Patents

Literature

70results about How to "Stable and efficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

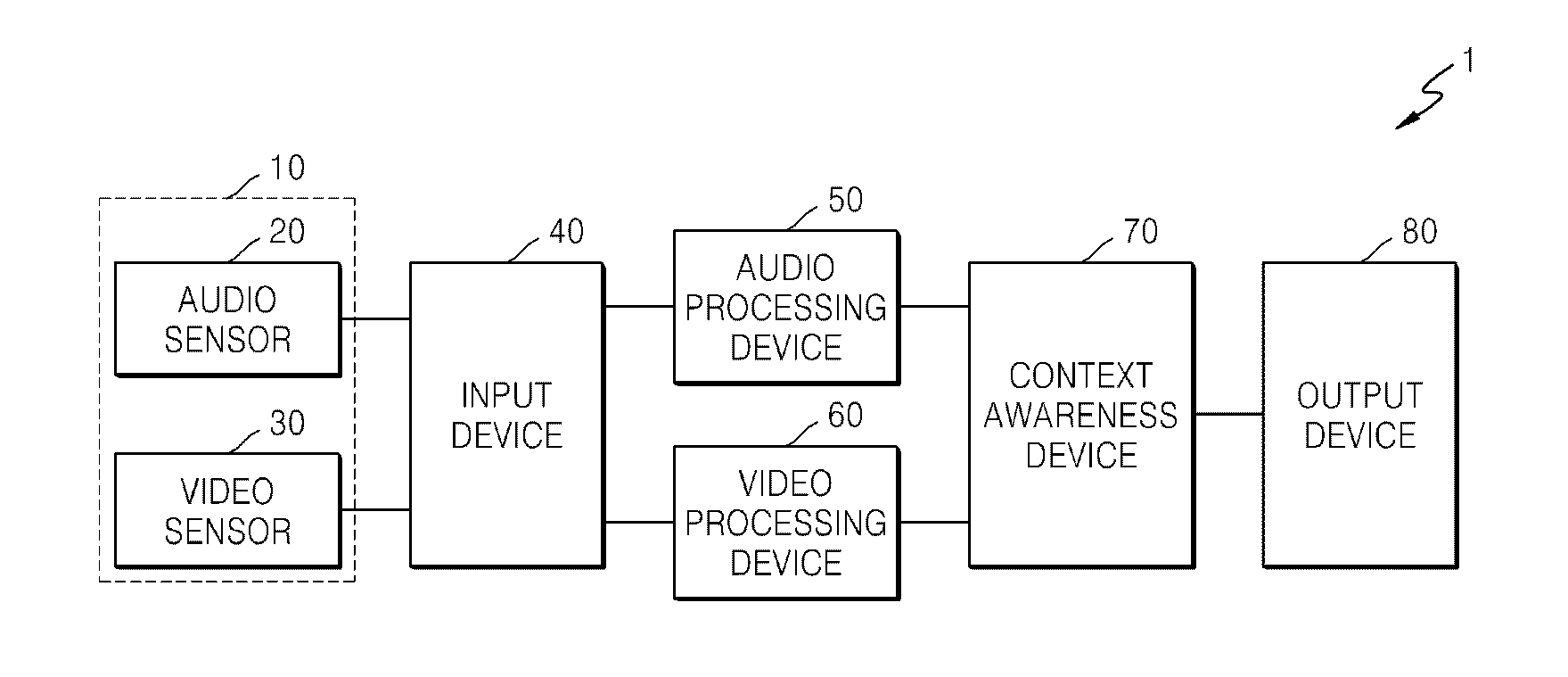

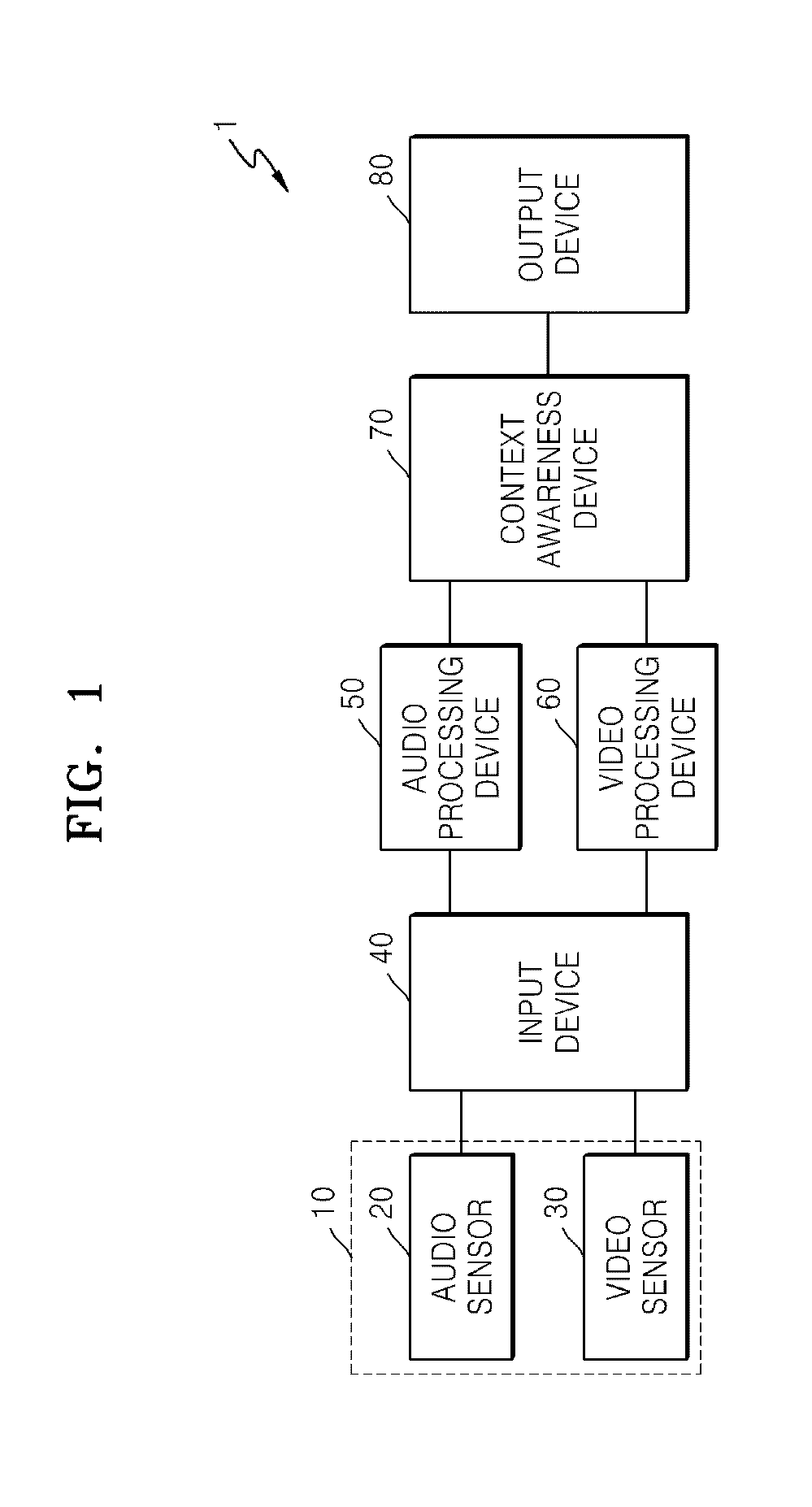

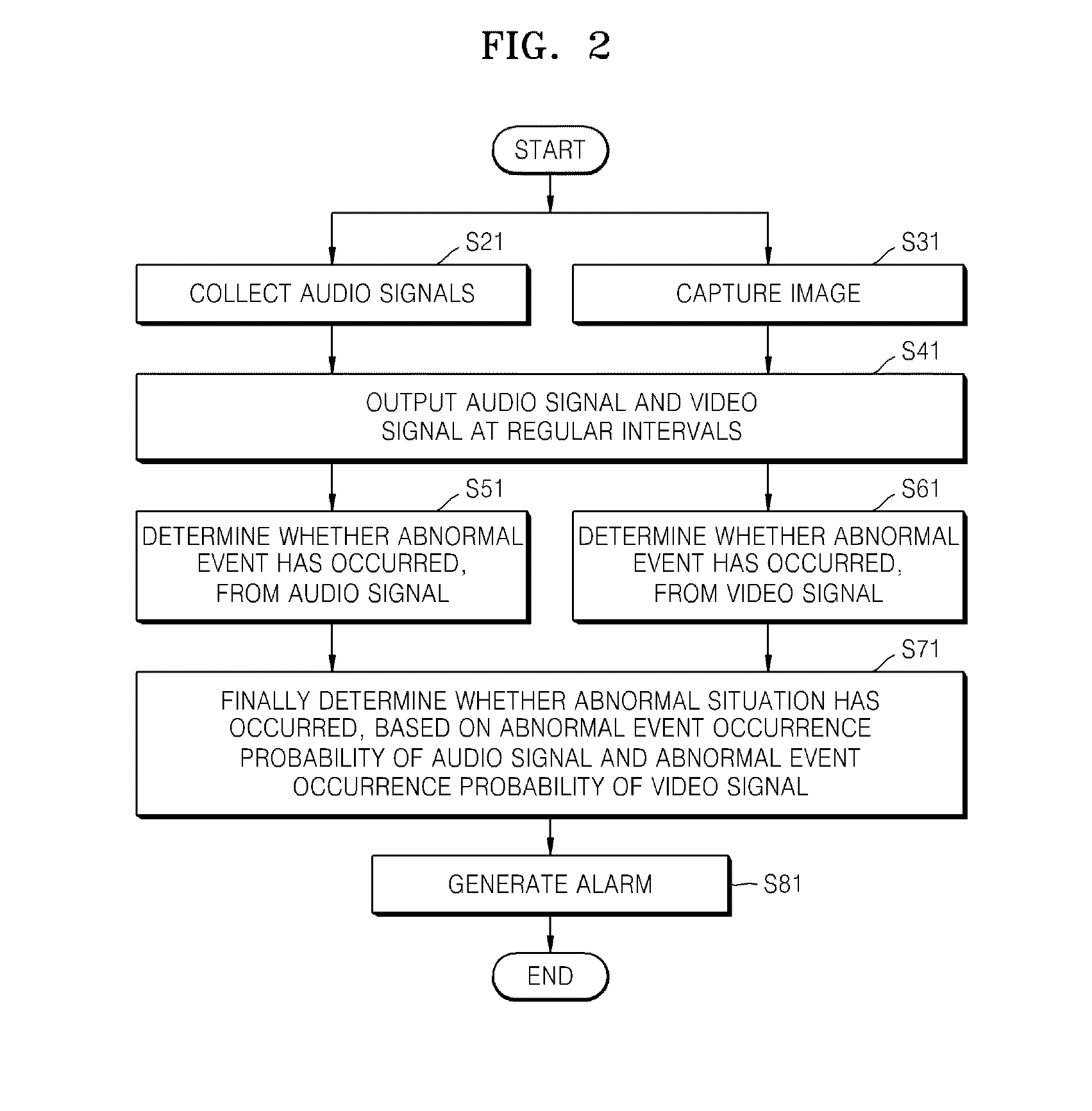

Indoor surveillance system and indoor surveillance method

ActiveUS20140055610A1Stable and efficientReliably determinedImage enhancementImage analysisSurveillance MethodsAudio signal

A surveillance system and method are provided. The surveillance system includes an audio processing device which extracts an audio feature of an audio signal, and determines whether an abnormal event has occurred in a monitoring region, based on the audio feature; a video processing device which extracts a foreground region from a video signal, and determines whether an abnormal event has occurred in the monitoring region, based on motion information of the foreground region; and a context awareness device which calculates an audio abnormal probability and a video abnormal probability by respectively accumulating results of abnormal event occurrence / non-occurrence determinations performed on audio signals and results of abnormal event occurrence / non-occurrence determinations performed on video signals for a certain period of time, and finally determines whether an abnormal situation has occurred in the monitoring region, by using respective combined probability distribution models for a normal situation and the abnormal situation.

Owner:HANWHA TECHWIN CO LTD +1

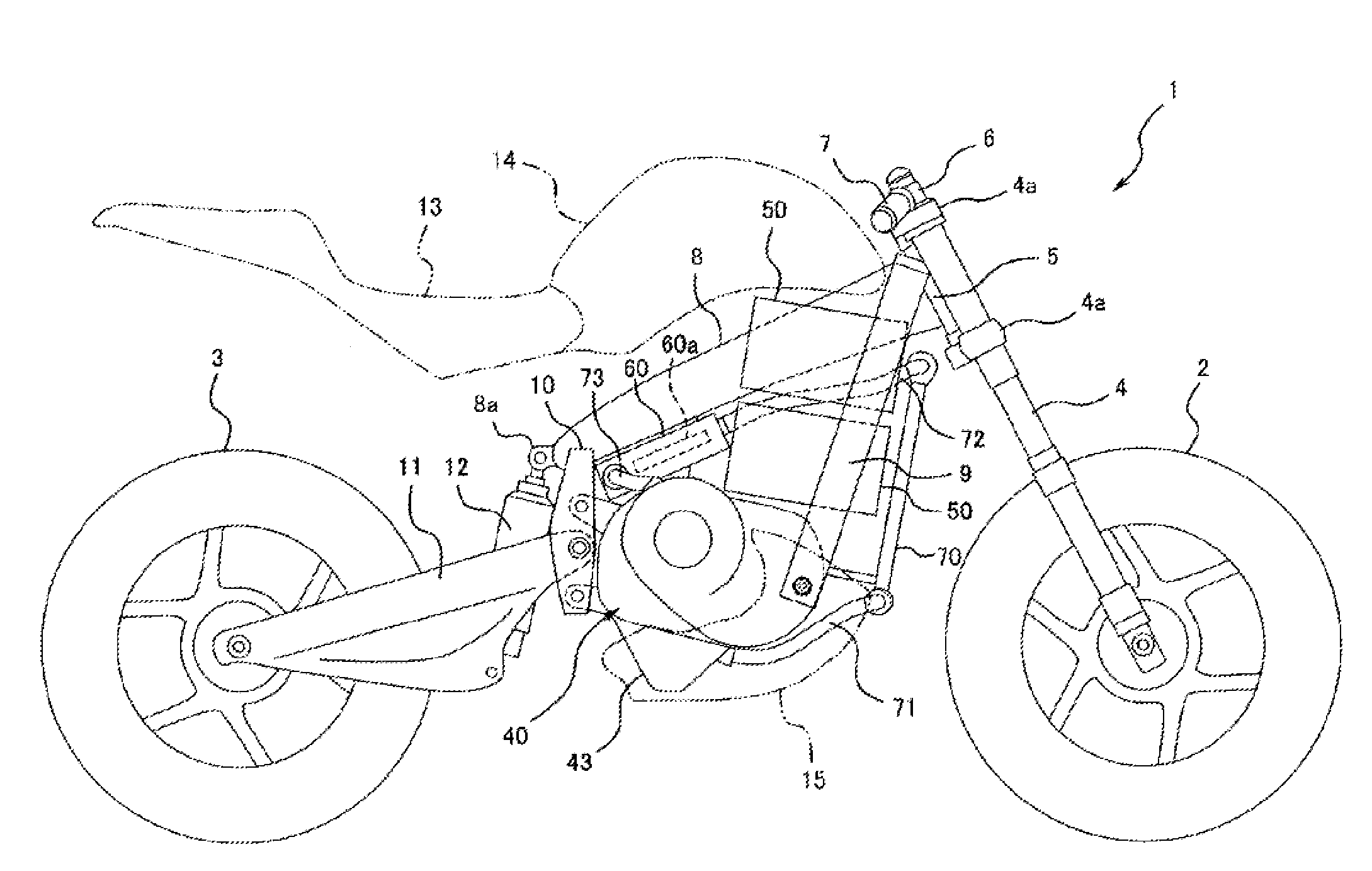

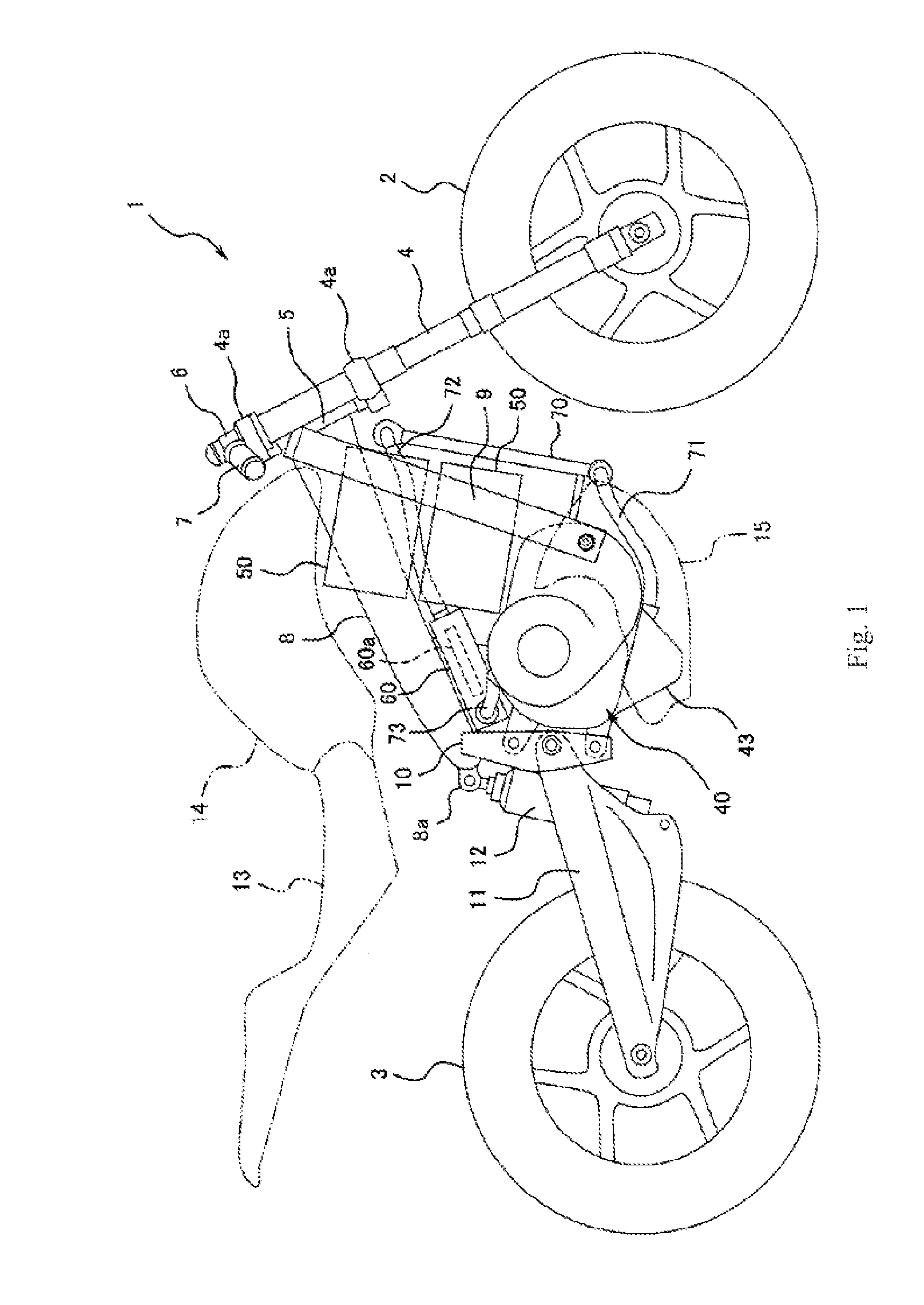

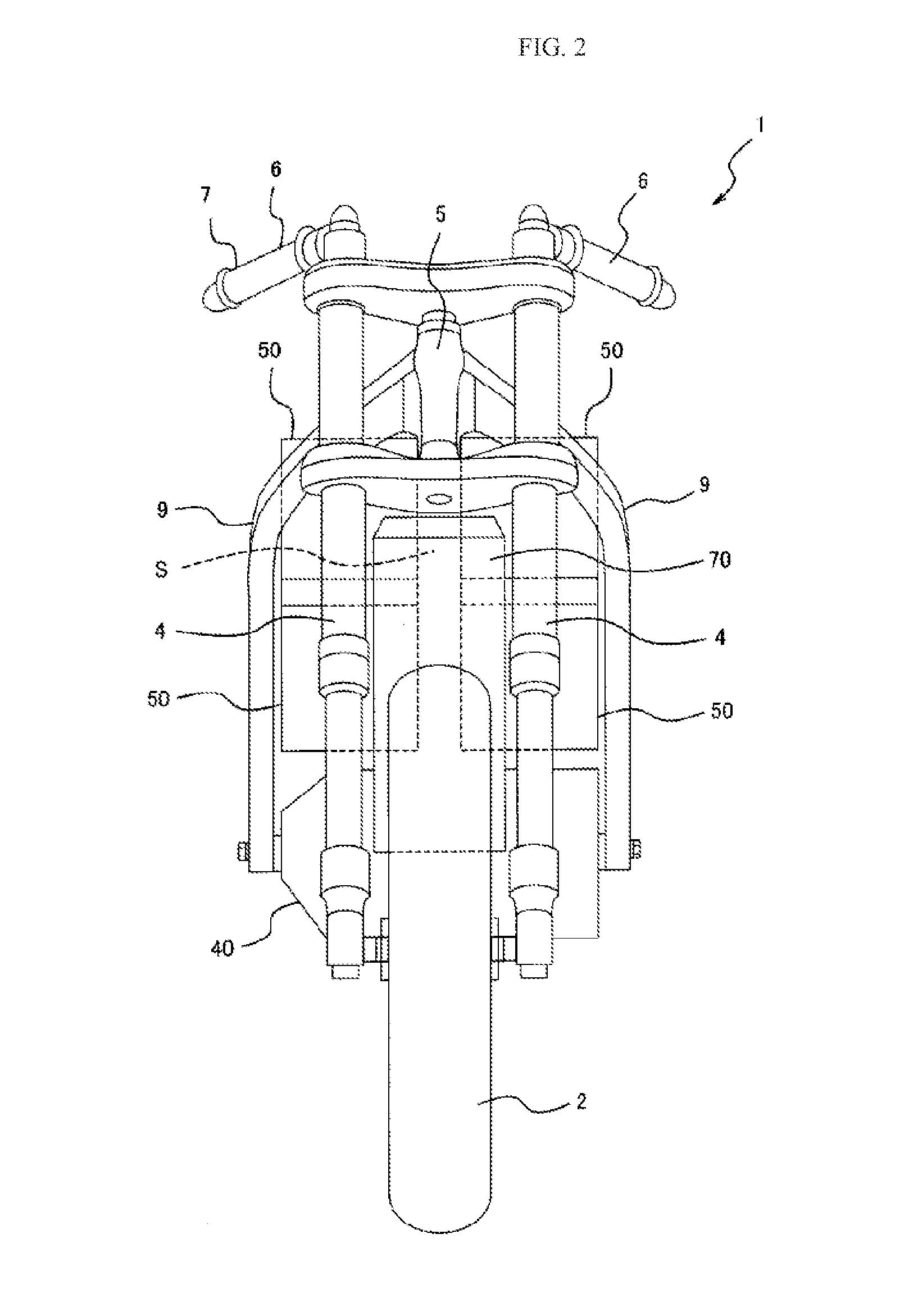

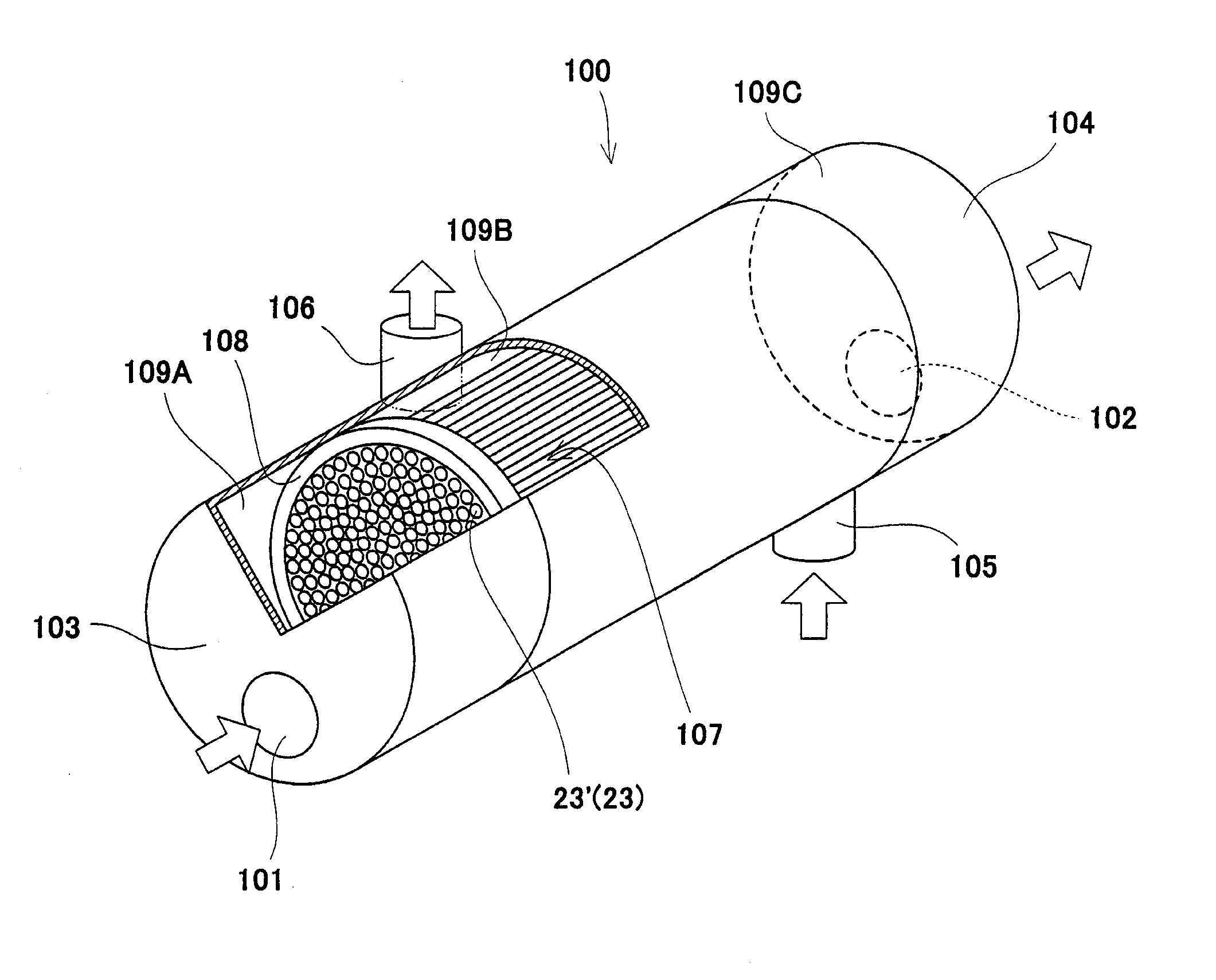

Cooling Structure for Cooling Electric Motor for Vehicle

InactiveUS20130229072A1Simplify structureStable and efficientCycle equipmentsElectric machinesStatorCoolant

