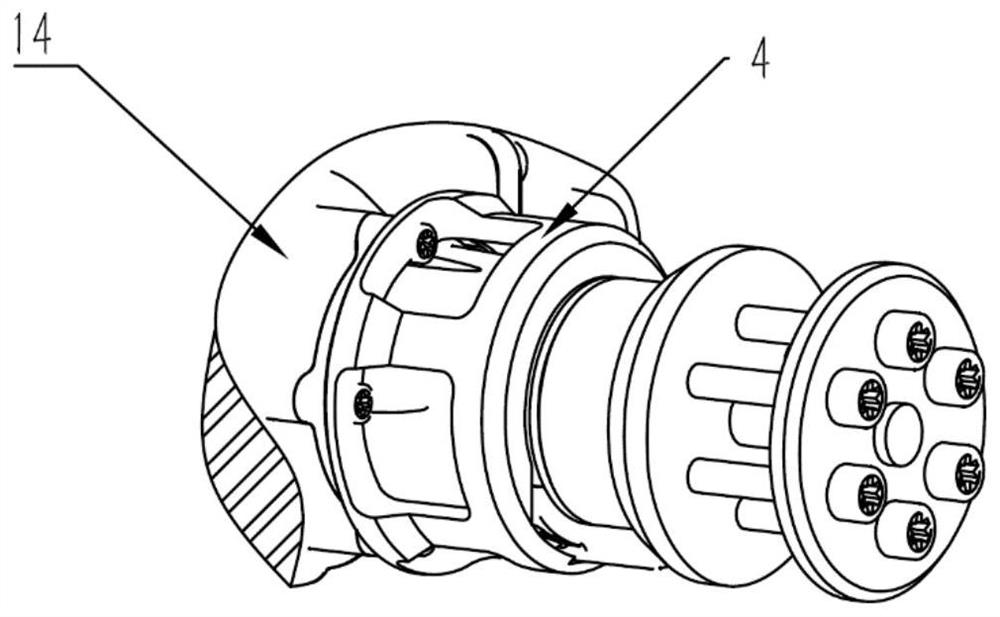

Direct drive type inner rotor starting generator system of aero-engine

ActiveCN113612349AIncrease operating speedHigh output powerManufacturing stator/rotor bodiesMechanical energy handlingStarter generatorUncrewed vehicle

The invention relates to a direct drive type inner rotor starting generator system of an aero-engine and belongs to the field of unmanned aerial vehicle oil-electricity hybrid power. A starter generator outer stator assembly is fixedly installed on the aero-engine through a stator support, so that the starting generator system is compact in structure, short in axial length, high in integration level and high in power-to-weight ratio; coaxiality of a starting generator stator and the engine is guaranteed through supporting of the stator support, a starting generator inner rotor assembly is directly installed on an aero-engine shaft, the starting generator system does not need to be supported by a bearing on the side close to the engine, the starting generator system is supported by a single bearing on the side far away from the engine, bearing heating is reduced, and bearing reliability is improved; and a rotary transformer is arranged at the end, away from the aero-engine, of the rotating shaft of the starting generator inner rotor assembly, the position of a rotor can be accurately detected, and therefore the starting generator system can output high-power direct current in a controllable rectification mode, and the power generation efficiency is high.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com