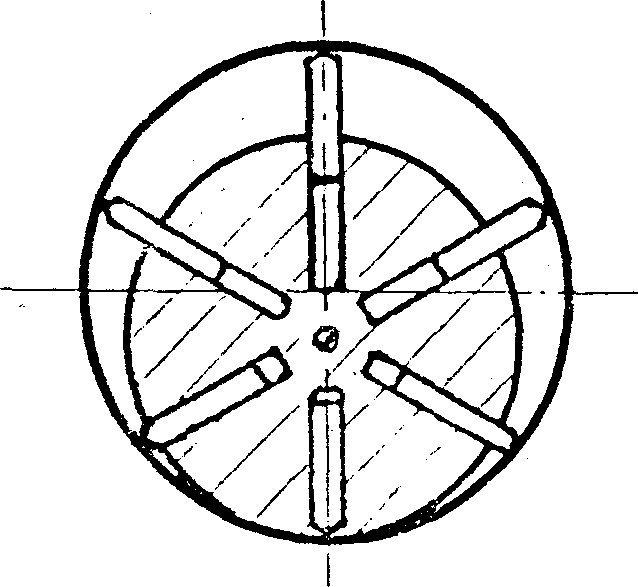

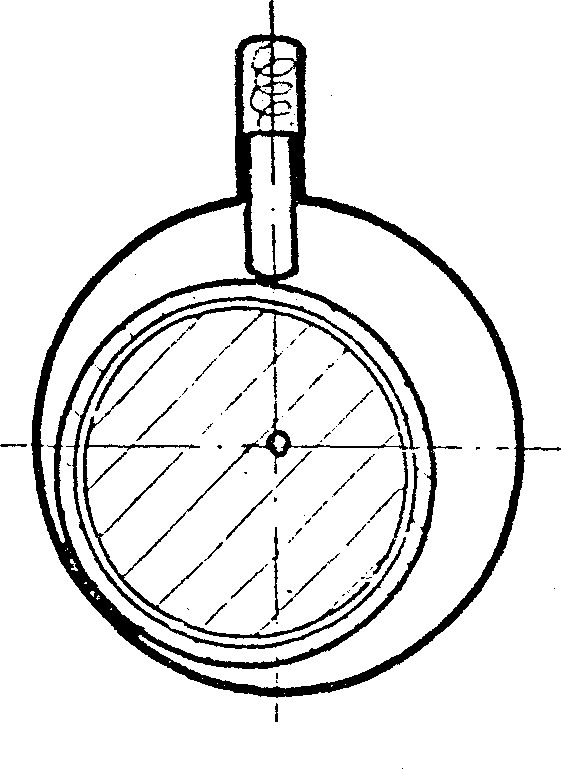

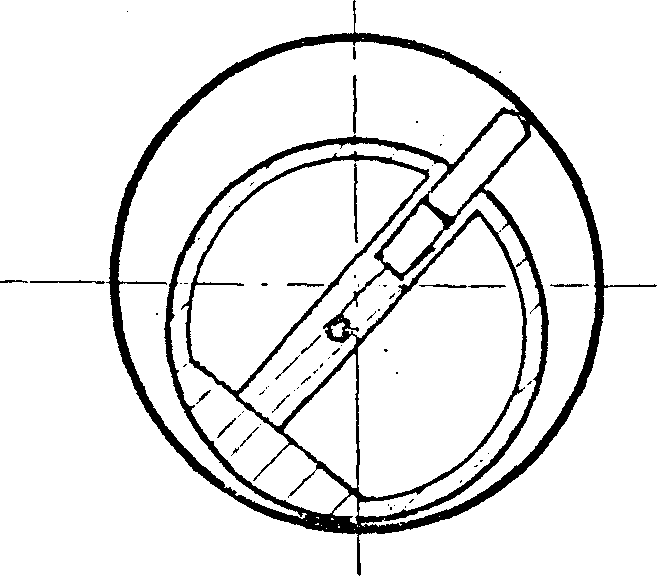

Coaxial multi-slip-sheet wave-ring rotor machine

A wave ring rotor and sliding vane technology, applied in the field of coaxial multi-sliding vane wave ring rotor machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0025] Below we recommend some of the most distinctive applications that can be successfully developed in the near future:

[0026] 1. Since this model can be designed to operate without internal compression process, the thickness of the sliding vane can be designed to be larger; the outer rotor can transmit larger torque, especially suitable for high-flow high-pressure oil pumps or hydraulic motors.

[0027] 2. The air intake of this model is concentrated in one place, and it is easy to develop into a high-speed and large-flow vacuum pump.

[0028] 3. In view of the characteristics of small size, large displacement, low vibration, low noise, and no need for pile foundation even for machines with large displacement, this model is most suitable for developing mobile air compressors for pneumatic tools in road and bridge trestle projects station, and other small multi-purpose mobile air compressors.

[0029] 4. For the same reason, we can also combine wave ring air compressors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com