Owner:KAWASAKI HEAVY IND LTD

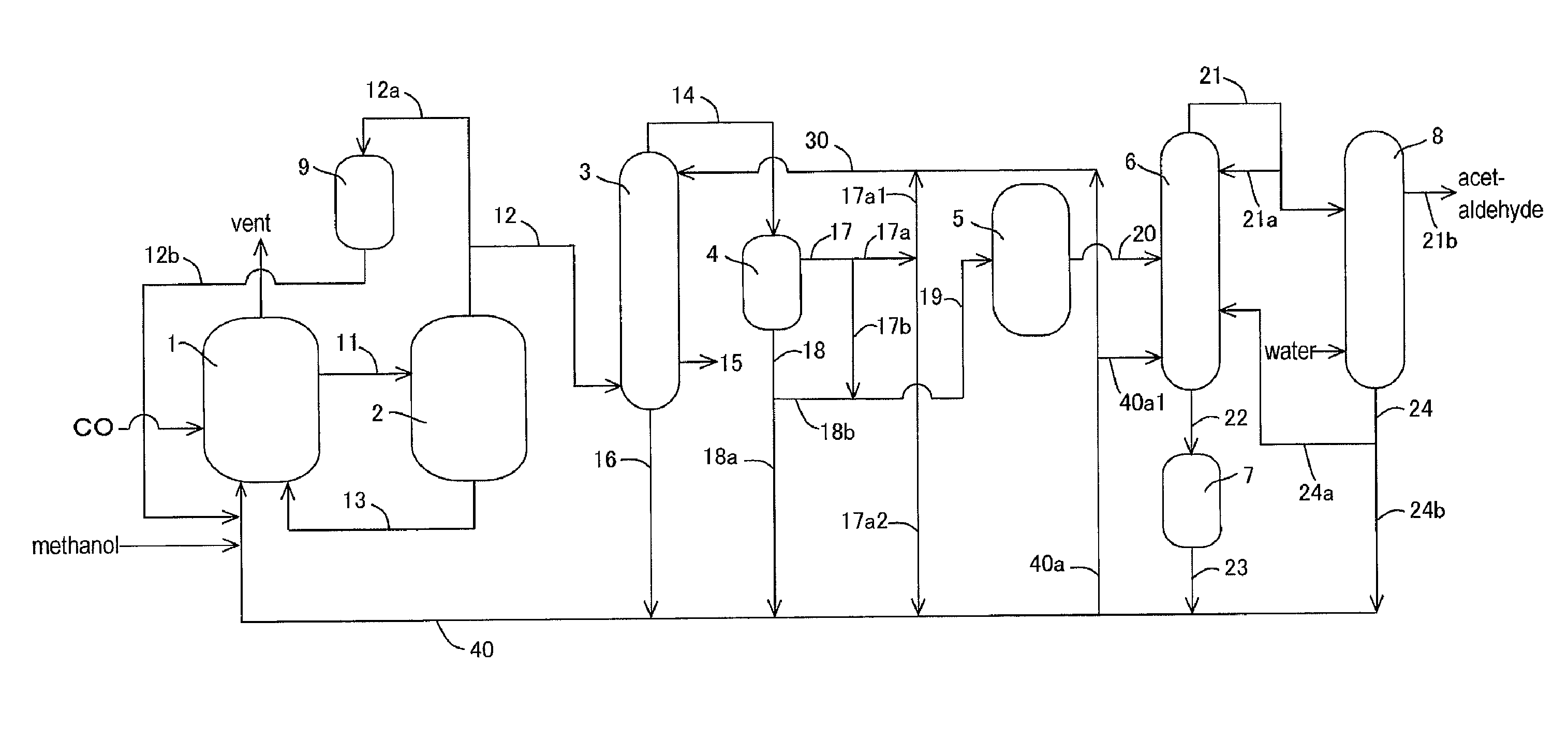

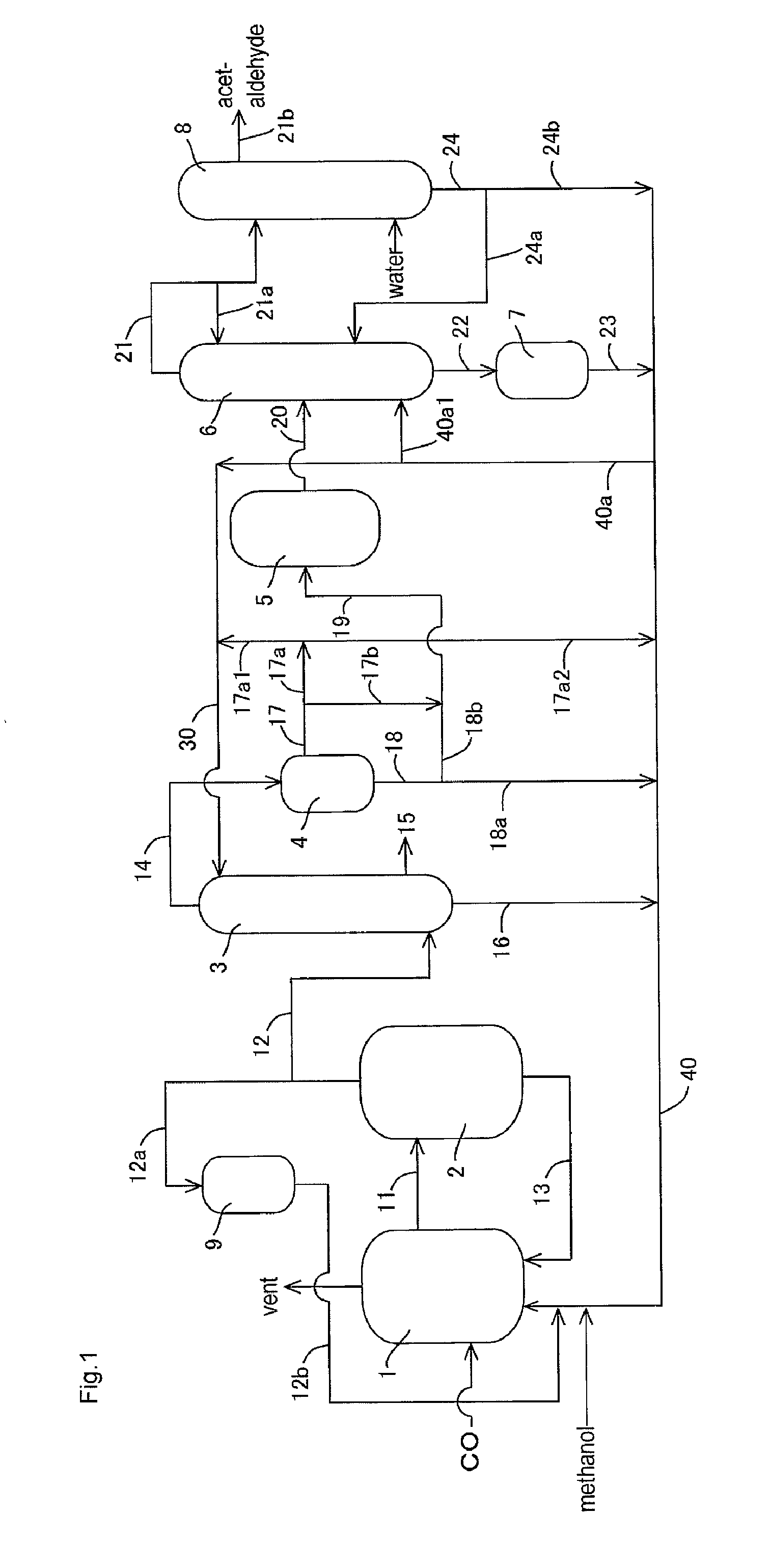

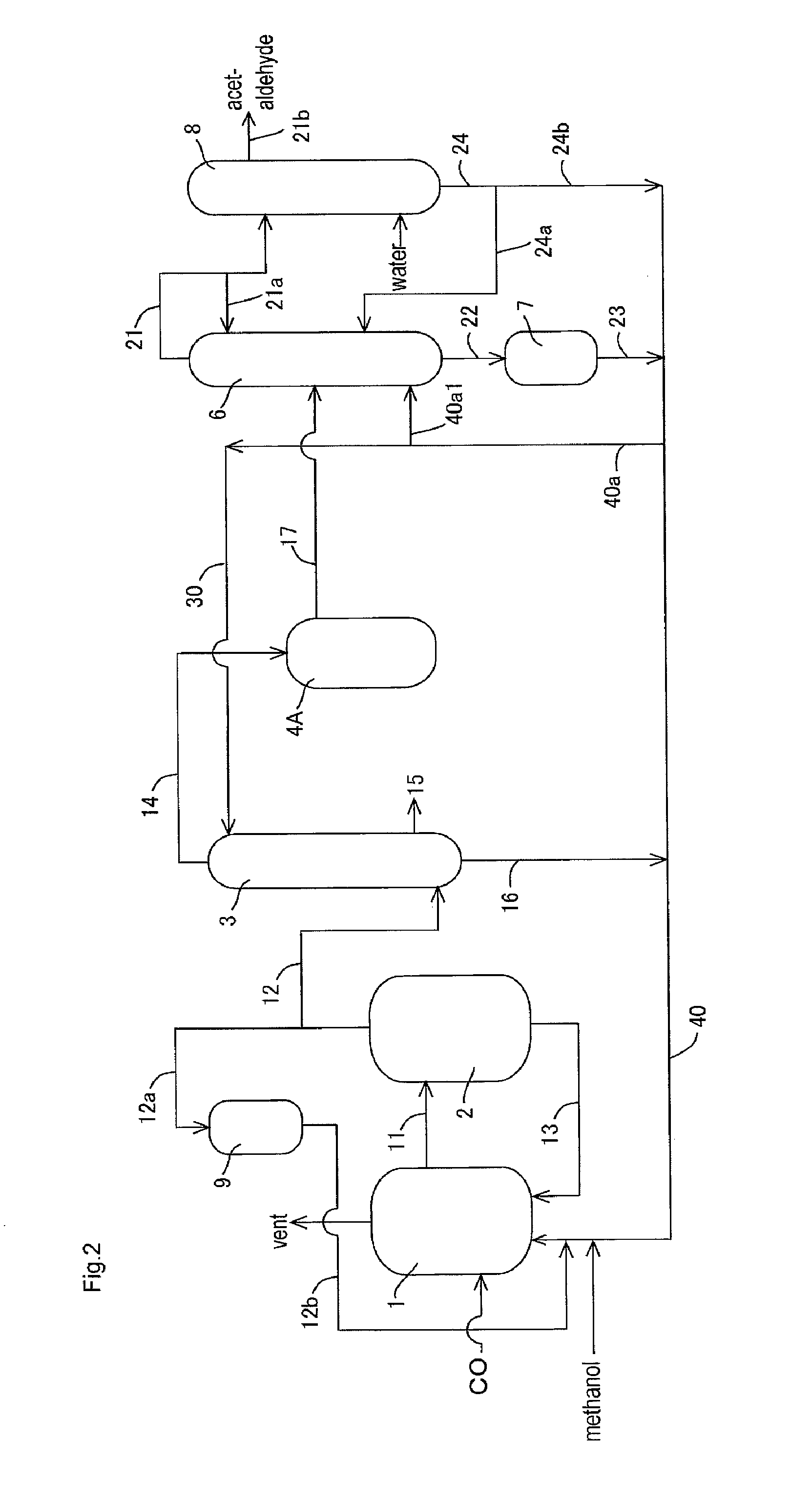

Process for producing acetic acid

ActiveUS20130303800A1Stable productionEfficient removalOrganic compound preparationCarboxylic preparation from carbon monoxide reactionPtru catalystDistillation

A process for stably producing high-purity acetic acid while efficiently removing acetaldehyde is provided.The process for producing acetic acid comprises a reaction step for allowing methanol to react with carbon monoxide in the presence of a metal catalyst, a halide salt, and methyl iodide; a step for continuously feeding a flasher with the reaction mixture and separating a lower boiling point component (2A) containing acetic acid and methyl iodide and a higher boiling point component (2B) containing the metal catalyst and the halide salt; a step for feeding a distillation column with the lower boiling point component (2A), and separating a lower boiling point component (3A) containing methyl iodide and acetaldehyde and a stream (3B) containing acetic acid to collect acetic acid; a condensation step for condensing and temporarily holding the lower boiling point component (3A) in a decanter and discharging the lower boiling point component (3A) from the decanter; and a step for separating the lower boiling point component (3A) discharged from the decanter into acetaldehyde and a liquid residue and recycling the liquid residue to the reaction system. In the condensation step, the amount of the lower boiling point component (3A) to be held is controlled based on a fluctuating flow rate of the lower boiling point component (3A) to be fed to the decanter.

Owner:DAICEL CHEM IND LTD

Method for ultra-fast controlling of a magnetic cell and related devices

InactiveUS20070183190A1Stable and efficientIncrease dampingNanomagnetismOne-port networksResonatorAcoustic wave

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

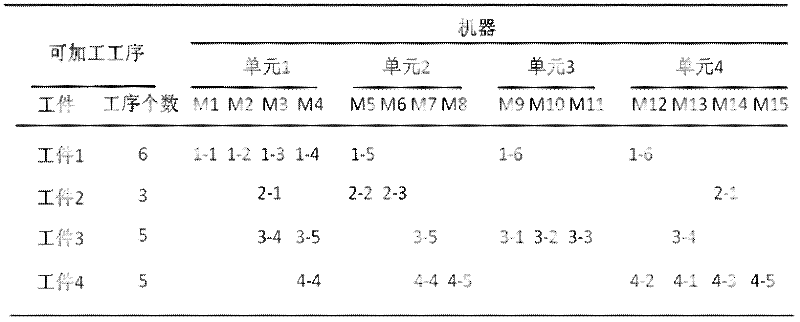

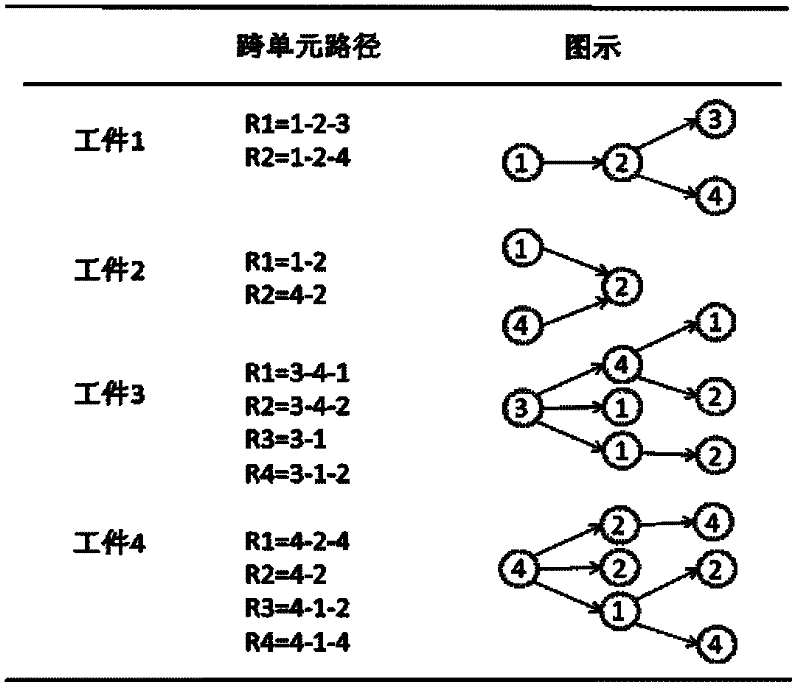

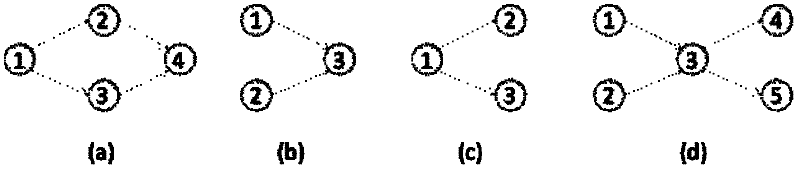

Cross-operation-unit control method under flexible path

InactiveCN102385364AImprove performanceStable and efficientTotal factory controlProgramme total factory controlCompletion timeFlexible path

The invention relates to a cross-unit control method under a flexible path, which comprises the following steps: firstly, defining a set of signals for describing cross-unit control problems under the flexible paths; secondly, establishing a multi-agent negotiation model and defining four basic roles including a workpiece agent, a machine agent, a unit agent and a management agent, wherein the four agents allow free negotiation and interaction for solving complicated problems in coordination; and thirdly, the multiple agents negotiate with each other to accomplish cross-unit control. Overall situation is focused, performance indexes including the maximum completion time, average delay, the number of delayed workpieces, average cross-unit times are improved, and complexity of a dynamic negotiation mechanism is lowered.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

