Method for producing ethanediol from oxalic ester and hydrogen

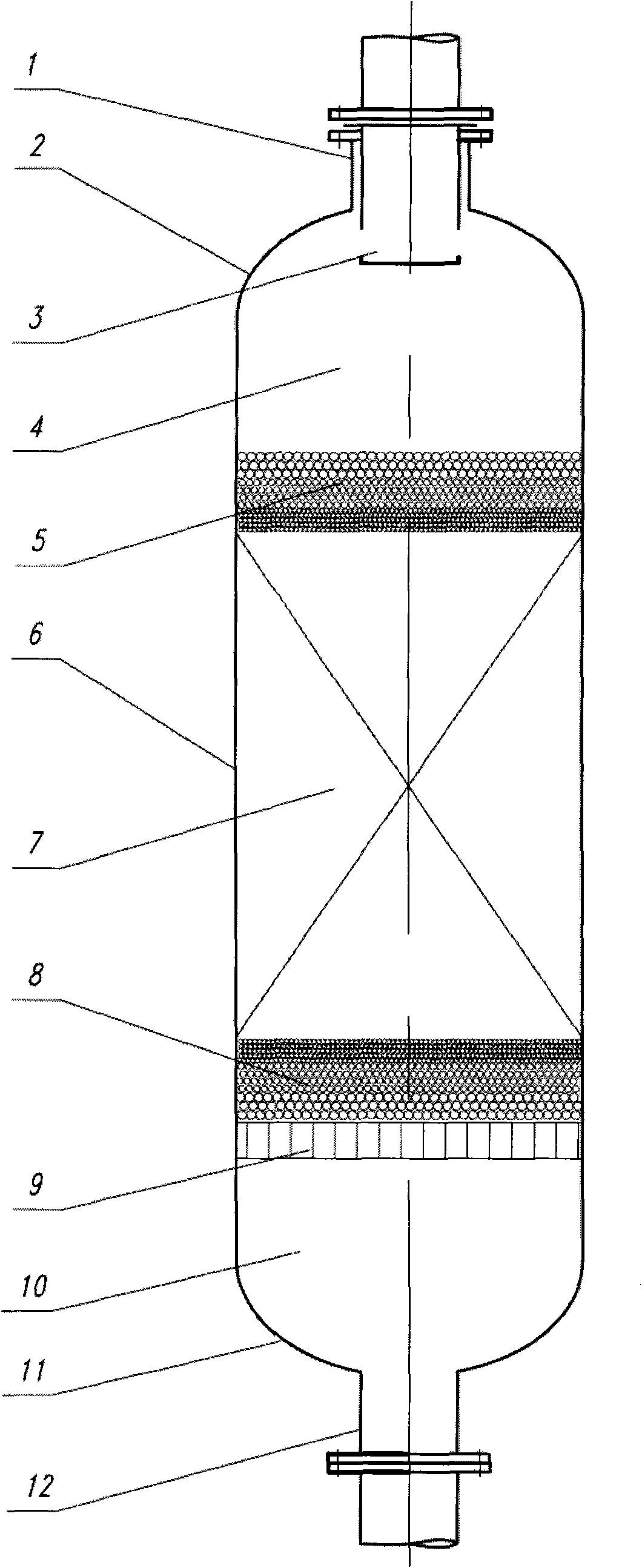

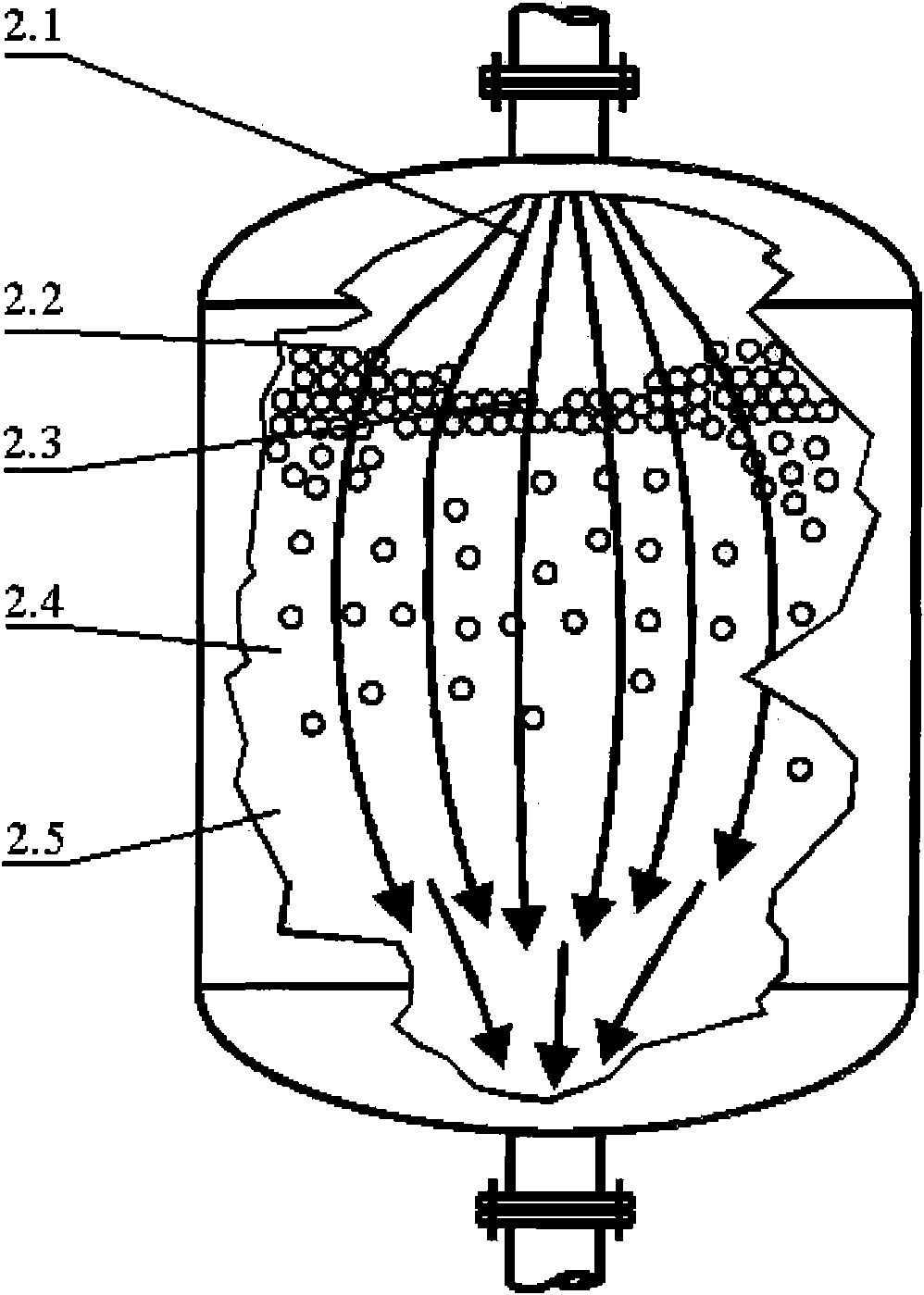

An oxalate and ethylene glycol technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of uneven air distribution, uneven distribution, and backflow, etc., and improve catalyst utilization. , avoid overload and load, eliminate the effect of short circuit and channel current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

