Sand screening box for municipal bridge construction

A sand screening and bridge technology, which is applied in the direction of screening, solid separation, grille, etc., can solve the problems of manpower consumption, low efficiency of sand screening, unusability, etc., and achieve labor-saving output, convenient sand screening work, and back and forth smooth moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

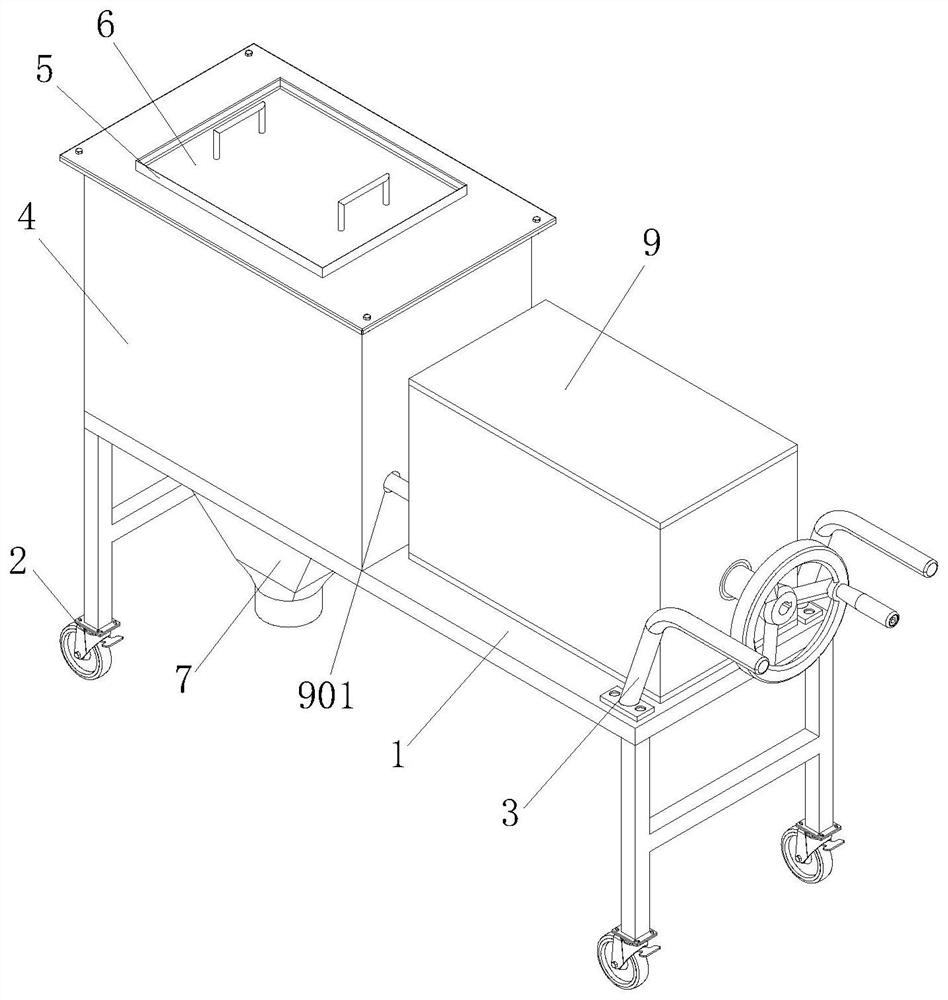

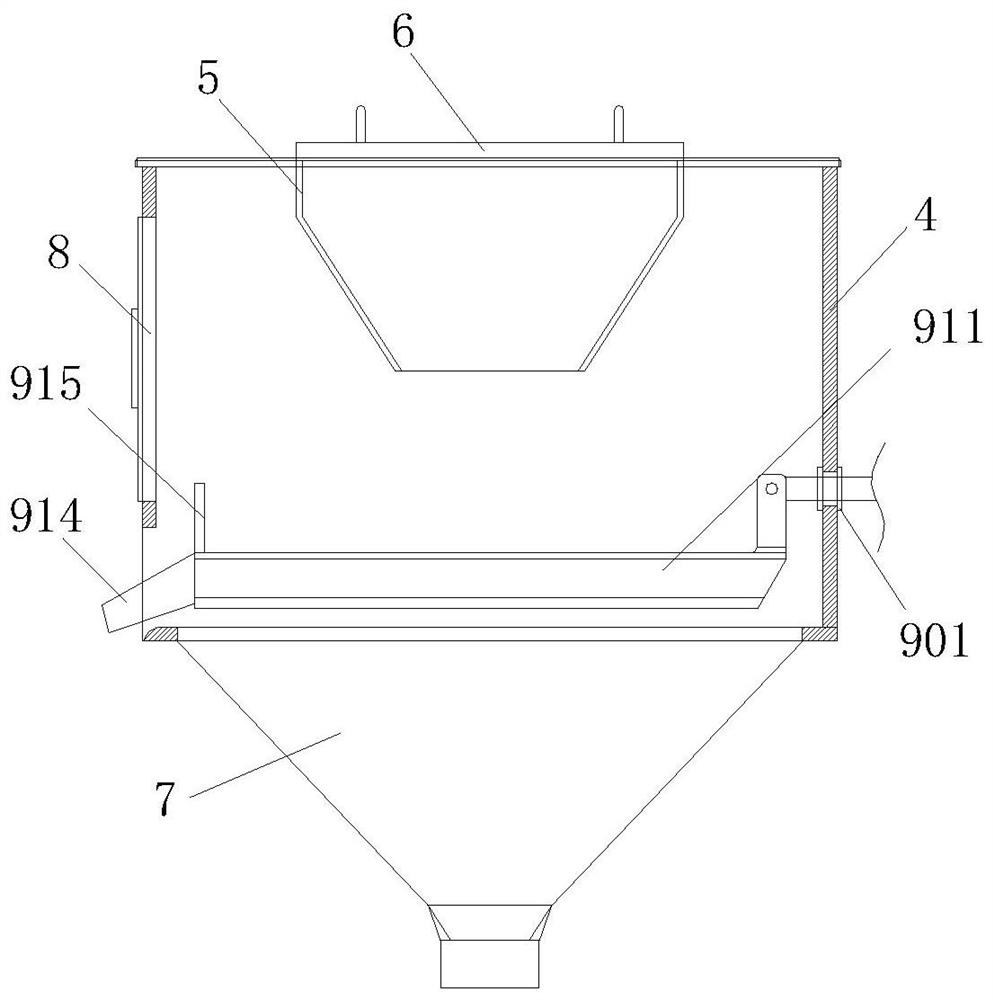

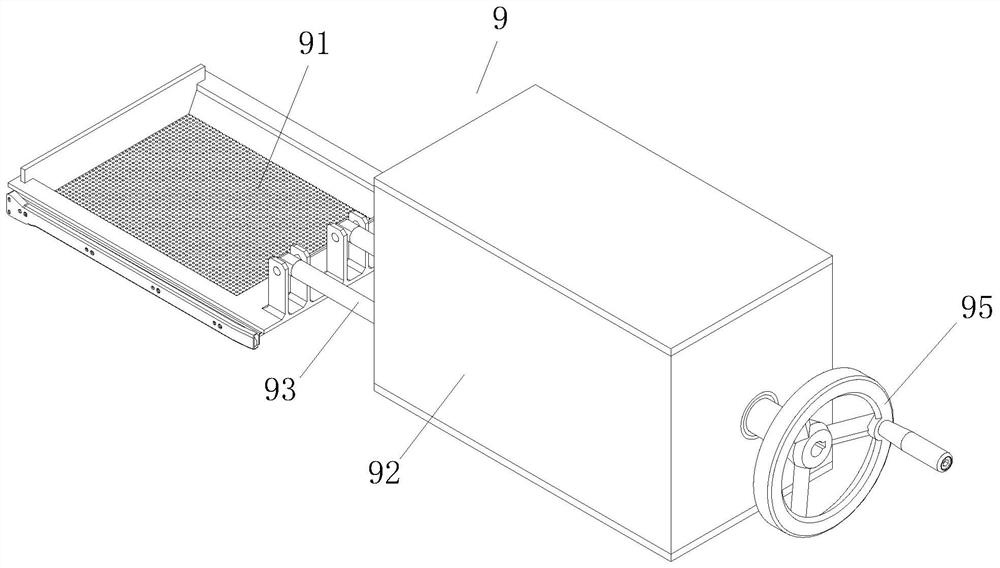

[0032] see Figure 1-2 As shown, the present invention provides a sand screening box for construction of municipal bridges through improvement, including supporting main frame 1, walking wheel 2, push rod 3, sand screening box body 4, sand entering bucket 5, top cover 6. Fine sand discharge port 7, cleaning door 8 and high-efficiency sand screening device 9, walking wheels 2 are installed on the bottom of the four supporting feet supporting the main frame 1 for moving, and a push rod is installed on the upper right end of the supporting main frame 1 3. For manual promotion, the sand screening box 4 is installed on the left side of the upper end of the supporting main frame 1, and is used for sand screening. The upper end of the sand screening box 4 is provided with a sand inlet bucket 5, which can discharge sand from the sand inlet bucket 5. It is fed into the screen 912, and the inside of the sand bucket 5 is provided with a top cover 6, which covers the sand bucket 5 when no...

Embodiment 2

[0039] The present invention provides a kind of sieve box that is used for municipal bridge construction here through improvement, and the baffle plate 915 that is provided can be used for the blocking of sand when sifting sand, prevents from being directly discharged from coarse sand discharge bucket 914 place, and will block After the plate 915 is removed, the sand will move back and forth through the sieve to discharge the coarse sand on its upper end, and the coarse sand that cannot be discharged can be cleaned out by means of a brush and other tools after the cleaning door 8 is opened. , so as to ensure the efficiency of subsequent sand screening, the two ends of the baffle 915 are embedded in the grooves at both ends of the front side of the movable sand screening mechanism 91, and when dismounting, the baffle 915 is lifted up to disengage it from the groove , when installing, it can be fixed by inserting into the groove. The disassembly and assembly of the baffle plate 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com