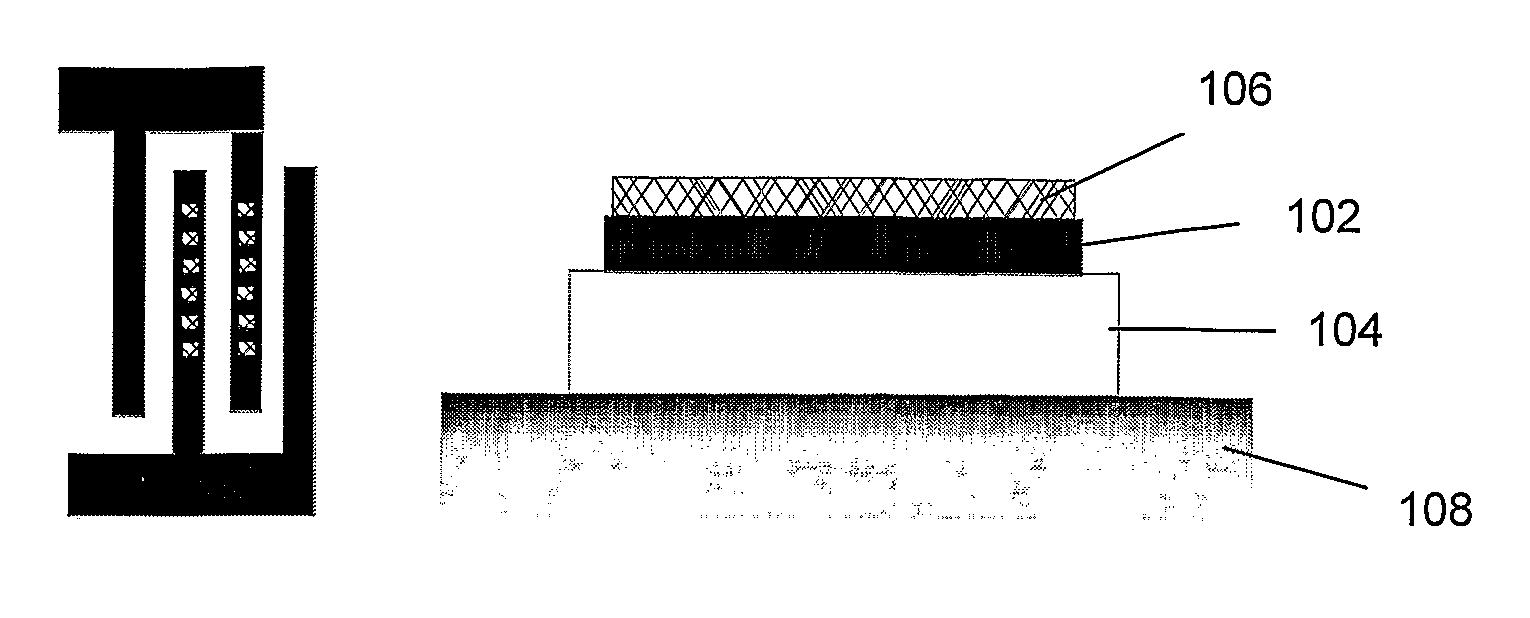

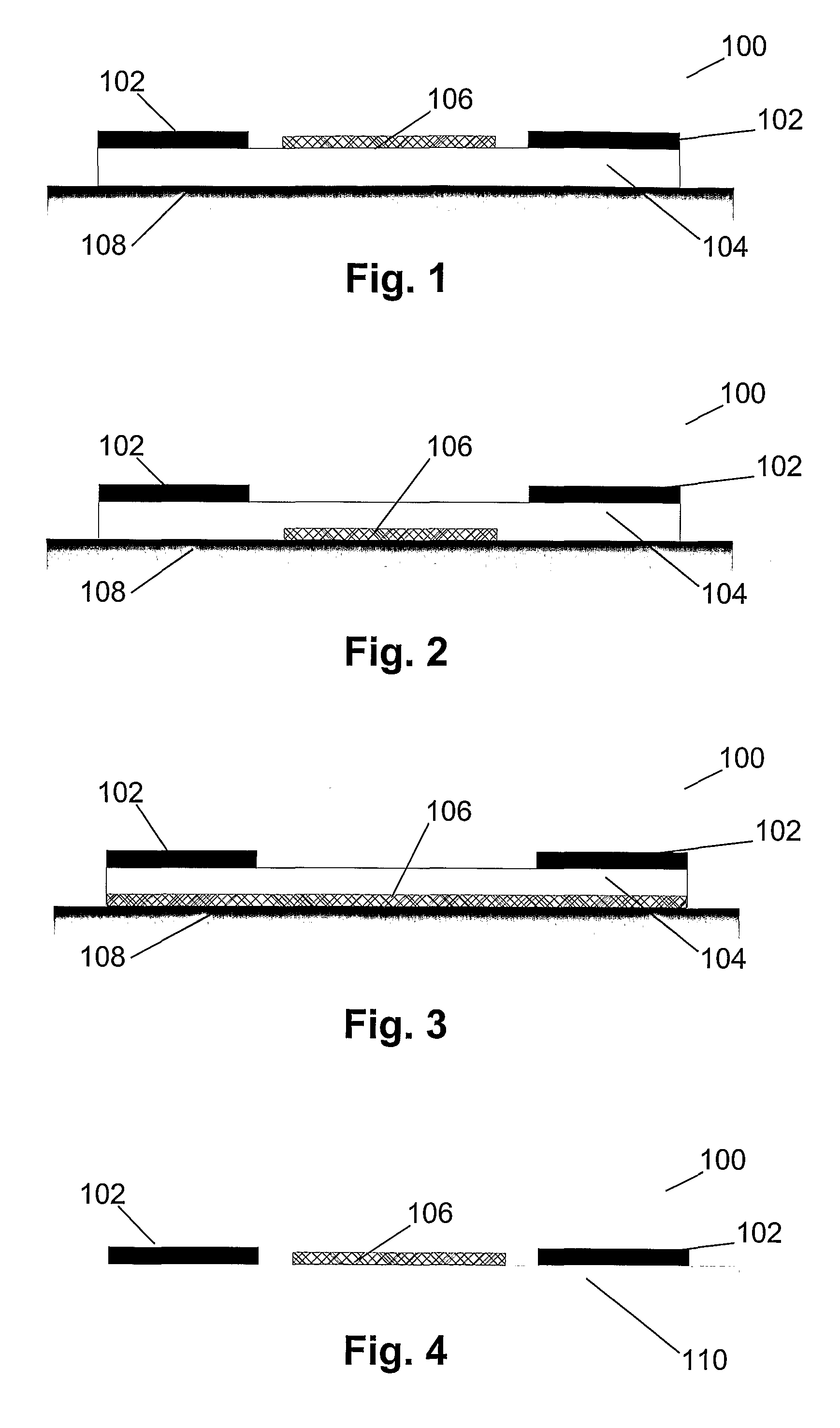

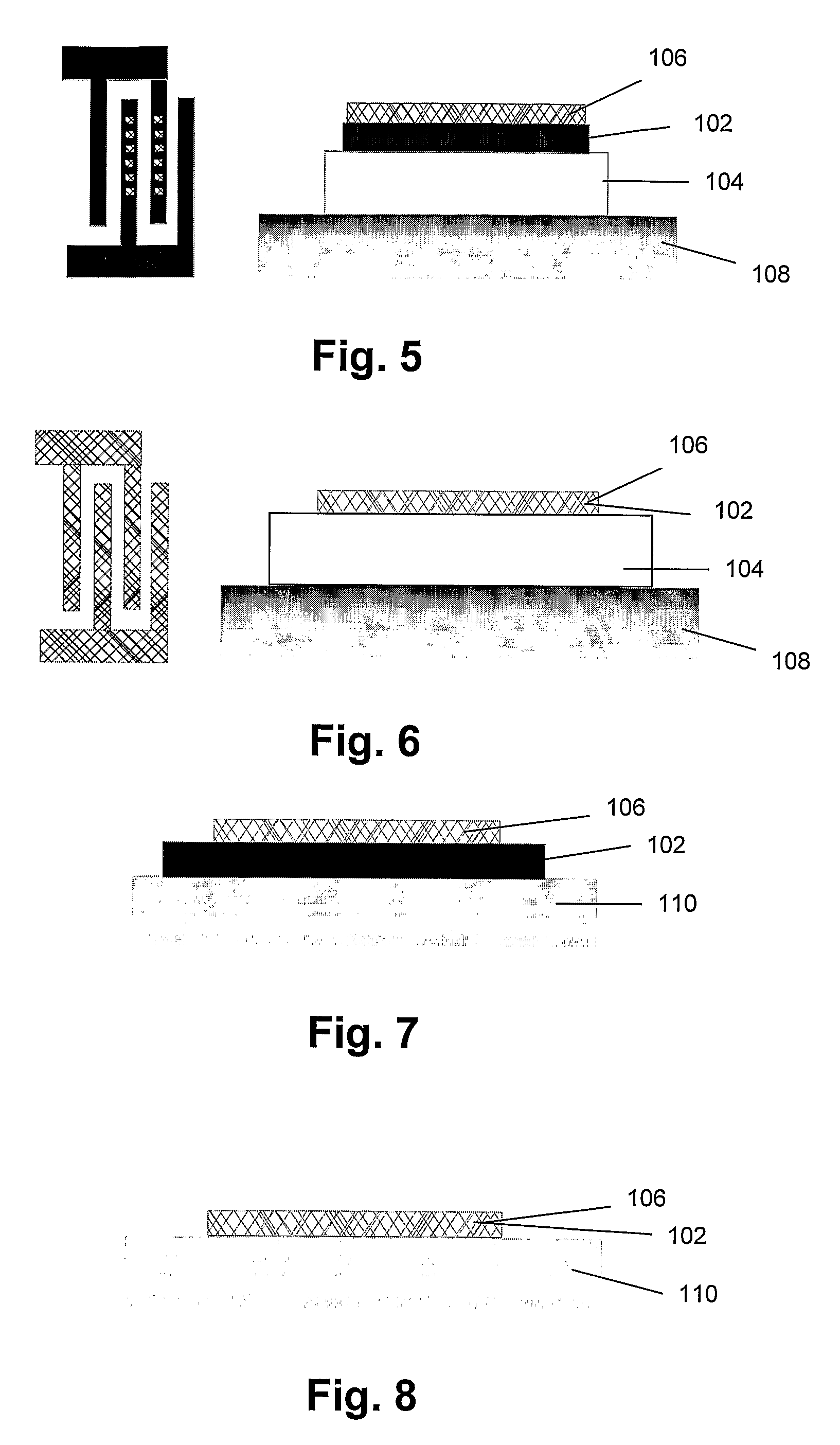

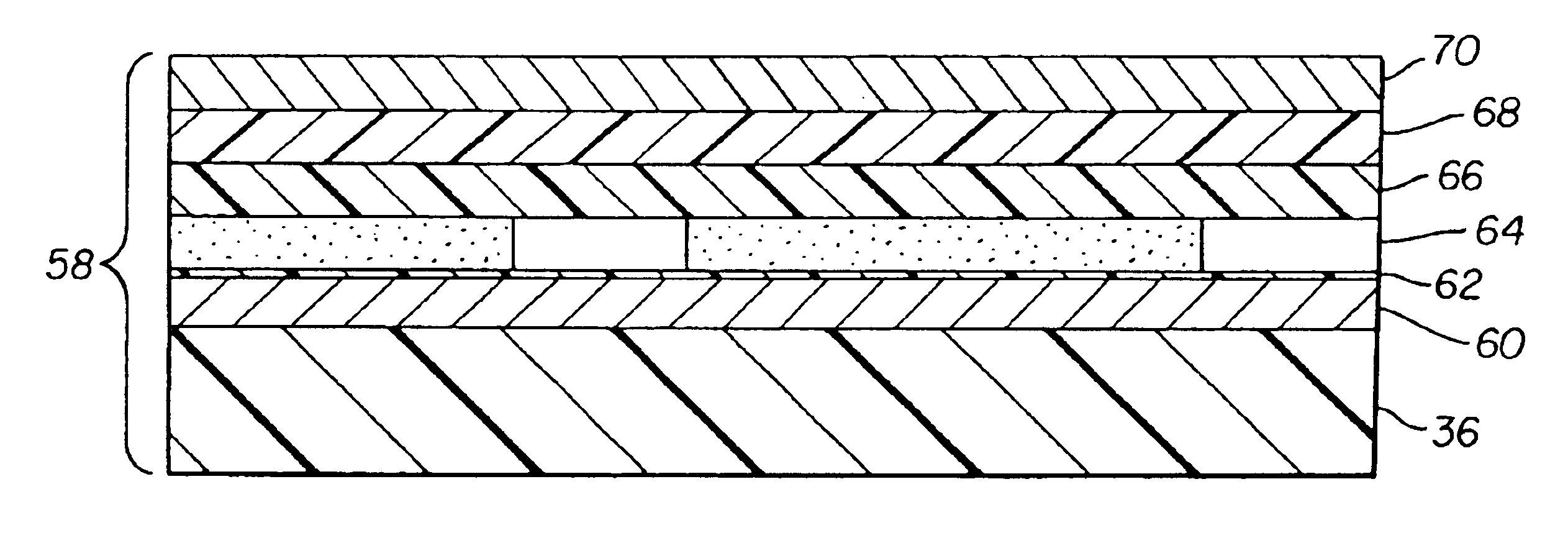

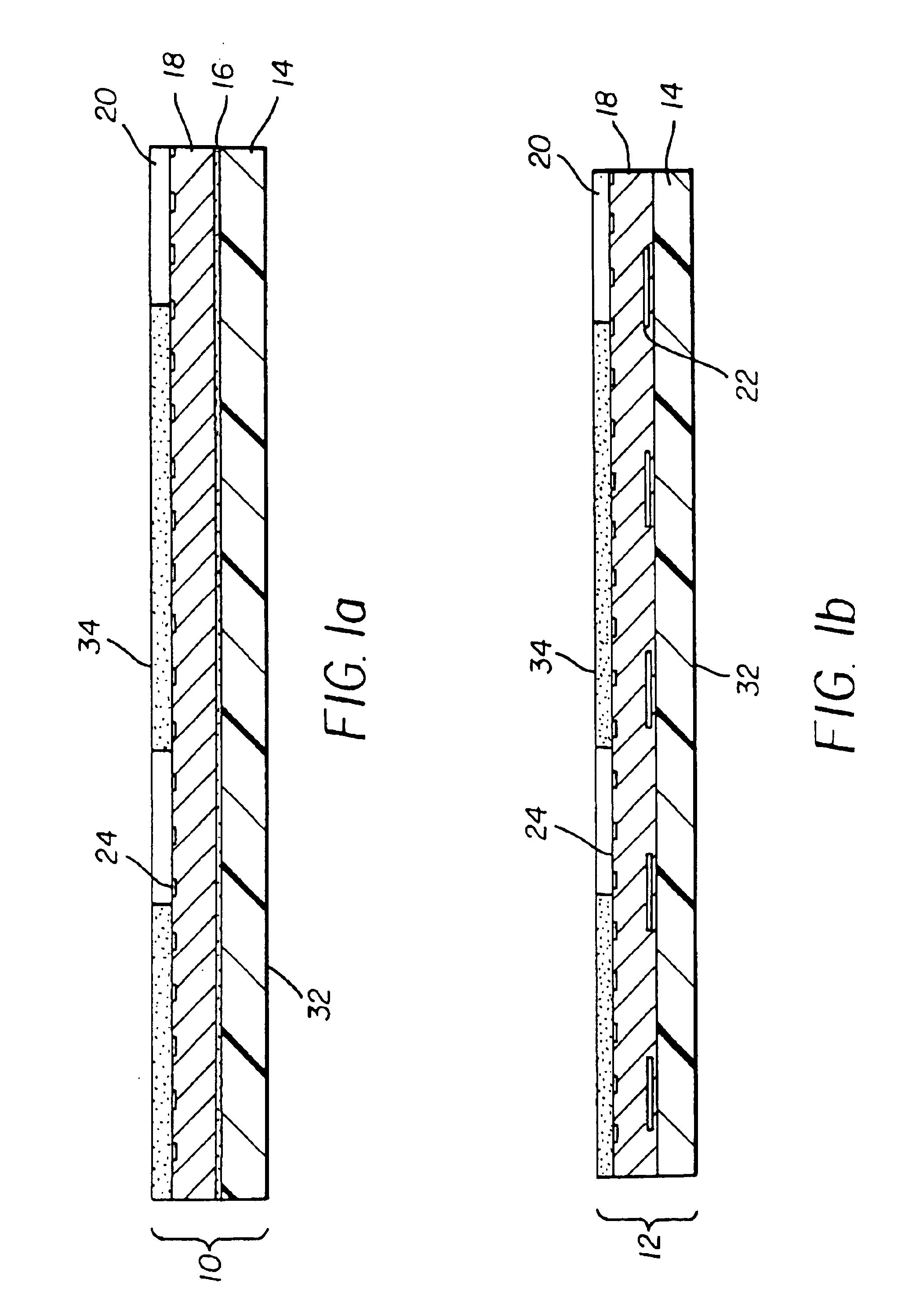

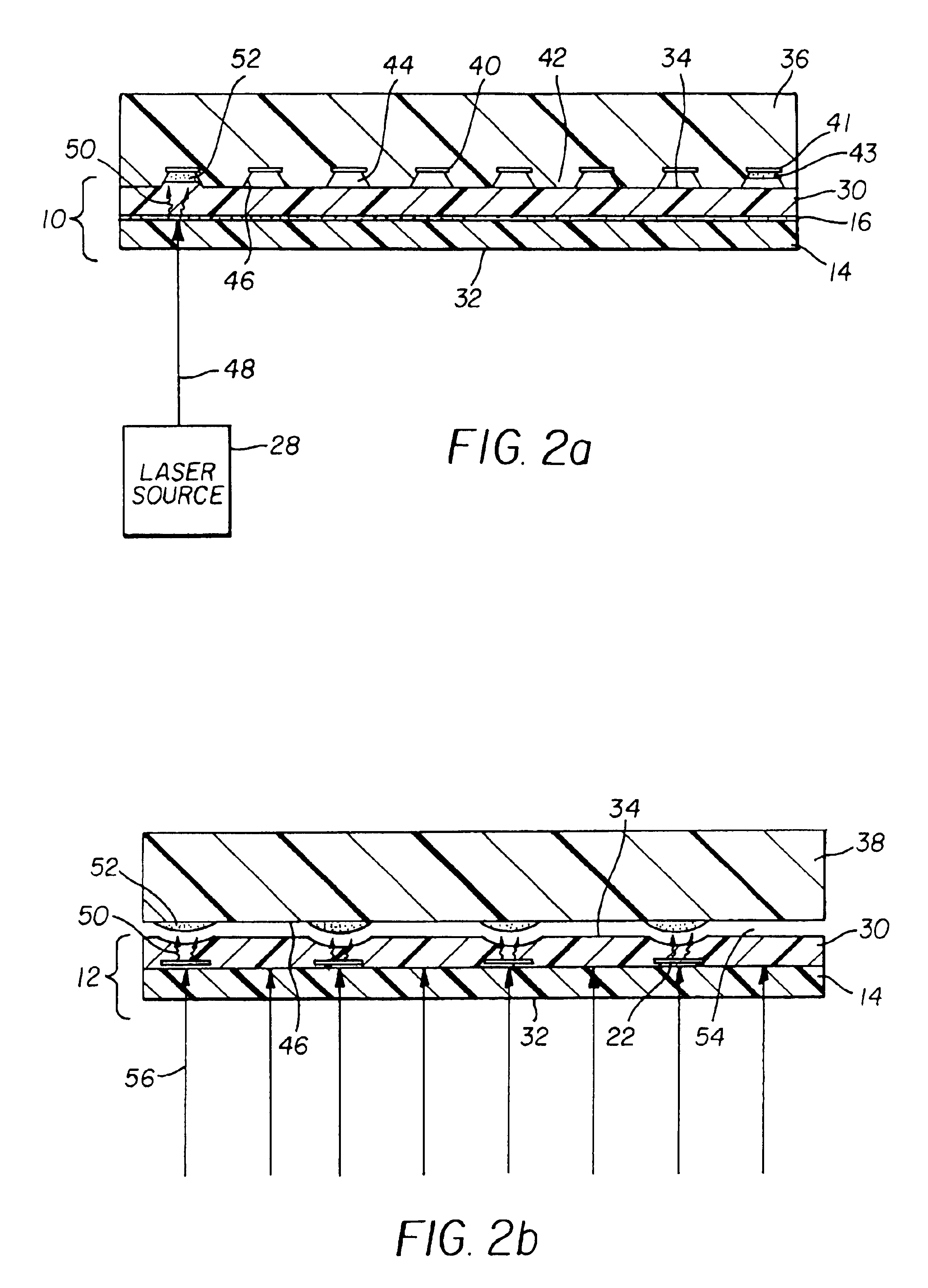

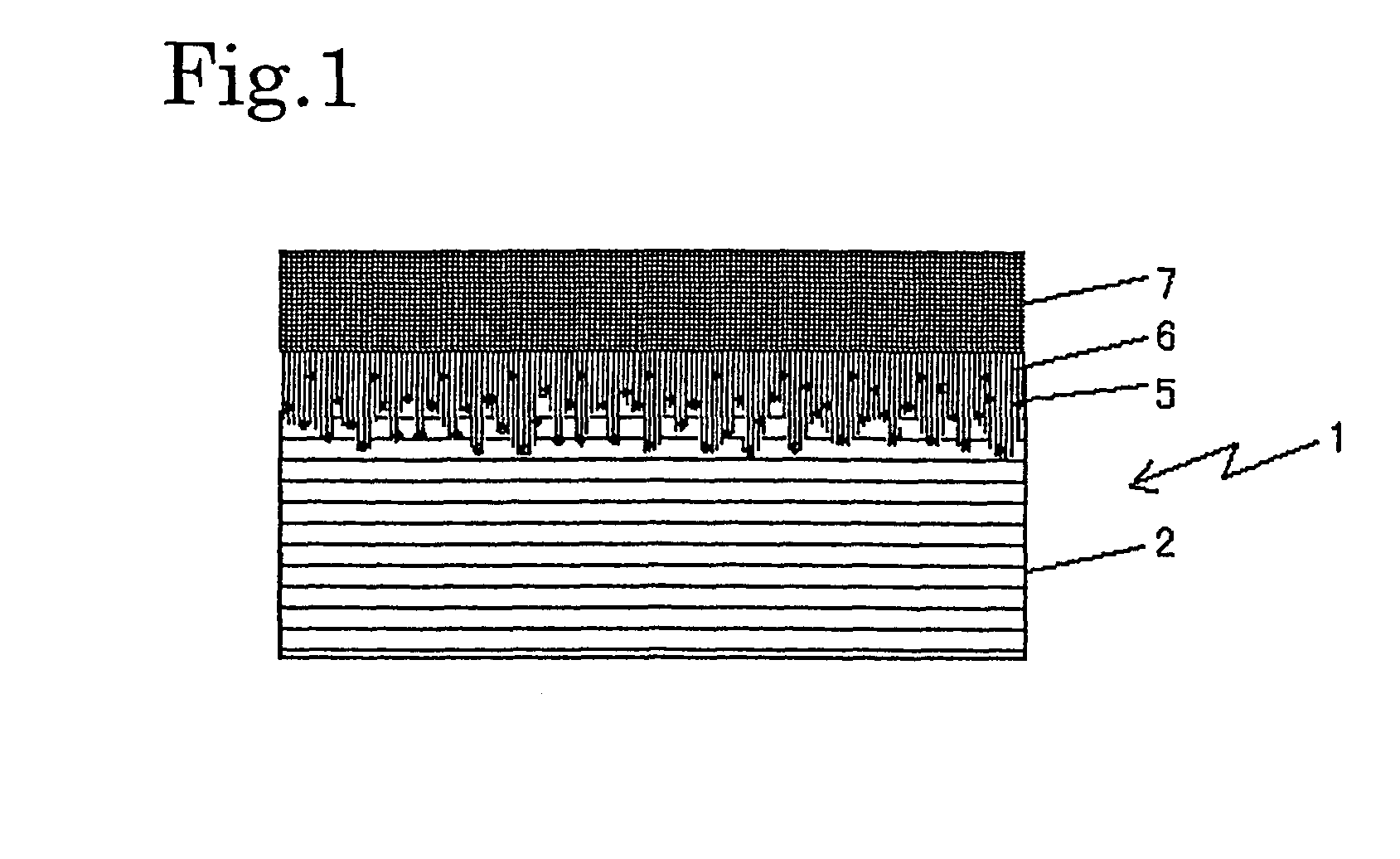

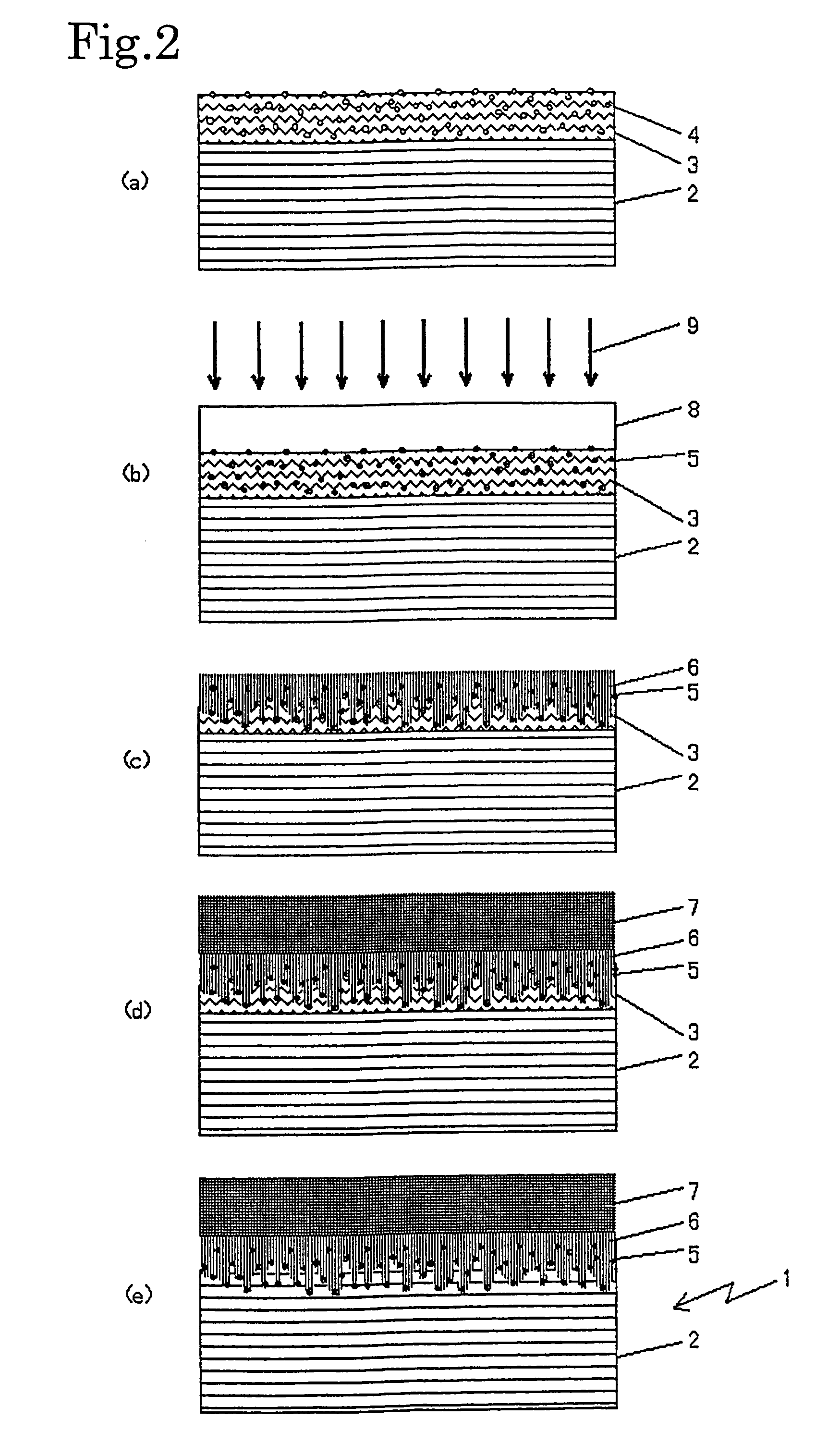

Laser thermal transfer from a donor element containing a hole-transporting layer

InactiveUS6890627B2Stable and efficientCathode ray/electron stream lampsElectric lighting sourcesEngineeringVaporization

A donor element adapted for use in making an OLED device, includes a donor support substrate; a light-absorbing layer disposed over the substrate which, in response to light, produces heat; an emissive layer disposed over the light-absorbing layer; and a hole-transporting layer disposed over the emissive layer such that when the donor element is positioned in a transfer relationship with the OLED device and when light is absorbed by the light-absorbing layer, heat is produced that causes the vaporization transfer across a gap, of hole-transporting materials and emissive materials to the OLED device.

Owner:GLOBAL OLED TECH

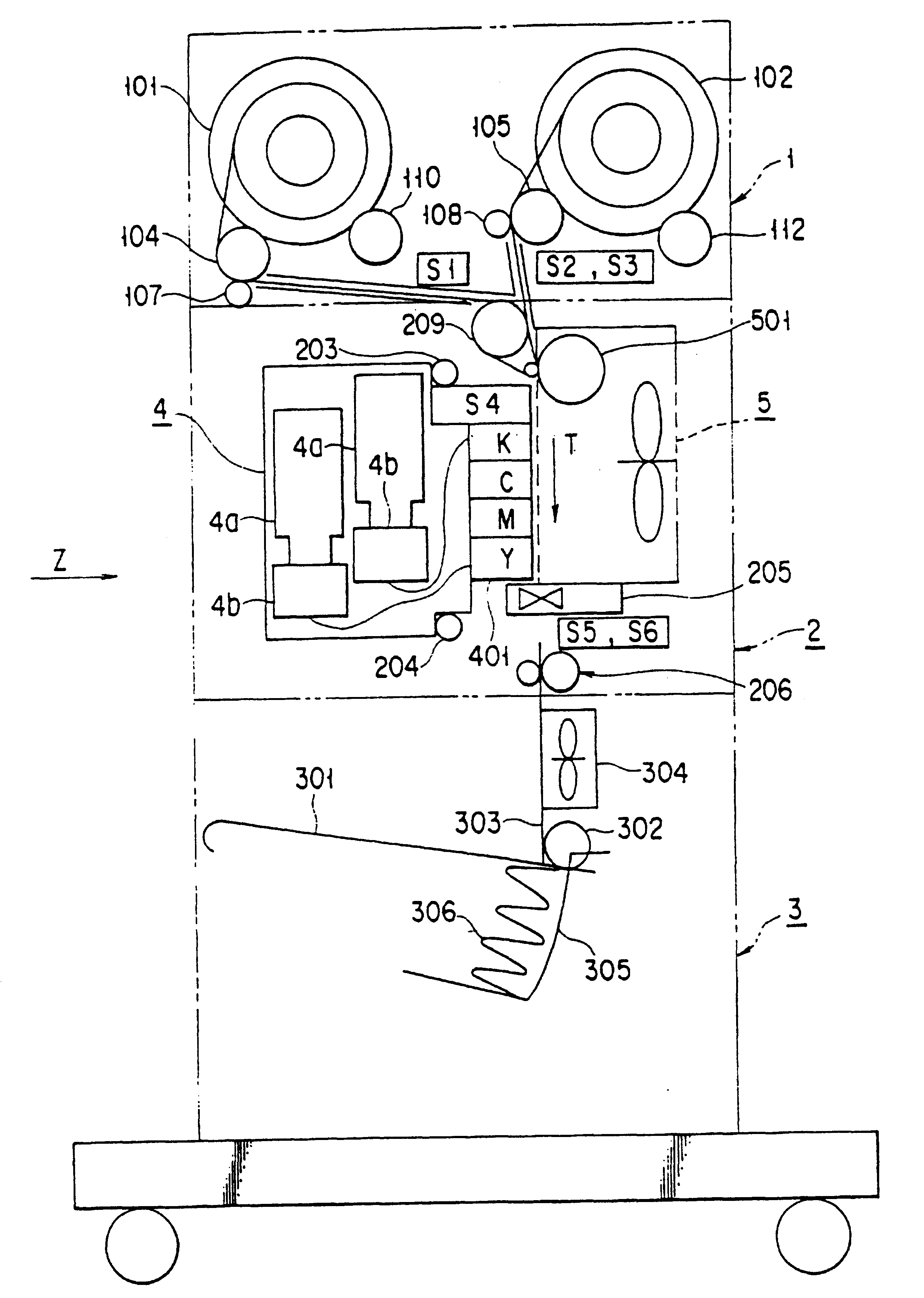

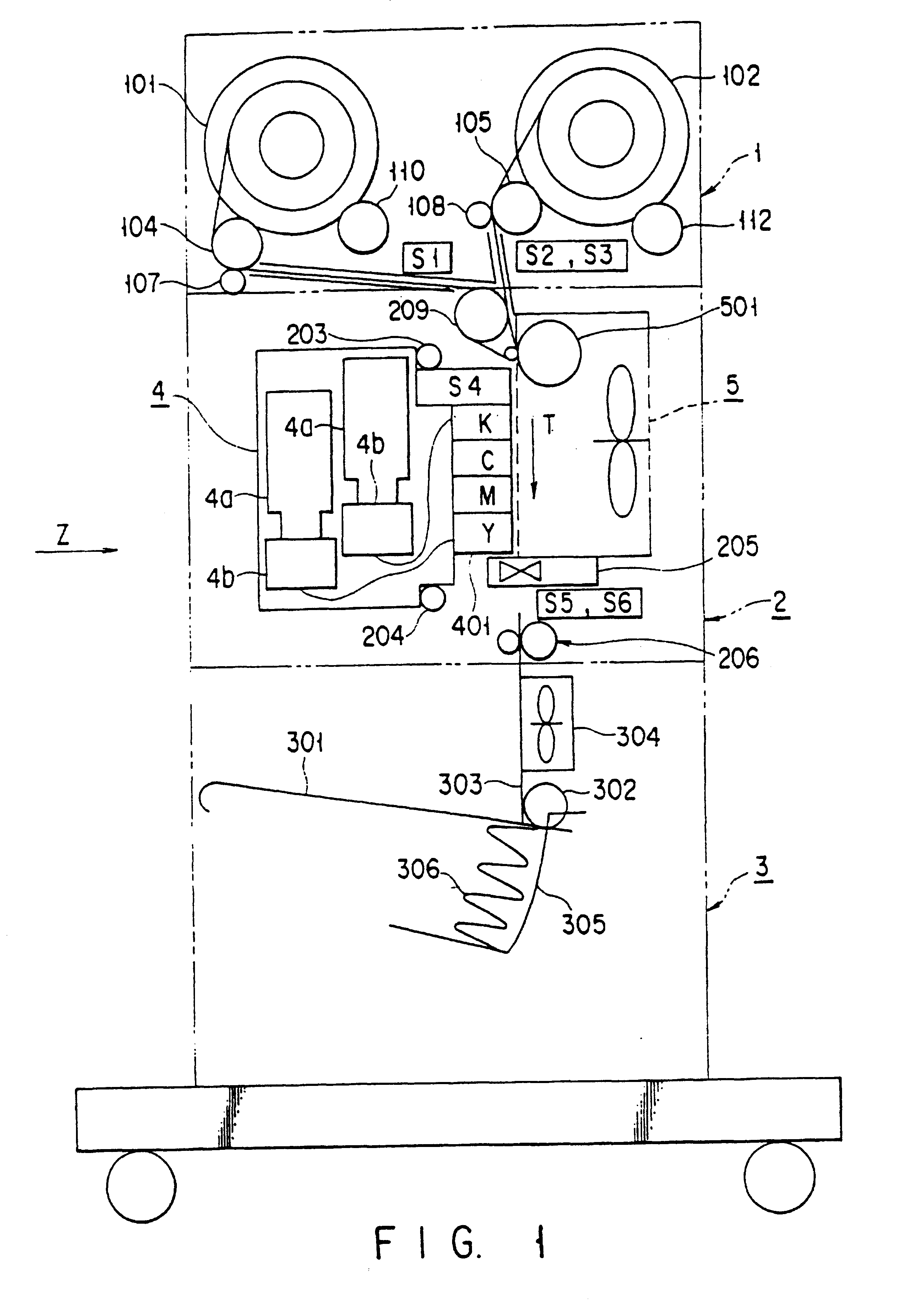

Image forming apparatus

InactiveUSRE38092E1High operabilityStable and efficientOther printing apparatusWebs handlingPaper sheetEngineering

An image forming apparatus includes a paper feed station from which sheets can be fed from a plurality of roll sheets only by placing the roll sheets in the station, a recording station for recording desired images on the sheets, and a processing station for delivering the sheets on which the images are recorded. The recording station includes a platen roller and a driving pinch roller for pushing and conveying a fed sheet while the sheet is drawn by suction by a suction chamber, a carriage unit for recording an image on the sheet on the suction chamber while moving along the sheet, and a pair of paper delivery rollers for delivering the sheet on which the image is recorded. The processing station includes a table on which the delivered sheets can be sequentially stacked in a predetermined position, and a biasing spring for biasing the pivotal distal end portion of the table.

Owner:OLYMPUS OPTICAL CO LTD

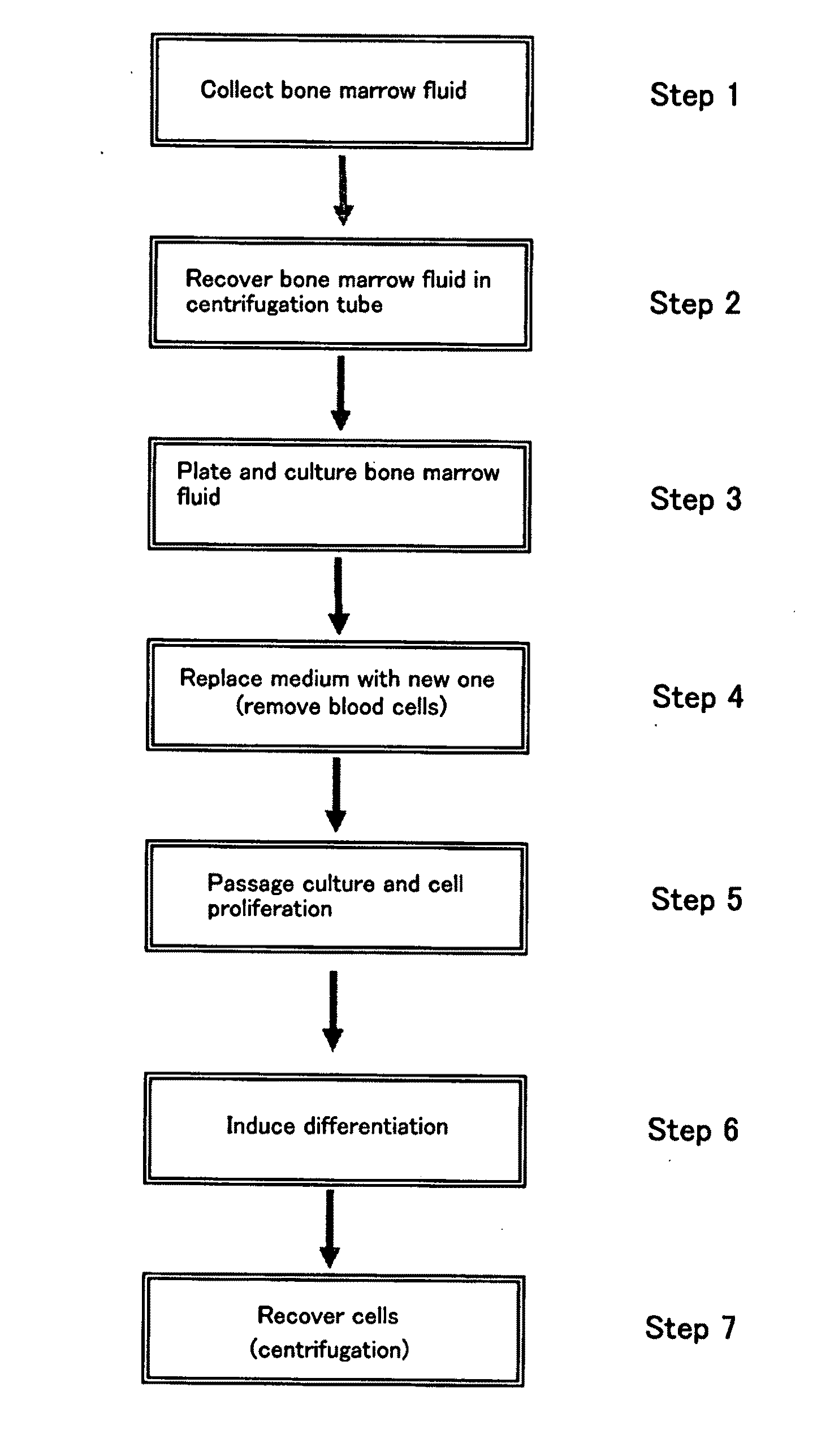

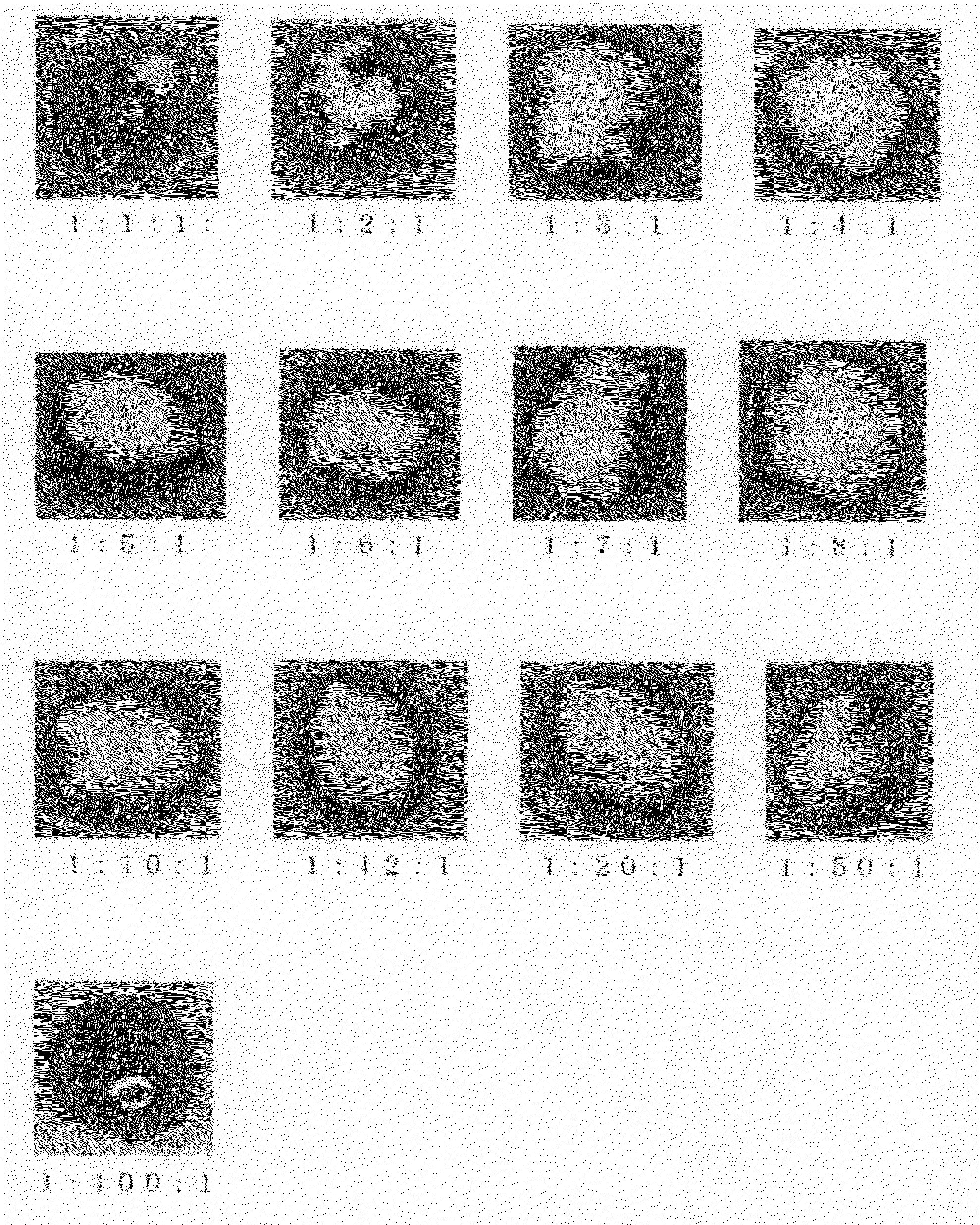

Method of preparing cell for bone tissue formation and application of cell for bone tissue formation

InactiveUS20090298173A1High treatment effectEasy to operateCell differentiationSkeletal disorderBone tissueTherapeutic effect

It is intended to provide a method of efficiently and stably preparing a cell having a bone tissue formation ability by a simple operation. Further, it is intended to provide a method of preparing a composition for bone tissue formation with high safety and an excellent therapeutic effect by a simple operation. The cell for bone tissue formation is obtained by (1) culturing bone marrow after isolating it from a living body, diluting it at a predetermined dilution ratio and inoculating it to a culture vessel, (2) culturing the remaining adhesive cells after removing floating components, (3) inducing differentiation of proliferated cells to bone cells and (4) recovering the cells. The thus obtained cells, a thrombin solution, platelet-rich plasma and air are mixed at a predetermined mixing ratio (based on volume) in the presence of calcium ions and the mixture is gelled, whereby a gelled composition is obtained.

