Cross-operation-unit control method under flexible path

A flexible path and scheduling method technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as complex flexible path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

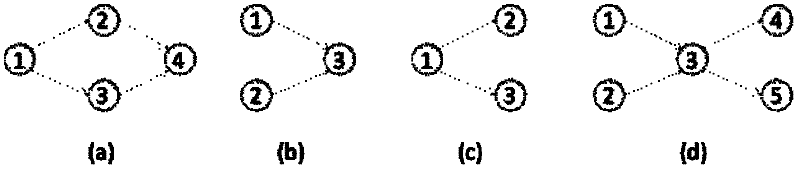

[0118] The preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0119] This embodiment specifically implements a flexible path cross-unit scheduling method according to the present invention, including the following steps:

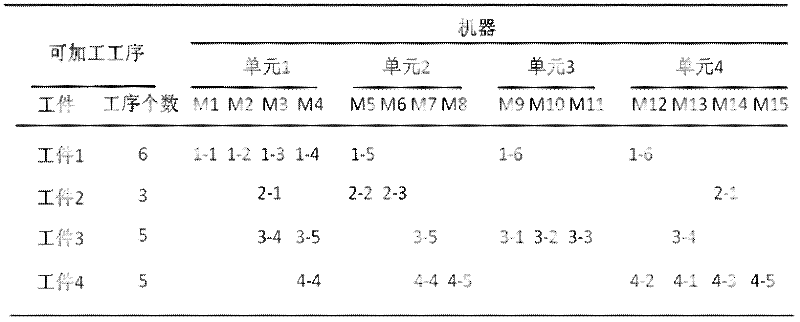

[0120] 1. Define the following symbols to describe the cross-unit scheduling problem under the flexible path:

[0121] i The index of the workpiece set i=1,...,J, where J is the number of special workpieces that require cross-unit scheduling

[0122] q i The index of the operation set for job i (q i =1,...,N), where N is the process number of workpiece i

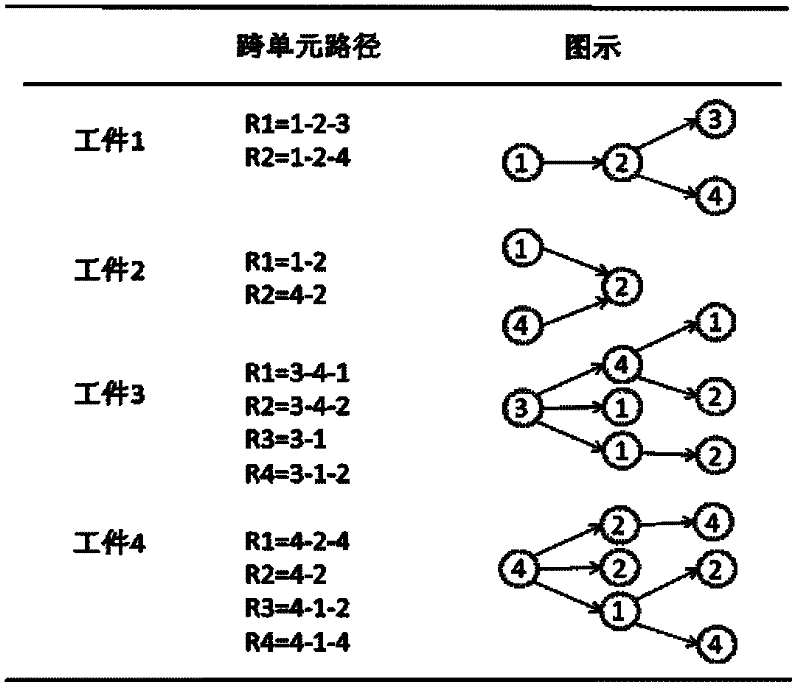

[0123] L i collection of cross-unit paths for artifact i

[0124] l ir Index (r=1,...,R) of the cross-unit path set of workpiece i, where R is the number of paths

[0125] m The index of the optional processing machine for the next process of the workpiece

[0126] t the current moment

[0127] t m The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com