Waterproof method of mining method tunnel

A mining method and tunnel technology, which is applied in the field of waterproofing of mining method tunnels, can solve the problems that affect the driving safety and structural life in the tunnel, easy water channeling, damage, etc., to achieve convenient hot-melt fixing construction, not easy to leak, and eliminate channeling The effect of the water channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

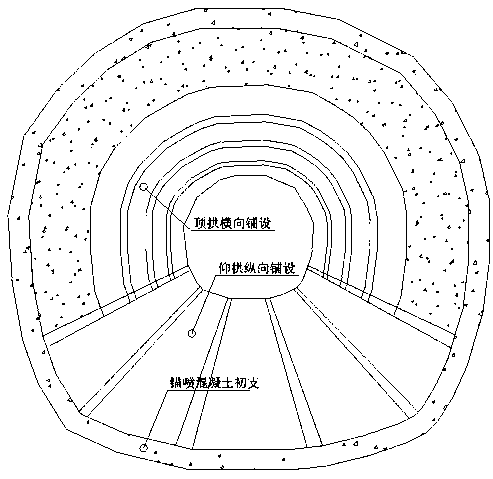

[0019] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0020] The invention provides a method for waterproofing mine tunnels, in which a self-adhesive waterproof board is laid between the primary support and the secondary primary laying;

[0021] The self-adhesive waterproof board is composed of a transparent substrate, a polymer self-adhesive film and a cladding material, wherein the polymer self-adhesive film is bonded to the post-cast concrete;

[0022] The transparent substrate comprises: 5-30 parts by weight polyethylene, 5-30 parts by weight polypropylene, 20-50 parts by weight ethylene-propylene copolymer, and 20-50 parts by weight ethylene-octene copolymer; the transparent The substrate is made by blen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com