Owner:UEDA MINORU +2

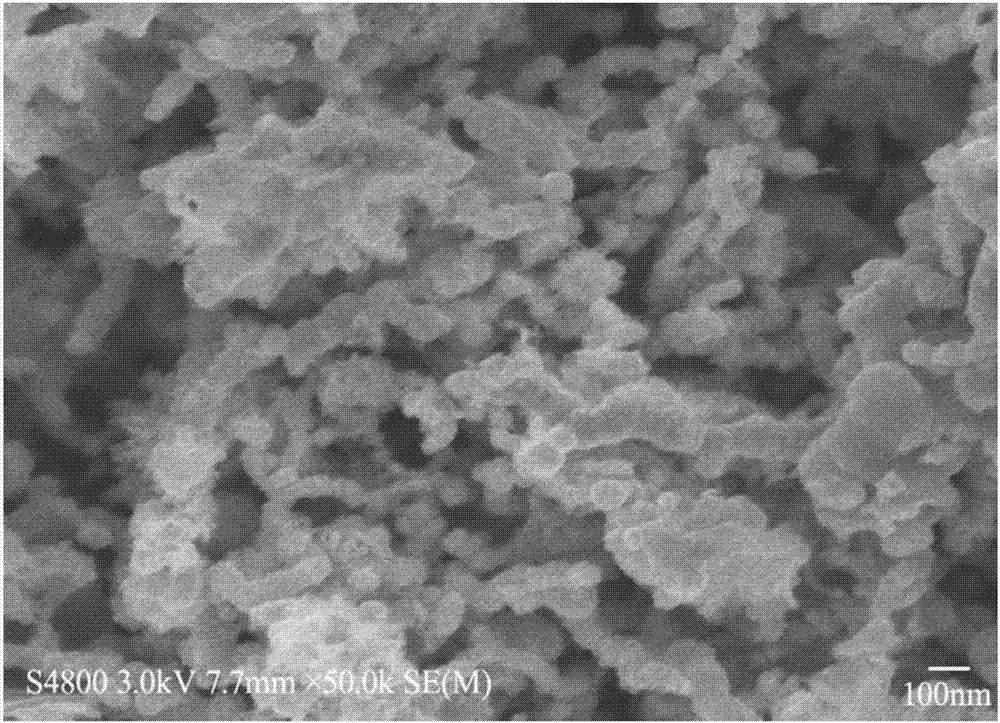

Modified nanoscale zero-valent iron and preparation method and application thereof

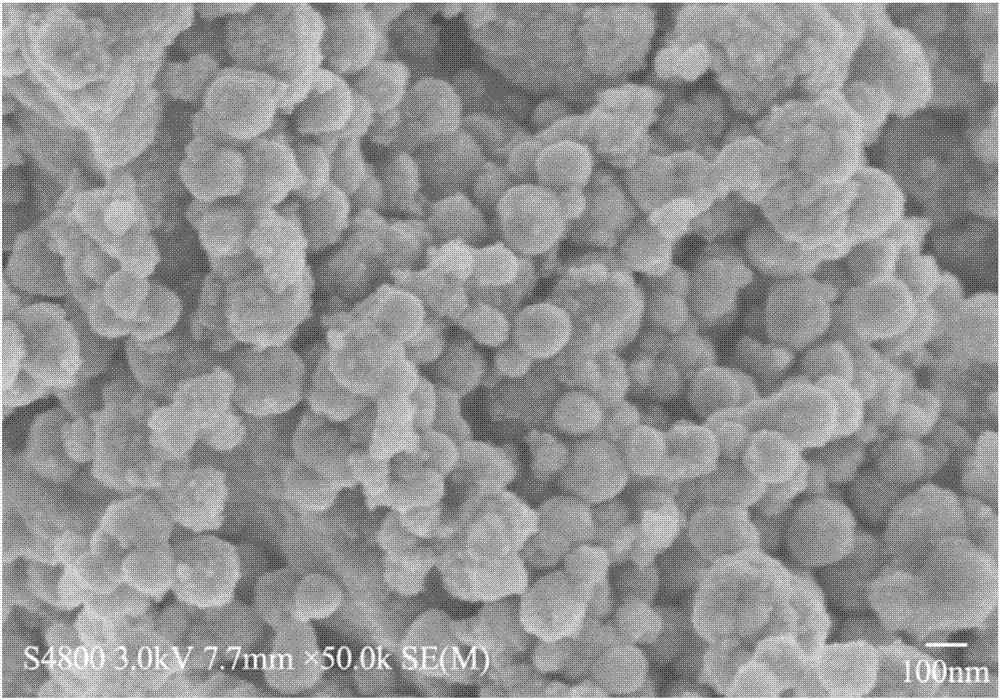

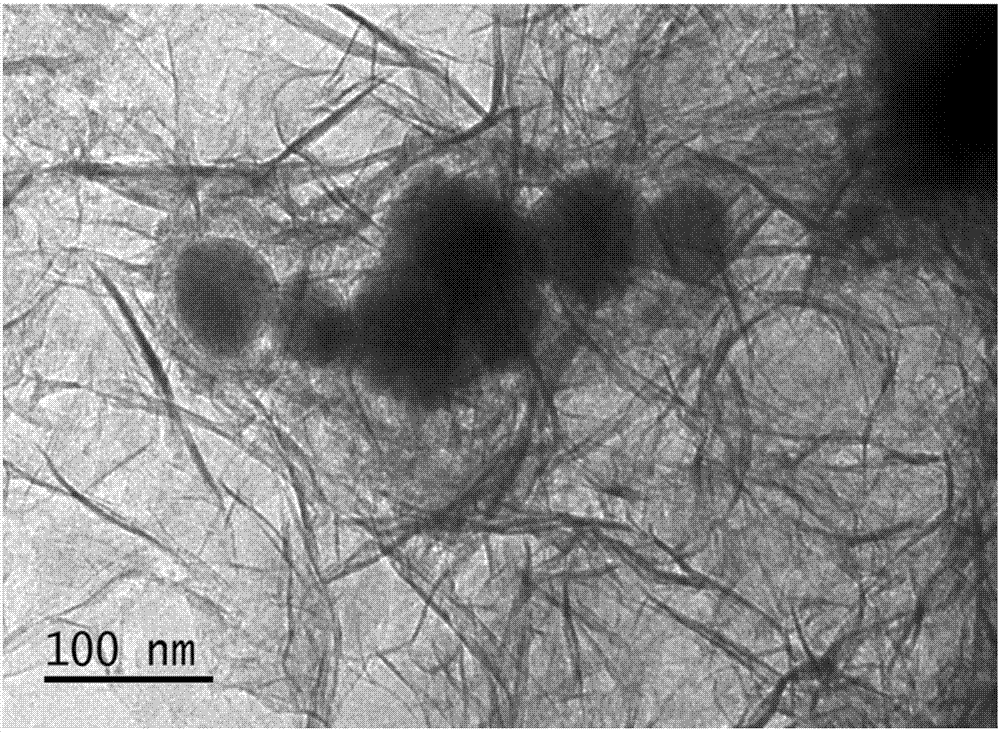

ActiveCN106891017AEvenly dispersedGood dispersionTransportation and packagingMetal-working apparatusSulfateMetal

The invention discloses modified nanoscale zero-valent iron and a preparation method and application of the modified nanoscale zero-valent iron. The modified nanoscale zero-valent iron comprises rhamnolipid and nanoscale zero-valent iron. The surface of the nanoscale zero-valent iron is modified through the rhamnolipid, and the mass ratio of the rhamnolipid to the nanoscale zero-valent iron is 0.1-2:1. The preparation method comprises the steps that a rhamnolipid solution and a ferrous sulfate solution are mixed, and a NaHB4 solution is dropwise added for a reaction to obtain the modified nanoscale zero-valent iron. The modified nanoscale zero-valent iron has the advantages of being good in dispersing performance, good in stability, high in reaction activity, high in permeability and the like, has the good stabilization efficiency for metal lead in bottom mud, brings no secondary pollution to environment, has a good application value, and has the wide application prospect in the technical field of bottom mud heavy metal pollution treatment.

Owner:HUNAN UNIV

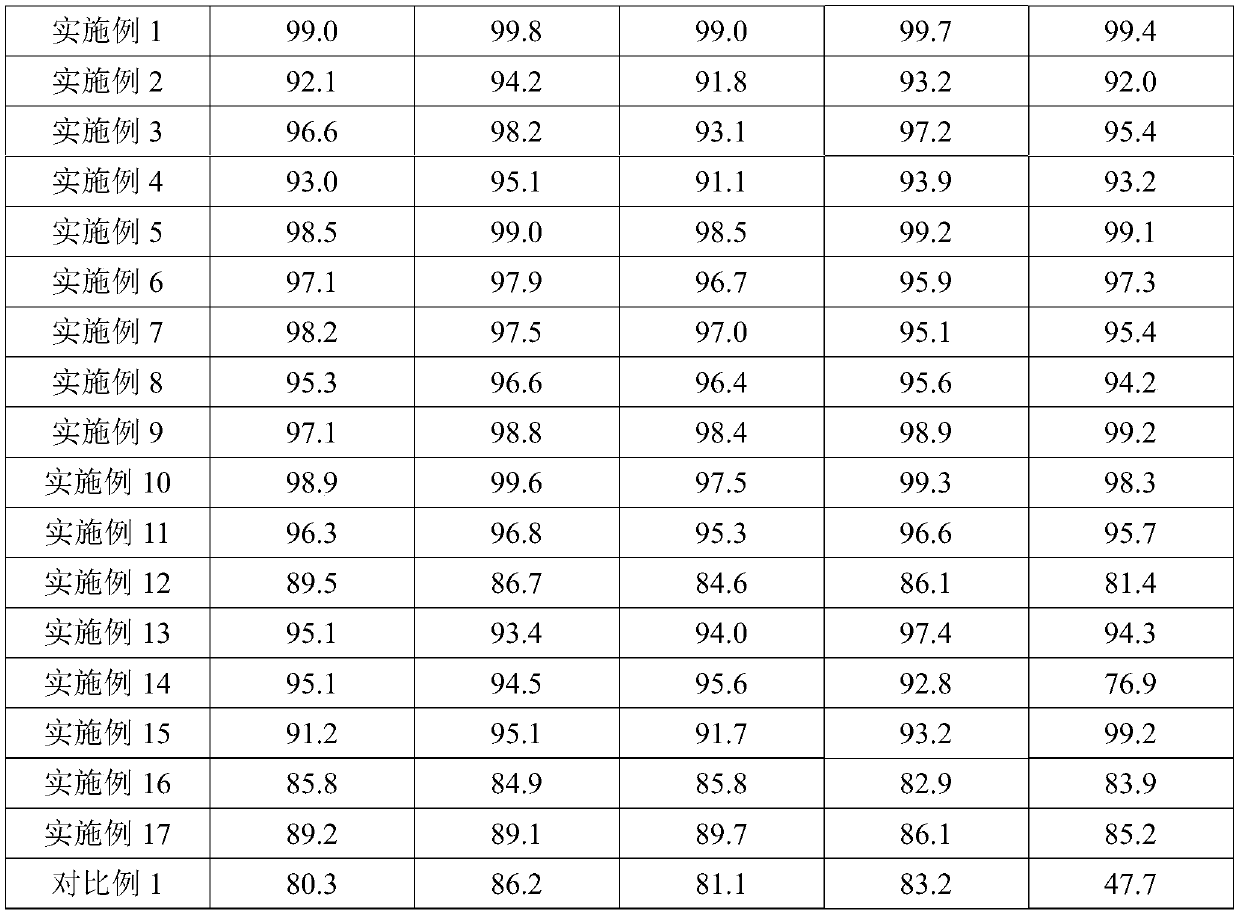

Heavy metal stabilizer and preparation method and use thereof

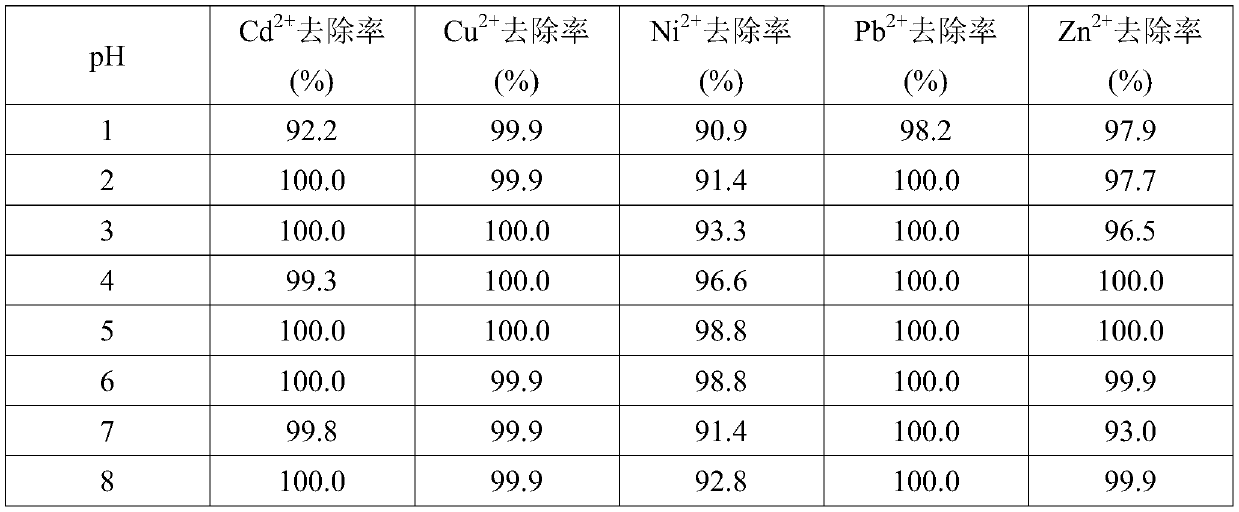

InactiveCN110104751AChange the spatial structureGood removal effectWater contaminantsWater/sewage treatment by flocculation/precipitationIron saltsFerrous salts

The invention provides a heavy metal stabilizer and a preparation method and use thereof. The heavy metal stabilizer is prepared through the following steps that (1) small molecule polyamine and carbon disulfide react in an alkaline environment to obtain a dithiocar-bamate solution; (2) soluble iron salt and / or ferrous salt is mixed with the dithiocar-bamate solution obtained in step (1) to obtaina dithiocar-bamate solution modified by the iron salt and / or ferrous salt; (3) the dithiocar-bamate solution modified by the iron salt and / or ferrous salt obtained in step (2) and a crosslinking agent are mixed and react to form the heavy metal stabilizer. Compared with a common dithiocar-bamate polymeric chelating agent, the heavy metal stabilizer has a better removal effect on heavy metal ions,especially Zn<2+>, and has a wider pH application range.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

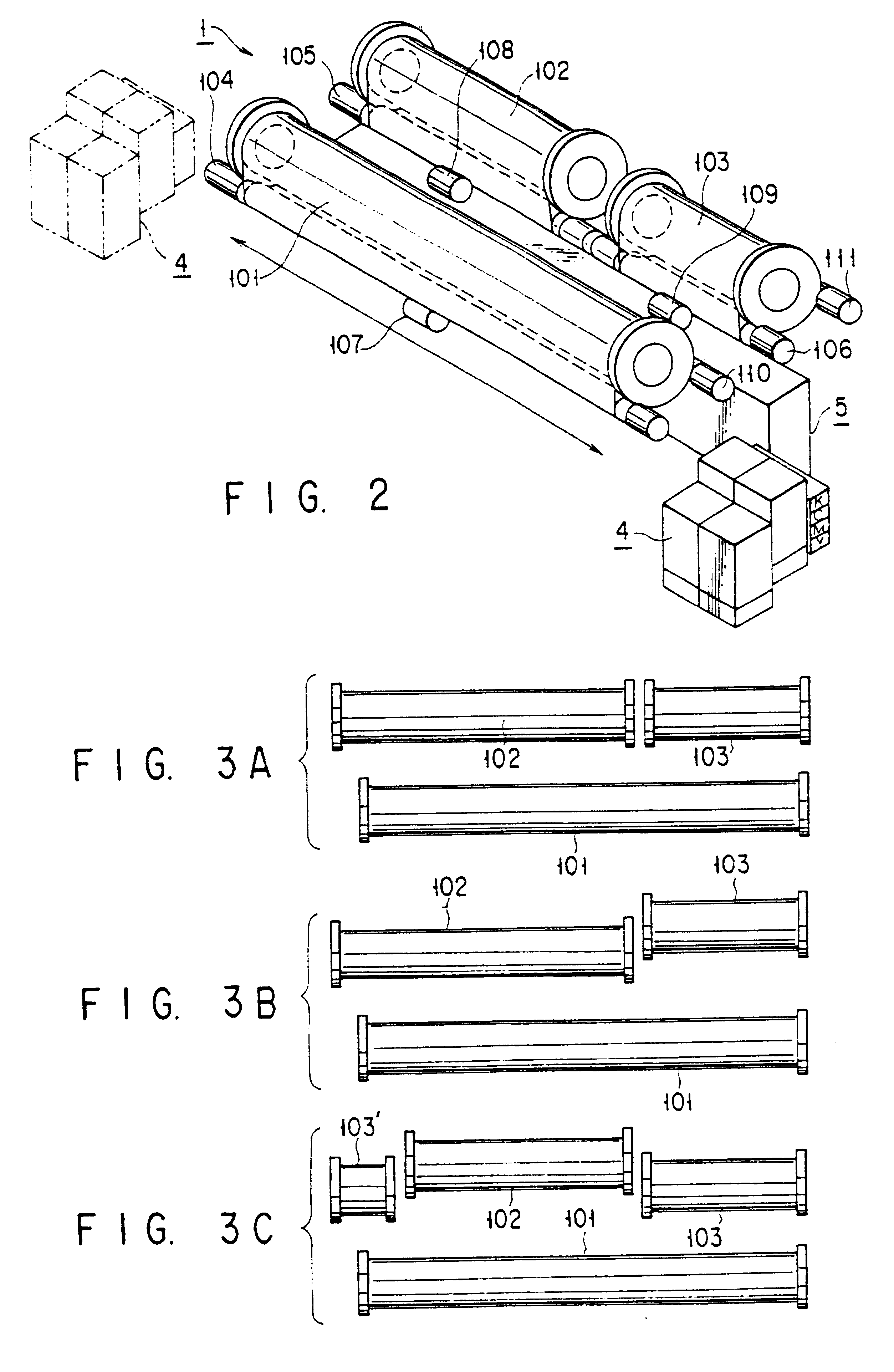

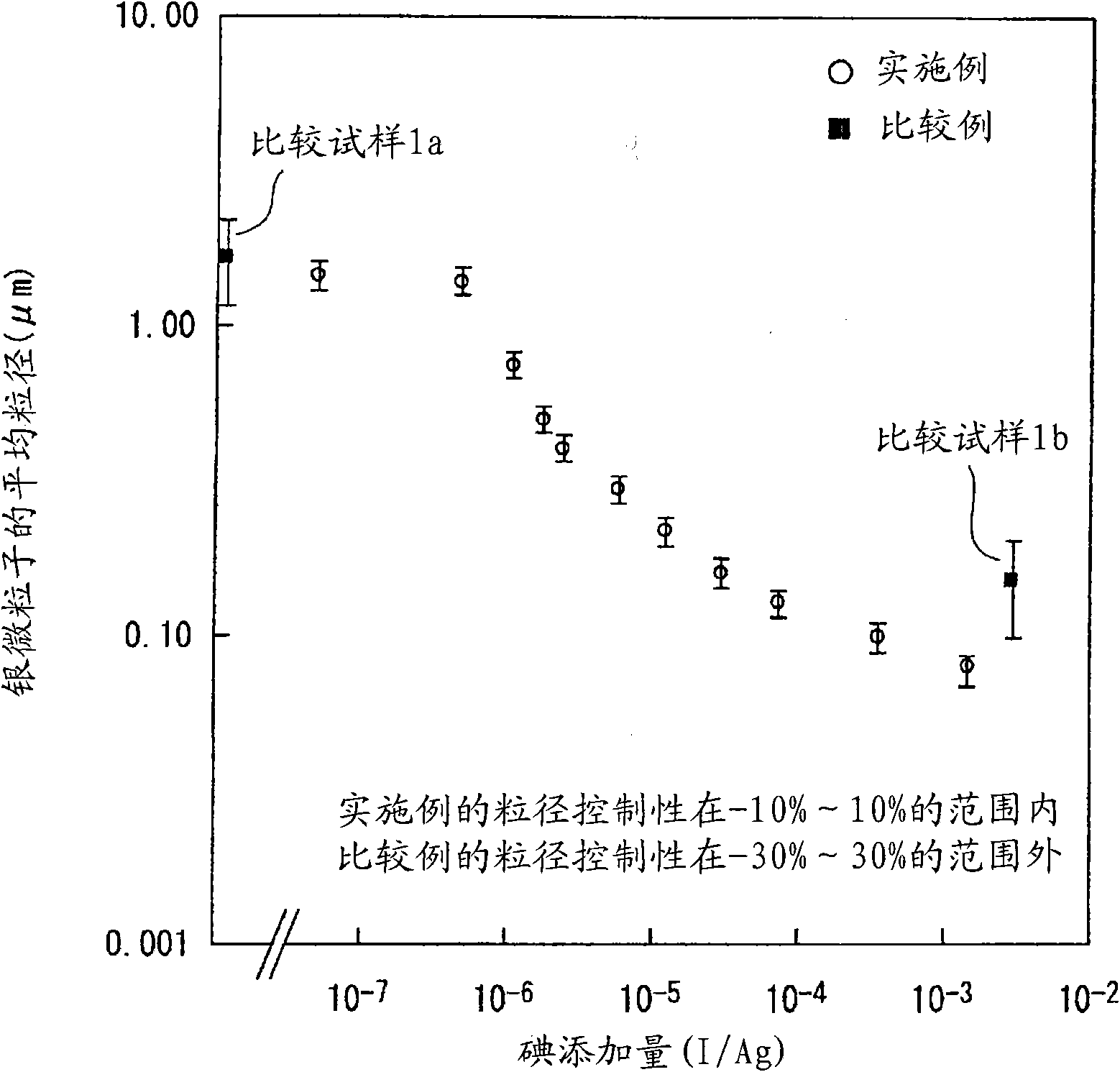

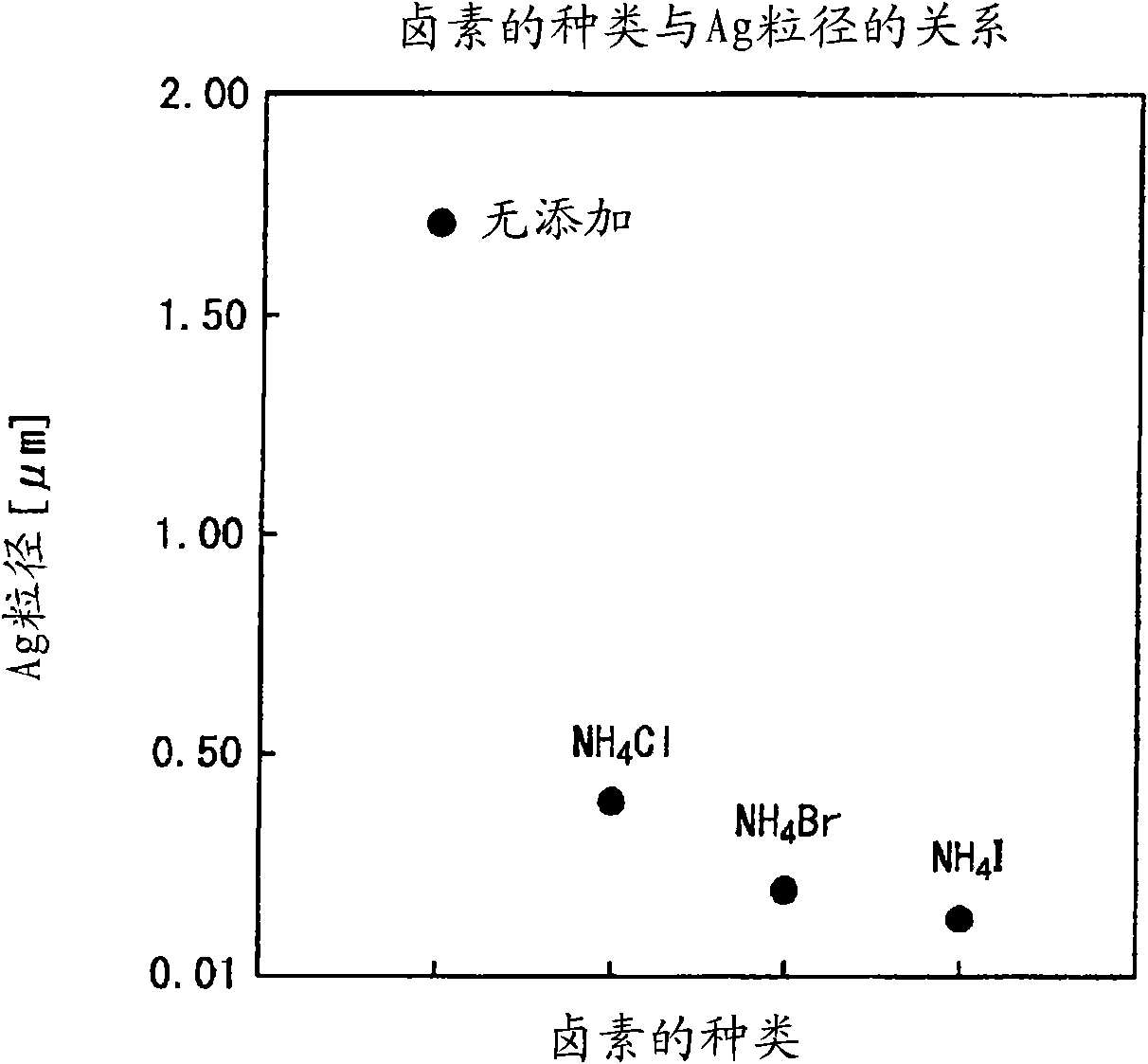

Fine silver particle, process for producing fine silver particle, and apparatus for producing fine silver particle

Fine silver particles which contain a halogen in an amount of 5.0OE0<-8> to 1.5OE0<-3> mol per mol of the silver. Also provided is a process for producing the fine silver particles which includes a step in which a reducing agent is added to a silver ion solution to reduce the silver ions and thereby precipitate fine silver particles, the silver ion reduction being conducted in the presence of a nucleating substance which constitutes nuclei for the fine silver particles. Furthermore provided is an apparatus for producing the fine silver particles which comprises a silver ion solution tank, a first pipeline connected to the silver ion solution tank, an aqueous-ammonia-solution tank, a second pipeline connected to the aqueous-ammonia-solution tank, a reducing-liquid tank, a third pipeline connected to the reducing-liquid tank, and a fourth pipeline extending from a part where the first and second pipelines cross each other. The apparatus has a constitution in which a reducing liquid supplied through the third pipeline is mixed with a liquid mixture of a silver ion solution and an ammonia solution, the liquid mixture being supplied through the fourth pipeline.