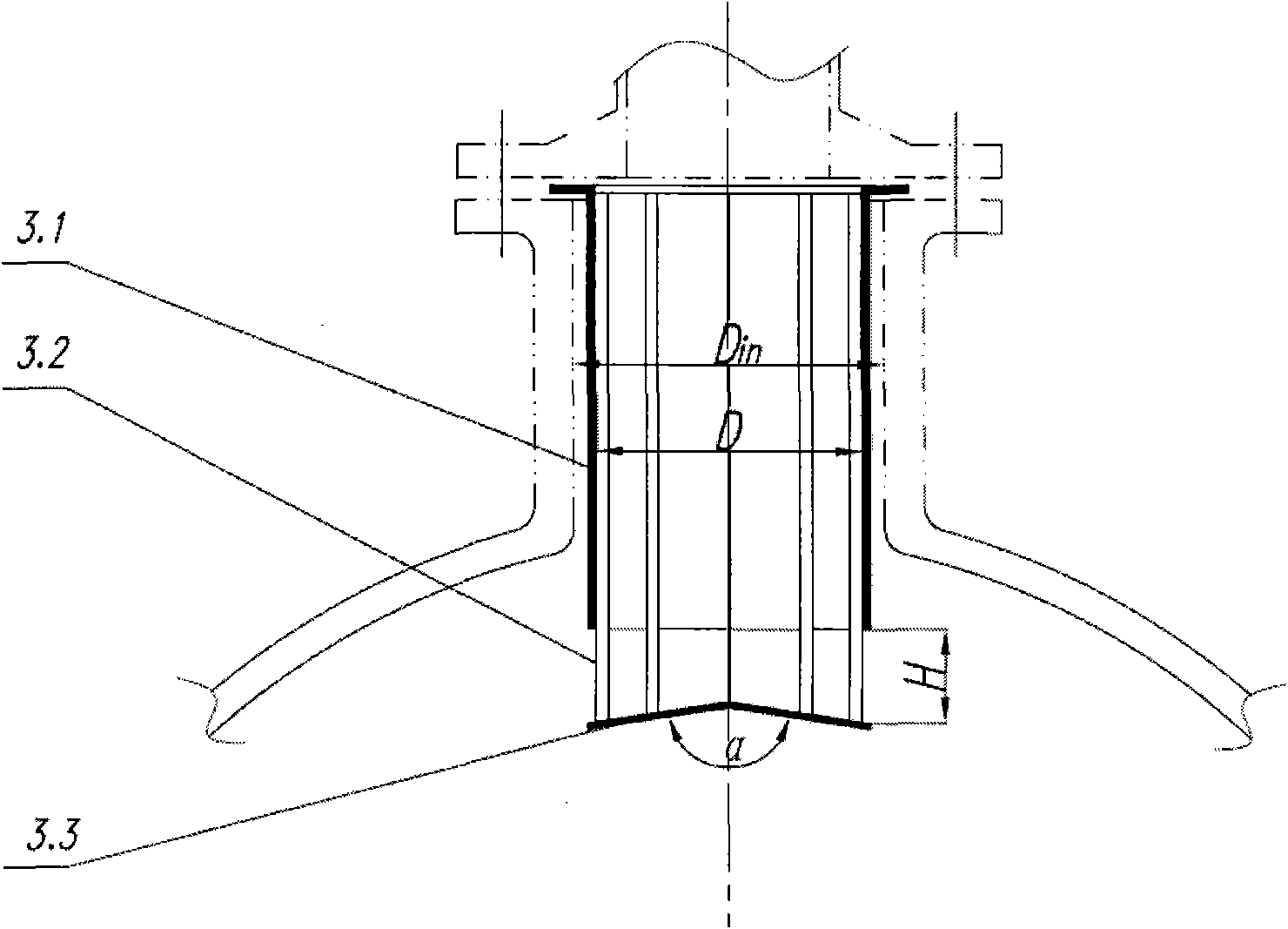

[0028] The inner diameter of the axial flow fixed bed gas-solid catalytic reactor is 2 meters, and the inner diameter of the feed port is D in for 350 mm, using as Figure 4 The two-stage porous baffle type inlet gas predistributor shown above, the upper and lower porous baffles are spherical porous baffles, the distributor cylinder and the porous upper baffle are connected by 4 evenly distributed tie bars, the porous upper baffle The plate and the perforated lower baffle are connected by 4 evenly distributed tie bars. The inner diameter D of the distributor cylinder is 300 mm, the diameter d of the large hole of the porous upper baffle is 150 mm, and the diameter of the circular small hole 5 mm, the opening rate is 30%, the diameter of the circular small hole of the porous lower baffle is 5 mm, the opening rate is 25%, the lateral annular gap height H1 between the distributor cylinder and the porous upper baffle is 130 mm, and the lateral annular gap height H2 between the...

Embodiment 2

[0030] The inner diameter of the axial flow fixed bed gas-solid catalytic reactor is 4 meters, and the inner diameter of the feed port is D in for 700mm, using as Figure 4The two-stage porous baffle type inlet gas predistributor shown above, the upper and lower porous baffles are spherical porous baffles, the distributor cylinder and the porous upper baffle are connected by 8 evenly distributed tie bars, the porous upper baffle The board and the perforated lower baffle are connected by 8 evenly distributed tie bars. The inner diameter D of the distributor cylinder is 660 mm, the diameter d of the large hole of the porous upper baffle is 500 mm, and the diameter of the circular small hole 8 mm, the opening rate is 60%, the circular hole diameter of the porous lower baffle is 8 mm, the opening rate is 50%, the lateral annular gap height H1 between the distributor cylinder and the porous upper baffle is 240 mm, and the lateral annular gap height H2 between the porous upper a...

Embodiment 3

[0032] The inner diameter of the axial flow fixed bed gas-solid catalytic reactor is 3.4 meters, and the inner diameter of the feed port is D in for 600mm, using as Figure 4 The two-stage porous baffle type inlet gas predistributor shown above, the upper and lower porous baffles are spherical porous baffles, the distributor cylinder and the porous upper baffle are connected by 6 evenly distributed tie bars, the porous upper baffle The board and the perforated lower baffle are connected by 6 evenly distributed tie bars. The inner diameter D of the distributor cylinder is 540 mm, the diameter d of the large hole of the porous upper baffle is 360 mm, and the diameter of the circular small hole 6 mm, the opening rate is 40%, the circular hole diameter of the porous lower baffle is 8 mm, the opening rate is 35%, the lateral annular gap height H1 between the distributor cylinder and the porous upper baffle is 180 mm, and the lateral annular gap height H2 between the porous uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com