Spot welding equipment for machining metallic material and with monitoring function

A technology of metal materials and functional points, applied in the direction of metal processing equipment, welding equipment, arc welding equipment, etc., can solve the problems of reducing work efficiency, staff interference, and affecting the working environment of the workshop, so as to shorten the time and speed of intermediate pauses The control is stable and reliable, and the alarm prompt effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

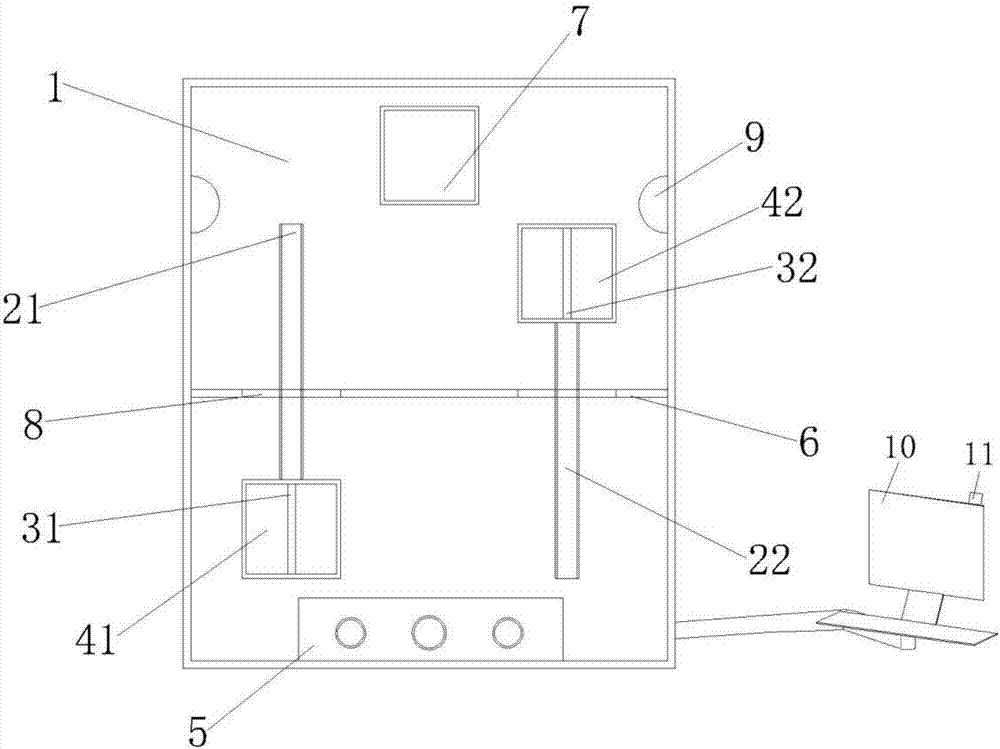

[0024] Such as figure 1 As shown, a spot welding equipment with monitoring function for processing metal materials in this embodiment includes a fuselage 1, a first guide rail 21, a second guide rail 22, a first slide bar 31, a second slide bar 32, The first automatic clamping mechanism 41, the second automatic clamping mechanism 42, the electrical control panel 5, the closing mechanism 6, the spot welding manipulator 7, the through hole 8, the CCD camera 9, the display 10 and the automatic alarm device 11.

[0025] The connection relationship of the above-mentioned components is as follows: the left and right sides of the middle part of the fuselage 1 are respectively provided with a first guide rail 21 and a second guide rail 22, and the first automatic clamping mechanism 41 is provided with the first slide bar 31 at the bottom. Slide back and forth on the first guide rail 21, and the second automatic clamping mechanism 42 slides back and forth on the second guide rail 22 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com