Owner:MITSUBISHI MATERIALS CORP

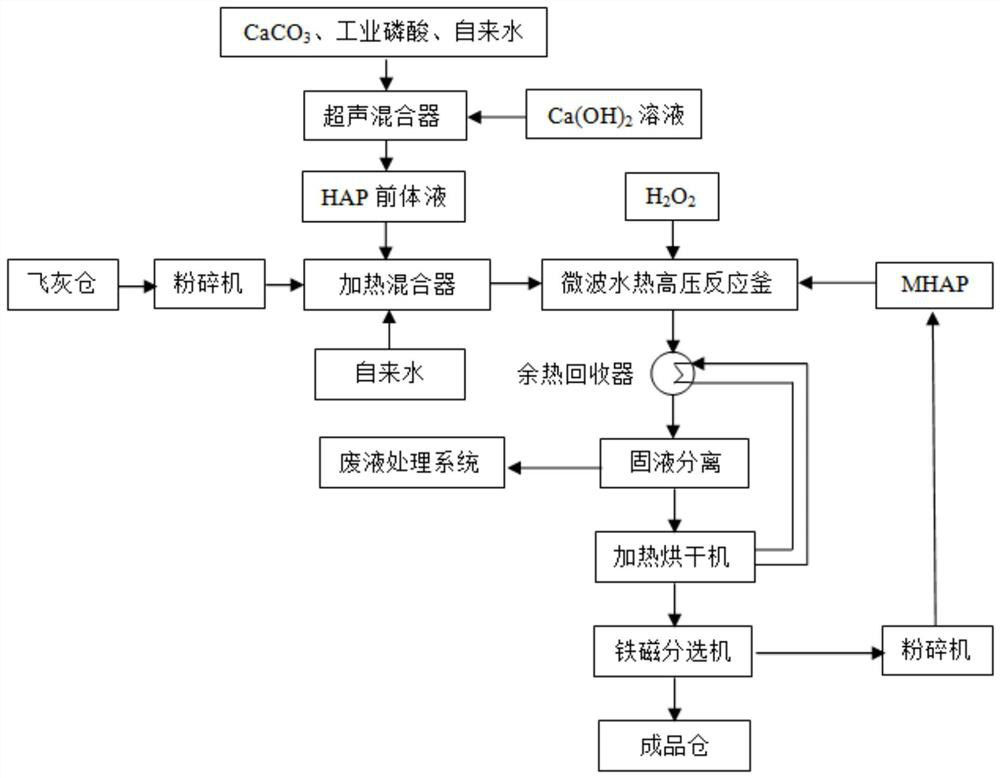

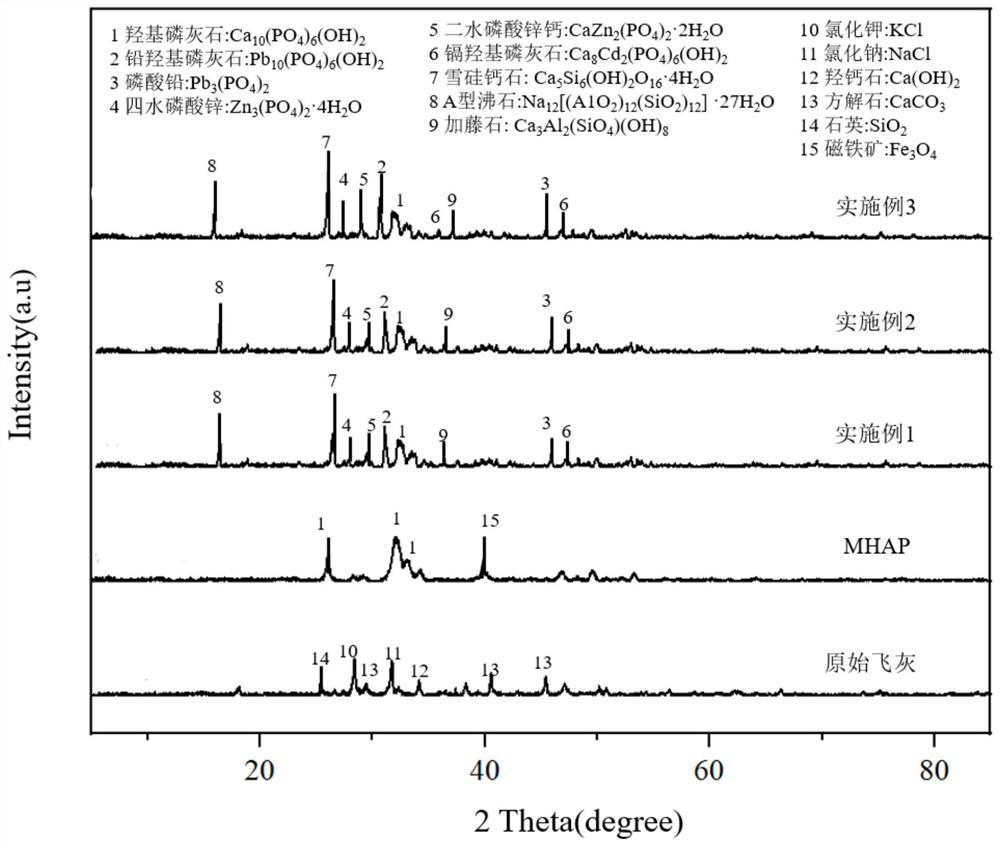

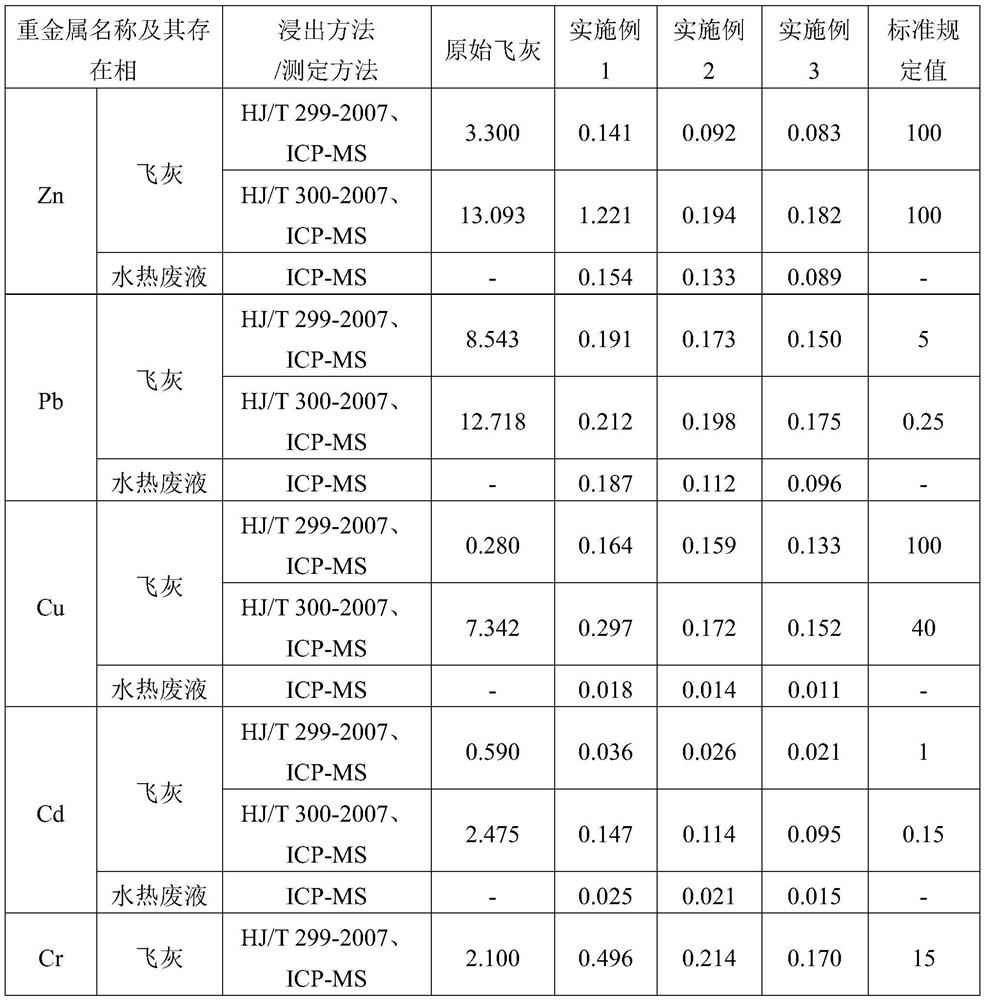

Method for harmless treatment of waste incineration fly ash through hydrothermal technology

ActiveCN111672876AStable and efficientImprove adsorption capacitySolid waste disposalTransportation and packagingEngineeringPolyaromatic hydrocarbon

The invention discloses a method for harmless treatment of waste incineration fly ash through a hydrothermal technology. The method comprises the following steps of (1) adding a hydroxyapatite precursor liquid into fly ash, and then performing first-step hydrothermal reaction under normal pressure at 40 to 50 DEG C to stabilize heavy metals in the fly ash; and (2) adding magnetic hydroxyapatite powder and hydrogen peroxide into a mixture obtained by the reaction of the step (1), and then performing second-step microwave hydrothermal reaction under a high pressure at 20 to 150 DEG C to furtherstabilize the heavy metals in the fly ash and degrade polyaromatic hydrocarbons. According to the method, stabilization of the heavy metals and degradation and detoxification of the polyaromatic hydrocarbons in the waste incineration fly ash can be realized efficiently and synchronously; the leaching toxicity of the heavy metals is lower than identification standards for hazardous wastes and can meet domestic waste landfill pollution control standards; the heavy metals are actually stabilized in the fly ash rather than being transferred to a hydrothermal waste liquid on a large scale; the toxic equivalent degradation rate of sixteen polyaromatic hydrocarbons is up to 95.06 percent; and secondary pollution is prevented.

Owner:CHONGQING UNIV

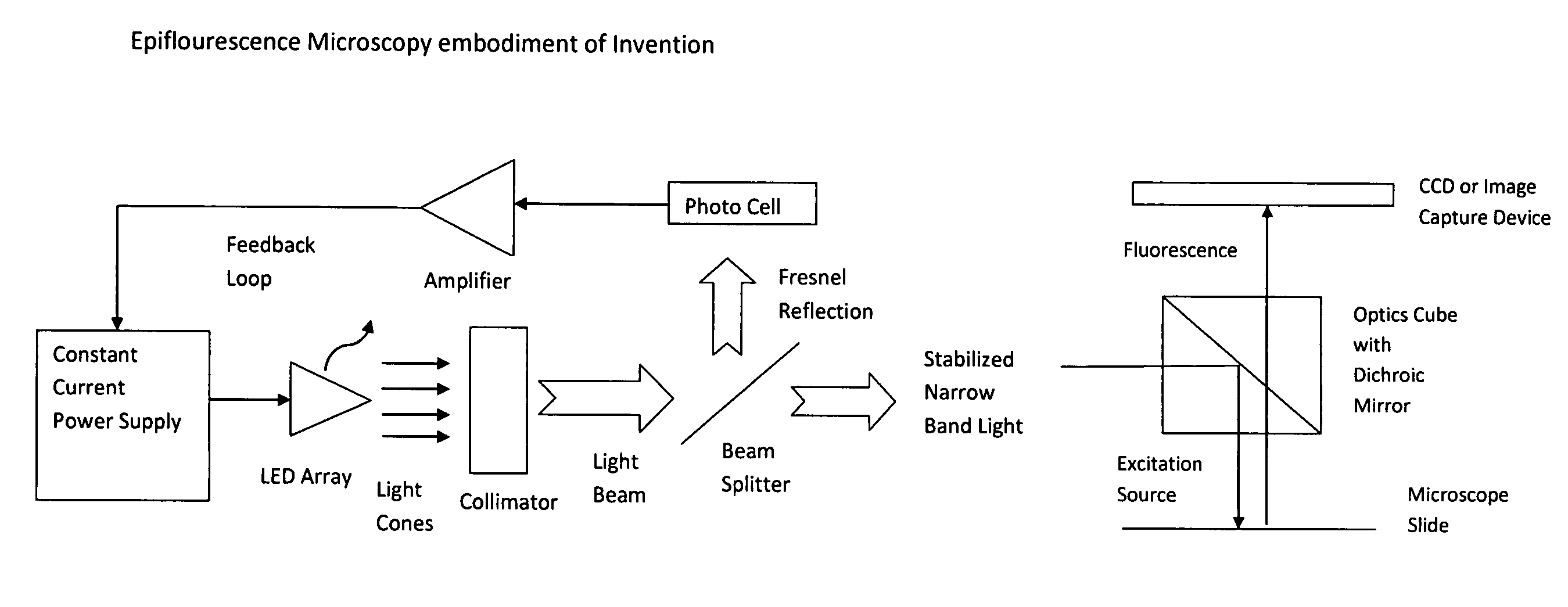

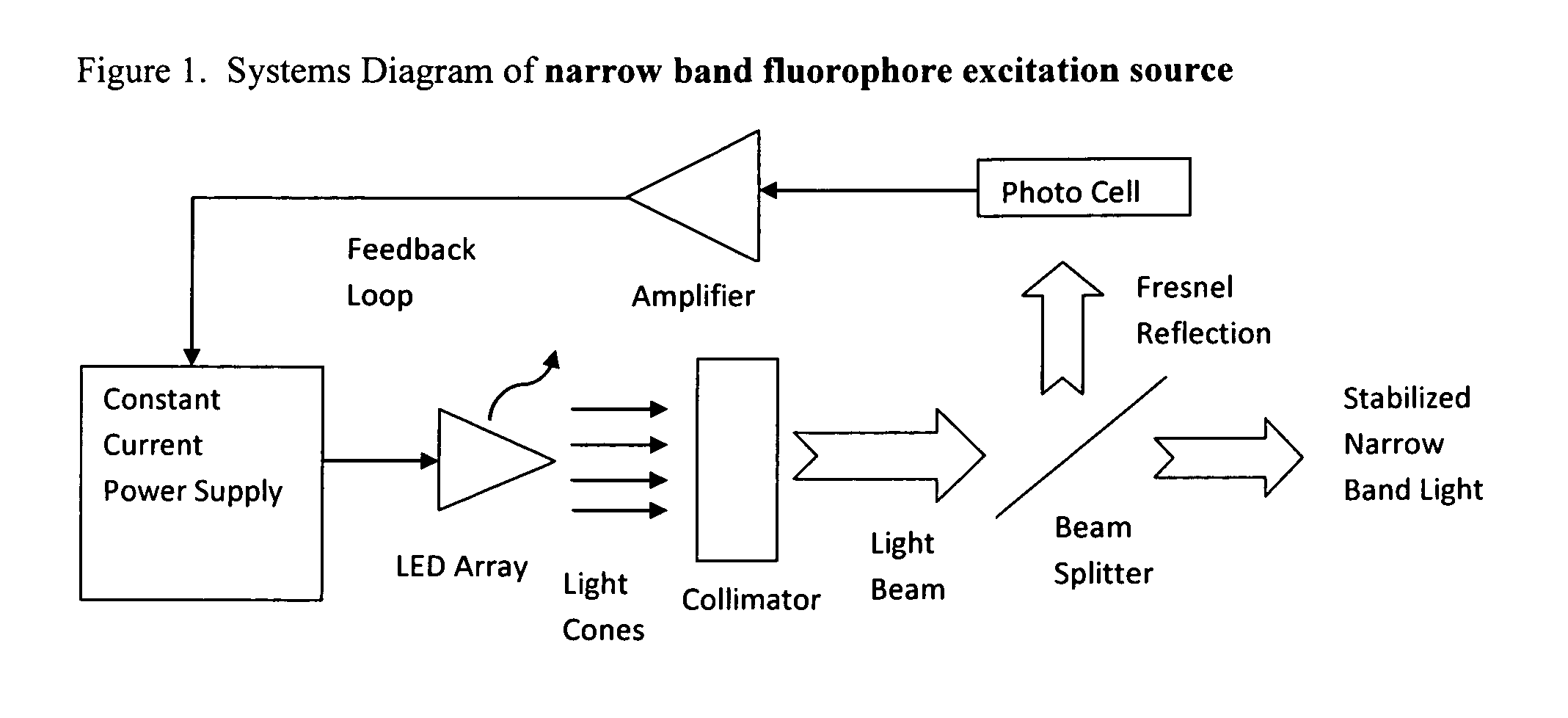

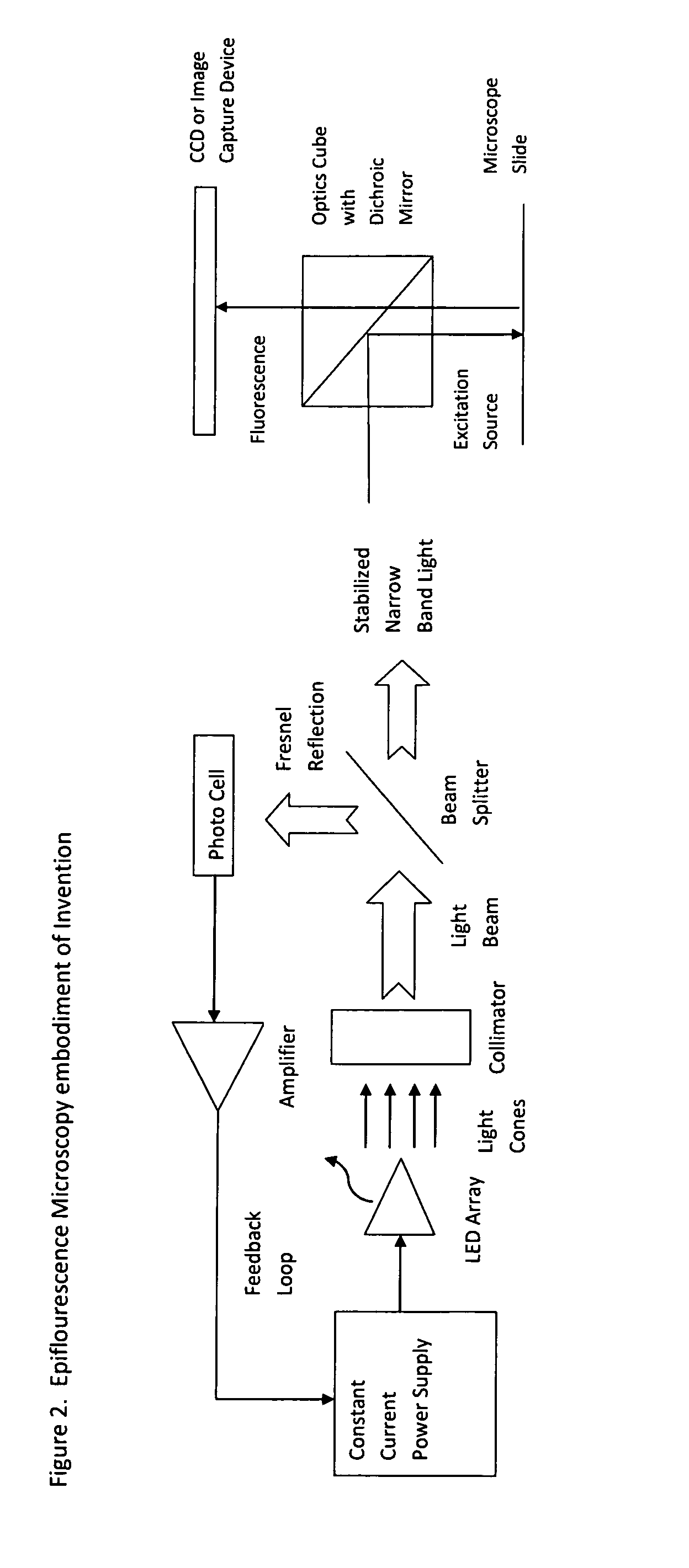

Narrow band fluorophore exciter

InactiveUS20130105708A1Reduce operating expensesReduce outputPhotometryLuminescent dosimetersBroadbandLight source

Disclosed is a solid-state light source based on a light emitting diode (LED) array driven by a constant current power source with an active feedback control. This system can be implemented for broad frequency ranges or for narrow band frequencies depending on the characteristics of the LEDs chosen to populate the array and the geometry of the array. The invention can be used as an excitation light source for fluorescent microscopy and flow cytometry applications as an efficient and stable alternative to existing light sources such as broadband mercury vapor bulbs and plasma-based light sources. Benefits of the current invention include: durability; stability; reduced operating expenses; reduced variance of output; and increased accuracy of frequency and amplitude. This system will provide benefits as the excitation mechanism in fluorescent identification and measurement systems such as microscopy and flow cytometry.

Owner:BENNETT GORDON +1

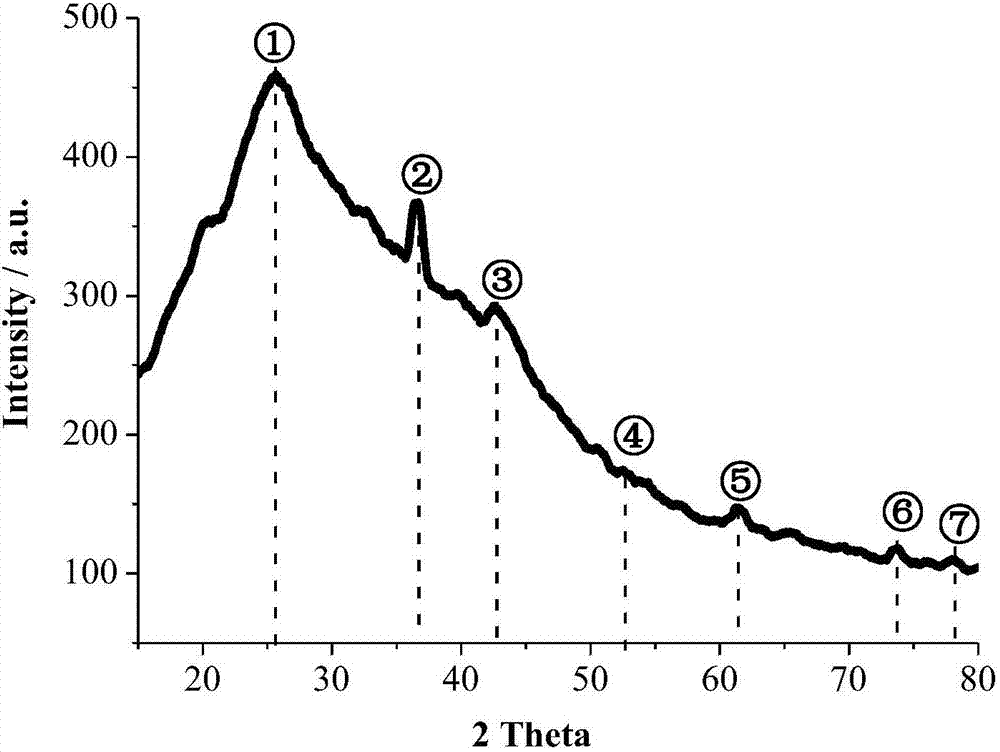

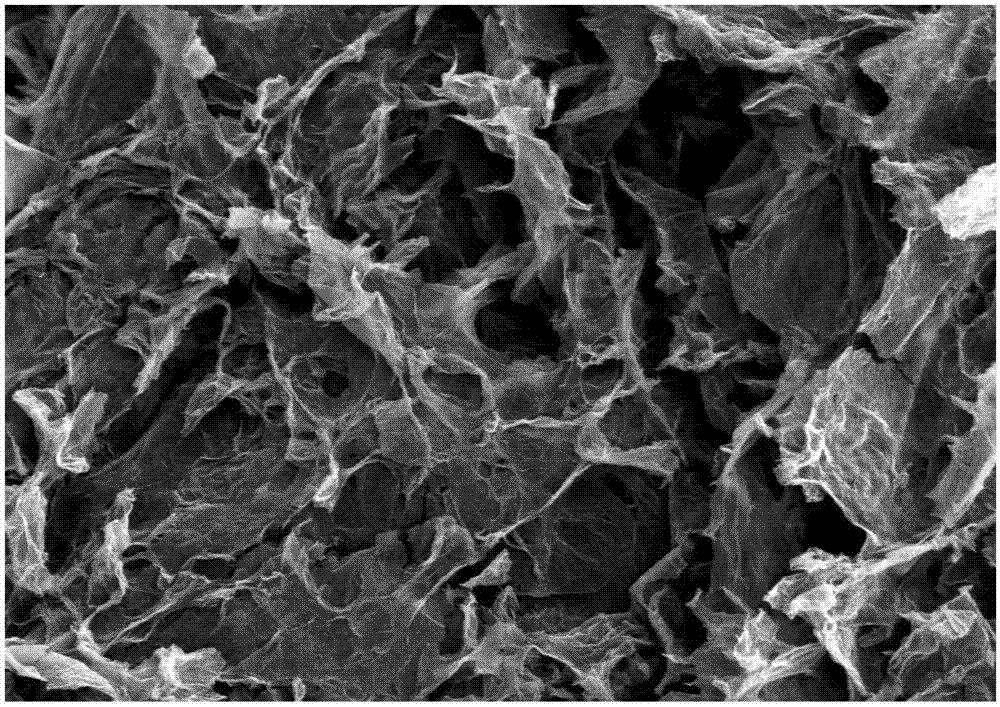

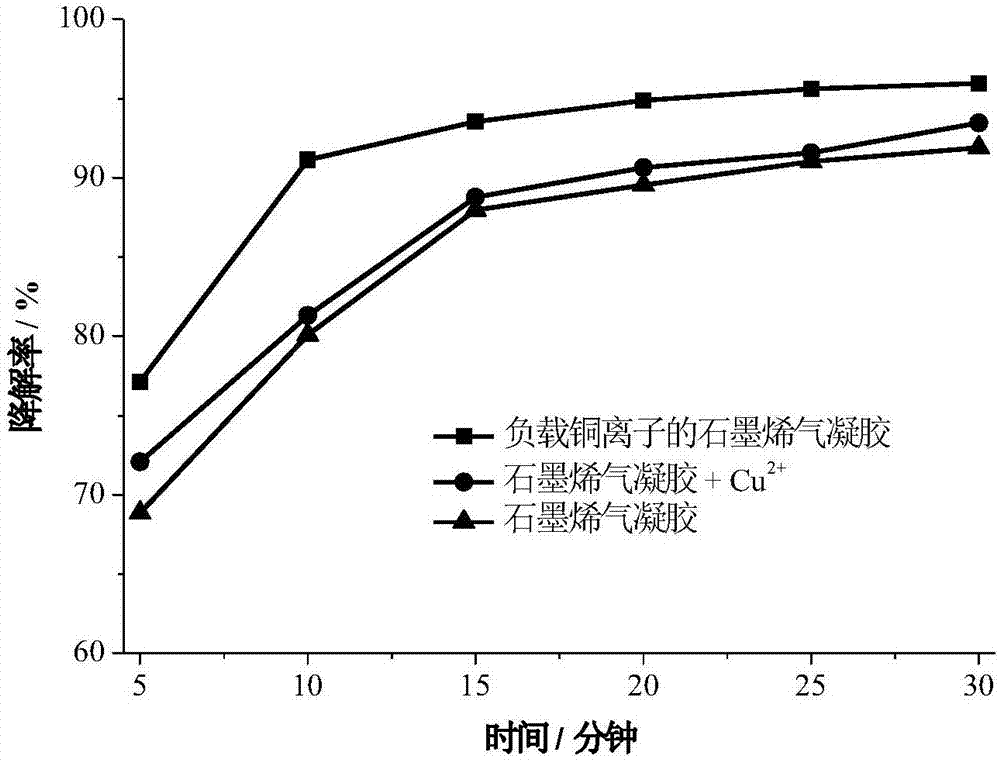

Graphene aerogel electrode material loaded with copper ions and preparation method thereof

ActiveCN107324454AImprove conductivityImprove adsorption capacityWater contaminantsWater/sewage treatmentSludgeElectron

The invention relates to a graphene aerogel electrode material loaded with copper ions. The diffraction angle 2 theta of the crystal form has diffraction peaks at 29.689 + / - 0.2 degrees, 36.547 + / - 0.2 degrees, 42.484 + / - 0.2 degrees, 52.686 + / - 0.2 degrees, 61.646 + / - 0.2 degrees, 73.858 + / - 0.2 degrees and 77.738 + / - 0.2 degrees. The graphene aerogel electrode material provided by the invention has ultrahigh adsorption capacity to organic dyestuff wastewater, is capable of assisting in promoting electricity-fenton reaction efficiency and is capable of effectively avoiding iron sludge generation; the graphene aerogel electrode material loaded with copper ions applied to the electricity-fenton system not only can keep high degradation rate under the condition of pH equal to 3 but also can keep higher degradation rate under the condition of pH equal to 7; the excellent electrical conductivity of the graphene aerogel can effectively increase the transfer rate of the electrons on the surface of the graphene aerogel electrode material loaded with copper ions and can further accelerate the continuous in-situ generation of H2O2 at cathode; H2O2 also reacts with an electrode-loaded copper ionic catalyst so as to generate. OH, so that stable high efficiency in the electricity-fenton process can be kept.

Owner:CHONGQING THREE GORGES UNIV

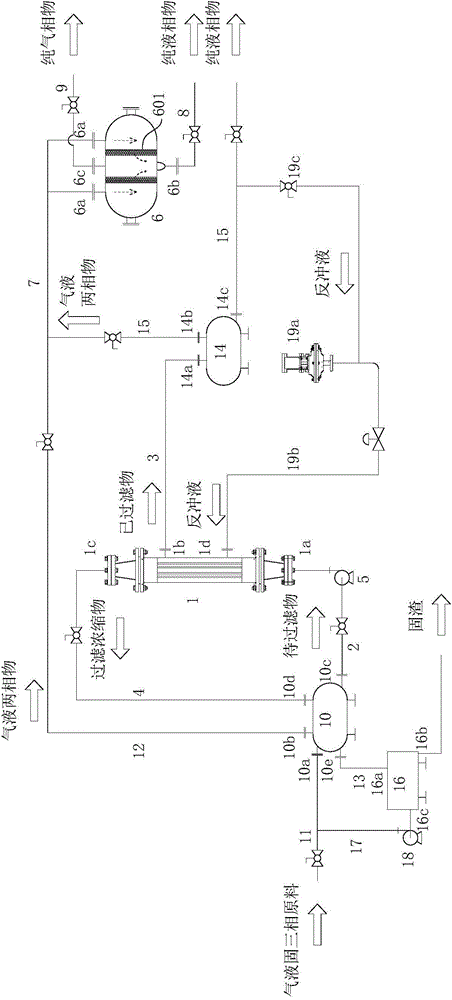

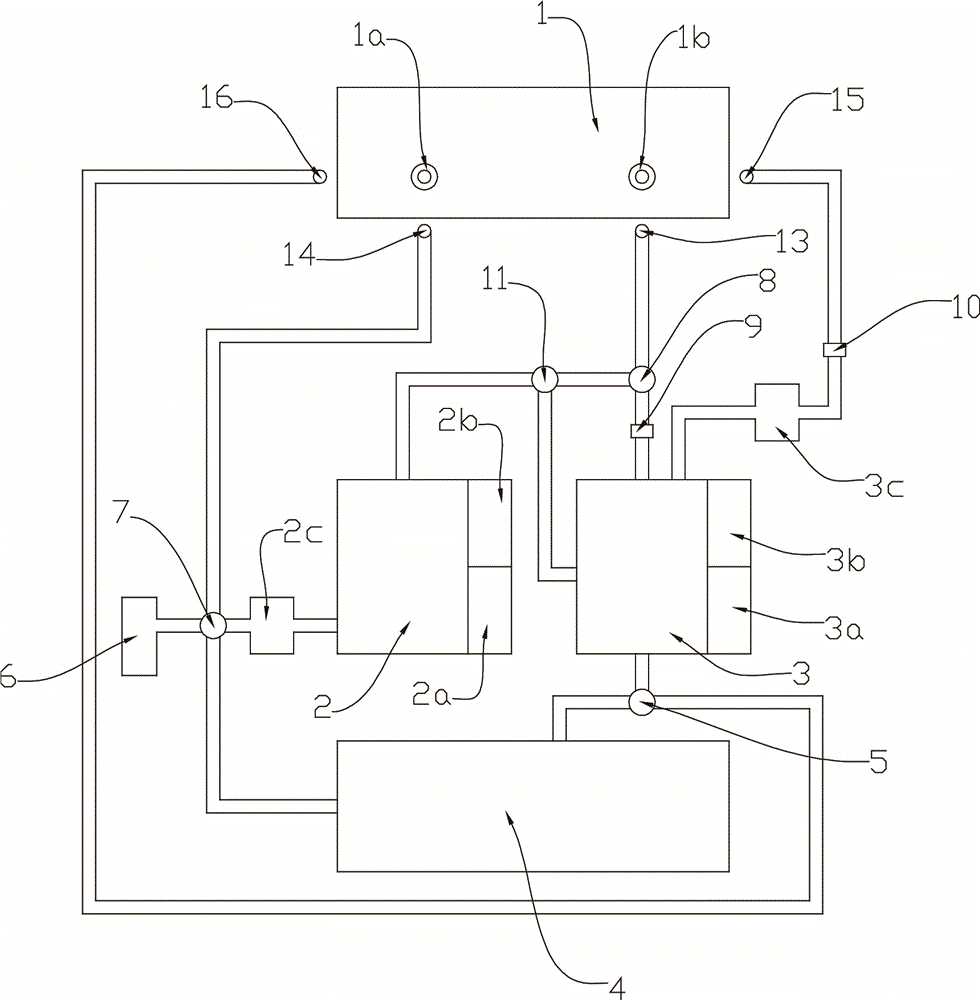

Gas, liquid and solid three-phase separation system

ActiveCN104474773AEfficient separationFully utilizeMultistage water/sewage treatmentFiltration circuitsCross-flow filtrationSlurry

The invention discloses a gas, liquid and solid three-phase separation system which can be used for realizing high-efficiency separation of three phases of gas, liquid and solid. The system comprises a cross flow filter, a gas and liquid coalescer, a front flow dividing container, a rear flow dividing container and a slurry concentrator, wherein a to-be-filtered material charging hole of the cross flow filter is connected with an output end of a to-be-filtered material conveying pipe; a filtered material discharging hole is connected with an input end of a filtered material conveying pipe; a filtered and concentrated material discharging hole is connected with the input end of a concentrated material refluxing pipe; a gas and liquid two-phase material charging hole of the gas and liquid coalescer is connected with the input end of a gas and liquid two-phase material conveying pipe; a gas and liquid two-phase material discharging hole of the front flow dividing container is connected with the input end of the gas and liquid two-phase material conveying pipe; a to-be-filtered material discharging hole is connected with the input end of the to-be-filtered material conveying pipe; the filtered and concentrated material charging hole is connected with the output end of the concentrated material refluxing pipe; a bottom slurry discharging hole is connected with a slurry conveying pipe; the filtered material charging hole of the rear flow dividing container is connected with the output end of the filtered material conveying pipe; the gas and liquid two-phase material discharging hole is connected with the gas and liquid two-phase material conveying pipe; and a to-be-treated slurry charging hole of the slurry concentrator is connected with the slurry conveying pipe.

