Rotary shell type nonstop rotating pendulum engine

An engine and rotor technology, which is applied in the field of rotary-shell type non-stop rotary pendulum type engines, can solve the problems of unformed products, low output power and efficiency of micro-energy power system, and achieve obvious advantages of miniaturization and reduced structure. Complex, easy-to-process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

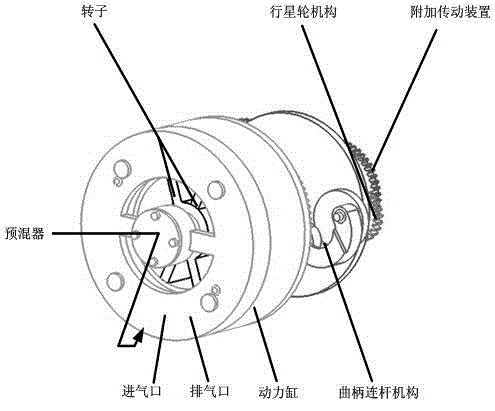

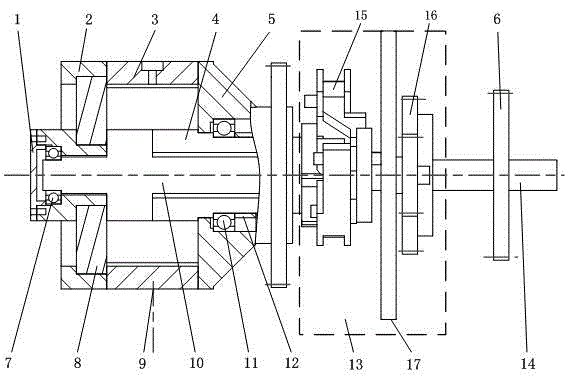

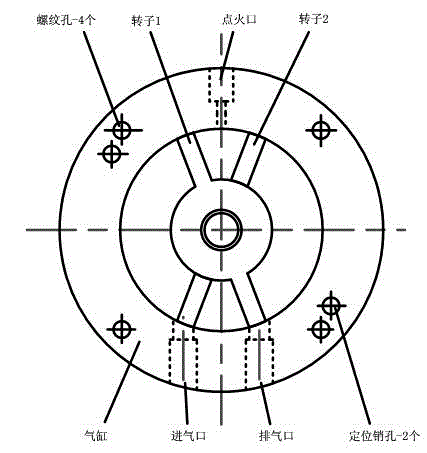

[0042] A prototype of a miniature spiral shell type non-stop rotary pendulum engine. The model uses a self-designed premixer, uses a mixture of butane and propane as fuel, and has a design pressure ratio of 4; a dual rotor has a total of 4 vane pistons, and the thickness of the vane The angle is 10 degrees, the maximum piston angle is 128 degrees, the minimum is 32 degrees, the rotor center radius is 15cm; the power cylinder is divided into 4 independent working chambers, the cylinder body radius is 30cm, the air intake, exhaust, and ignition ports on the cylinder The position is fixed, and the number is one; the planetary gear train is externally meshed, and the radius ratio of the planetary gear and the sun gear is 1:1; the additional transmission device makes the cylinder speed half of the main shaft, and the steering is the same. Calculate the displacement of each working chamber 0.015L, four chambers total 0.06L, from the current internal combustion engine technology level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com