Control system and control method for cooling bed steel unloading system

A technology of control system and cooling bed, applied in cooling bed, rolling mill control device, metal rolling, etc., can solve the problems of cycle error, frequent failure of steel unloading system on cooling bed, easy sticking of relay contacts, etc. Reduce the number of cooling bed downtime and maintenance, shorten downtime and maintenance time, and ensure the effect of high efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described now in conjunction with accompanying drawing.

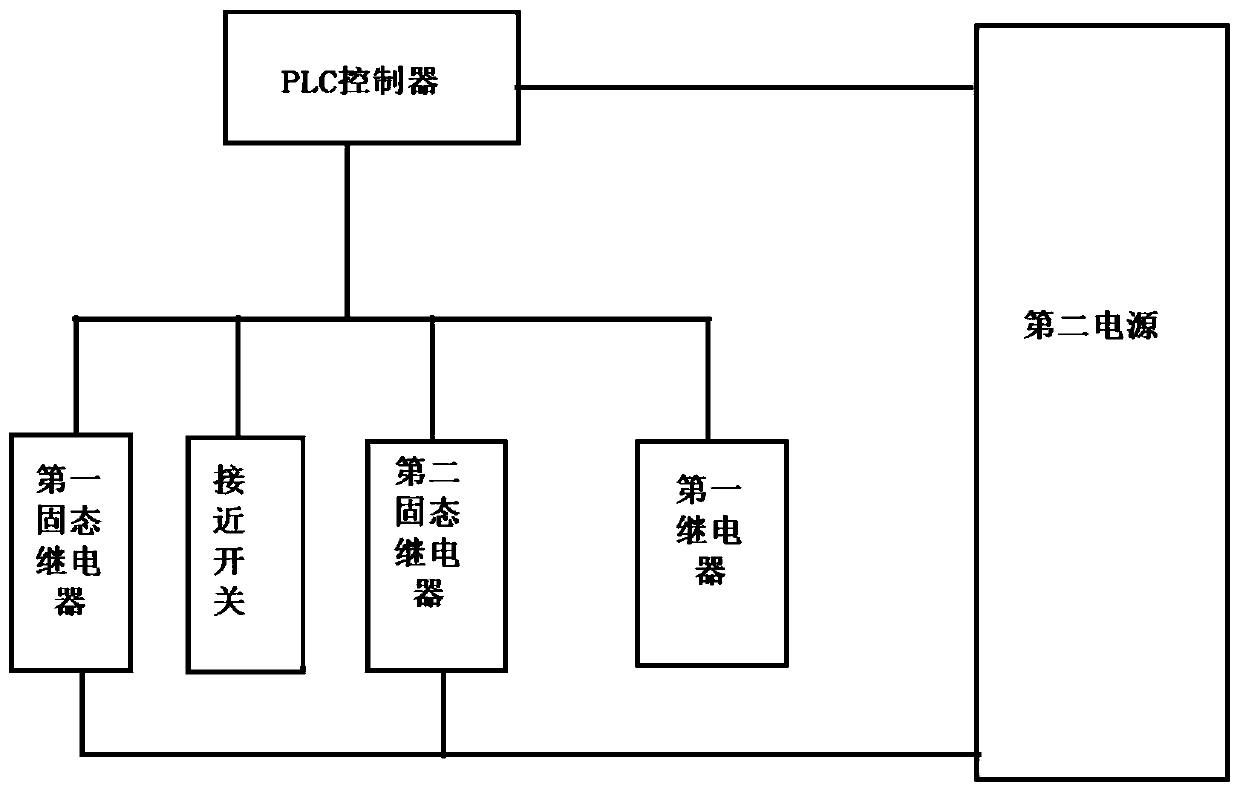

[0034] The invention provides a control system for a steel unloading system on a cooling bed. The control system is efficient, stable, safe, energy-saving, easy to maintain, and effectively improves the safe and reliable operation of unloading steel on a cooling bed.