Owner:CHENGDU INTERMENT TECH

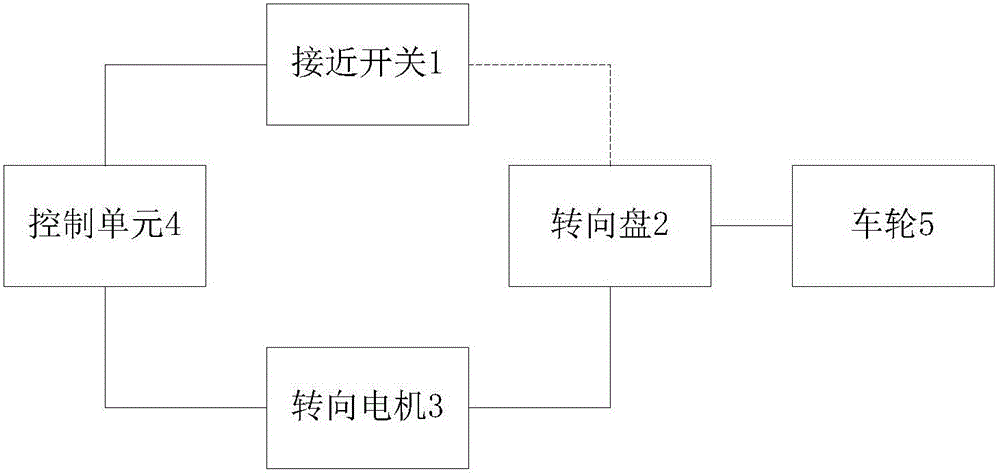

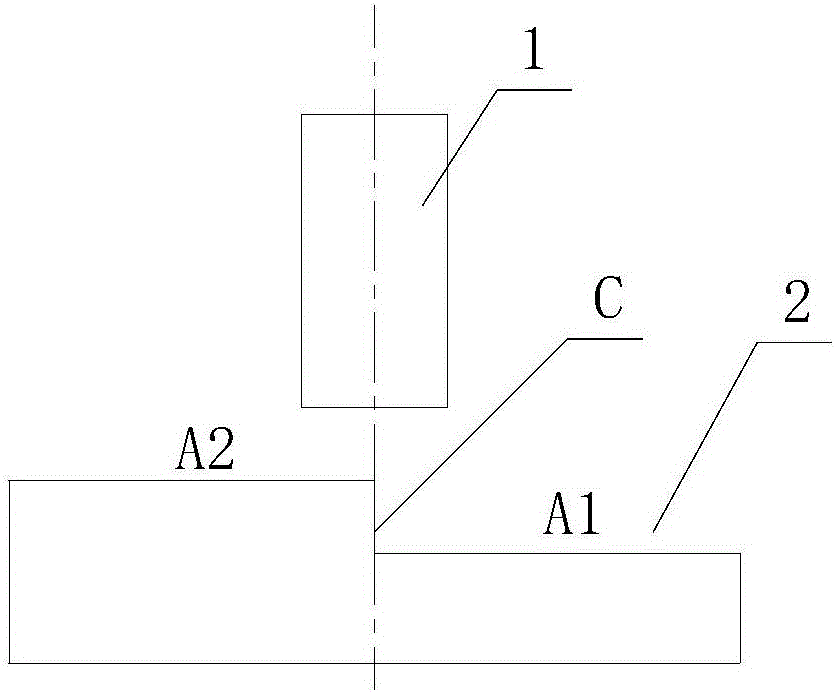

Vehicle, vehicle steering system and return control device and method of vehicle steering system

ActiveCN107433975ASimple structureEasy to installSteering linkagesAutomatic steering controlSteering wheelElectric machinery

The invention discloses a return control device of a vehicle steering system. The return control device comprises a proximity switch, a steering motor and a control unit, wherein the proximity switch right faces the detection surface of a steering wheel, a detection signal is generated according to the distance between the proximity switch and the detection surface of the steering wheel, and the detection surface of the steering wheel has a height difference; the steering motor is used for driving the steering wheel to rotate; the control unit is connected with the proximity switch and the steering motor separately, the control unit controls the steering motor according to the detection signal to make the steering wheel located in a preset return position, so that return control is conducted through the proximity switch, control over complex programs and the movement rule can be achieved, the control precision is high, and return control can be stably and efficiently achieved; the structure of a hardware circuit of a system can be simplified, and the production and maintenance cost of the system is reduced. The invention further discloses a vehicle, the vehicle steering system and a return control method of the vehicle steering system.

Owner:BYD CO LTD

Intelligent vehicle cleaning and oil replacing system and oil replacing method

ActiveCN106115596AStable and efficientWon't splashLiquid transferring devicesControl systemOil quality

The invention discloses an intelligent vehicle cleaning and oil replacing system and an oil replacing method. A whole oil replacing process including automatic setting and metering, automatic oil quality detection, automatic recovery of discharged oil, oil tank cleaning and new oil injection is achieved through a single-chip microcomputer. The oil replacing operation is stable and efficient in efficiency and quality, and the situations that oil is spilled, and waste is caused due to the fact that oil is contaminated are avoided. In addition, the amount and operation data of the oil replacing process can be recorded by a control system, and functions of memorizing and retracing are achieved.

Owner:ZHTWY BEIJING TECH

Fabricated door and window installation auxiliary assembly

PendingCN112160550AEasy to installImprove protectionBuilding constructionsStructural engineeringMechanical engineering

The invention discloses a fabricated door and window installation auxiliary assembly. The fabricated door and window installation auxiliary assembly comprises a bottom plate, a push plate, a first lifting rod, a second lifting rod, a connecting column and a connecting seat. A clamping and fixing plate is fixedly connected to one end of the connecting seat, a groove is formed in one side of the clamping and fixing plate, and a movable plate is movably connected into the groove. A baffle is fixedly connected to one end of the movable plate, a first contraction rod is fixedly connected with one side of the baffle, and a fixing plate is fixedly connected to the other end of the movable plate. The fabricated door and window installation auxiliary assembly has the main advantages that in the using process, a worker can pull the clamping and fixing plate through a handle, then places a door and window needing to be installed on a first installation frame and a second installation frame on thetwo sides of an installation seat, at the moment, the handle is loosened, and a second contraction rod can contract under the action of a spring in the first contraction rod to drive a clamping and fixing block to clamp and fix the door and window.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

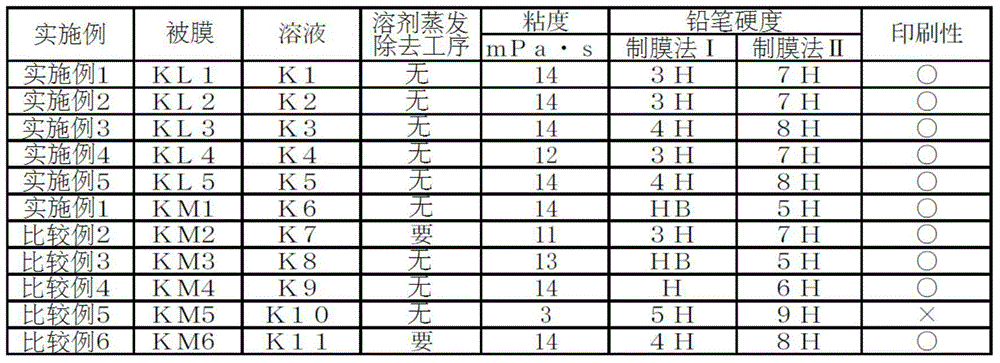

Method for producing coating solution for metal oxide coating, coating solution for metal oxide coating, and metal oxide coating

ActiveCN104011260AStable and efficientFull hardnessInksLiquid/solution decomposition chemical coatingIn planeOrganic solvent

Provided are: a method for producing a coating solution for metal oxide coating whereby ample hardness is obtained even at low-temperature firing and without involving a solvent substitution step, and which possesses favorable printability and in-plane uniformity in flexographic printing; a coating solution for metal oxide coating thus produced; and a metal oxide coating. The method for producing a coating solution for metal oxide coating, the method being characterized in including: a first step for hydrolyzing a first metal alkoxide in the presence of a metal salt and organic solvent to obtain a first-step solution; a second step for adding to the first-step solution a second metal alkoxide of lower reactivity in comparison with the first metal alkoxide, and hydrolyzing / condensing to obtain a second-step solution; and a third step for adding a precipitation inhibitor to the second-step solution.

Owner:NISSAN CHEM IND LTD

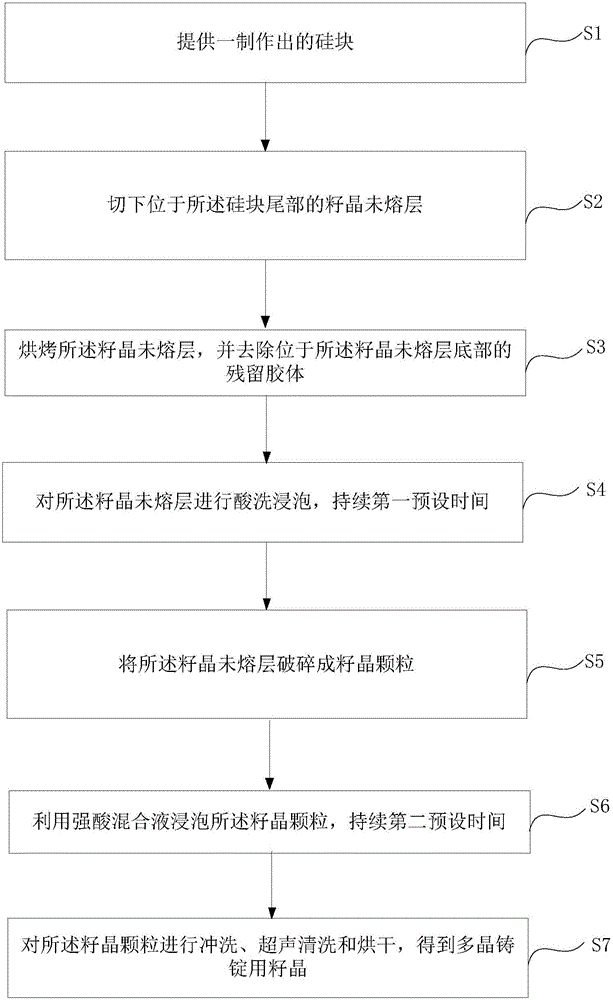

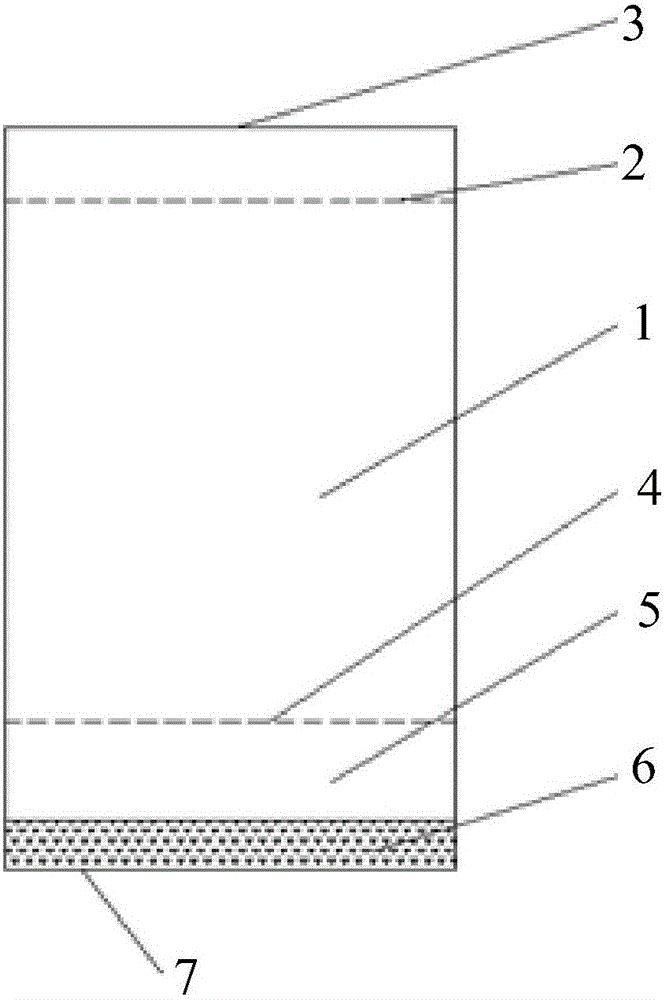

Making method of seed crystal for polycrystalline ingot

InactiveCN106087042AImprove crystal qualityStable and efficientPolycrystalline material growthSingle crystal growth detailsStrong acidsColloid

The invention discloses a making method of a seed crystal for a polycrystalline ingot. The making method comprises the steps that a made silicon block is provided; a seed crystal unmelted layer located at the tail portion of the silicon block is cut off; the seed crystal unmelted layer is roasted, and remained colloid located at the bottom of the seed crystal unmelted layer is removed; pickling and soaking are conducted on the seed crystal unmelted layer for first preset time; the seed crystal unmelted layer is crushed into seed crystal particles; the seed crystal particles are soaked with a strong acid mixed liquor for second preset time; the seed crystal particles are subjected to washing, ultrasonic cleaning and drying, and the seed crystal for the polycrystalline ingot is obtained. According to the making method of the seed crystal for the polycrystalline ingot, the bottom unmelted layer can be recycled, the efficient seed crystal which is stable in performance is obtained, the crystal quality of the polycrystalline ingot is improved, and the production cost is reduced.

Owner:JINKO SOLAR CO LTD +1

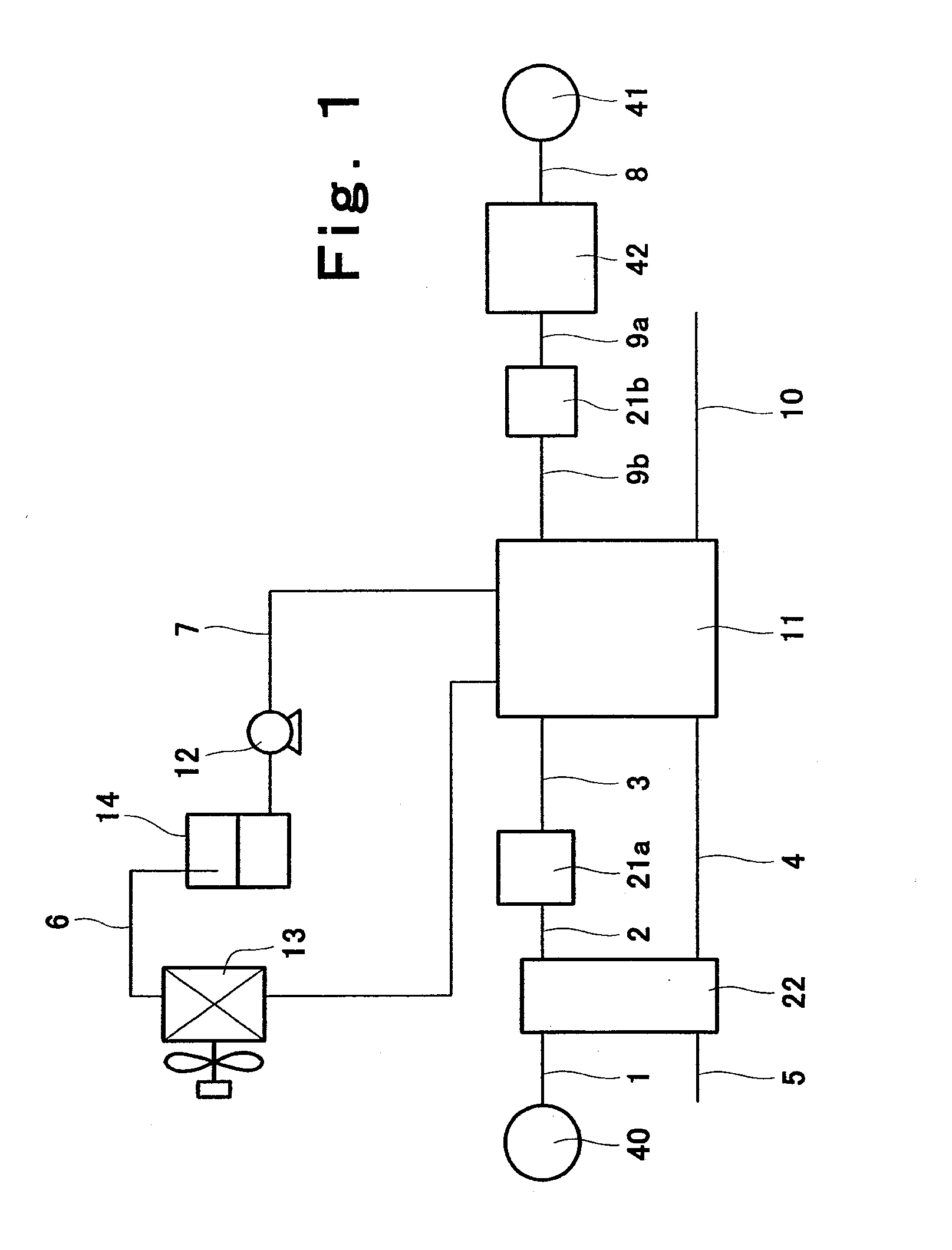

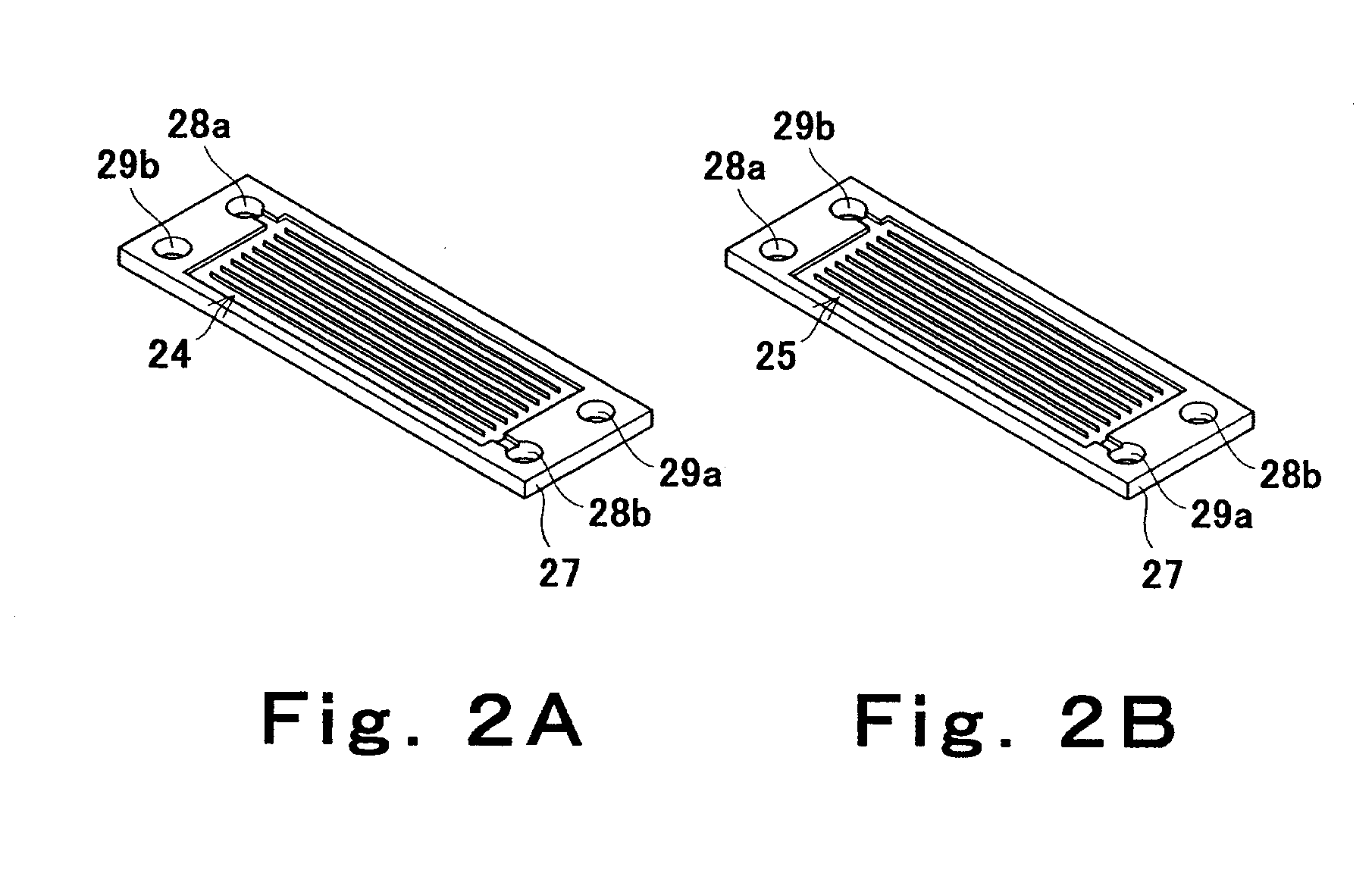

Fuel cell system operation method

InactiveUS20100255390A1Improvement in stability and energy efficiencyStable and efficientFuel cell auxillariesExhaust gasAutomotive engineering

A method of operating fuel cell system includes generating electricity by a fuel cell using fuel gas and oxidizing gas and allowing cooling water to flow in the fuel cell and thereby cooling the fuel cell. The method includes transferring moisture from exhaust gas to supply gas using a first humidifier, the exhaust gas being discharged from the fuel cell, the supply gas being supplied to the fuel cell, and transferring moisture from the cooling water to the supply gas humidified using a second humidifier. The method includes at least one of detecting humidity of the supply gas humidified, detecting temperature of the cooking water, detecting the flow rate of the supply gas and detecting the amount of electricity generated by the fuel cell. The method also includes controlling the humidity of the supply gas humidified based on the value detected.

Owner:PANASONIC CORP

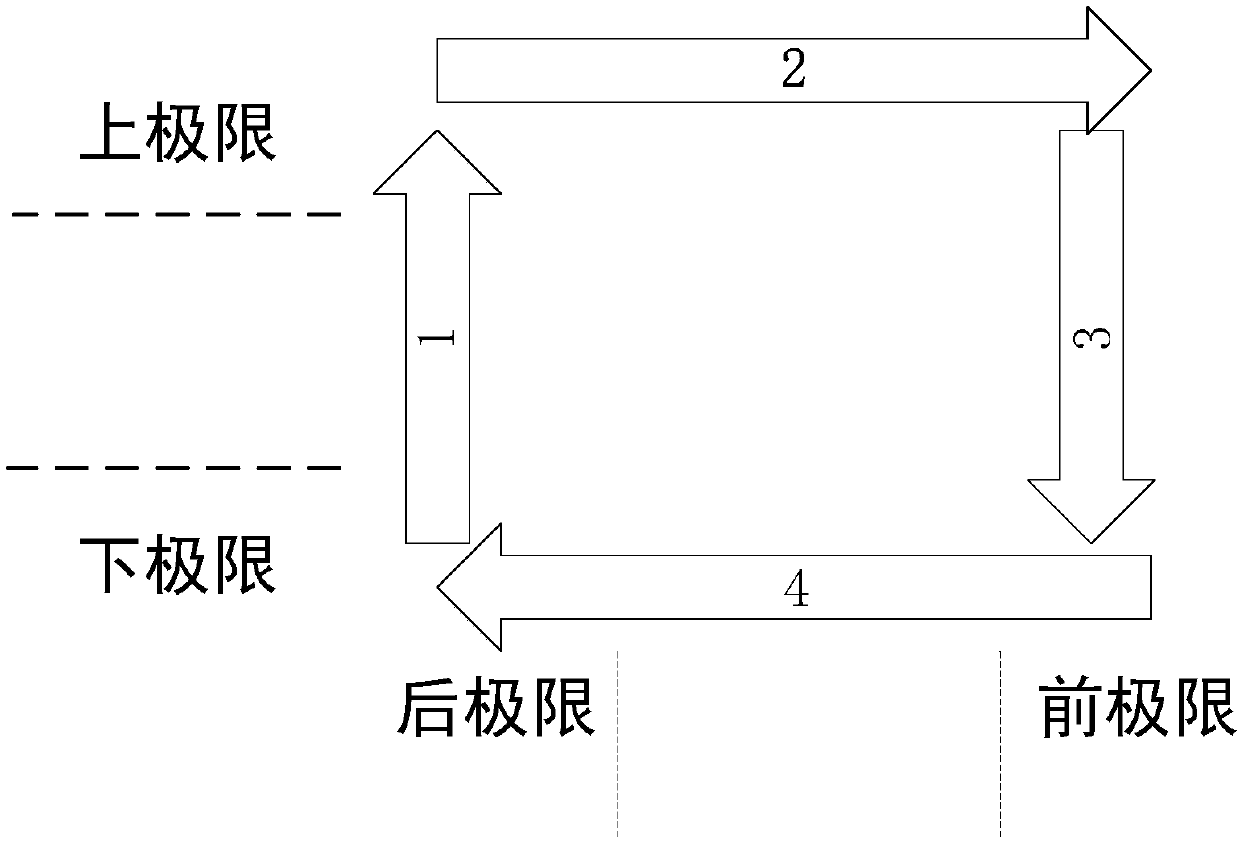

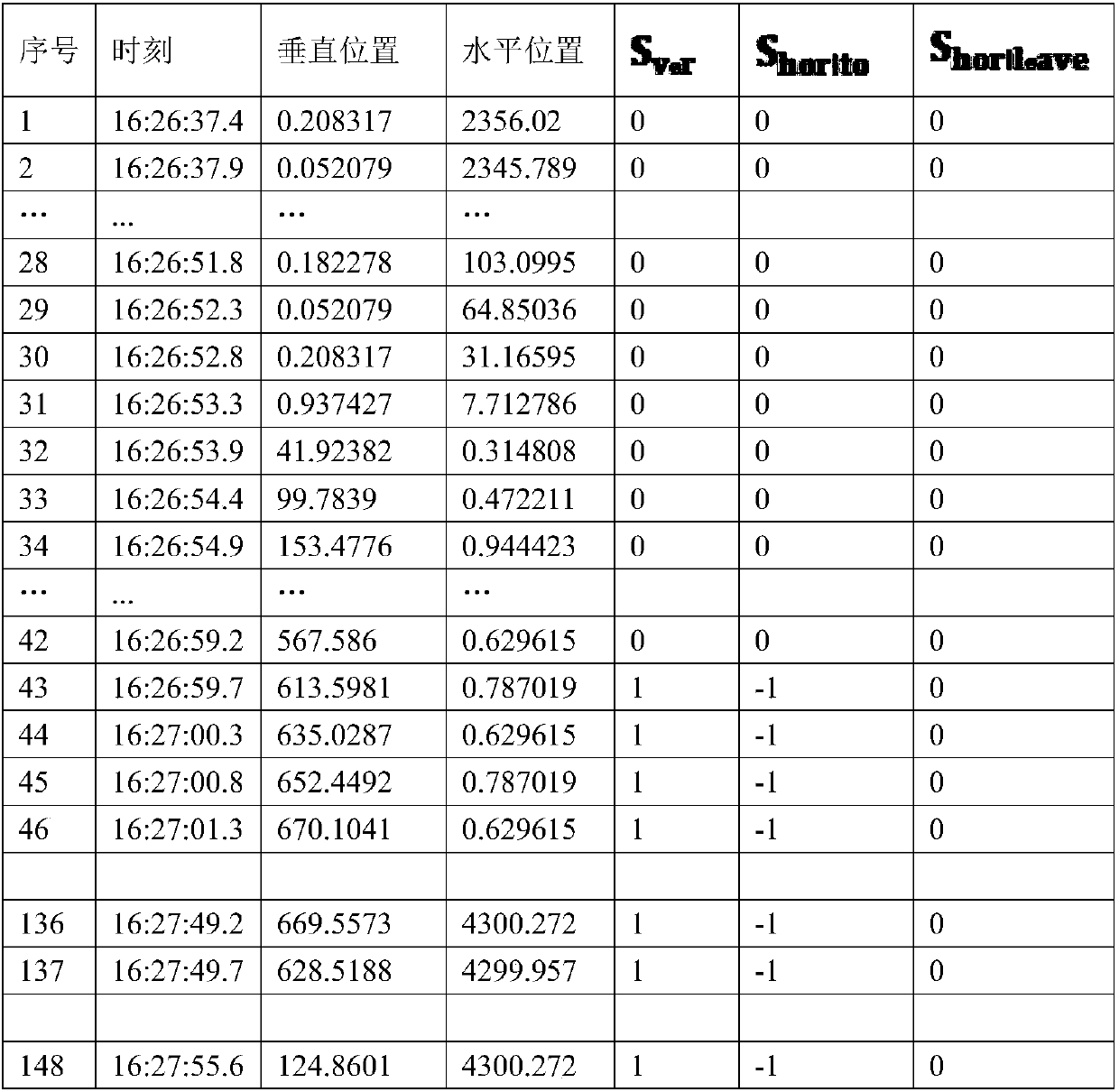

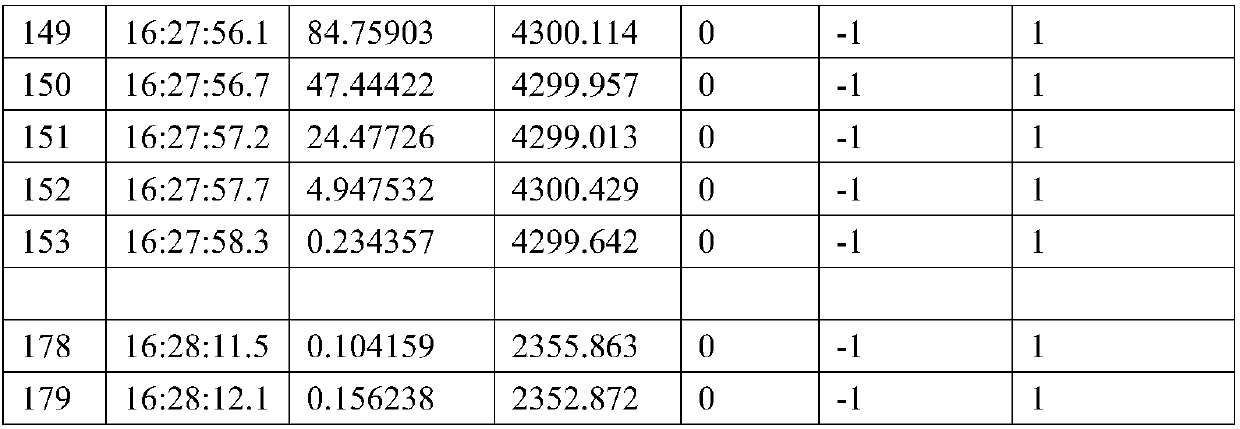

Cold rolling processing line stepping beam steel coil tracking method

ActiveCN107748541AStable and efficientEasy programmingProgramme controlComputer controlSemi automaticSwitching signal

The invention relates to a cold rolling processing line stepping beam steel coil tracking method. The method comprises the following steps of step1, setting a shared memory and setting an initial value of the shared memory; step2, carrying out parameter configuration on a stepping beam and storing the parameter configurations; and step3, tracking a steel coil on the stepping beam: S1, reading theparameter configurations in the step2; S2, according to a set frequency, periodically acquiring a real-time horizontal position and a vertical position of the stepping beam; S3, then comparing the real-time horizontal position and the vertical position of the stepping beam with the parameter configurations respectively, and determining a current state of the stepping beam; and S4, and then carrying out stepping determination. In the method, when one grade adopts a non-automatic (semi-automatic and manual) mode, or a proximity switch signal is not stable because of equipment shaking, phenomenaof a steel coil tracking error or missing and the like are not generated. The tracking method is completed under a PC platform and is not completed in a PLC system so that programming is simple and maintenance is convenient.

