Hybrid wind power generation system

A technology for wind power generation systems and induction generators, applied in wind power generator components, wind power generation, wind power engines, etc., can solve the problems of permanent magnet generators such as loss of magnetism, excessive volume, and large losses, and achieve high reliability, Improved reliability and high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

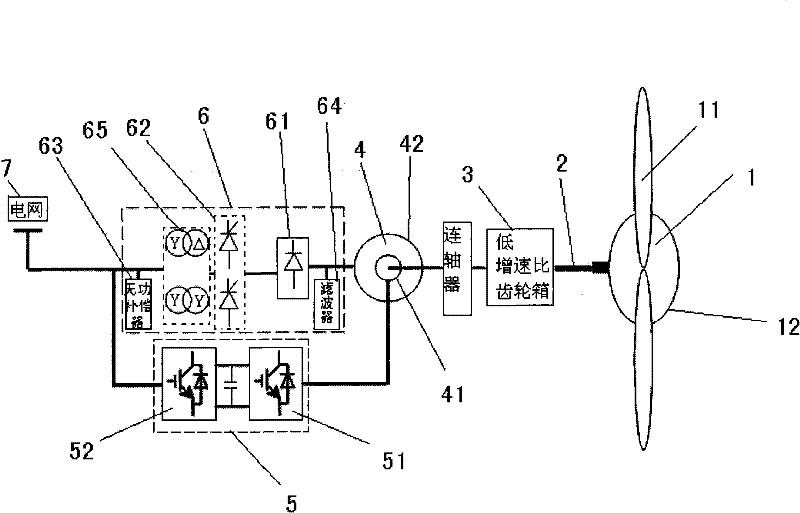

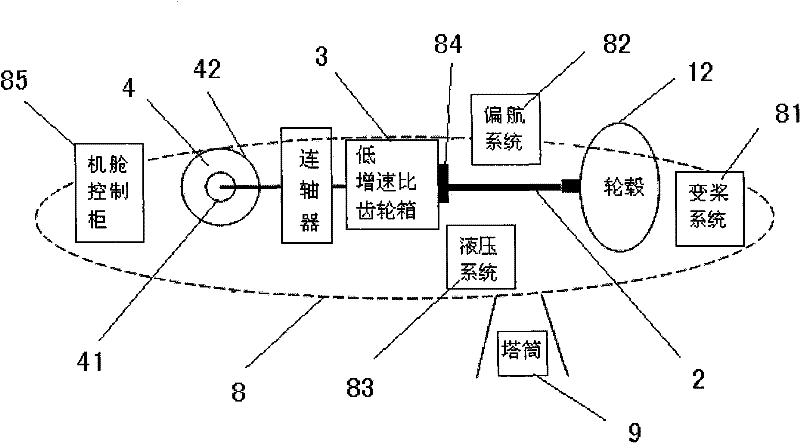

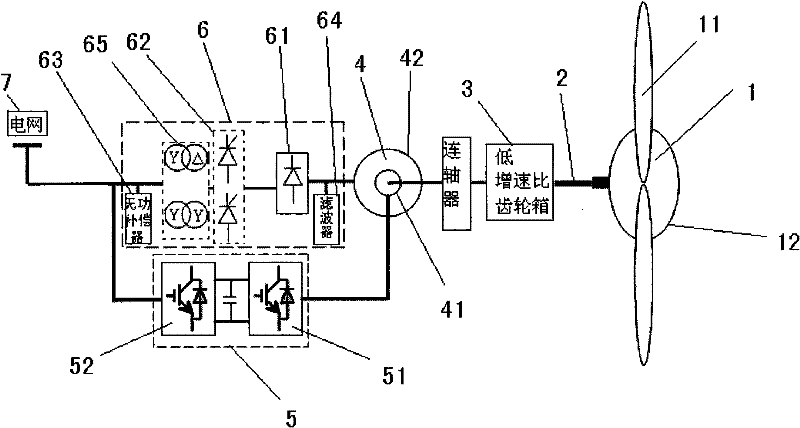

[0019] Such as figure 1 As shown, the present invention includes a wind wheel 1, the wind wheel 1 is connected with a main shaft 2 through a bearing, the main shaft 2 is connected with a low speed-up ratio gear box 3, and the low speed-up speed ratio gear box 3 can be connected at a lower speed through a coupling. The wire-wound doubly-fed induction generator 4 connected under operation, the speed of the wire-wound doubly-fed induction generator 4 is lower than 800 revolutions per minute, and the rotor winding 41 of the wire-wound doubly-fed induction generator 4 operates with four-quadrant operation One end of the converter 5 is connected, the other end of the rotor converter 5 is connected to the grid 7, the stator winding 42 of the wound doubly-fed induction generator 4 is connected to one end of the stator AC-DC converter 6, and the stator AC-DC c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com