Compressor and heat pump equipment

A compressor and cylinder technology, applied in the field of compressors and rotary compressors, can solve the problems of cylinder inner diameter deformation, bearing damage clearance, affecting the performance and reliability of the compressor, and achieve safe, reliable, and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

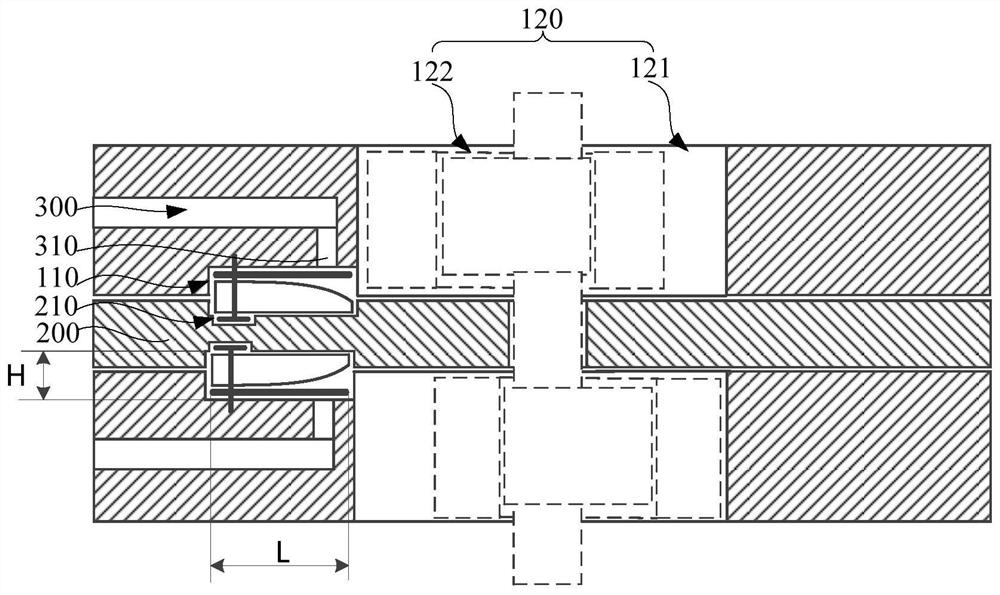

[0051] Such as figure 1 As shown, the present invention proposes a compressor, including: at least one cylinder assembly 100, each cylinder assembly 100 has a discharge cavity 121, and the end surface of each cylinder assembly 100 is provided with a first installation groove 110; a support member 200, It is arranged on one side of one cylinder assembly 100 in at least one cylinder assembly 100, and the end surface of the support member 200 is provided with a second installation groove 210, and the second installation groove 210 and the first installation groove 110 are arranged oppositely, and the first installation groove 110 and / or Or the second installation groove 210 communicates with the exhaust chamber 121; the air injection channel 300 is arranged on at least one cylinder assembly 100 and / or the support member 200, and the air injection channel 300 can communicate with the first installation groove 110 and the second installation groove 210; The one-way valve 400 is dis...

Embodiment 2

[0055] Such as figure 1 As shown, on the basis of the first embodiment above, the sum of the depth of the first installation groove 110 and the depth of the second installation groove 210 is H, and the depth of the first installation groove 110 is H1, which satisfies 0

[0056]In these embodiments, by taking the sum of the depth of the first installation groove 110 and the depth of the second installation groove 210 as H, the depth of the first installation groove 110 is H1, and 0<H1 / H≤0.7, it can be further guaranteed The structure of the cylinder assembly 100 and the supporting member 200 is stable, and it is not easy to break and produce a gap. Specifically, if the depth of the first installation groove 110 is too large, the inner diameter of the cylinder assembly 100 will be deformed too much, which will affect the strength of the cylinder assembly and be easily broken, thereby affecting the safety of the compressor. According to actual production, the depth o...