Owner:WISDRI ENG & RES INC LTD

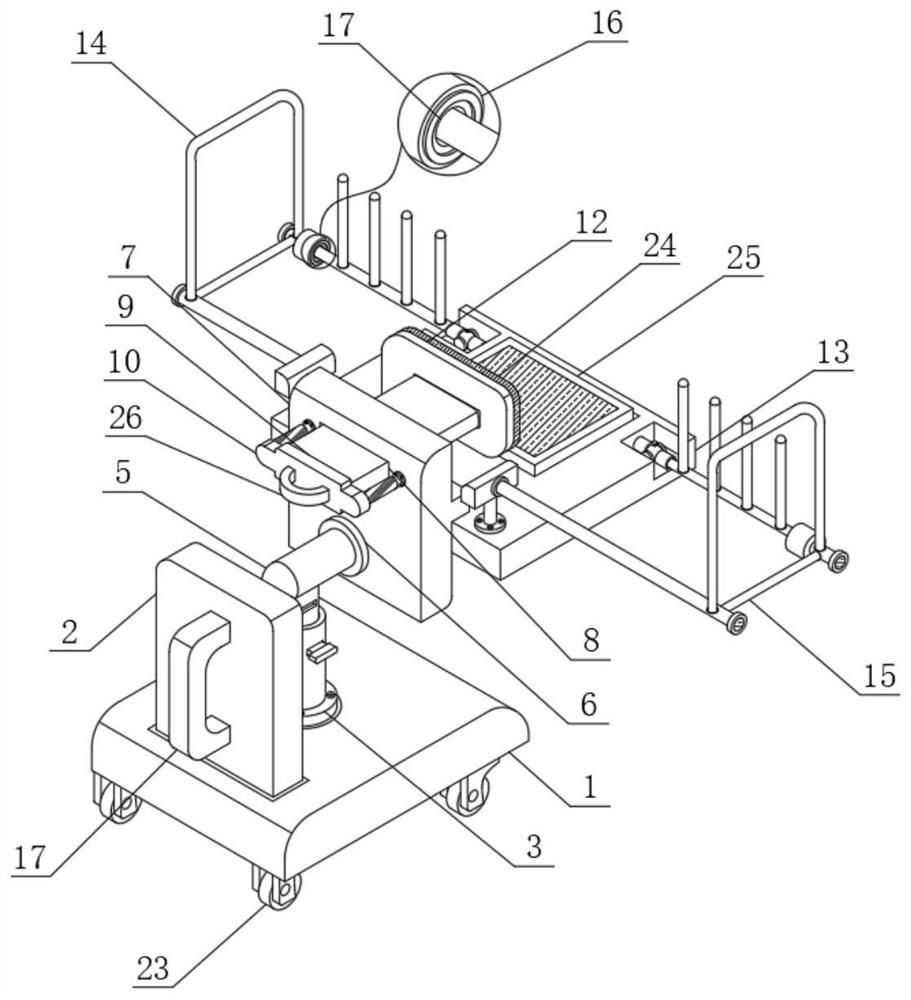

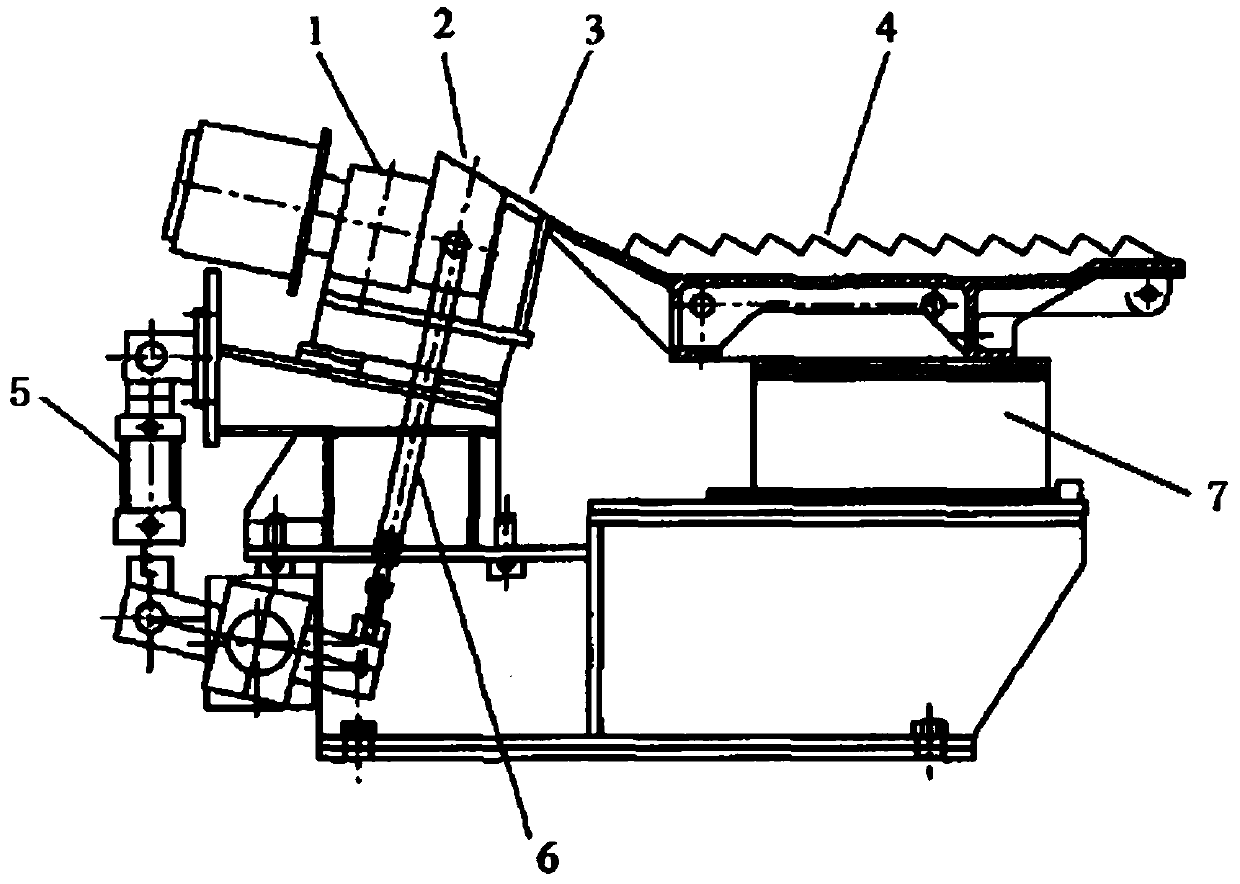

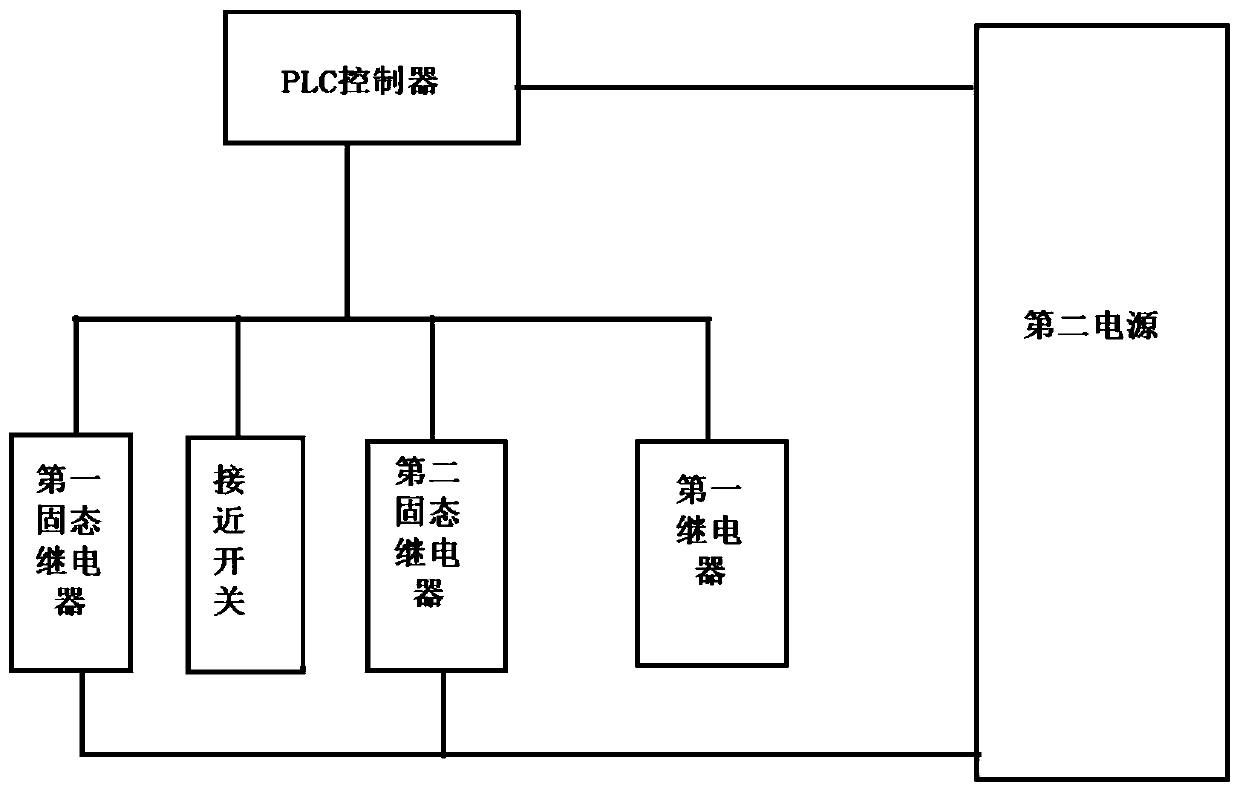

Control system and control method for cooling bed steel unloading system

PendingCN111558623AOvercome the problem of frequent repetitive failuresStable and efficientRoll mill control devicesCooling bedsHydraulic cylinderControl system

The invention belongs to the technical field of controlling a cooling bed steel unloading system, and particularly relates to a control system for a cooling bed steel unloading system. The cooling bedsteel unloading system comprises a plurality of cooling bed steel unloading devices. The cooling bed steel unloading devices are all connected to an outdoor control system. The control system comprises a first solid state relay, a second solid state relay, a second power supply and a PLC. The PLC is respectively connected to the first solid state relay and the second solid state relay. The firstsolid state relay and the second solid state relay are connected with a first solenoid valve installed on a hydraulic cylinder (5) in each cooling bed steel unloading device, so as to drive the corresponding hydraulic cylinder (5) to expand and contract, then drive a mechanical linkage mechanism (6), and control a lifting baffle (2) to reach the corresponding high gear and low gear.

Owner:SHANDONG IRON & STEEL CO LTD

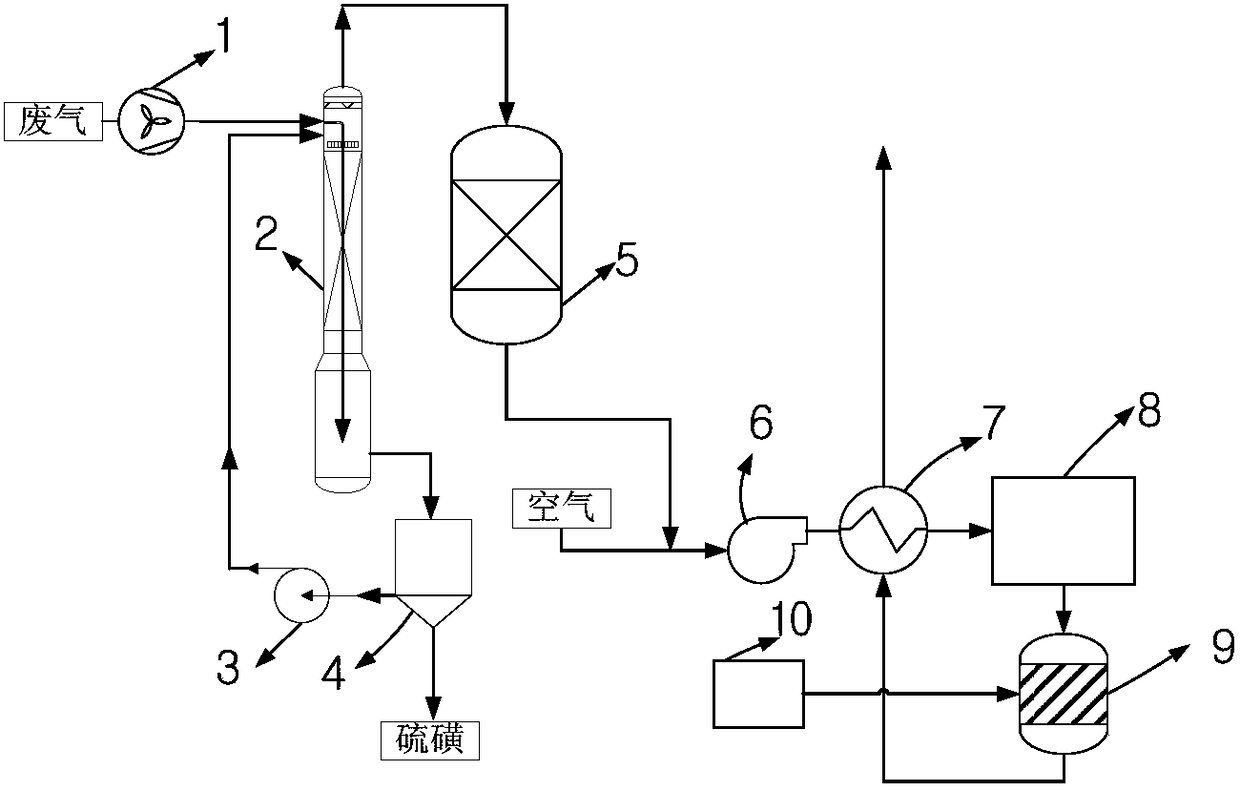

Method for treating volatile sulfur-bearing organic exhaust gases

ActiveCN108939867AAchieving zero emissionsConcentration equalizationGas treatmentDispersed particle separationSulfideFlammability limit

The invention relates to a method for treating volatile sulfur-bearing organic exhaust gases. The method comprises three steps, i.e., wet type real-time regeneration desulfurization, non-dipping dry-type fine desulfurization and hydrocarbon removal. According to the method, a wet type real-time regeneration desulfurization process can be used for treating sulfides in a concentration range of 0ppmto 100,000ppm and achieving the normal-temperature normal-pressure regeneration of a desulfurizer under the condition that the oxygen content of the exhaust gases is higher than 10%; and due to the non-dipping dry-type fine desulfurization, various sulfides can be removed and purified to achieve the zero discharge of the sulfides, the concentration of non-methane total hydrocarbons is further homogenized, the high efficiency of a terminal dealkylation unit is stabilized, the time for entry of non-methane total hydrocarbon gases in an explosive limit range under abnormal conditions is retarded,and thus, the safety of a terminal dealkylation system is effectively guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

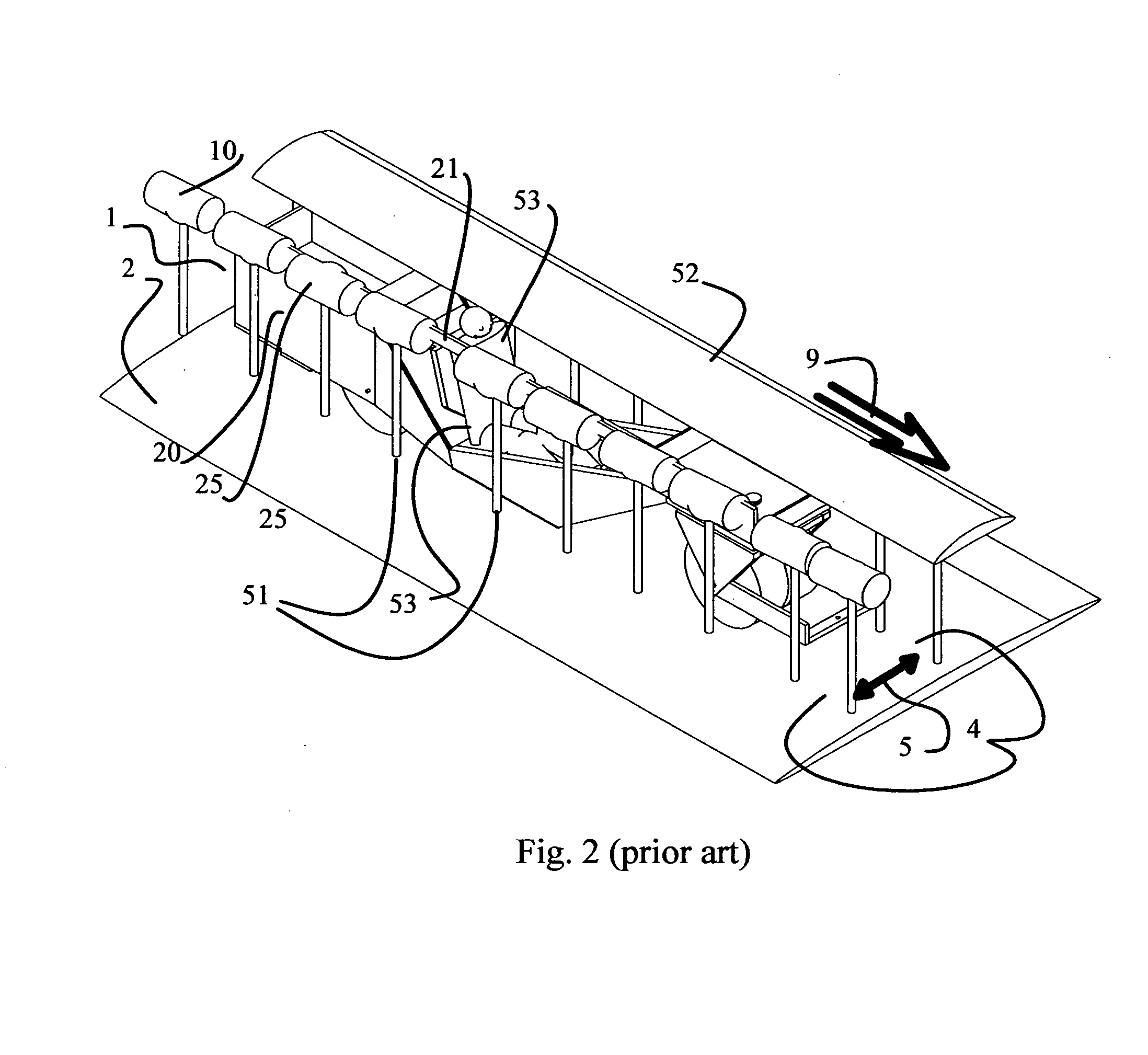

Vineyard configuration

InactiveUS20150068116A1Stable and efficientCanopy becomes thinVehicle seatsTractorsEngineeringSunlight

Owner:BULLIS JAMES K

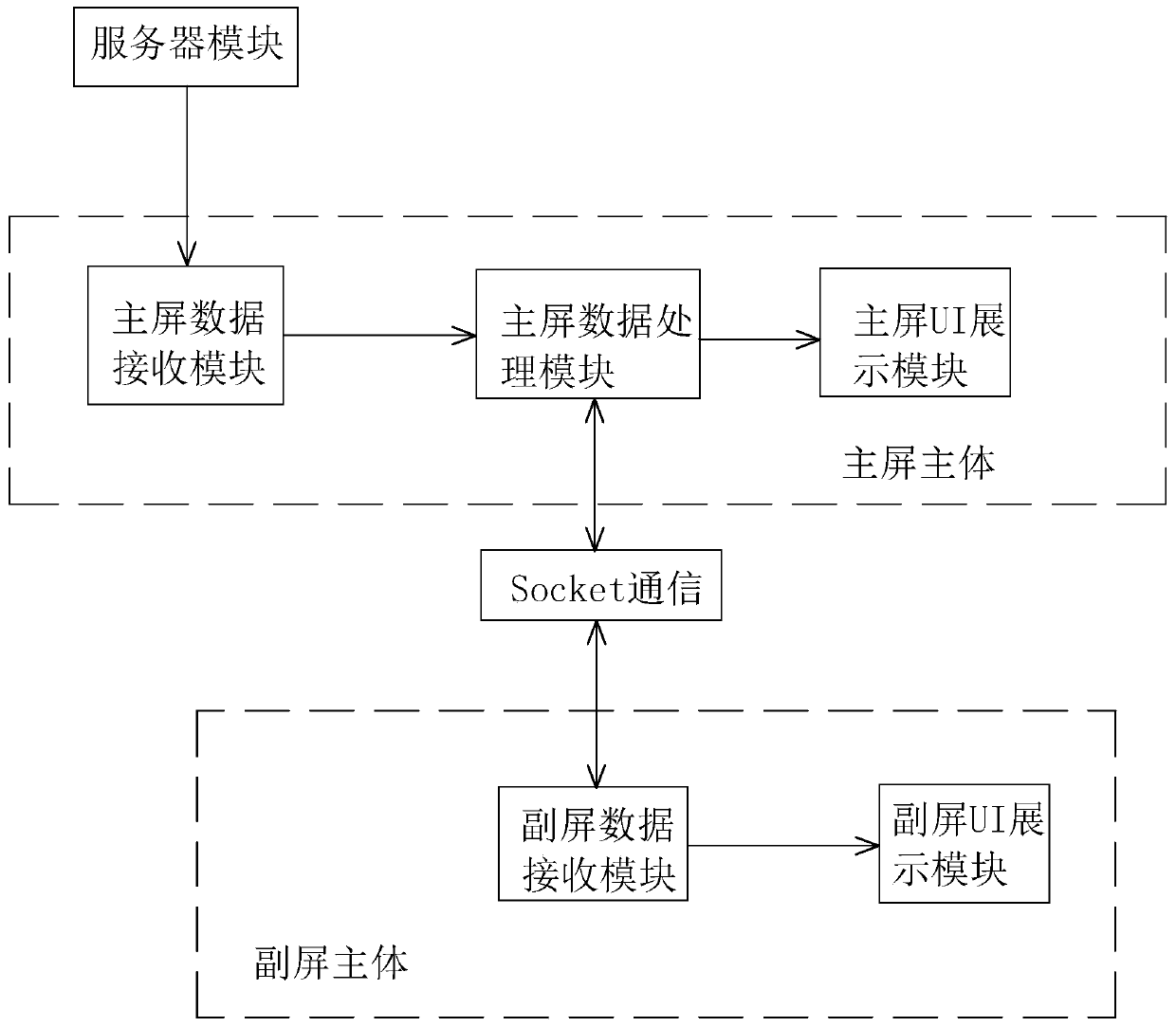

Main and auxiliary screen system capable of displaying auxiliary information

InactiveCN111464839AStable and efficientEfficient deliverySelective content distributionComputer hardwareEngineering

The invention relates to the field of display screens, discloses a main and auxiliary screen system capable of displaying auxiliary information, and solves the problem that a traditional main screen and an auxiliary screen need to be networked at the same time to set correct IPs and dns. The key points of the technical scheme are that: the system comprises a server module and a main scree body; the main screen body comprises a main screen data receiving module, a main screen data processing module and a main screen UI display module; the main screen data receiving module receives data providedby the server module; the main screen data processing module processes data; the main screen UI display module is used for displaying the data processed by the main screen data processing module in real time; the main and auxiliary screen system comprises an auxiliary screen data receiving module and an auxiliary screen UI display module; the auxiliary screen data receiving module receives data processed by the main screen data processing module through Socket communication and sends the data to the auxiliary screen UI display module for display, and the effects that communication is established between the main screen body and the auxiliary screen body, only the main screen needs to be connected with a network, and use is convenient for a user are achieved.

Owner:NANJING SKYWORTH INST OF INFORMATION TECH CO LTD

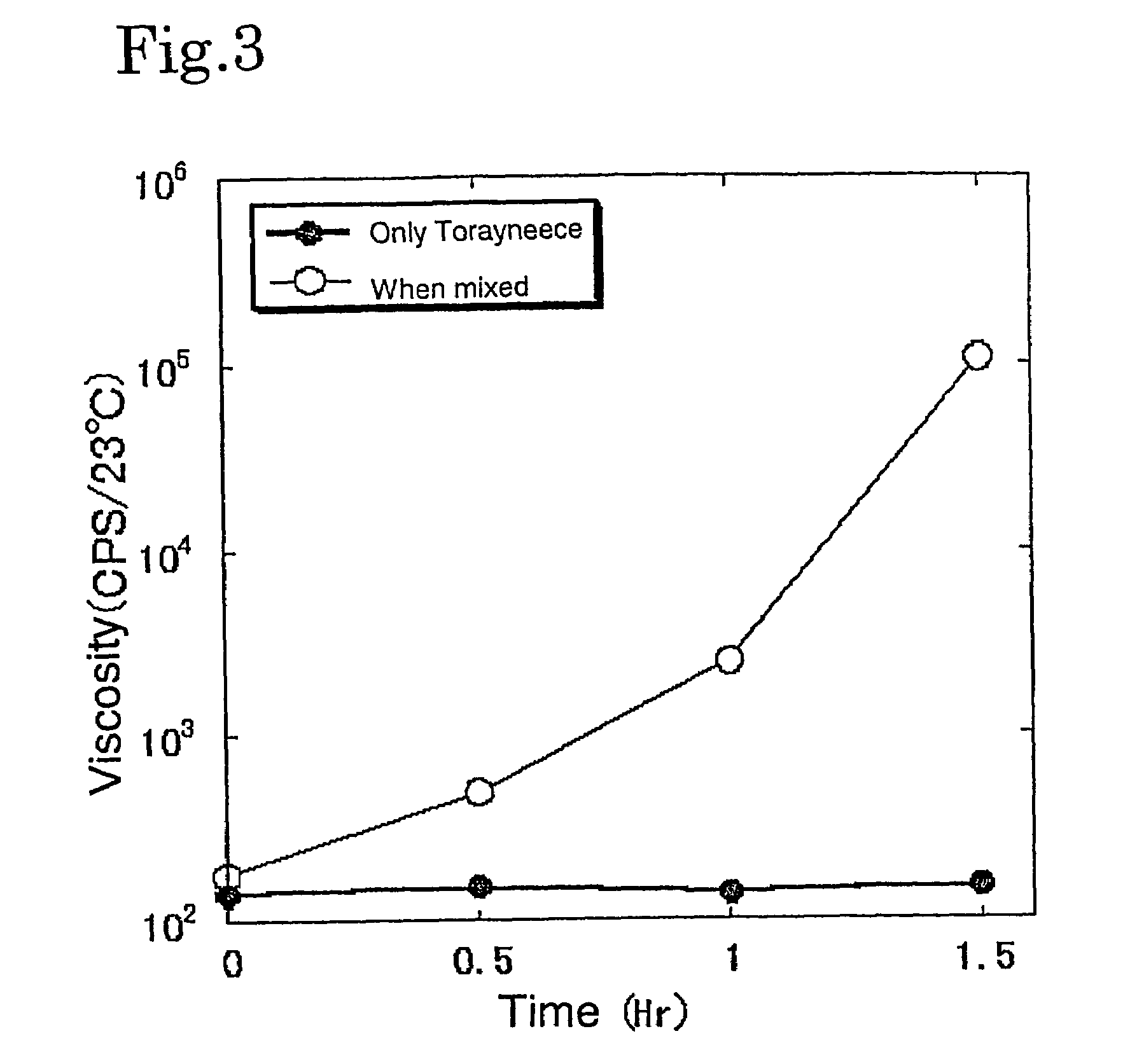

Polyimide resin precursor solution, laminates for electronic components made by using the solution and process for production of the laminates

InactiveUS7144679B2Stable and efficientThe process is stable and efficientInsulating substrate metal adhesion improvementLiquid surface applicatorsPolyimide substrateChemistry

Laminates for electronic components are produced by applying a polyimide resin precursor solution containing a palladium compound on a polyimide substrate, drying the resulting coating to form a polyimide resin precursor layer, irradiating this layer with ultraviolet rays in the presence of a hydrogen donor to form nuclei for primer plating, forming a metal primer layer by electroless plating, and converting the polyimide resin precursor layer into a polyimide resin layer through imidation by heating either after or before the formation of a surface plating layer. The invention provides laminates for electronic components which are extremely improved in adhesion to metal layers without impairing the characteristics inherent in the substrate and are excellent in insulating properties, and polyimide resin precursor resin solution to be used in the production of the laminates.