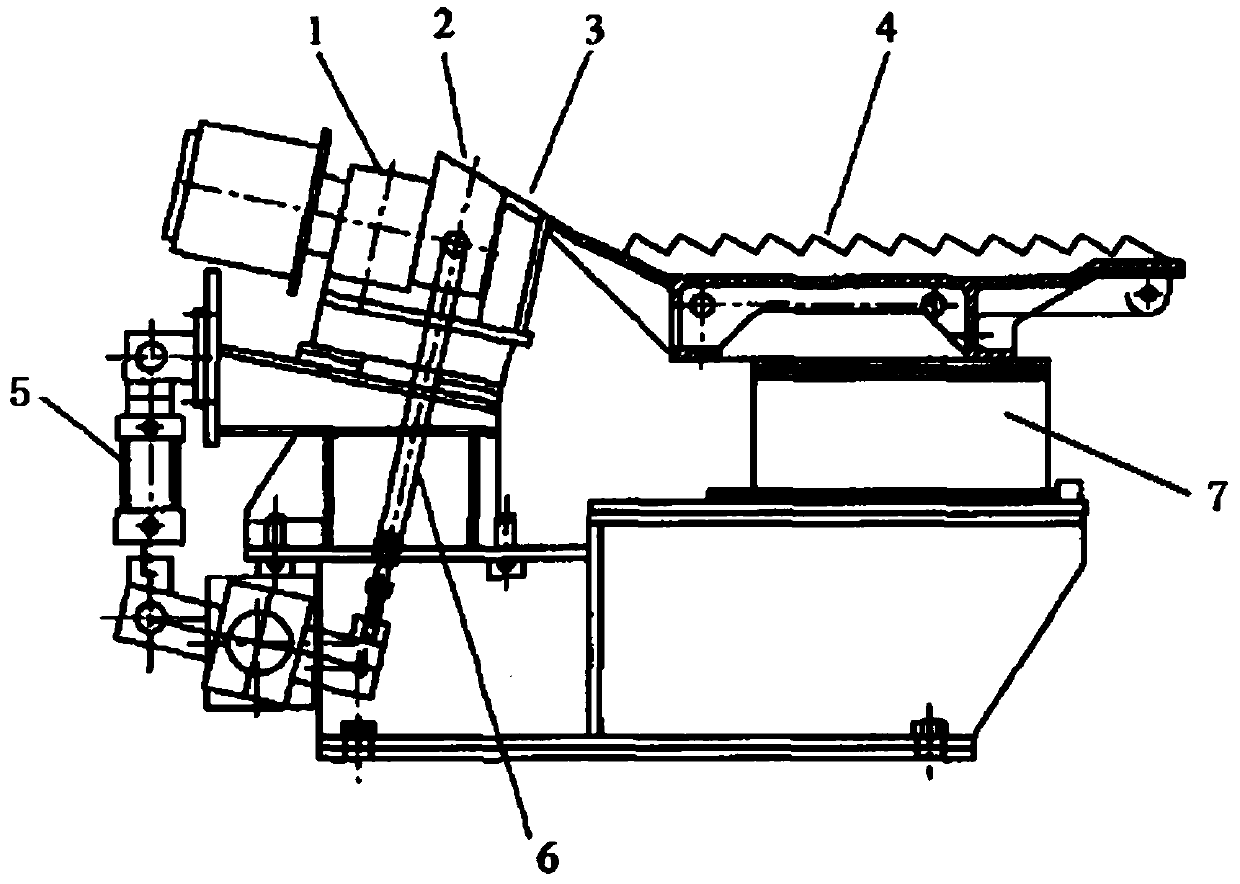

[0035] Such as figure 1 As shown, the steel unloading system on the cooling bed includes: multiple steel unloading devices on the cooling bed; multiple steel unloading devices on the cooling bed are arranged around the cooling bed 7; Lifting baffle 2, fixed plate 3, cooling bed surface rack straightening plate 4, hydraulic cylinder 5 and mechanical linkage mechanism 6;

[0036] The lifting baffle 2 is located between the cooling bed conveying roller table 1 and the fixed plate 3, and the rack straightening plate 4 on the cooling bed surface is set on one side of the fixed plate 3, which is used to transfer the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com