Embodiment 3

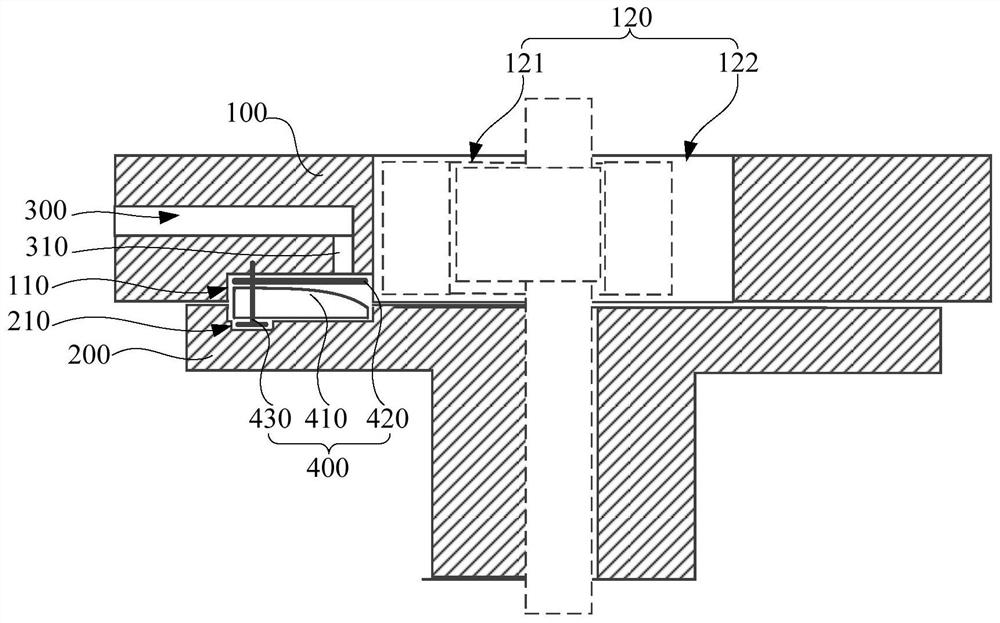

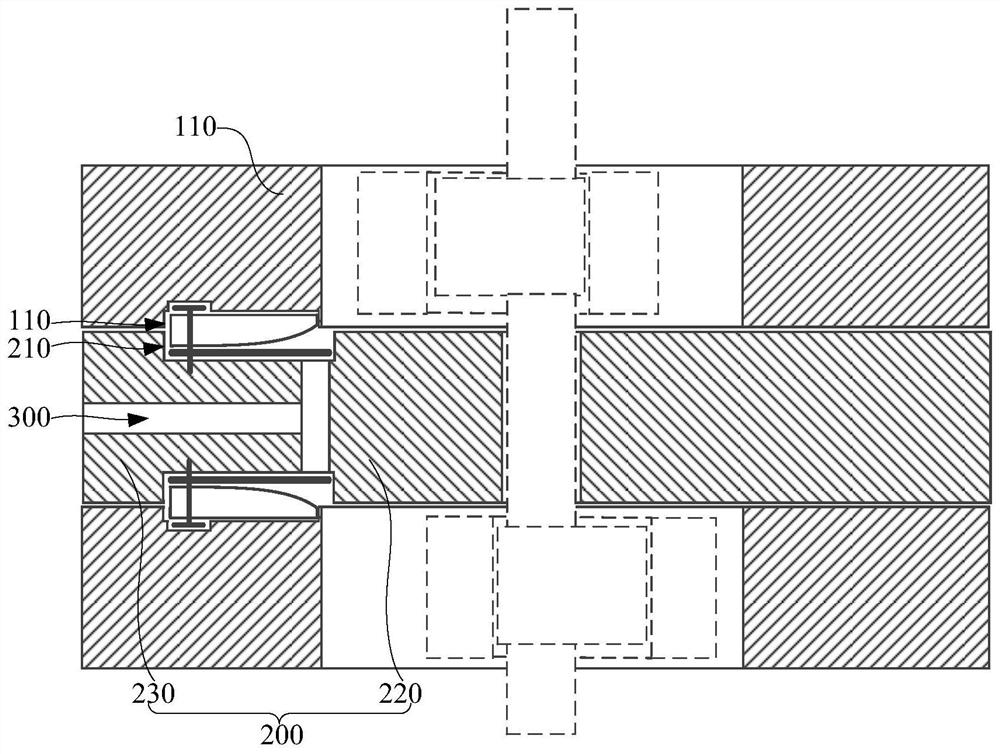

[0060] Such as figure 2 and image 3 As shown, on the basis of any of the above-mentioned embodiments, the first installation groove 110 and the second installation groove 210 are surrounded to form an air supply cavity; the air supply cavity includes a first cavity wall and a second cavity wall, and the first cavity wall and the second cavity wall The second cavity wall is the opposite cavity wall; the air injection end 310 is arranged on the first cavity wall, and the flow cross section of the air supply cavity decreases from the first cavity wall to the second cavity wall.

[0061] In these embodiments, the air supply chamber is formed by surrounding the first installation groove 110 and the second installation groove 210, so that the air supply chamber is partially set on the cylinder assembly 100 and partially on the support member 200, ensuring that the air cylinder assembly The structural strength and stability of 100 and support member 200 are not easy to be deformed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com