Owner:TORAY ENG CO LTD

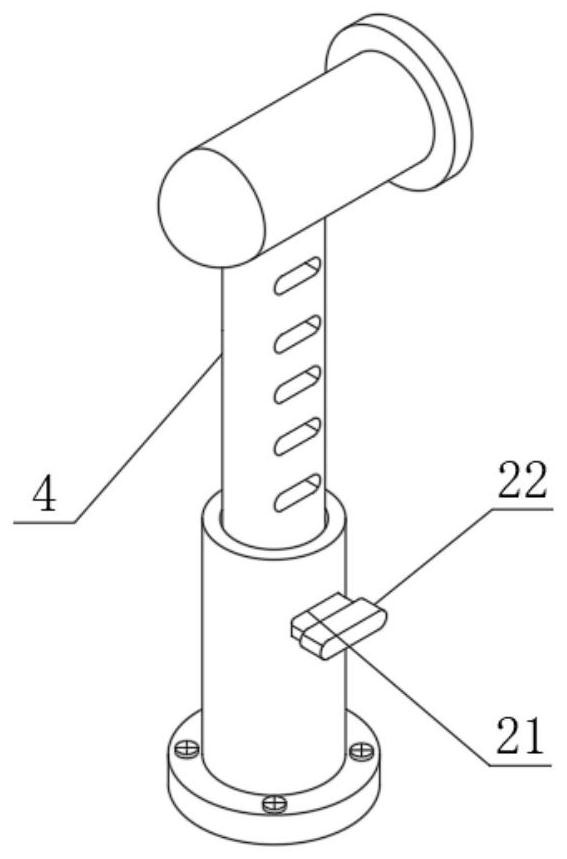

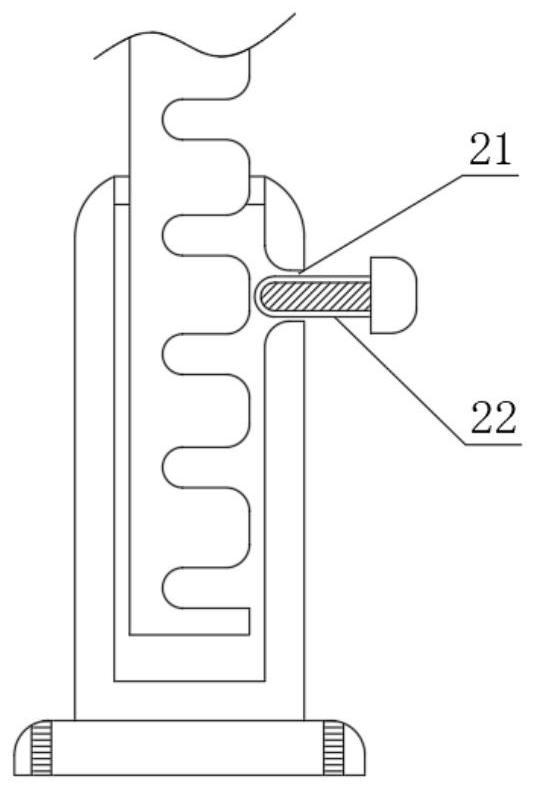

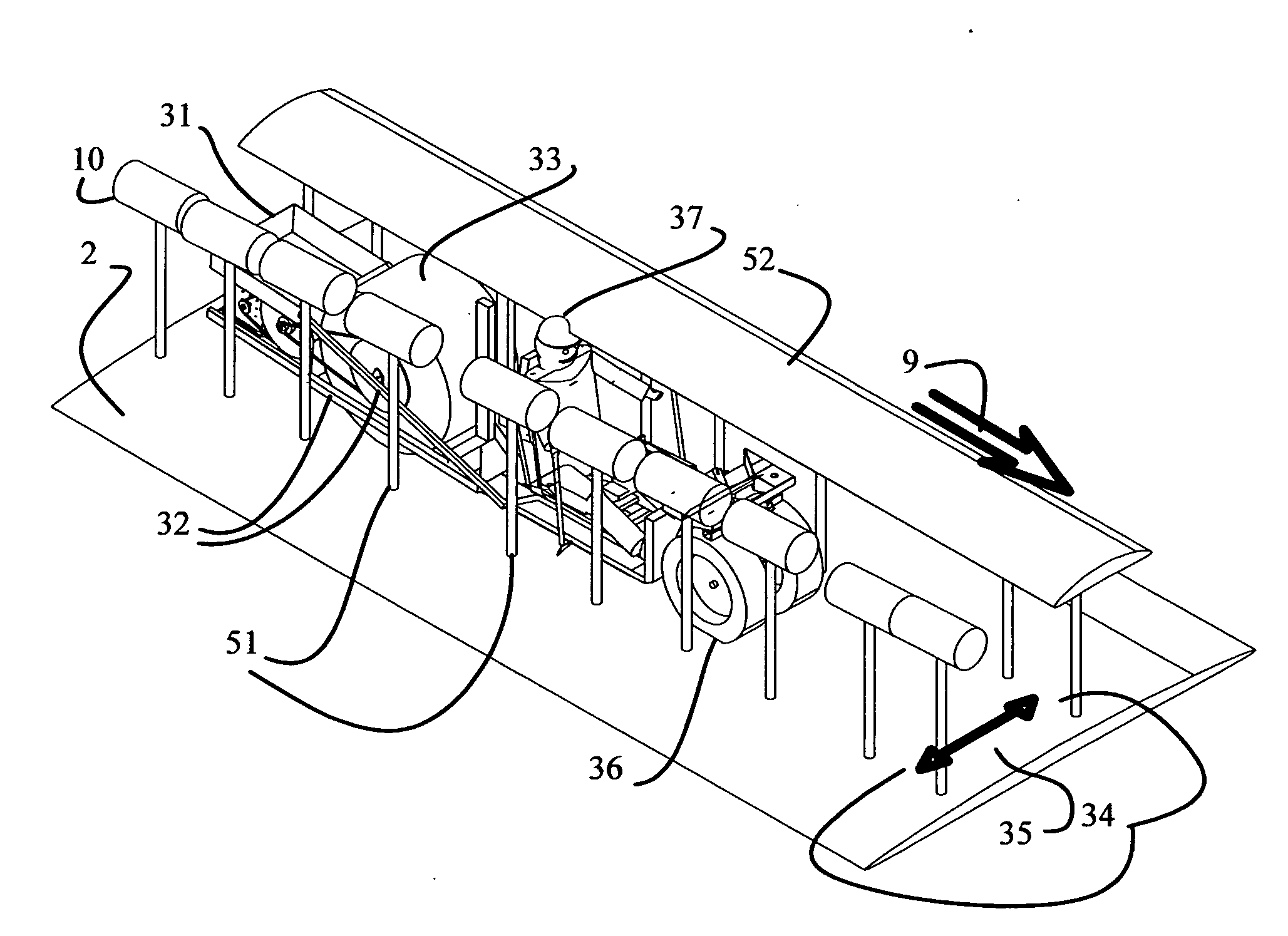

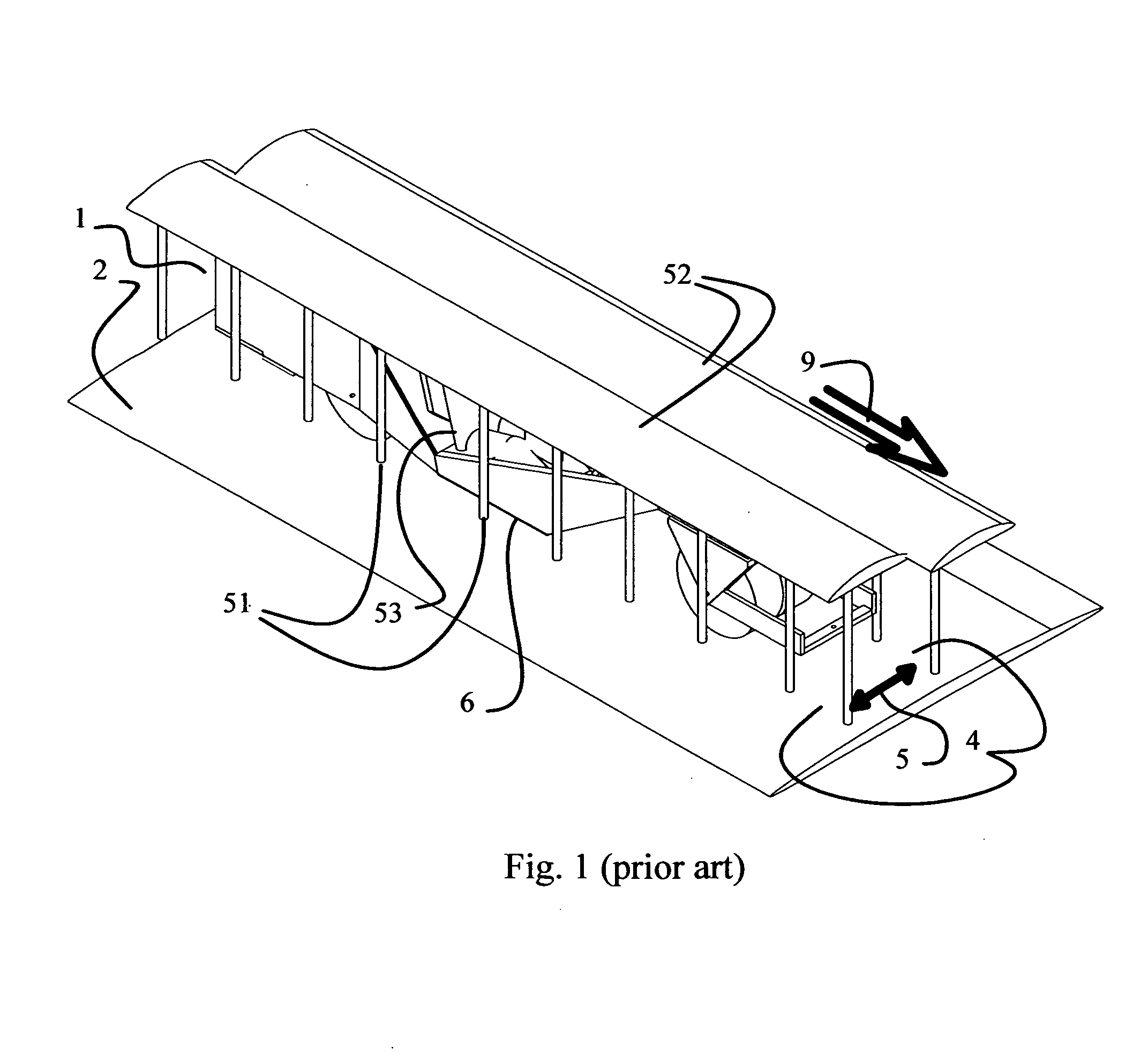

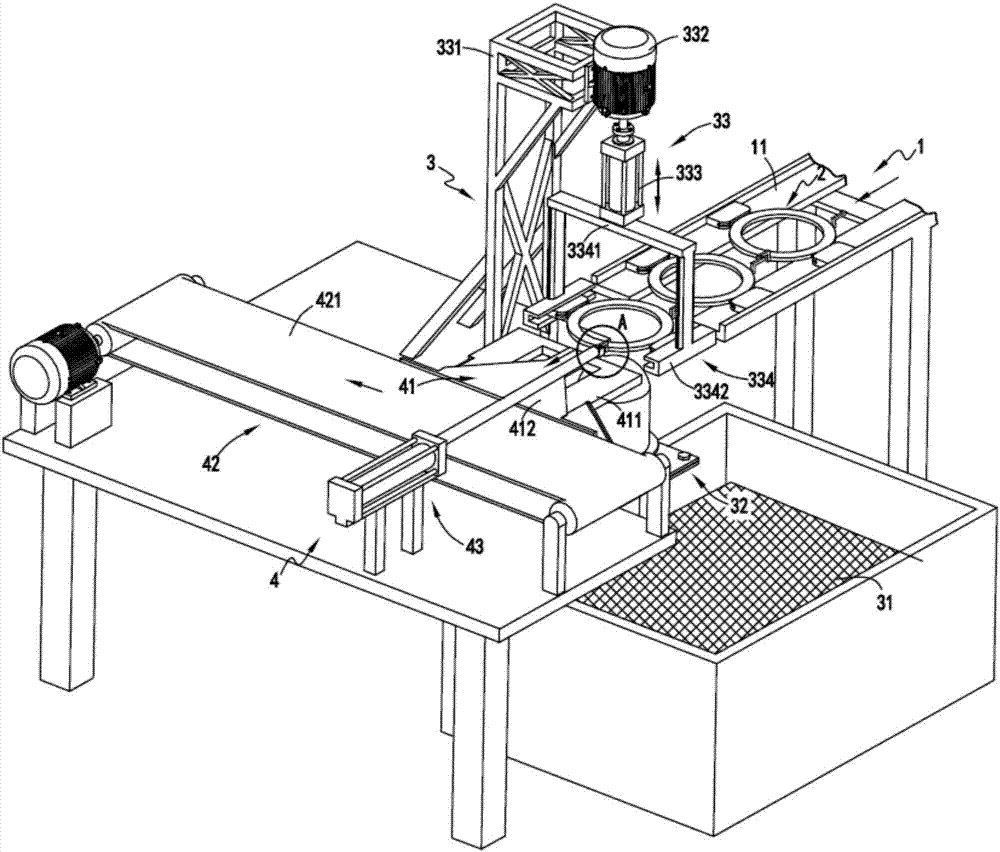

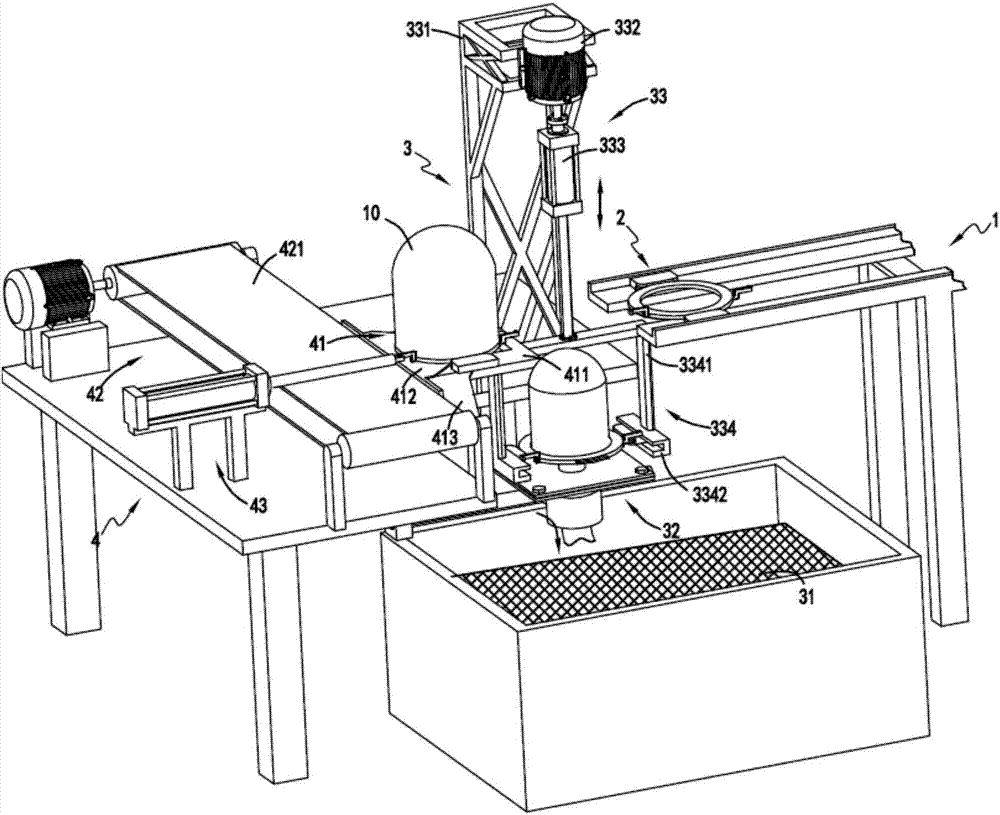

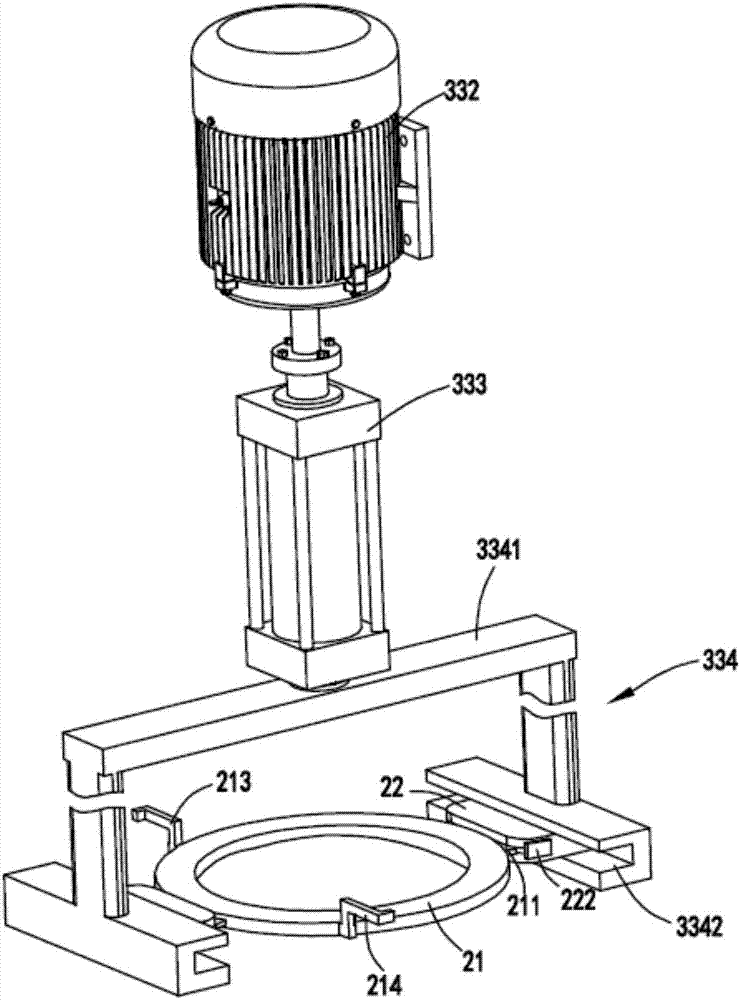

Efficient heat preservation dead head production device

ActiveCN106890943AStable and efficientWon't wasteFoundry mouldsFoundry coresEngineeringMechanical engineering

The invention relates to an efficient heat preservation dead head production device. The efficient heat preservation dead head production device comprises a conveying part used for conveying a tray assembly, a forming part and a discharging part. The tray assembly comprises a material supporting piece and a supporting piece. The forming part comprises a mud pit, a forming mechanism and a lifting rotating mechanism. The lifting rotating mechanism is used for driving the tray assembly conveyed by the conveying part to the forming mechanism. After the forming mechanism finishes dead head forming, the tray assembly and a formed dead head are driven to be separated from the forming mechanism and return to the initial position. The discharging part is arranged at the rear end of the forming part. The discharging part comprises an assembly separating mechanism, an output mechanism arranged at the rear end of the assembly separating mechanism, and a pulling mechanism, wherein the pulling mechanism is used for pulling the tray assembly on the lifting rotating mechanism and the formed dead head to move to the output mechanism from the lifting rotating mechanism via the assembly separating mechanism. The problems that in the prior art, the production efficiency in the dead head production process is low, continuity cannot be achieved, and the dead head is prone to deformation are solved.

Owner:长兴鼎峰铸材科技股份有限公司

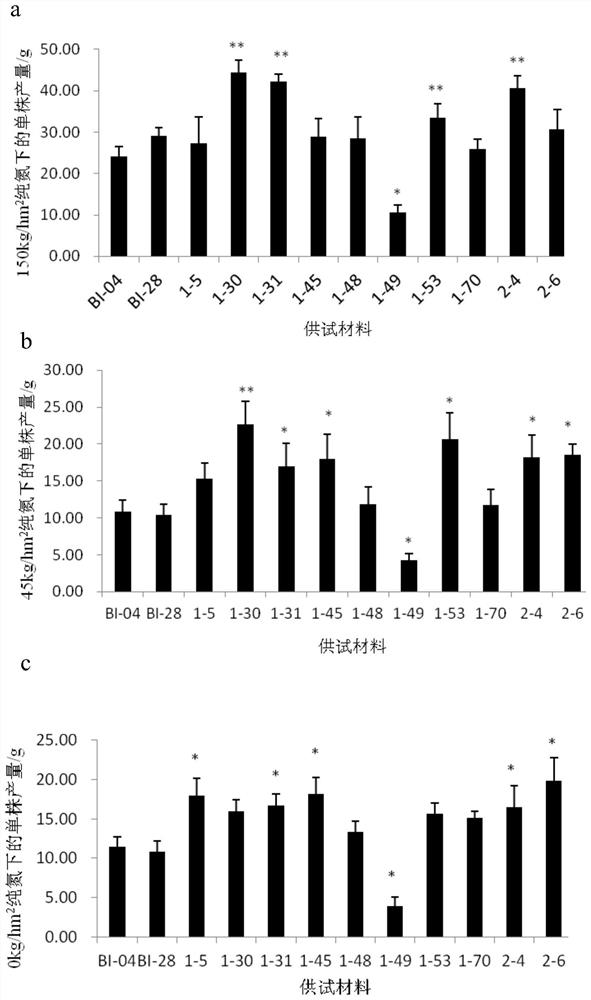

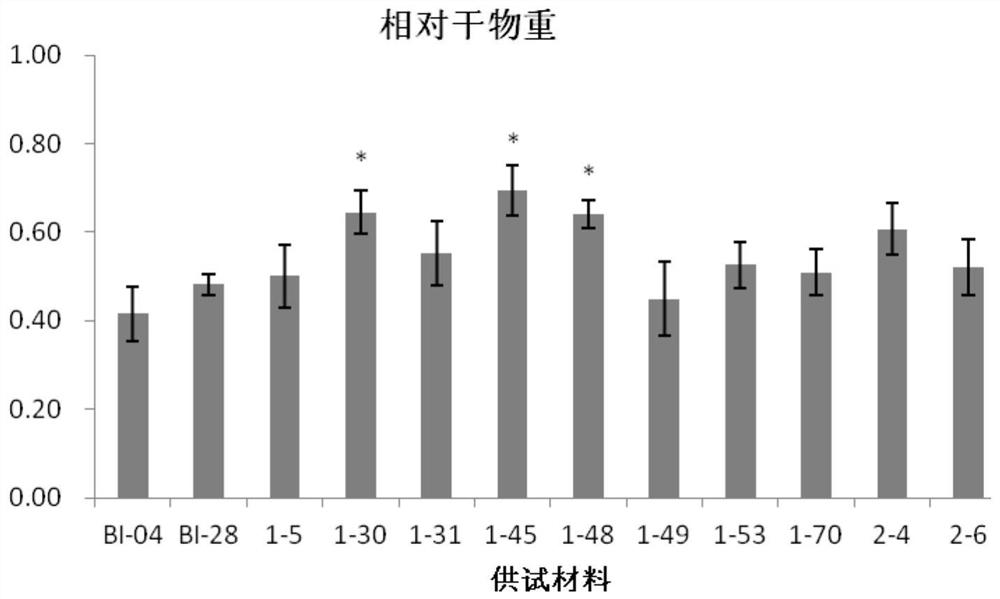

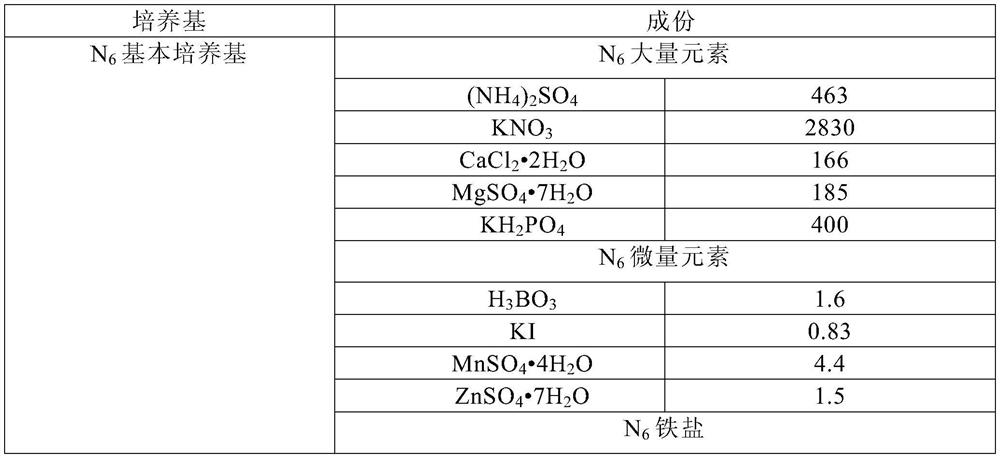

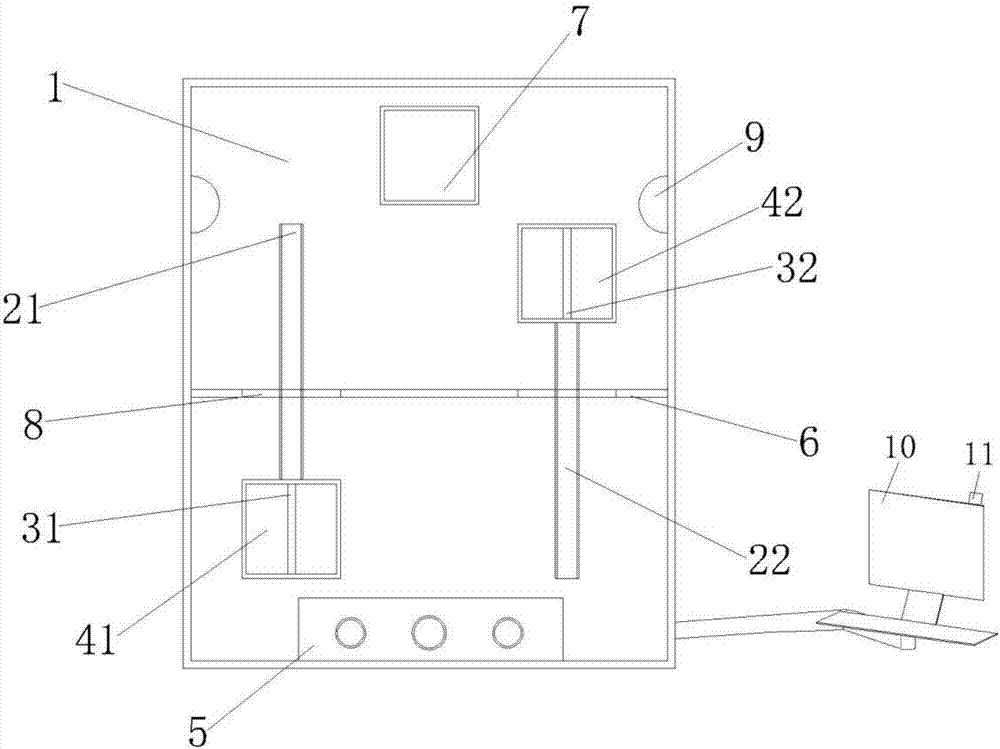

Method for rapidly obtaining stable homozygous nitrogen efficient material by using hybrid F1-generation microspore culture

ActiveCN112273219AImprove overall utilizationStable and efficientAgriculture gas emission reductionPlant tissue cultureSporelingNitrogen stress

The present invention relates to the technical field of agriculture, particularly to a method for quickly obtaining a genetically stable homozygous nitrogen efficient material by using hybrid F1-generation microspore culture. The method comprises the following steps: selecting two identified low-nitrogen-tolerant barley parents for hybridizing, harvesting F1-generation microspores, after in-vitroculture and through a differentiation and dedifferentiation process of the microspores, performing rapid homozygosis and immobilization on low-nitrogen-tolerant parent nitrogen efficient (dominant orrecessive) genes, performing culture to obtain regenerated doubled haploid M0-generation seeds, through multi-year multi-point multi-repetition low-nitrogen stress culture identification via water culture and field trials, and finally, rapidly performing screening to obtain the homozygous barley germplasm material whose seedling-stage biomass, mature-stage single-plant yield and nitrogen utilization efficiency are stably improved under a low-nitrogen condition and exceed those of parents.

Owner:SHANGHAI ACAD OF AGRI SCI

Spot welding equipment for machining metallic material and with monitoring function

InactiveCN107363378AMoves smoothly back and forthStable and reliable speed controlWelding protection meansCcd cameraManipulator

The invention discloses spot welding equipment for machining a metallic material and with a monitoring function, and relates to the technical field of automatic equipment. A first automatic clamping mechanism slides back and forth on a first guide rail through a first sliding rod arranged at the bottom. A second automatic clamping mechanism slides back and forth on a second guide rail through a second sliding rod arranged at the bottom. A sealing mechanism is arranged in the center of a machine body, and the left side and the right side of the sealing mechanism are provided with through holes. An electric control panel and a spot welding manipulator are arranged at the two ends of the machine body correspondingly. The machine body is connected with a displayer through a telescopic rod. An automatic warning device is arranged at the top of the displayer. CCD cameras connected with the displayer are arranged on the surfaces of the parts, on the two sides of the spot welding manipulator, of the machine body. Through the spot welding equipment, the spot welding efficiency and quality of metallic workpieces are greatly improved, harm of arc light and smoke to operators is reduced, the equipment is safe and environmentally friendly, operators can operate the equipment easily, working noise is low, and long-time efficient and stable spot welding operation is ensured.

Owner:SUZHOU CONYET AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com